ASTM E106-83(2004)

(Test Method)Standard Test Methods for Chemical Analysis of Copper-Beryllium Alloys (Withdrawn 2011)

Standard Test Methods for Chemical Analysis of Copper-Beryllium Alloys (Withdrawn 2011)

SIGNIFICANCE AND USE

These test methods for the chemical analysis of metals and alloys are primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these test methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of copper-beryllium alloys having chemical compositions within the following limits: ElementConcentrationRange,%Copper97 to 98Beryllium0.4 to 2.05Nickel0.0 to 0.30Cobalt0.0 to 0.3Iron0.0 to 0.30

1.2 The analytical procedures appear in the following order:SectionsCopper by the Electrolytic MethodBeryllium:Phosphate Gravimetric MethodAluminon (Photometric) MethodNickel by the Dimethylglyoxime (Photometric) MethodCobalt by the Nitroso-R-Salt (Photometric) MethodIron by the Thiocyanate (Photometric) Method

1.3 This test method covers the determination of beryllium in concentrations from 0.1 to 3.0 %.

WITHDRAWN RATIONALE

These test methods cover procedures for the chemical analysis of copper-beryllium alloys having chemical compositions within specific limits.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, these test methods were withdrawn in January 2011. This standard was withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E106–83(Reapproved2004)

Standard Test Methods for

Chemical Analysis of Copper-Beryllium Alloys

This standard is issued under the fixed designation E106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E76 Test Methods for ChemicalAnalysis of Nickel-Copper

Alloys

1.1 These test methods cover procedures for the chemical

E173 Practice for Conducting Interlaboratory Studies of

analysis of copper-beryllium alloys having chemical composi-

Methods for Chemical Analysis of Metals

tions within the following limits:

Concentration

3. Significance and Use

Element Range,%

3.1 These test methods for the chemical analysis of metals

Copper 97 to 98

and alloys are primarily intended to test such materials for

Beryllium 0.4 to 2.05

compliance with compositional specifications. It is assumed

Nickel 0.0 to 0.30

Cobalt 0.0 to 0.3

that all who use these test methods will be trained analysts

Iron 0.0 to 0.30

capable of performing common laboratory procedures skill-

1.2 The analytical procedures appear in the following order:

fully and safely. It is expected that work will be performed in

a properly equipped laboratory.

Sections

Copper by the Electrolytic Method 8-12

4. Apparatus, Reagents, and Photometric Practice

Beryllium:

4.1 Apparatus and reagents required for each determination

Phosphate Gravimetric Method 13-19

Aluminon (Photometric) Method 20-27

are listed in separate sections preceding the procedure. The

Nickel by the Dimethylglyoxime (Photometric) Method 28-36

apparatus, standard solutions, and certain other reagents used

Cobalt by the Nitroso-R-Salt (Photometric) Method 37-44

Iron by the Thiocyanate (Photometric) Method 45-52 in more than one procedure are referred to by number and shall

conform to the requirements prescribed in Practices E50,

2. Referenced Documents

except that photometers shall conform to the requirements

2.1 ASTM Standards:

prescribed in Practice E60.

E29 Practice for Using Significant Digits in Test Data to

4.2 Photometric practice prescribed in these methods shall

Determine Conformance with Specifications

conform to Practice E60.

E50 Practices for Apparatus, Reagents, and Safety Consid-

5. Safety Precautions

erations for Chemical Analysis of Metals, Ores, and

Related Materials

5.1 For precautions to be observed in these methods, refer-

E55 Practice for Sampling Wrought Nonferrous Metals and

ence shall be made to Practices E50. Both beryllium metal and

Alloys for Determination of Chemical Composition

its compounds may be toxic. Care should be exercised to

E60 Practice for Analysis of Metals, Ores, and Related

prevent contact of beryllium-containing materials with the

Materials by Molecular Absorption Spectrometry

skin. The inhalation of any beryllium-containing substance,

either as a volatile compound or as finely divided powder,

should be especially avoided. Beryllium-containing residues

These test methods are under the jurisdiction of ASTM Committee E01 on

(especially ignited oxide) should be carefully disposed of.

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

responsibility of Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, theirAlloys, and

6. Sampling

Related Metals.

CurrenteditionapprovedJune1,2004.PublishedJuly2004.Originallyapproved

6.1 Sampling shall conform to Practice E55.

in 1954. Last previous edition approved in 1996 as E106 – 83 (1996). DOI:

10.1520/E0106-83R04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E106–83 (2004)

7. Rounding Off Calculated Values 12. Precision and Bias

7.1 Calculated values shall be rounded off to the desired

12.1 This test method was originally approved for publica-

number of places in accordance with the rounding-off method

tion before the inclusion of precision and bias statements

given in 3.4 and 3.5 of Practice E29.

within standards was mandated. The original interlaboratory

test data for this test method are no longer available. The user

COPPER BY THE ELECTROLYTIC TEST METHOD

is cautioned to verify by the use of reference materials, if

available, that the precision and bias of this test method are

8. Apparatus

adequate for the contemplated use.

