ASTM E2004-18

(Test Method)Standard Test Method for Facing Cleavage of Sandwich Panels

Standard Test Method for Facing Cleavage of Sandwich Panels

SIGNIFICANCE AND USE

4.1 This test method determines the cleavage force required to peel stiff facings from the core of sandwich panels, and is used to determine how well the facing is bonded to the core. Test Method D1781 only works well with flexible facings. As a guideline, the cleavage test method would work better on sandwich panels that have facings with a bending stiffness (EI) of greater than approximately 27.3 lb-in2/inch width (3.09 kN·mm 2/mm width). This converts to approximately 0.032 in. (0.81 mm) 6061 T6 aluminum alloy, 0.023 in. (0.57 mm) steel, and 0.046 in. (1.18 mm) fiberglass facings.

SCOPE

1.1 This test method covers the determination of the cleavage force to peel stiff facings from sandwich panels.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2004 − 18

Standard Test Method for

1

Facing Cleavage of Sandwich Panels

This standard is issued under the fixed designation E2004; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E631 and for general terms related to rigid wall relocatable

shelters, refer to Terminology E1749.

1.1 This test method covers the determination of the cleav-

age force to peel stiff facings from sandwich panels. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 adhesive failure—failure that is completely within the

1.2 The values stated in inch-pound units are to be regarded

adhesive layer with no evidence of interfacial disbonding

as standard. The values given in parentheses are mathematical

between the core and the adhesive, between the adhesive and

conversions to SI units that are provided for information only

the facing, and no evidence of tearing or rupture within the

and are not considered standard.

core.

1.3 This standard does not purport to address all of the

3.2.2 bond failure—failure that is interfacial and is either (a)

safety concerns, if any, associated with its use. It is the

between the adhesive and the core, or (b) between the adhesive

responsibility of the user of this standard to establish appro-

and the facing; no core or adhesive failure will be in evidence

priate safety, health, and environmental practices and deter-

in this type of failure.

mine the applicability of regulatory limitations prior to use.

3.2.2.1 Discussion—If bond failure occurs it should be

1.4 This international standard was developed in accor-

specified as to whether it is type (a)or(b).

dance with internationally recognized principles on standard-

3.2.3 core failure—failure that is completely within the core

ization established in the Decision on Principles for the

material and is comprised of a tearing or rupture of the core

Development of International Standards, Guides and Recom-

material with no evidence of interfacial disbonding between

mendations issued by the World Trade Organization Technical

the core and the adhesive, within the adhesive itself, or

Barriers to Trade (TBT) Committee.

between the adhesive and the facing.

2. Referenced Documents

3.2.4 mixed-mode failure—failure that shows evidence of

2

more than one of the three failure modes described above.

2.1 ASTM Standards:

3.2.4.1 Discussion—Visually estimate and report the per-

D1781 Test Method for Climbing Drum Peel for Adhesives

centofthetotalfailuresurfaceareathatiscoveredbyeachtype

E4 Practices for Force Verification of Testing Machines

of failure.

E631 Terminology of Building Constructions

E1749 Terminology Relating to Rigid Wall Relocatable

4. Significance and Use

Shelters

4.1 This test method determines the cleavage force required

to peel stiff facings from the core of sandwich panels, and is

3. Terminology

used to determine how well the facing is bonded to the core.

3.1 Definitions:

Test Method D1781 only works well with flexible facings. As

3.1.1 For definitions of general terms related to building

a guideline, the cleavage test method would work better on

construction used in this test method, refer to Terminology

sandwich panels that have facings with a bending stiffness (EI)

2

of greater than approximately 27.3 lb-in /inch width (3.09

2

kN·mm /mm width). This converts to approximately 0.032 in.

1

This test method is under the jurisdiction of ASTM Committee E06 on

(0.81 mm) 6061 T6 aluminum alloy, 0.023 in. (0.57 mm) steel,

Performance of Buildings and is the direct responsibility of Subcommittee E06.53

and 0.046 in. (1.18 mm) fiberglass facings.

on Materials and Processes for Durable Rigidwall Relocatable Structures.

Current edition approved Oct. 1, 2018. Published November 2018. Originally

5. Apparatus

approved in 1999. Last previous edition approved in 2010 as E2004–10. DOI:

10.1520/E2004–18.

5.1 Test Machine, capable of maintaining a controlled load-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ing rate and indicating the load with an accuracy of 61%of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the indicated value. The accuracy of the test machine shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. verified in accordance with Practices E4.

