ASTM D1282-05

(Test Method)Standard Test Method for Resistance to Airflow as an Indication of Average Fiber Diameter of Wool Top, Card Sliver, and Scoured Wool

Standard Test Method for Resistance to Airflow as an Indication of Average Fiber Diameter of Wool Top, Card Sliver, and Scoured Wool

SCOPE

1.1 This test method covers the estimation of the average fiber diameter of wool fibers by use of the Port-Ar and the WIRA Fiber Fineness Meter instrument, which operate on the air-flow principle. Other air-flow instruments have not been tested with this method. The method is directly applicable to non-medullated, carded wool and wool top.

1.2 This test method is applicable to grease wool and scoured wool after the samples of such materials have been prepared as directed in Test Method D 2130. Note 1The use of the Micronaire instrument for measuring the fineness of cotton fibers is covered in Test Method D 1448.The assignment of grade for wool and mohair is covered in Specifications D 3991 and D 3992.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1282 – 05

Standard Test Method for

Resistance to Airflow as an Indication of Average Fiber

1

Diameter of Wool Top, Card Sliver, and Scoured Wool

This standard is issued under the fixed designation D1282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Mean Diameter of Wool Fibers in Combed Sliver Using

the Air-Flow Apparatus

1.1 This test method covers the estimation of the average

IWTO-28-82(E) Determination By The Airflow Method of

fiber diameter of wool fibers by use of the Port-Ar and the

the Mean Fibre Diameter of Core Samples of Raw Wool

WIRAFiber Fineness Meter instrument, which operate on the

air-flow principle. Other air-flow instruments have not been

3. Terminology

tested with this method. The method is directly applicable to

3.1 For all terminology related to wool and wool felt, refer

non-medullated, carded wool and wool top.

to Terminology D4845.

1.2 This test method is applicable to grease wool and

3.1.1 The following terms are relevant to this standard:

scoured wool after the samples of such materials have been

sliver, specific area, top, and wool.

prepared as directed in Test Method D2130.

3.2 For all other terminology related to textiles, see Termi-

NOTE 1—The use of the Micronaire instrument for measuring the

nology D123.

fineness of cotton fibers is covered in Test Method D1448.

The assignment of grade for wool and mohair is covered in Specifica-

4. Summary of Test Method

tions D3991 and D3992.

4.1 The resistance to air flow of predetermined mass of

wool compressed to a fixed volume is measured. The instru-

2. Referenced Documents

2

ments approved for use have been calibrated to read average

2.1 ASTM Standards:

diameterinmicrometres.Specimensofwooltopareratedwith

D123 Terminology Relating to Textiles

a Wool Top Scale and specimens of carded, scoured wool and

D1060 Practice for Core Sampling of Raw Wool in Pack-

1

scoured ⁄2-in. (13.0-mm) cores are rated with a Scoured Wool

ages for Determination of Percentage of CleanWool Fiber

Scale. If instruments are properly calibrated, results are inter-

Present

changeable.

D1448 Test Method for Micronaire Reading of Cotton

Fibers

5. Significance and Use

D2130 Test Method for Diameter of Wool and Other

5.1 Thistestmethodisnotrecommendedfortheacceptance

Animal Fibers by Microprojection

testing of commercial shipments of wool top, card sliver, or

D3991 Specification for Fineness of Wool or Mohair and

scouredwoolsincetherefereemethod,TestMethodD2130,is

Assignment of Grade

recommended for that purpose. Although this test method is

D3992 Specification for Fineness of Wool Top or Mohair

not recommended for acceptance testing, it is useful for fast

Top and Assignment of Grade

quality control checks.

D4845 Terminology for Wool

5.1.1 .If there are differences of practical significance be-

2.2 Other Standard:

tween reported test results for two laboratories (or more),

IWTO-6-92(E) MethodofTestfortheDeterminationofThe

comparativetestshouldbeperformedtodetermineifthereisa

statistical bias between them, using competent statistical assis-

tance.As a minimum, use the samples for such a comparative

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

test that are as homogenous as possible, drawn from the same

and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt.

lot of material as the samples that resulted in disparate results

Current edition approved March 1, 2005. Published April 2005. Originally

approved in 1953. Last previous edition approved in 2005 as D1282–96 (2005).

during initial testing and randomly assigned in equal numbers

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to each laboratory. The test results from the laboratories

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

involved should be compared using a statistical test for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. unpaired data, a probability level chosen prior to the testing

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1282–05

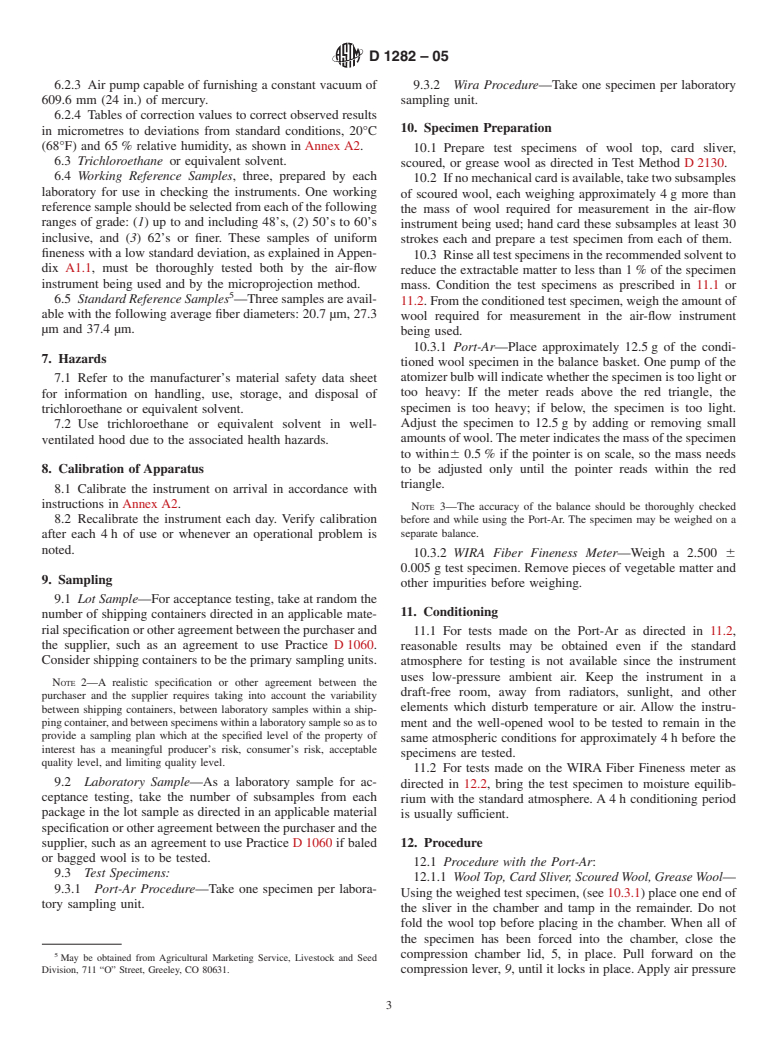

1) Balance Adjustment Knob 8) Porosity Calibration Control

2) Balance Pan 9) Compression Lever

3) Air Reservoir 10) Calibrator Plug Plunger

4) Meter Zero Adjustment Screw 11) Porosity Calibrator Plug

5) Porosity Test Chamber Lid 12) Calibration Weight

6) Differential Pressure Gage 13) Weighing Balance Mechanism

7) Porosity Zero Control 14) Atomizer Bulb

FIG. 1 Port-Ar Apparatus

series

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.