ASTM A489-18e1

(Specification)Standard Specification for Carbon Steel Eyebolts

Standard Specification for Carbon Steel Eyebolts

ABSTRACT

This specification covers the chemical, mechanical, grain size, and dimensional requirements for weldless forged, quenched, and tempered carbon steel threaded lifting eyes (formerly pertained to as eyebolts) for overhead lifting. This specification covers two types denoting shank pattern, and one style denoting shank length, as follows: Type 1, plain pattern (straight shank); Type 2, shoulder pattern; and Style B, short length. The lifting eyes shall be manufactured as specified for the melting, forging, heat treatment, and machining processes. The mechanical properties to which the lifting eyes shall adhere are proof, breaking strength, tensile stress and strength, bend strength, impact strength, yield point, elongation, and reduction of area.

SCOPE

1.1 This specification covers chemical, physical and mechanical requirements for forged, carbon steel threaded eyebolts intended for overhead lifting.

1.2 The specification includes two types denoting shank pattern and two styles denoting shank length (both defined in ASME B 18.15) as follows:

1.2.1 Type 1—Plain pattern (straight shank).

1.2.2 Type 2—Shoulder pattern.

1.2.3 Style A—Long length.

1.2.4 Style B—Short length.

1.3 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 The terms used in this specification are defined in Terminology F1789 unless otherwise defined herein.

1.5 The following safety hazard caveat pertains to the test methods portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation:A489 −18

Standard Specification for

1

Carbon Steel Eyebolts

This standard is issued under the fixed designation A489; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—A value in Table 2 was editorially corrected in May 2018.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers chemical, physical and me- 2.1 ASTM Standards:

chanical requirements for forged, carbon steel threaded eye- A751Test Methods, Practices, and Terminology for Chemi-

bolts intended for overhead lifting. cal Analysis of Steel Products

F541Specification for Alloy Steel Eyebolts

1.2 The specification includes two types denoting shank

F606/F606MTest Methods for Determining the Mechanical

pattern and two styles denoting shank length (both defined in

Properties of Externally and Internally Threaded

ASME B18.15) as follows:

Fasteners, Washers, Direct Tension Indicators, and Rivets

1.2.1 Type 1—Plain pattern (straight shank).

F1470Practice for Fastener Sampling for Specified Me-

1.2.2 Type 2—Shoulder pattern.

chanical Properties and Performance Inspection

1.2.3 Style A—Long length.

F1789Terminology for F16 Mechanical Fasteners

1.2.4 Style B—Short length.

F1941/F1941MSpecification for Electrodeposited Coatings

1.3 The values stated in inch-pound units are to be regarded

on Mechanical Fasteners, Inch and Metric

asstandard.Nootherunitsofmeasurementareincludedinthis

F2329/F2329MSpecification for Zinc Coating, Hot-Dip,

standard.

Requirements for Application to Carbon and Alloy Steel

Bolts, Screws, Washers, Nuts, and Special Threaded

1.4 The terms used in this specification are defined in

Terminology F1789 unless otherwise defined herein. Fasteners

3

2.2 ASME Standards:

1.5 The following safety hazard caveat pertains to the test

B1.1Unified Inch Screw Threads (UN and UNR Thread

methods portion of this specification: This standard does not

Form)

purport to address all of the safety concerns, if any, associated

B1.3 Screw Thread Gaging Systems forAcceptability: Inch

with its use. It is the responsibility of the user of this standard

and Metric Screw Threads (UN, UNR, UNJ, M, and MJ)

to establish appropriate safety, health, and environmental

B18.15 Forged Eyebolts

practices and determine the applicability of regulatory limita-

B18.24Part Identifying Number (PIN) Code System Stan-

tions prior to use.

dard for B18 Fastener Products

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Ordering Information

ization established in the Decision on Principles for the

3.1 Orders for eyebolts under this specification should

Development of International Standards, Guides and Recom-

include the following information:

mendations issued by the World Trade Organization Technical

3.1.1 ASTM specification number and date of issue.

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction of ASTM Committee F16 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Standards volume information, refer to the standard’s Document Summary page on

Nuts, Rivets and Washers. the ASTM website.

3

Current edition approved March 1, 2018. Published May 2018. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 1964. Last previous edition approved in 2012 as A489–12. DOI: International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

10.1520/A0489-18E01. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

A489−18

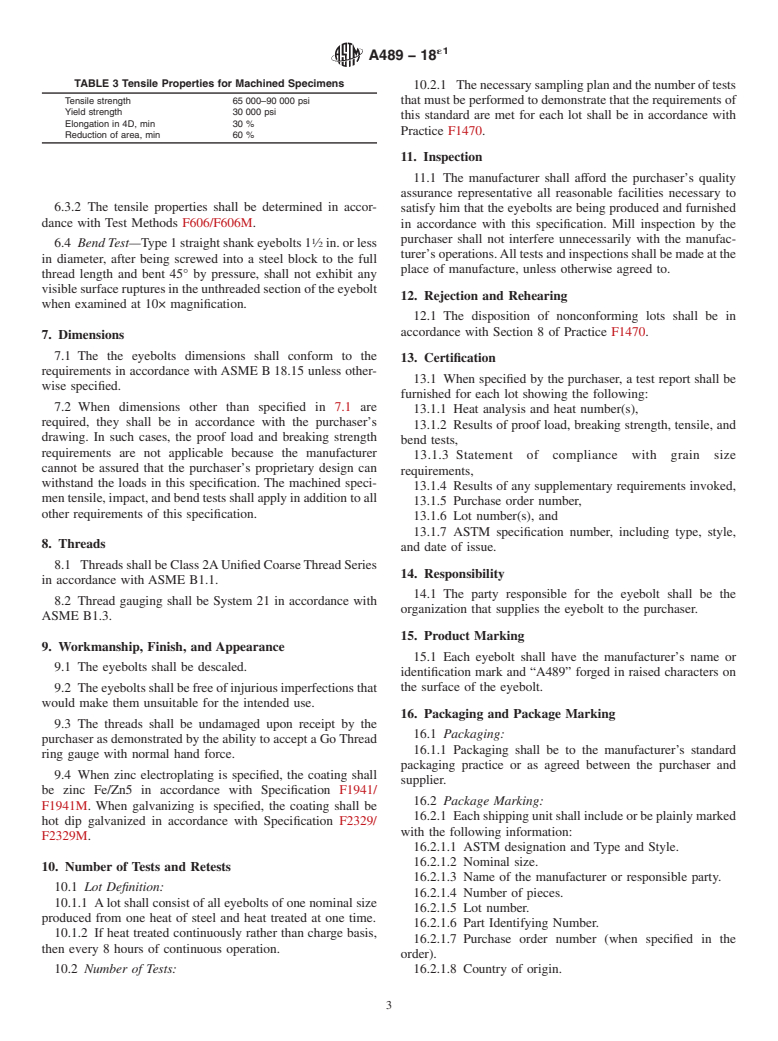

TABLE 2 Breaking Strength and Proof Load Requirements, Types

3.1.2 Name of product (carbon steel eyebolt).

1and2

3.1.3 Nominal Size.

Nominal Thread Size Tensile Stress Breaking Proof Load,

3.1.4 Type and style (see 1.2).

A C

Thread Size Area Strength, min

3.1.5 Number of pieces.

B

min

3.1.6 Coating, if required (see 9.4).

2

in. in. in. lbf lbf

1 1

3.1.7 Supplementary requirements, if required. ⁄4 ⁄4 –20 0.0318 2 100 800

5 5

⁄16 ⁄16 –18 0.0524 3 400 1 400

3.1.8 Certification, if required (se

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.