ASTM C1078-87(1992)e1

(Test Method)Test Methods for Determining the Cement Content of Freshly Mixed Concrete (Withdrawn 1998)

Test Methods for Determining the Cement Content of Freshly Mixed Concrete (Withdrawn 1998)

General Information

Standards Content (Sample)

ASTM C1078xEl 87 - 0759530 0507599 442 -

AMERICAN SCClElY FCR TESTING AND MATERIALS

Designation: C 1078 - 87 (Reapproved 1992)”

1916 Race St Philadelphia, Pa 19103

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Nb

If not listed in the current combined index, will appear in the next edition.

Standard Test Methods for

Determining the Cement Content of Freshly Mixed

Concrete’

This standard is issued under the fixed designation C 1078; the number immediately following the designation indicates the year of

original adoption or, in the case. of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (6) indicates an editorial change since the last revision or reapprowl.

“NOTE--Editorial corrections were made in March 1992.

1. Scope from the concrete (those particles passing the finest sieve) are

uniformly suspended. A constant-volume representative

1.1 These test methods cover two procedures for deter-

sample of the cement suspension is obtained and diluted

mining the cement content of a sample of freshly mixed

with a known volume of nitric acid and water. The diluted

concrete. These methods are applicable to all freshly mixed

sample is agitated, without heat, to dissolve some of the

portland-cement concrete batches for which calibration can

calcium compounds in the cement. The calcium-ion concen-

be obtained in advance, except those containing certain

tration of the resulting solution is determined by manual

aggregates or admixtures, that, when washed over a 150~pm

volumetric titration in Procedure A or instrumental

(No. 100) sieve, yield significant and varying amounts of

fluorometric determination in Procedure B and is correlated

calcium ions in solution under the conditions of the test. The

to the cement content of the specimen by a previously

choice of which procedure to use is at the discretion of the

developed calibration curve.

user. The environment in which these test methods are used

may have some bearing on the choice.

4. Significance and Use

1.2 The values stated in inch-pound units are to be

regarded as the standard except in regard to sieve sizes which 4.1 These test methods can be used to determine vari-

are in accordance with Specification E 11. ability of cement content in a batch of concrete and the

1.3 This standard does not purport to address all of the variability of cement content between batches of nominally

safety problems, if any, associated with its use. It is the identical concrete. If these test methods are used to indicate

concrete uniformity, correct and appropriate sampling pro-

responsibility of the user of this standard to establish appro-

cedures must be followed. Sampling procedures are refer-

priate safety and health practices and determine the applica-

enced in Section 6 of these test methods.

bility of regulatory limitations prior to use.

4.2 The water-cement ratio of a concrete sample can be

2. Referenced Documents

estimated when these test methods are used in conjunction

with Test Methods C 1079.

2.1 ASTM Standards:

4.3 These test methods are not applicable to concretes

C 94 Specification for Ready-Mixed Concrete2

containing certain aggregates, or admixtures, that when

C 127 Test Method for Specific Gravity and Absorption of

washed over a 150~pm (No. 100) sieve yield significant and

Coarse Aggregate*

varying amounts of calcium ions in solution under the

C 138 Test Method for Unit Weight, Yield, and Air

conditions of the test. The variation of calcium ions will be

Content (Gravimetric) of Concrete

apparent when performing the calibration procedure. This

C 172 Practice for Sampling Fresh Concrete2

variation will result in the inability to achieve less than a 5 %

C 670 Practice for Preparing Precision and Bias State-

variation in the calibration test results or a linear calibration

ments for Test Methods for Construction Materials2

curve (see 9.4 and 15.4).