8.1 Electrodes for Electroanalysis—Apparatus No. 9.

BERYLLIUM BY THE PHOSPHATE GRAVIMETRIC

9. Reagents TEST METHOD

9.1 Sulfuric-Nitric Acid Mixture—Add slowly, while stir-

13. Scope

ring, 300 mL of H SO to 750 mL of water. Cool and add 210

2 4

mL of HNO . 13.1 This test method covers the determination of beryllium

in concentrations from 0.1 to 3.0 %.

10. Procedure

14. Summary of Test Method

10.1 Transfer 5.00 g of sample to a 300-mL electrolysis

beaker. Add 42 mL of the H SO -HNO mixture, cover, and

14.1 Interferingelementsarecomplexedwith(ethylenedini-

2 4 3

allow to stand a few minutes until reaction has nearly ceased.

trilo) tetraacetate solution. Beryllium is precipitated as the

Heat at 80 to 90°C until dissolution is complete and brown

phosphate, which is filtered, ignited, and weighed as beryllium

fumes have been expelled. Wash down the cover glass and the

pyrophosphate.

sides of the beaker and dilute to about 175 mL (enough to

submerge the cathode when it is inserted).

15. Interferences

10.2 Insert the electrodes, cover the solution with a pair of

15.1 The elements ordinarily present in beryllium-copper

splitwatchglasses,andelectrolyzeatacurrentdensityofabout

alloys do not interfere if their concentrations are under the

0.6 A/dm for about 16 h. Wash down the cover glasses, sides

maximum limits shown in 1.1.

of beaker, and electrode stems and continue electrolysis for

about 15 min. If no copper plates on the newly exposed

16. Reagents

cathode surface, copper deposition may be considered com-

16.1 Ammonium Acetate Solution (500 g/L)—Dissolve 500

pleted.

g of ammonium acetate in water, and dilute to 1 L.

10.3 Quickly withdraw the cathode from the electrolyte

16.2 AmmoniumAcetate Wash Solution—Dilute5mLofthe

while directing a gentle stream of water from a wash bottle

ammonium acetate solution to 1 L, and adjust the pH to 5.2 6

over its surface. Rinse the cathode in a water bath and then dip

0.05 with acetic acid.

in two successive baths of ethanol or acetone. Dry in an oven

at 110°C for 3 to 5 min, cool, and weigh. Reserve the spent

NOTE 1—Use a pH meter for all pH adjustments.

electrolyte.

16.3 Ammonium Dihydrogen Phosphate (100 g/L)—

where: Dissolve 100 g of ammonium dihydrogen phosphate

A = grams of copper, and (NH H PO ) in water and dilute to 1 L.

4 2 4

B = grams of sample used.

16.4 Ammonium (Ethylenedinitrilo) Tetraacetate Solution

10.4 Reserved Electrolyte—Evaporate the spent electrolyte (28 g/L)—To2.5gof(ethylenedinitrilo)tetraaceticacidadd30

to dense white fumes and fume for about 5 min to dehydrate

mLof water and a drop of methyl red solution. Neutralize with

silicic acid. Cool, add about 50 mL of water, and heat until all NH OH (1 + 1), and warm gently to dissolve the last traces of

salts are in solution. Filter through a small, medium-texture

solid. Cool and dilute to 100 mL.

paper, catching the filtrate in a 250-mL volumetric flask. Wash

16.5 Methyl Red Indicator Solution (0.5 g/L ethanol)—

the beaker and paper thoroughly with hot H SO (1 + 99),

Dissolve 0.05 g of methyl red in 100 mL of ethanol.

2 4

combining the washings with the filtrate. Cool the solution in

the volumetric flask, dilute to the mark, and mix. Reserve for

17. Procedure

the determinations of beryllium, nickel, cobalt, and iron as

17.1 Using a pipet, transfer 50 mL of the electrolyte

described in Sections 17, 34, 43, and 51 respectively. If the

reservedin10.4toa400-mLbeaker.Add3dropsofHFand10

filtrate is not to be used for the gravimetric determination of

mL of H SO (1 + 2), and evaporate to fumes. Cool to room

2 4

beryllium, the removal of silica is not necessary and the

temperature and add 100 mLof water. Heat to dissolve soluble

electrolyte may be diluted to volume directly.

salts and again cool to room temperature.

