ASTM E990-13

(Specification)Standard Specification for Core-Splice Adhesive for Honeycomb Sandwich Structural Panels

Standard Specification for Core-Splice Adhesive for Honeycomb Sandwich Structural Panels

ABSTRACT

This specification covers the requirements for core-splice adhesive for use with nonmetallic honeycomb cores in the fabrication of honeycomb sandwich panels used in relocatable structures. The adhesive shall be thermosetting, of film form, and capable of expanding to several times its original thickness and shall be cured at specific curing time, temperature, and pressure. Materials shall be tested for physical properties qualification which shall conform to water migration, volatility, expansion, sag, density, flexural shear strength or assembly compatibility, and tube shear or core splice integrity requirements. The adhesive shall be suitable for application to core material, edge members, and integral parts.

SCOPE

1.1 This specification covers core-splice adhesive for use with nonmetallic honeycomb cores in the fabrication of honeycomb sandwich panels used in relocatable structures. The adhesive shall be used for new production or depot repair. The adhesive shall be suitable for forming bonds that can withstand long combinations of stress, temperature, and relative humidity expected to be encountered in service. The adhesive shall be used for bonding core segments and for bonding core segments to edge members and to integral members in a honeycomb sandwich panel. The adhesive shall not allow the transfer of water from one part of the panel to another either through or along the line of the adhesive.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E990 −13

Standard Specification for

Core-Splice Adhesive for Honeycomb Sandwich Structural

1

Panels

This standard is issued under the fixed designation E990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D792Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This specification covers core-splice adhesive for use

E631Terminology of Building Constructions

with nonmetallic honeycomb cores in the fabrication of hon-

E864Practice for Surface Preparation of Aluminum Alloys

eycomb sandwich panels used in relocatable structures. The

to Be Adhesively Bonded in Honeycomb Shelter Panels

adhesive shall be used for new production or depot repair.The

E865Specification for Structural Film Adhesives for Hon-

adhesiveshallbesuitableforformingbondsthatcanwithstand

eycomb Sandwich Panels

longcombinationsofstress,temperature,andrelativehumidity

E874Practice for Adhesive Bonding of Aluminum Facings

expected to be encountered in service. The adhesive shall be

to Nonmetallic Honeycomb Core for Shelter Panels

usedforbondingcoresegmentsandforbondingcoresegments

E1091Specification for Nonmetallic Honeycomb Core for

to edge members and to integral members in a honeycomb

Use in Shelter Panels

sandwich panel. The adhesive shall not allow the transfer of

E1749Terminology Relating to Rigid Wall Relocatable

water from one part of the panel to another either through or

Shelters

along the line of the adhesive.

3

2.2 Federal Standards:

1.2 The values stated in SI units are to be regarded as the

QQ-A-250/4 Aluminum Alloy 2024, Plate and Sheet

standard. The values given in parentheses are for information

QQ-A-250/8d Aluminum Alloy 5052H34, Plate and Sheet

only.

QQ-A-250/11d Aluminum Alloy 6061T6, Plate and Sheet

3

1.3 The following precautionary caveat pertains only to the

2.3 Military Standards:

test method portion, Section 6, of this specification: This

MIL-S-8802 Sealing Compound, Temperature-Resistant,

standard does not purport to address all of the safety concerns,

Integral Fuel Tanks, and Fuel Cell Cavities, High-

if any, associated with its use. It is the responsibility of the user

Adhesion

of this standard to establish appropriate safety and health

3. Terminology

practices and determine the applicability of regulatory limita-

tions prior to use.

3.1 Definitions—See Terminologies E631 and E1749 for

definitions of general terms used in this specification.

2. Referenced Documents

4. Materials and Manufacture

2

2.1 ASTM Standards:

B209Specification for Aluminum and Aluminum-Alloy 4.1 The adhesive shall be free of foreign materials, be

noncorrosive to the metal parts, and have the structural

Sheet and Plate

C393/C393MTest Method for Core Shear Properties of integrity equal to or better than that of an unspliced panel

section as specified in Table 1, Flexural Sheer.