Copyright © ASTM International, 100 Barr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2004 − 10 E2004 − 18

Standard Test Method for

1

Facing Cleavage of Sandwich Panels

This standard is issued under the fixed designation E2004; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the cleavage force to peel stiff facings from sandwich panels.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1781 Test Method for Climbing Drum Peel for Adhesives

E4 Practices for Force Verification of Testing Machines

E631 Terminology of Building Constructions

E1749 Terminology Relating to Rigid Wall Relocatable Shelters

3. Terminology

3.1 Definitions:

3.1.1 For definitions of general terms related to building construction used in this test method, refer to Terminology E631 and

for general terms related to rigid wall relocatable shelters, refer to Terminology E1749.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 adhesive failure—failure that is completely within the adhesive layer with no evidence of interfacial disbonding between

the core and the adhesive, between the adhesive and the facing, and no evidence of tearing or rupture within the core.

3.2.2 bond failure—failure that is interfacial and is either (a) between the adhesive and the core, or (b) between the adhesive

and the facing; no core or adhesive failure will be in evidence in this type of failure.

1

This test method is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.53 on Materials

and Processes for Durable Rigidwall Relocatable Structures.

Current edition approved Oct. 1, 2010Oct. 1, 2018. Published October 2010November 2018. Originally approved in 1999. Last previous edition approved in 20042010

as E2004 – 04.E2004–10. DOI: 10.1520/E2004-10.10.1520/E2004–18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.2.2.1 Discussion—

If bond failure occurs it should be specified as to whether it is type (a) or (b).

3.2.3 core failure—failure that is completely within the core material and is comprised of a tearing or rupture of the core material

with no evidence of interfacial disbonding between the core and the adhesive, within the adhesive itself, or between the adhesive

and the facing.

3.2.4 mixed-mode failure—failure that shows evidence of more than one of the three failure modes described above.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2004 − 18

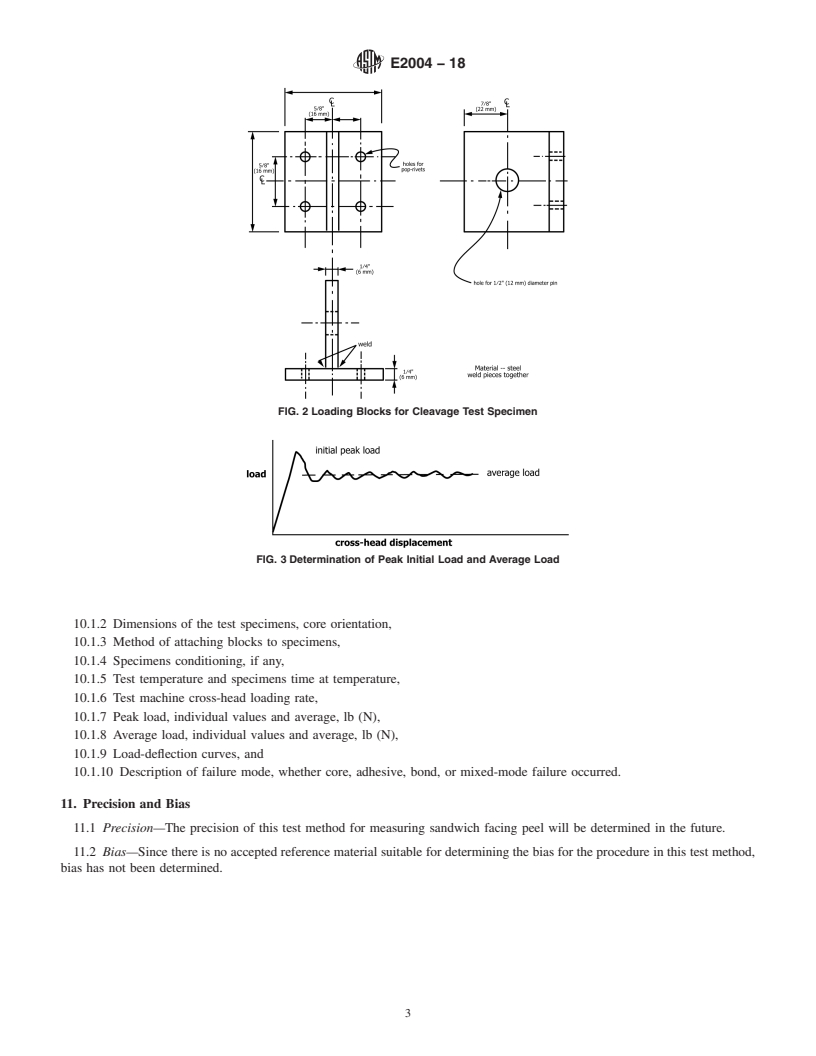

FIG. 1 Cleavage Test Specimen

3.2.4.1 Discussion—

Visually estimate and report the percent of the total failure surface area that is covered by each type of failure.

4. Significance and Use

4.1 This test method determines the cleavage force required to peel stiff facings from the core of sandwich panels, and is used

to determine how well the facing is bonded to the core. Test Method D1781 only works well with flexible facings. As a guideline,

the cleavage test method would work better on sandwich panels that have facings with a bending stiffness (EI) of greater than

2 2

approximately 27.3 lbs-inlb-in /inch width (3.09 kN

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.