ASTM D4028/D4028M-13

(Specification)Standard Specification for Solar Screening Woven from Vinyl-Coated Fiber Glass Yarn

Standard Specification for Solar Screening Woven from Vinyl-Coated Fiber Glass Yarn

ABSTRACT

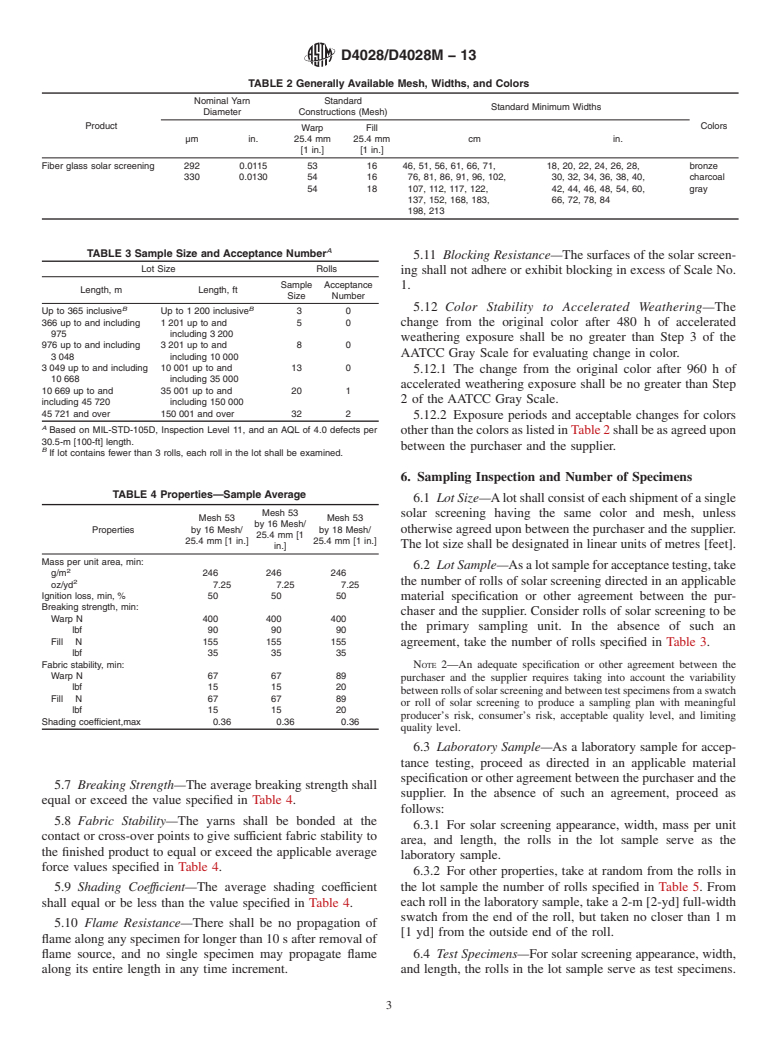

This specification covers the general and physical requirements for commercial standard solar screening woven from vinyl-coated fiber glass yarn. The material shall conform to general and physical requirements of this specification. General requirements include workmanship, plasticizers, color, selvage, yarn splices, and container dimensions and rolls put-up. Physical requirements include roll appearance, mesh, roll length, roll width, mass per unit area, ignition loss, breaking strength, fabric stability, shading coefficient, flame resistance, blocking resistance, and color stability to accelerated weathering. Testing of both general and physical requirements shall conform to the test methods detailed in this specification. Lot and sample size shall be according to the acceptance number of the specification.

SCOPE

1.1 This specification covers the requirements for vinyl-coated fiber glass solar screening, and should help users recognize the characteristics of acceptable vinyl-coated fiber glass solar screening. This specification is limited in application to vinyl-coated fiber glass solar screening that is produced with a ribbed pattern woven in the warp direction. The applicability of this specification to vinyl-coated fiber glass type solar screening of a non-rib, a double rib (ribs in both warp and filling direction), or a filling rib construction is not known.