C 1079 Test Methods for Determining Water Content of

Freshly Mixed Concrete2

5. Purity of Reagents

E 11 Specification for Wire-Cloth Sieves for Testing

5.1 Purity of Reagents-Reagent grade chemicals shall be

Purposes3

used in all tests. Unless otherwise indicated, it is intended

3. Summary of Test Methods

that all reagents shall conform to the specifications of the

Committee on Analytical Reagents of the American Chem-

3.1 A given mass of freshly mixed concrete is washed with

ical Society, where such specifications are available.4 Other

a given volume of water over a nest of sieves. The water is

grades may be used, provided it is first ascertained that the

agitated so that the cement and other fine particles washed

reagent is of sufficiently high purity to permit its use without

I These test methods are under the jurisdiction of ASTM Committee C-9 on

Concrete and Concrete Aggregates and are the direct responsibility of Subcom-

4 “Reagent Chemicals, American Chemical Society Specifications,” Am. Chem-

mittee CO9.03.03 on Methods of Testing Fresh Concrete. ical Sot., Washington, DC. For suggestions on the testing of reagents not listed by

Current edition approved May 29, 1987. Published July 1987. the American Chemical Society, see “Reagent Chemicals and Standards,” by

z Annual Book of ASTM Standards, Vol 04.02.

Joseph Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

3 Annual Book of ASTM Standards. Vols 04.02 and 14.02. Pharmacopeia.”

ASTM Cl,078*EL 87 W 0759510 0507600 T94 D

'fjb Cl078

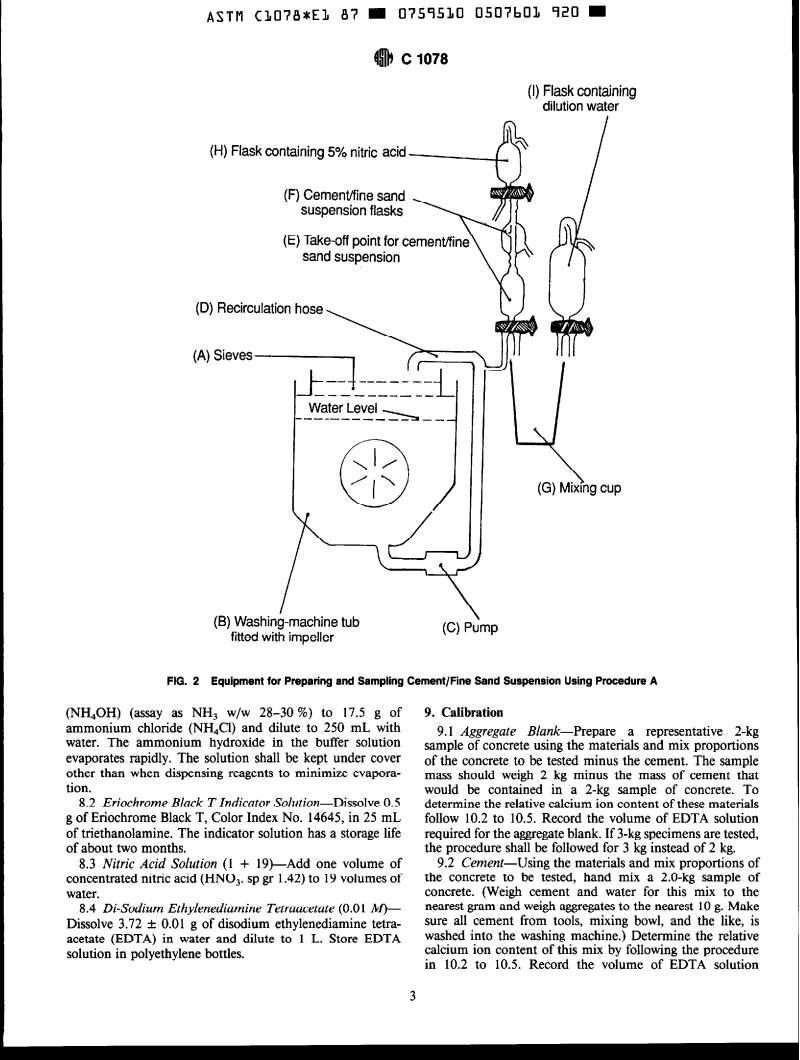

propeller, and a recirculating pump and hose. The

recirculating hose shall be fitted with a T connector and 3 ft

(0.9 m) of G-in. (6.4 mm) inside diameter, latex tubing to be

connected to the linked pipet. The working or rated capacity

of the tub shall be 10 gal (37.9 L). The inside dimensions of

the washing machine tub shall be large enough to hold a 15

5/16 by 12 5/16-in. (389 by 313-mm) nest of sieves. The

washing machine, nest of sieves, and linked pipets are shown

in Fig. 2. The cement suspension tank described in 13.1.5

may be fitted with the T connector and substituted for this

washing machine.