17.2 Add 10 mL of ammonium (ethylenedinitrilo) tetraac-

11. Calculation

etate solution, and adjust the pH to 2.0 6 0.05 (see Note 1)

11.1 Calculate the percentage of copper as follows:

withNH OH(1 + 1).Boil1minandcooltoroomtemperature.

Add 10 mL of ammonium dihydrogen phosphate solution and

Copper, % 5 ~A/B! 3 100 (1)

adjust the pH to 5.2 6 0.05 with ammonium acetate solution.

E106–83 (2004)

17.3 Heat to boiling cautiously to prevent bumping, and 21. Concentration Range

then maintain just below the boiling point until the precipitate

21.1 The recommended concentration range is from 0.004

becomes granular. Remove from the source of heat and allow

to 0.09 mg of beryllium in 100 mL of solution, using a cell

to stand at least 12 h.

depth of 2 cm.

17.4 Filter using an 11-cm fine paper and wash six times

with ammonium acetate wash solution. Discard the filtrate.

22. Stability of Color

Dissolve the precipitate with 100 mL of hot HCl (1 + 4),

22.1 The intensity of the color of the beryllium lake

collecting the solution in the original beaker.

increases slowly on standing. Therefore, a uniform standing

17.5 Add 2 mL of ammonium (ethylenedinitrilo) tetraac-

time must be adhered to.

etate solution, and adjust the pH to 2.0 6 0.05 with NH OH

(1 + 1). Cool, add 2 mL of ammonium dihydrogen phosphate

23. Interfering Elements

solution, and adjust the pH to 5.2 6 0.05 with ammonium

23.1 Provision is made in the procedure for preventing, or

acetate solution. Proceed as directed in 17.3.

compensating for, interference from metals present in amounts

17.6 Filter using an 11-cm fine paper and wash six times

not exceeding the maximum limits given in 1.1

with ammonium acetate wash solution. Transfer the paper to a

weighed platinum crucible. Place the crucible in a muffle

24. Reagents

furnace, and dry and char the paper by gradually increasing the

24.1 Aluminon-Buffer Composite Solution—Add 500 g of

temperature to 500°C. When all the carbon has been removed,

ammonium acetate to 1 Lof water in a 2-Lbeaker.Add 80 mL

raise the temperature to 1000°C and maintain at this tempera-

of glacial acetic acid and stir until dissolution is complete.

ture for 4 h. Cool in a desiccator and weigh.

Filter if necessary. Dissolve 1.000 g of a suitable grade of

18. Calculation aluminon (aurin tricarboxylic acid-ammonium salt) in 50 mL

of water and add to the buffer solution. Dissolve3gof benzoic

18.1 Calculate the percentage of beryllium as follows:

acid in 20 mLof methanol and add to the buffer solution while

Beryllium, % 5 ~A 3 0.0939/B! 3 100 (2)

stirring. Dilute the mixture to 2 L.Add 10 g of gelatin to 250

mL of water in a 400-mL beaker. Place the beaker in a boiling

water bath and allow to remain, with frequent stirring, until the

where:

A = grams of beryllium pyrophosphate, and gelatin has dissolved completely. Pour the warm gelatin

B = grams of sample used solution into 500 mL of distilled water, while stirring. Cool to

room temperature, dilute to 1 L, and mix. Transfer the

19. Precision and Bias

aluminon and gelatin solutions to a 4-L chemically resistant

glass-stopperedbottle,mixwell,andstoreinacool,darkplace.