1.2 This specification shows the definitions, general requirements, and physical requirements for commercial standard vinyl-coated fiber glass solar screening designed and woven for installation in any dwelling, building, or structure for the purpose of providing a significant reduction in solar heat gain, while providing outward view and interior light. Solar screening provides a structure that has insect-restraining capabilities equivalent to standard insect screening. Note 1—For information on standard insect screening, see Specification D3656.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The following precautionary caveat pertains only to the test method portion, Sections 8-21 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

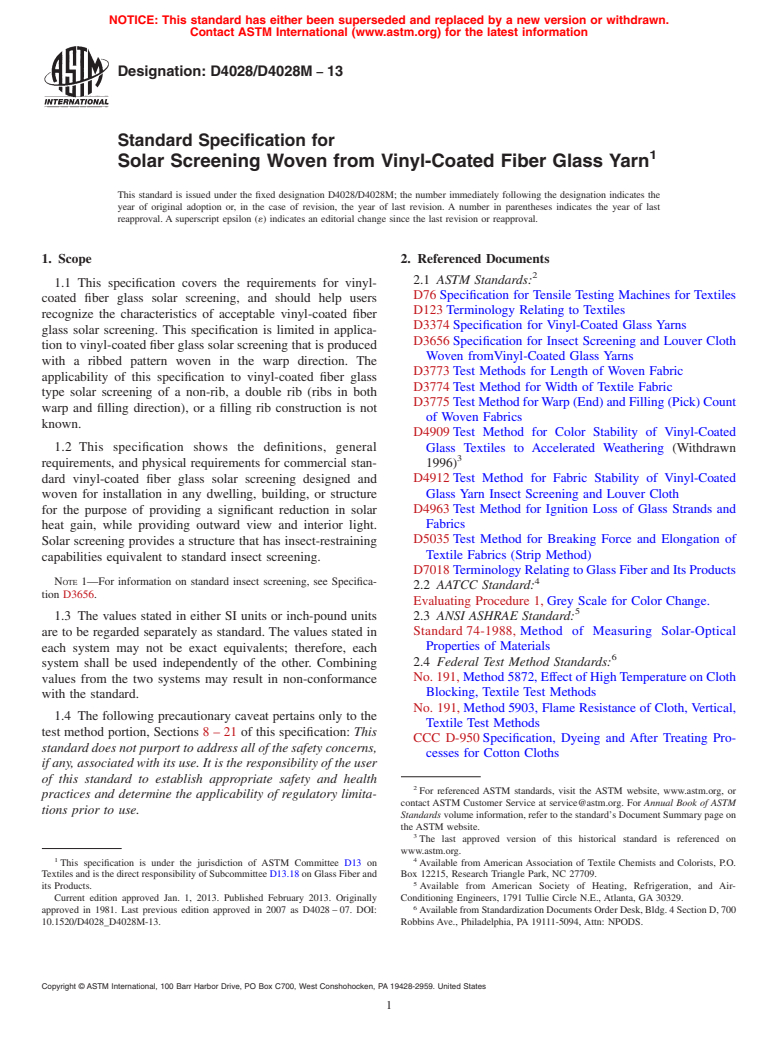

Designation:D4028/D4028M −13

Standard Specification for

1

Solar Screening Woven from Vinyl-Coated Fiber Glass Yarn

This standard is issued under the fixed designation D4028/D4028M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers the requirements for vinyl-

D76Specification for Tensile Testing Machines for Textiles

coated fiber glass solar screening, and should help users

D123Terminology Relating to Textiles

recognize the characteristics of acceptable vinyl-coated fiber

D3374Specification for Vinyl-Coated Glass Yarns

glass solar screening. This specification is limited in applica-

D3656Specification for Insect Screening and Louver Cloth

tion to vinyl-coated fiber glass solar screening that is produced

Woven fromVinyl-Coated Glass Yarns

with a ribbed pattern woven in the warp direction. The

D3773Test Methods for Length of Woven Fabric

applicability of this specification to vinyl-coated fiber glass

D3774Test Method for Width of Textile Fabric

type solar screening of a non-rib, a double rib (ribs in both

D3775TestMethodforWarp(End)andFilling(Pick)Count

warp and filling direction), or a filling rib construction is not

of Woven Fabrics

known.