7.1.6 Sieve Nest, having a rectangular steel frame, 15 ‘/l6

by 12 ‘/16 by 8 in. (389 X 3 13 x 203 mm) with a 300~urn

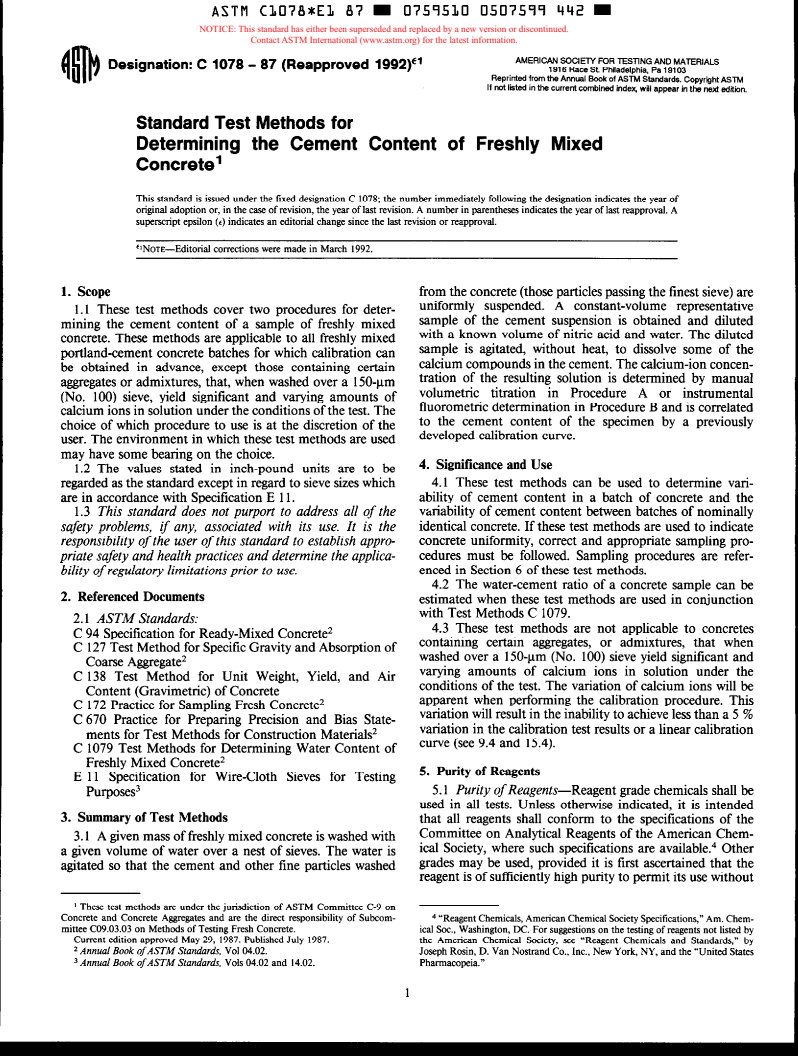

a. Balance i. Stirrer

(No. 50) sieve at the bottom and a 4.75-mm (No. 4) sieve at

b. Hand scoop j. &ret, 100 mL

c. Sample tub k. Pipet, 25 mL mid-height. The 4.75-mm sieve shall be removable. There

