ASTM C482-81(1996)

(Test Method)Standard Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste

Standard Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste

SCOPE

1.1 This test method covers the determination of the ability of glazed ceramic wall tile, ceramic mosaic tile, quarry tile, and pavers to be bonded to portland cement. This test method includes both face-mounted and back-mounted tile.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation:C482–81 (Reapproved 1996)

Standard Test Method for

Bond Strength of Ceramic Tile to Portland Cement

This standard is issued under the fixed designation C 482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 Because the laboratory method of applying shear stress

rapidly loads both tile and setting bed in compression, a

1.1 This test method covers the determination of the ability

stronger than normal setting bed for the test specimens is

ofglazedceramicwalltile,ceramicmosaictile,quarrytile,and

specified. This avoids failure of the setting bed before the

pavers to be bonded to portland cement. This test method

desired failure at the tile-bond coat interface occurs. In real tile

includes both face-mounted and back-mounted tile.

installations with portland cement an entirely different loading

1.2 The values stated in inch-pound units are to be regarded

mechanism, usually generated primarily by shrinking of the

as the standard. The values given in parentheses are for

setting bed or structural backing, results in mild tension in

information only.

setting bed and mild compression in the tile, but the same type

1.3 This standard does not purport to address all of the

of shear stress occurs between tile and bond coat as does in

safety concerns, if any, associated with its use. It is the

response to the laboratory loading method. The finding of an

responsibility of the user of this standard to establish appro-

adequate bond strength under the conditions of this test method

priate safety and health practices and determine the applica-

can be taken as proof that the tested tile could be permanently

bility of regulatory limitations prior to use.

bonded in a properly installed conventional installation using

2. Referenced Documents

the lean, low-shrinkage mortars customarily specified for this

particular purpose.

2.1 ASTM Standards:

4.4 To maintain practical sample size and limit maximum

C 150 Specification for Portland Cement

breaking load, tile larger than nominal 4 ⁄4 in. (108 mm) on a

C 185 Test Method for Air Content of Hydraulic Cement

side must be cut to 4 in. (102 mm).

Mortar

C 207 Specification for Hydrated Lime for Masonry Pur-

5. Significance and Use

poses

5.1 This test method provides a means of determining

C 242 Terminology of Ceramic Whitewares and Related

whether or not tile of the types indicated in 1.1 can be bonded

Products

with adequate strength to portland cement. Tile specifications

3. Terminology

can refer to this test method in order to establish minimum

bond strength limits appropriate to the service conditions that

3.1 Definitions:

are anticipated.

3.1.1 For definitions of the types of tile listed in 1.1, refer to

5.2 Separation between bond coat and setting bed, or

Terminology C 242.

breakage of the setting bed itself shall not be considered

4. Summary of Test Method

failures of tile bond.

4.1 This test method consists of bonding tile under con-

6. Apparatus

trolled conditions to a pure cement bond coat, supported by a

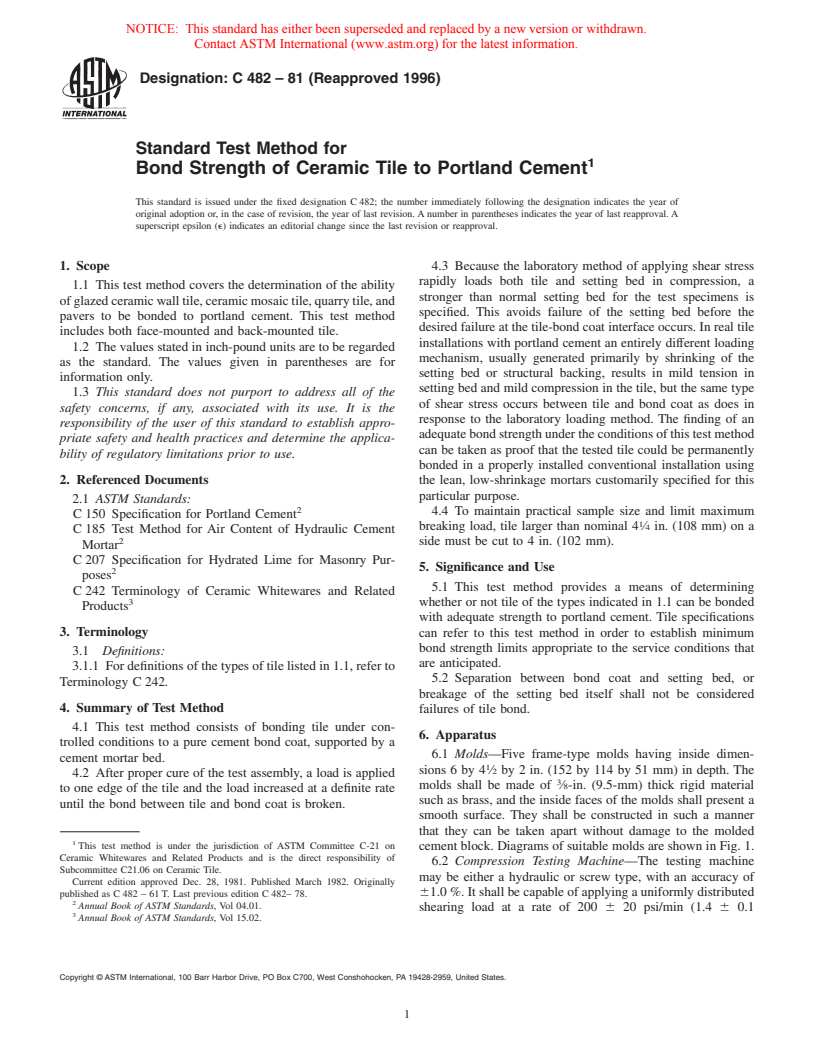

6.1 Molds—Five frame-type molds having inside dimen-

cement mortar bed.