D4909Test Method for Color Stability of Vinyl-Coated

1.2 This specification shows the definitions, general

Glass Textiles to Accelerated Weathering (Withdrawn

3

requirements, and physical requirements for commercial stan- 1996)

dard vinyl-coated fiber glass solar screening designed and D4912Test Method for Fabric Stability of Vinyl-Coated

Glass Yarn Insect Screening and Louver Cloth

woven for installation in any dwelling, building, or structure

for the purpose of providing a significant reduction in solar D4963Test Method for Ignition Loss of Glass Strands and

Fabrics

heat gain, while providing outward view and interior light.

D5035Test Method for Breaking Force and Elongation of

Solar screening provides a structure that has insect-restraining

Textile Fabrics (Strip Method)

capabilities equivalent to standard insect screening.

D7018TerminologyRelatingtoGlassFiberandItsProducts

4

NOTE 1—For information on standard insect screening, see Specifica-

2.2 AATCC Standard:

tion D3656.

Evaluating Procedure 1,Grey Scale for Color Change.

5

1.3 The values stated in either SI units or inch-pound units 2.3 ANSI ASHRAE Standard:

Standard 74-1988, Method of Measuring Solar-Optical

are to be regarded separately as standard. The values stated in

Properties of Materials

each system may not be exact equivalents; therefore, each

6

2.4 Federal Test Method Standards:

system shall be used independently of the other. Combining

No.191,Method5872,EffectofHighTemperatureonCloth

values from the two systems may result in non-conformance

Blocking, Textile Test Methods

with the standard.

No. 191,Method5903, Flame Resistance of Cloth, Vertical,

1.4 The following precautionary caveat pertains only to the

Textile Test Methods

test method portion, Sections8–21 of this specification: This

CCC D-950Specification, Dyeing and After Treating Pro-

standard does not purport to address all of the safety concerns,

cesses for Cotton Cloths

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

practices and determine the applicability of regulatory limita-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tions prior to use.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

The last approved version of this historical standard is referenced on

www.astm.org.

1 4

This specification is under the jurisdiction of ASTM Committee D13 on Available from American Association of Textile Chemists and Colorists, P.O.

TextilesandisthedirectresponsibilityofSubcommitteeD13.18onGlassFiberand Box 12215, Research Triangle Park, NC 27709.

5

its Products. Available from American Society of Heating, Refrigeration, and Air-

Current edition approved Jan. 1, 2013. Published February 2013. Originally Conditioning Engineers, 1791 Tullie Circle N.E., Atlanta, GA 30329.

6

approved in 1981. Last previous edition approved in 2007 as D4028–07. DOI: AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

10.1520/D4028_D4028M-13. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ------------------

...