I. Conical Beakers of Erfenmeyar flasks

d. Specimen tub

shall be an additional separate sieve frame, 4 in. (102 mm)

e. Washing machine m. Fixad-volume dispenser

deep, nested below the 300~pm sieve, and having a 150~urn

f. Sieve nest n. Carboys

(No. 100) sieve at the bottom. The combination of sieves

g. Linked pipet. 100 and 125 mL o. Wash Bottle, 500 mL

p. Dropping bottle

h. Automatic pipat, 300 mL

used for calibration and cement-content testing must be the

same. The 150~urn sieve may be omitted for siliceous line

Equipment Required for Determining the Cement Content

FIG. 1

aggregates but shall be used when a calcareous line aggregate

of Freshly Mixed Concrete Using Procedure A

is encountered. (A line aggregate is regarded as “calcareous”

when the results of a chemical analysis show in excess 20 ‘%

lessening the accuracy of the determination. A comparison

CaO.) If the cement suspension tank described in 13.1.5 is

of results obtained using the proposed grades with results

used, the sieve nest described in 13.1.6 shall be used instead

obtained using reagent grade chemicals shall be made to

of the nest described in this section.

ensure that the proposed grades are sufficiently pure, unless

7.1.7 Linked Pipets, 125 + IO-mL glass pipet with an

previous records confirm they are satisfactory.

automatic leveling and overflow device fitted with a three-

5.2 Purity of Water-Unless otherwise indicated, all refer-

way tap. To it is attached a 100 f lo-mL automatic pipet

ences to water shall be understood to mean distilled water or

with a three-way tap capable of emptying the smaller pipet’s

water of equal purity. (The primary use of the distilled water

contents through the 125 f lo-mL pipet without draining

is for reagent preparation.)

the contents out of the overllow device. The reproducibility

of the automatic pipet must be kO.20 %. The linked pipet

6. Sampling

apparatus is shown in Fig. 2.

6.1 The sample of concrete from which the cement-

7.1.8 Automatic Pipet, 300 + 25-mL automatic glass pipet

content test specimen is taken shall be representative of the

fitted with a three-way tap. The reproducibility of the

entire batch and have a mass of not less than 20 kg. It shall

automatic pipet must be 0.2 %.

be obtained in accordance with Specification C 94 or Prac-

7.1.9 Magnetic Stirrer, variable-speed magnetic stirrer

tice C 172. Specification C 94 outlines procedures for sam-

with a TFE-fluorocarbon-coated magnetic stirring rod.

pling for uniformity of concrete produced in truck mixers.

7.1.10 Buret, lOO-mL acrylic body Class A or B with a

polytetralluoroethylene (PTFE) plug. A three-pronged utility

PROCEDURE A-MANUAL VOLUMETRlC TITRATION

clamp, a support base, and rod are required to hold the

7. Apparatus

buret.

7.1.11 Pipet, 25-mL volumetric glass, Class A or B pipet.

7.1 The following comprises a recommended minimum

selection of apparatus for use in conducting the analysis.

NOTE 1-A rubber suction bulb is recommended for use during

pipetting of the 25-mL sample containing cement.

Apparatus other than that described in 7.1.1 through 7.1.14

can be used provided they serve the same function.5 A

7.1.12 Conical Beakers or Erlenmeyer Flasks, narrow-

photograph of an acceptable selection of apparatus is shown

mouth, glass, conical beakers or Erlenmeyer flasks. One

in Fig. 1.

500-mL and one 800- or lOOO-mL capacity.

7.1.1 Balance, having a minimum capacity of 2600 g, and

7.1.13 Fixed Volume Dispenser, 5-mL fixed-volume dis-

a sensitivity of at least 0.1 g.

penser of polyethylene with a polypropylene measuring

7.1.2 Shovels, Hand Scoops, and Rubber Gloves as re-

chamber.

quired.

7.1.14 Reagent Dispensing Containers, a 500-mL polyeth-

7.1.3 Sample Tub, 5-qt (4.7-L) polyethylene tub,

ylene wash bottle, a 30-mL polyethylene dropping bottle,

7.1.4 Specimen Tub, 2-qt (1.9-L) polyethylene tub.

two rectangular aspirator carboys of either 2- or 5-gal(7.6- or

7.1.5 Washing Machine, Domestic portable washing ma-

18.9-L) capacity, and amber rubber tubing, l/2 in. (12.7 mm)

chine. It must have a smooth interior, a side-mounted

in inside diameter by 20 ft (6.1 m) long.