Sandwich Constructions by Beam Flexure

5. Requirements

1 5.1 Material—The adhesive shall be thermosetting and

This specification is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.53 when tested in accordance with Section 6, shall meet the

on Materials and Processes for Durable Rigidwall Relocatable Structures.

requirements of Table 1. The adhesive shall not have a

Current edition approved Oct. 1, 2013. Published February 2014. Originally

deleterious effect on the panel nor on its component parts over

approved in 1984. Last previous edition approved in 2009 as E990–09. DOI:

the range of temperature at which the adhesive will be used.

10.1520/E0990-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Avenue,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil/.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

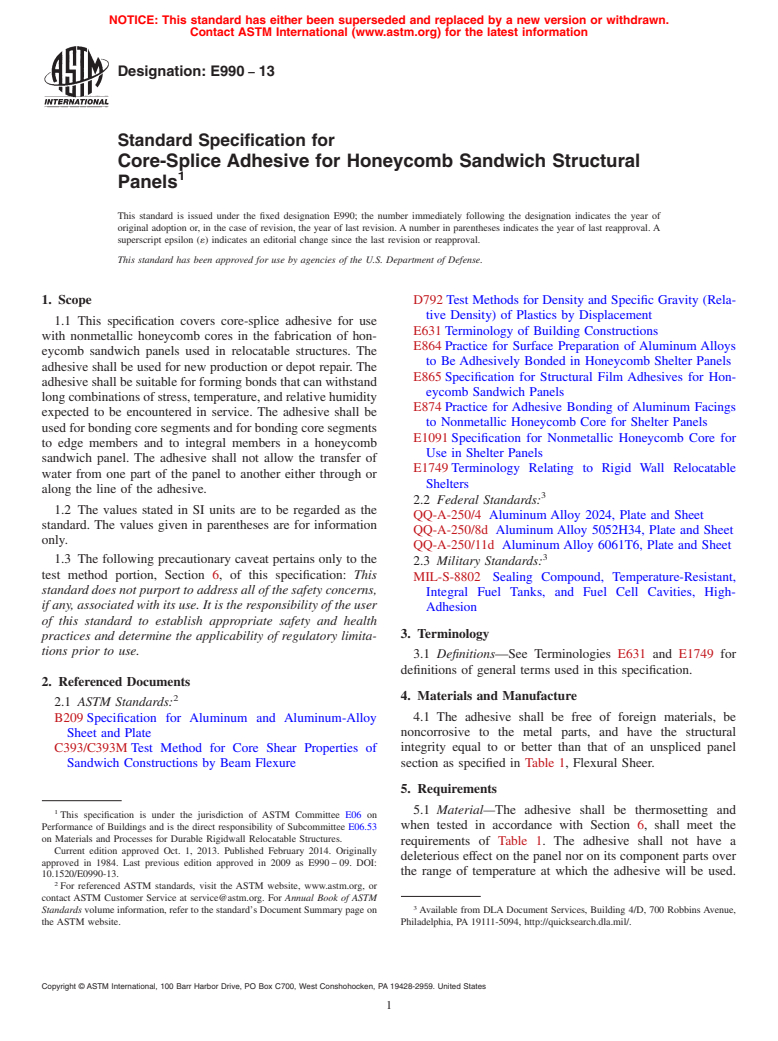

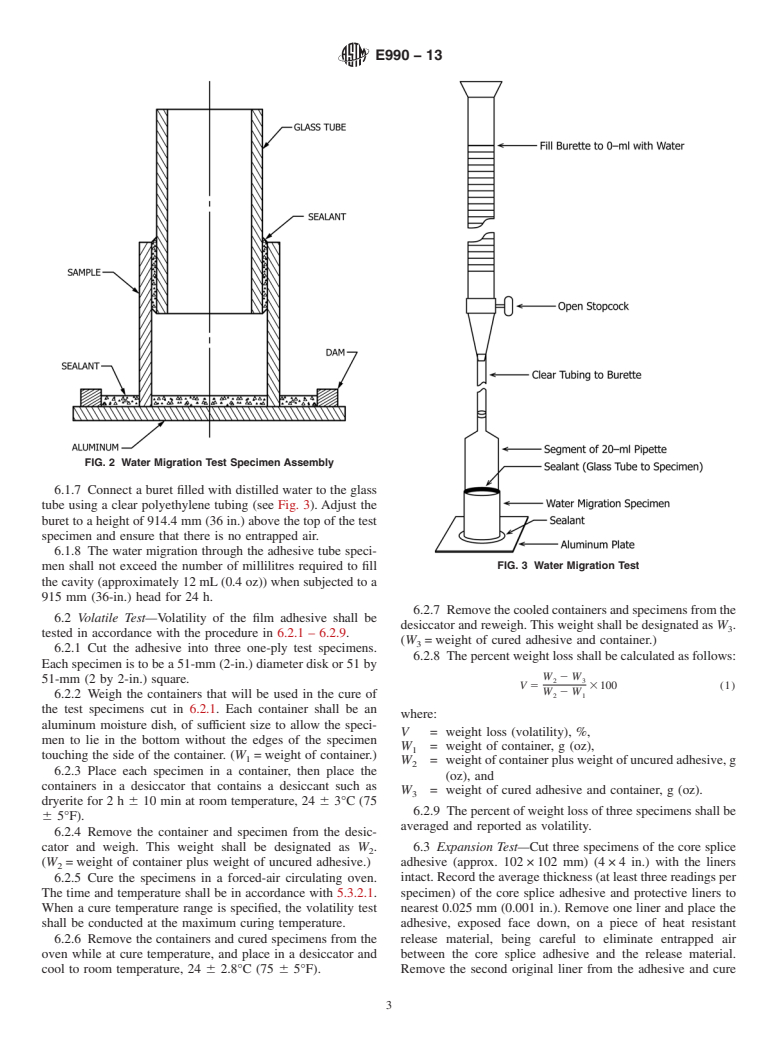

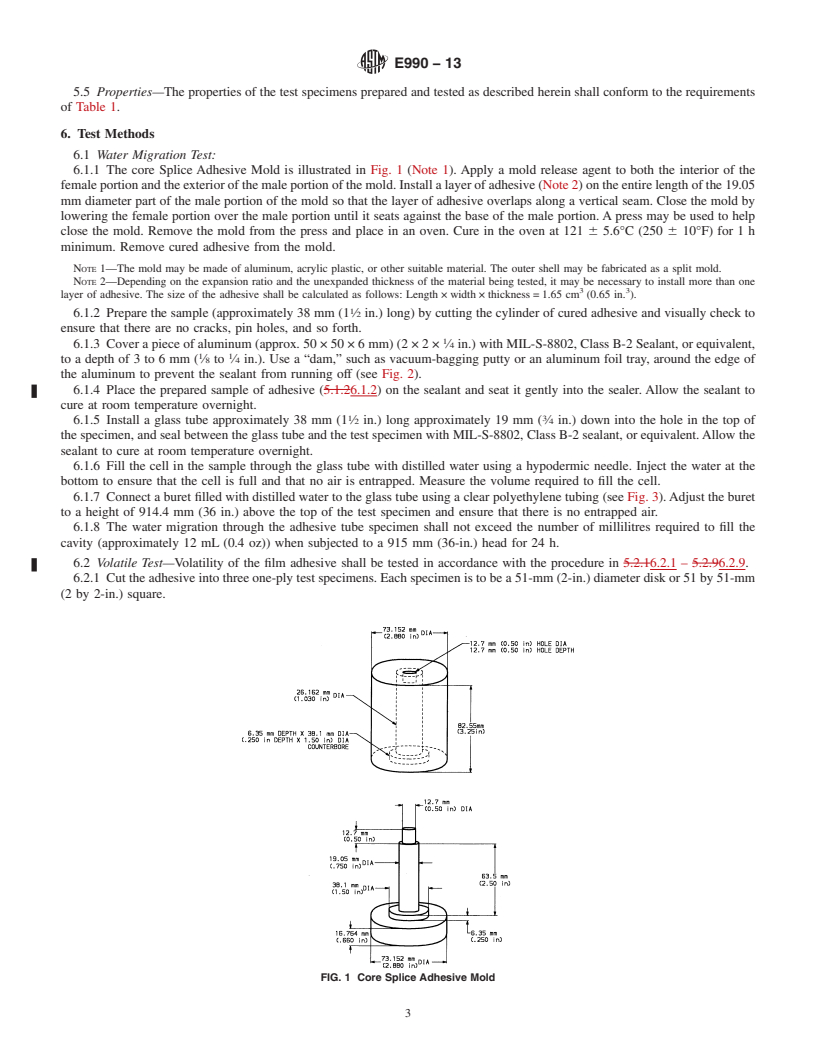

E990−13

TABLE 1 Physical Properties Qualification Requirements

Reference

Table Requirements

Paragraph

Water migration 6.1 Not more than the volume of

the cavity (in cell)

Volatility 6.2 1 % maximum

Expansion 6.3 1.75 minimum ratio

Sag for 1.27 mm (0.05 in.) 6.4 3.8 mm (0.15 in.) maximum

uncured thickness

Sag for 2.54 mm (0.1 in.) 6.4 12.7 mm (0.500 in.) maximum

unc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E990 − 09 E990 − 13

Standard Specification for

Core-Splice Adhesive for Honeycomb Sandwich Structural

1

Panels