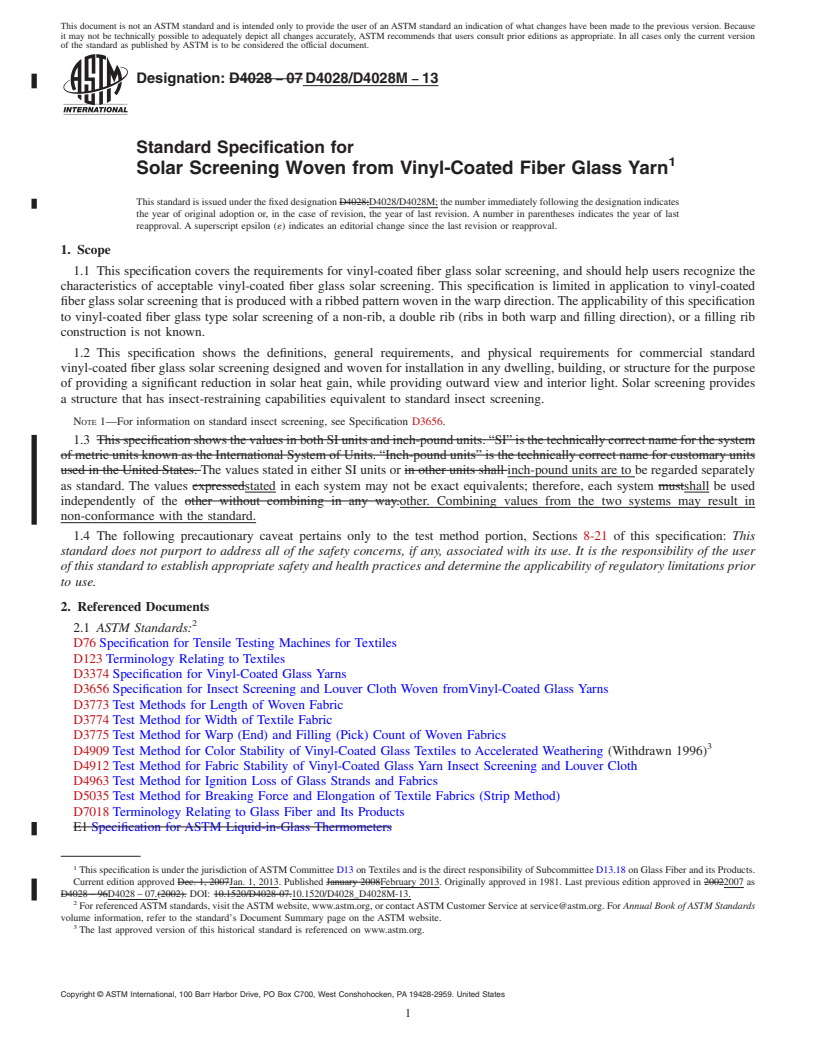

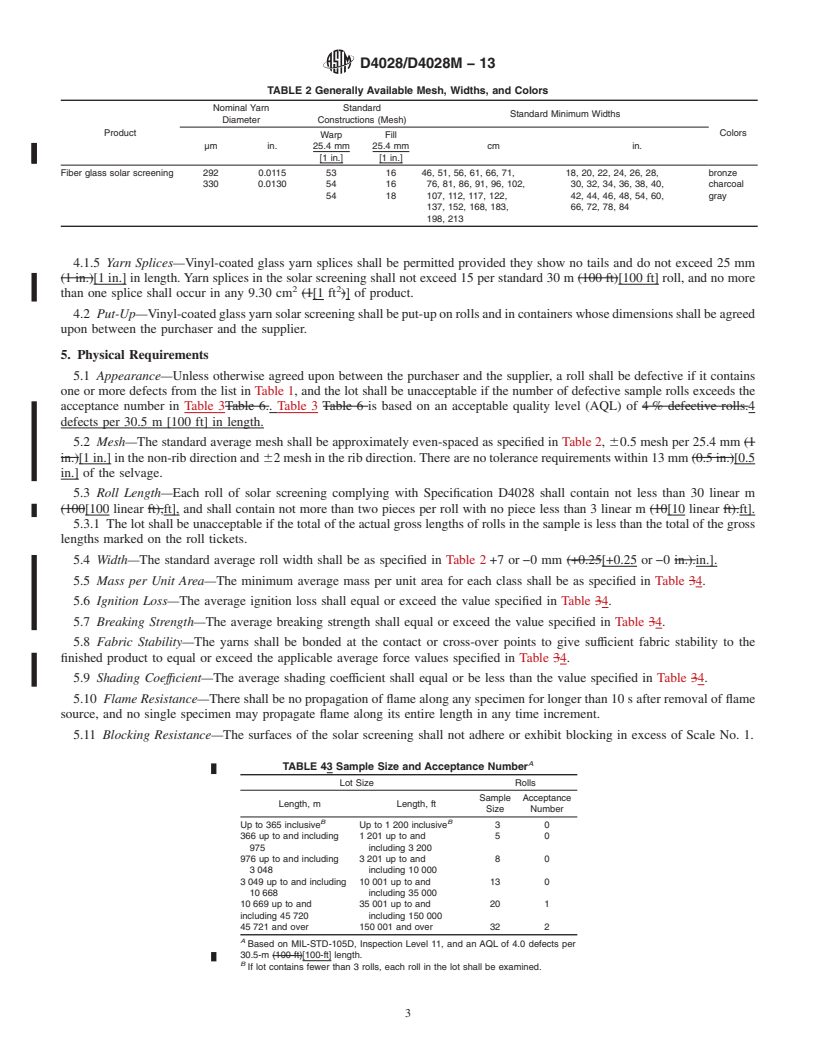

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4028 − 07 D4028/D4028M − 13

Standard Specification for

1

Solar Screening Woven from Vinyl-Coated Fiber Glass Yarn

This standard is issued under the fixed designation D4028;D4028/D4028M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for vinyl-coated fiber glass solar screening, and should help users recognize the

characteristics of acceptable vinyl-coated fiber glass solar screening. This specification is limited in application to vinyl-coated

fiber glass solar screening that is produced with a ribbed pattern woven in the warp direction. The applicability of this specification

to vinyl-coated fiber glass type solar screening of a non-rib, a double rib (ribs in both warp and filling direction), or a filling rib

construction is not known.

1.2 This specification shows the definitions, general requirements, and physical requirements for commercial standard

vinyl-coated fiber glass solar screening designed and woven for installation in any dwelling, building, or structure for the purpose

of providing a significant reduction in solar heat gain, while providing outward view and interior light. Solar screening provides

a structure that has insect-restraining capabilities equivalent to standard insect screening.

NOTE 1—For information on standard insect screening, see Specification D3656.

1.3 This specification shows the values in both SI units and inch-pound units. “SI” is the technically correct name for the system

of metric units known as the International System of Units. “Inch-pound units” is the technically correct name for customary units