8. Reagents

s Howdyshell, P. A., “Revised Operations Guide for a Chemical Technique to

8.1 Ammonium Hydroxide-Ammonium Chloride Bufer

Determine Water and Cement Content of Fresh Concrete,” Technical Report

M-2 12, U.S. Army Construction Engineering Research Laboratory, April 1977. Solution (pH = IO)-Add 142 mL of ammonium hydroxide

ASTM CLO?‘B*EL 87 - 0759510 050’i’bOl~ 920 m

e# C 1078

Flask containing

dilution water

Flask containing 5% nitric acid

U-U

(F) Cement/fine sand

suspension flasks

(E) Take-off point for cement/fin

sand suspension

(D) Recirculation hose

(B) Washing-machine tub

(C) P;mp

fitted with impeller

FIG. 2 Equipment for Preparing and Sampling Cement/Fine Sand Suspension Using Procedure A

9. Calibration

(NH,OH) (assay as NH, w/w 28-30 %) to 17.5 g of

ammonium chloride (NH&l) and dilute to 250 mL with

9.1 Aggregate Blank-Prepare a representative 2-kg

water. The ammonium hydroxide in the buffer solution

sample of concrete using the materials and mix proportions

evaporates rapidly. The solution shall be kept under cover

of the concrete to be tested minus the cement. The sample

other than when dispensing reagents to minimize evapora-

mass should weigh 2 kg minus the mass of cement that

tion.

would be contained in a 2-kg sample of concrete. To

8.2 Eriochrome Black T Indicator Solution--Dissolve 0.5 determine the relative calcium ion content of these materials

g of Eriochrome Black T, Color Index No. 14645, in 25 mL follow 10.2 to 10.5. Record the volume of EDTA solution

of triethanolamine. The indicator solution has a storage life required for the aggregate blank. If 3-kg specimens are tested,

of about two months. the procedure shall be followed for 3 kg instead of 2 kg.

9.2 Cement-Using the materials and mix proportions of

8.3 Nitric Acid Solution (1 + 19)-Add one volume of

the concrete to be tested, hand mix a 2.0-kg sample of

concentrated nitric acid (HNO,. sp gr 1.42) to 19 volumes of

concrete. (Weigh cement and water for this mix to the

water.

nearest gram and weigh aggregates to the nearest 10 g. Make

8.4 Di-Sodium Ethylenediamine Tetraacetate (0.01 M)-

sure all cement from tools, mixing bowl, and the like, is

Dissolve 3.72 f 0.01 g of disodium ethylenediamine tetra-

washed into the washing machine.) Determine the relative

acetate (EDTA) in water and dilute to 1 L. Store EDTA

calcium ion content of this mix by following the procedure

solution in polyethylene bottles.

in 10.2 to 10.5. Record the volume of EDTA solution

ASTM Cl1078*EL 87 - 0759510 0507602 867 -

required for the cement calibration specimen. 125-mL linked pipet. Squeeze the large-bore recirculating

hose again to direct the cement suspension into the pipet.

9.3 Cement Content versus EDTA Calibration Curve-To

construct the linear calibration curve for cement content (g) When the pipet is filled to the overflow device, switch off the

lower pipet tap and release the large-bore recirculating hose.

versus the volume of EDTA required, plot zero cement and

the volume of EDTA required for the aggregate blank (9.1) 10.3 Drain the 125-mL aliquot of cement suspension into

as one point. Plot the mass of cement in the 2-kg concrete the 800-mL beaker. Wash out the 125-mL linked pipet using

calibration sample and the volume of EDTA required (9.2) 100 mL of HN03 solution from the automatic pipet posi-

tioned above the 125-mL pipet. Leave the tap on the lower

as the other point. Connect the two points with a straight line

125mL linked pipet open during this washing so that the

to complete the calibration curve for these sources and types

of cement and aggregate, All unknown cement contents are acid wash solution will flow into the SOO-mL beaker. Dilute

linearly proportional in terms of calcium ion content6 An the cement-HN03 solution in the beaker with 300 mL of tap

example of a calibration curve is in 11.1. water from the 300-mL automatic pipet. Place a TFE-

fluorocarbon-coated magnetic stirring rod in a beaker and

9.4 Calibration Requirements-Both the cement calibra-

stir contents on a magnetic stirr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.