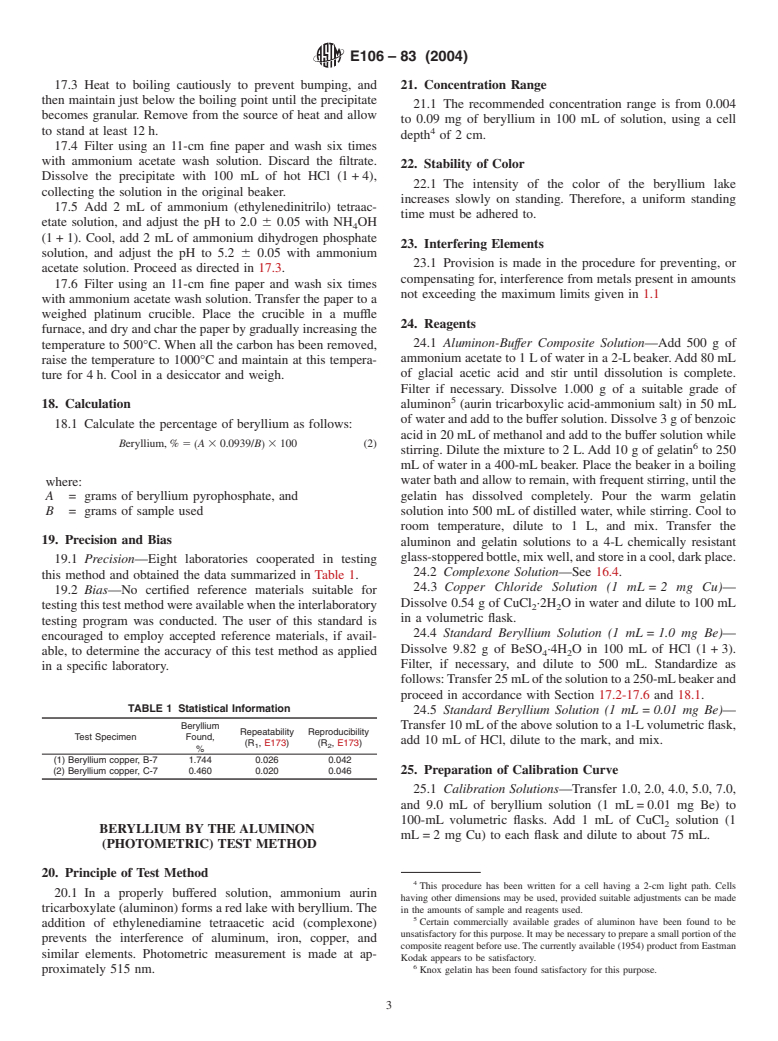

19.1 Precision—Eight laboratories cooperated in testing

24.2 Complexone Solution—See 16.4.

this method and obtained the data summarized in Table 1.

24.3 Copper Chloride Solution (1 mL = 2 mg Cu)—

19.2 Bias—No certified reference materials suitable for

Dissolve 0.54 g of CuCl ·2H O in water and dilute to 100 mL

testingthistestmethodwereavailablewhentheinterlaboratory 2 2

in a volumetric flask.

testing program was conducted. The user of this standard is

24.4 Standard Beryllium Solution (1 mL = 1.0 mg Be)—

encouraged to employ accepted reference materials, if avail-

Dissolve 9.82 g of BeSO ·4H O in 100 mL of HCl (1 + 3).

able, to determine the accuracy of this test method as applied

4 2

Filter, if necessary, and dilute to 500 mL. Standardize as

in a specific laboratory.

follows:Transfer25mLofthesolutiontoa250-mLbeakerand

proceed in accordance with Section 17.2-17.6 and 18.1.

TABLE 1 Statistical Information

24.5 Standard Beryllium Solution (1 mL = 0.01 mg Be)—

Beryllium Transfer 10 mLof the above solution to a 1-Lvolumetric flask,

Repeatability Reproducibility

Test Specimen Found,

add 10 mL of HCl, dilute to the mark, and mix.

(R , E173) (R , E173)

1 2

%

(1) Beryllium copper, B-7 1.744 0.026 0.042

(2) Beryllium copper, C-7 0.460 0.020 0.046 25. Preparation of Calibration Curve

25.1 Calibration Solutions—Transfer 1.0, 2.0, 4.0, 5.0, 7.0,

and 9.0 mL of beryllium solution (1 mL = 0.01 mg Be) to

100-mL volumetric flasks. Add 1 mL of CuCl solution (1

BERYLLIUM BY THE ALUMINON

mL = 2 mg Cu) to each flask and dilute to about 75 mL.

(PHOTOMETRIC) TEST METHOD

20. Principle of Test Method

This procedure has been written for a cell having a 2-cm light path. Cells

20.1 In a properly buffered solution, ammonium aurin

having other dimensions may be used, provided suitable adjustments can be made

tricarboxylate (aluminon) forms a red lake with beryllium.The

in the amounts of sample and reagents used.

Certain commercially available grades of aluminon have been found to be

addition of ethylenediamine tetraacetic acid (complexone)

unsatisfactory for this purpose. It may be necessary to prepare a small portion of the

prevents the interference of aluminum, iron, copper, and

composite reagent before use.The currently available (1954) product from Eastman

similar elements. Photometric measurement is made at ap-

Kodak appears to be satisfactory.

proximately 515 nm. Knox gelatin has been found satisfactory for this purpose.

E106–83 (2004)

25.2 Reference Solution—Add 1 mL of CuCl solution (1 29. Concentration Range

mL = 2 mg Cu) to a 100-mL volumetric flask and dilute to

29.1 The recommended concentration range is from 0.02 to

about 75 mL. 4

0.40 mg of nickel per 100 mL of solution, using a cell depth

25.3 Color Development—Add 2 mL of complexone solu-

of 2 cm.

tion and 15 mL of aluminon buffer composite solution to each

flask, mixing well between additions. Dilute to the mark and 30. Stability of Color

mix without de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.