used in the United States. The values stated in either SI units or in other units shall inch-pound units are to be regarded separately

as standard. The values expressedstated in each system may not be exact equivalents; therefore, each system mustshall be used

independently of the other without combining in any way.other. Combining values from the two systems may result in

non-conformance with the standard.

1.4 The following precautionary caveat pertains only to the test method portion, Sections 8-21 of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D3374 Specification for Vinyl-Coated Glass Yarns

D3656 Specification for Insect Screening and Louver Cloth Woven fromVinyl-Coated Glass Yarns

D3773 Test Methods for Length of Woven Fabric

D3774 Test Method for Width of Textile Fabric

D3775 Test Method for Warp (End) and Filling (Pick) Count of Woven Fabrics

3

D4909 Test Method for Color Stability of Vinyl-Coated Glass Textiles to Accelerated Weathering (Withdrawn 1996)

D4912 Test Method for Fabric Stability of Vinyl-Coated Glass Yarn Insect Screening and Louver Cloth

D4963 Test Method for Ignition Loss of Glass Strands and Fabrics

D5035 Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method)

D7018 Terminology Relating to Glass Fiber and Its Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

1

This specification is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and its Products.

Current edition approved Dec. 1, 2007Jan. 1, 2013. Published January 2008February 2013. Originally approved in 1981. Last previous edition approved in 20022007 as

D4028 – 96D4028 – 07.(2002). DOI: 10.1520/D4028-07.10.1520/D4028_D4028M-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4028/D4028M − 13

4

2.2 AATCC S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.