This standard is issued under the fixed designation E990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers core-splice adhesive for use with nonmetallic honeycomb cores in the fabrication of honeycomb

sandwich panels used in relocatable structures. The adhesive shall be used for new production or depot repair. The adhesive shall

be suitable for forming bonds that can withstand long combinations of stress, temperature, and relative humidity expected to be

encountered in service. The adhesive shall be used for bonding core segments and for bonding core segments to edge members

and to integral members in a honeycomb sandwich panel. The adhesive shall not allow the transfer of water from one part of the

panel to another either through or along the line of the adhesive.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 56, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B209 Specification for Aluminum and Aluminum-Alloy Sheet and Plate

C393C393/C393M Test Method for Flexural Core Shear Properties of Sandwich Constructions by Beam Flexure

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

E631 Terminology of Building Constructions

E864 Practice for Surface Preparation of Aluminum Alloys to Be Adhesively Bonded in Honeycomb Shelter Panels

E865 Specification for Structural Film Adhesives for Honeycomb Sandwich Panels

E874 Practice for Adhesive Bonding of Aluminum Facings to Nonmetallic Honeycomb Core for Shelter Panels

E1091 Specification for Nonmetallic Honeycomb Core for Use in Shelter Panels

E1749 Terminology Relating to Rigid Wall Relocatable Shelters

3

2.2 Federal Standards:

QQ-A-250/4 Aluminum Alloy 2024, Plate and Sheet

QQ-A-250/8d Aluminum Alloy 5052H34, Plate and Sheet

QQ-A-250/11d Aluminum Alloy 6061T6, Plate and Sheet

3

2.3 Military Standards:

MIL-S-8802 Sealing Compound, Temperature-Resistant, Integral Fuel Tanks, and Fuel Cell Cavities, High-Adhesion

3. Terminology

3.1 Definitions—See Terminologies E631 and E1749 for definitions of general terms used in this specification.

1

This specification is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.53 on Materials

and Processes for Durable Rigidwall Relocatable Structures.

Current edition approved Nov. 1, 2009Oct. 1, 2013. Published December 2009February 2014. Originally approved in 1984. Last previous edition approved in 20042009

as E990 – 04.E990 – 09. DOI: 10.1520/E0990-09.10.1520/E0990-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.DLA

Document Services, Building 4/D, 700 Robbins Avenue, Philadelphia, PA 19111-5094, http://quicksearch.dla.mil/.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E990 − 13

4. Materials and Manufacture

4.1 The adhesive shall be free of foreign materials, be noncorrosive to the metal parts, and have the structural integrity equal

to or better than that of an unspliced panel section as specified in Table 1, Flexural Sheer.

5. Requirements

5.1 Material—The adhesive shall be thermosetting and when tested in accordance with Section 56, shall meet the req

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.