sions 6 by 4 ⁄2 by 2 in. (152 by 114 by 51 mm) in depth. The

4.2 After proper cure of the test assembly, a load is applied

molds shall be made of ⁄8-in. (9.5-mm) thick rigid material

to one edge of the tile and the load increased at a definite rate

such as brass, and the inside faces of the molds shall present a

until the bond between tile and bond coat is broken.

smooth surface. They shall be constructed in such a manner

that they can be taken apart without damage to the molded

This test method is under the jurisdiction of ASTM Committee C-21 on

cement block. Diagrams of suitable molds are shown in Fig. 1.

Ceramic Whitewares and Related Products and is the direct responsibility of

6.2 Compression Testing Machine—The testing machine

Subcommittee C21.06 on Ceramic Tile.

may be either a hydraulic or screw type, with an accuracy of

Current edition approved Dec. 28, 1981. Published March 1982. Originally

61.0 %. It shall be capable of applying a uniformly distributed

published as C 482 – 61 T. Last previous edition C 482– 78.

Annual Book of ASTM Standards, Vol 04.01.

shearing load at a rate of 200 6 20 psi/min (1.4 6 0.1

Annual Book of ASTM Standards, Vol 15.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C482–81 (1996)

Metric Equivalents

Letter in. mm

A ⁄16 4.8

B ⁄8 9.5

C 6 152

D6 ⁄4 171

E4 ⁄2 114

F5 ⁄4 133

G1 ⁄4 32

H2 51

FIG. 1 Mold for Mortar Block (Five Required)

MPa/min) to the tile being tested. To obtain the actual loading 7. Materials

rate in lbf/min (kgf/min) for a particular tile size, multiply the

7.1 Portland Cement—Type I of Specification C 150.

bondedareaofthetileinsquareinchesby200 620(inpascals

7.2 Hydrated Lime—Type S of Specification C 207.

by 1.4 6 0.1).

7.3 Standard Sand—Dry, Standard Ottawa sand con-

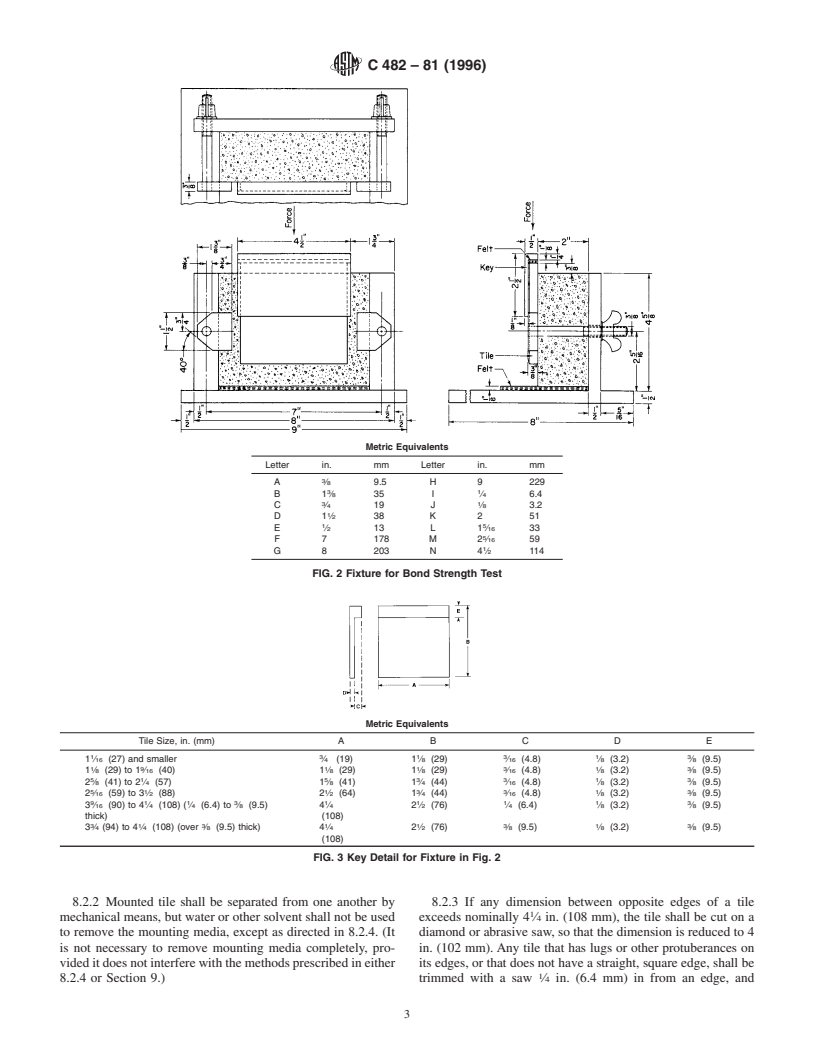

6.3 Fixture,forholdingthespecimenassemblyinanupright

forming to the requirements given in Section 9 of Test Method

position to prevent tilting while the specimen assembly is

C 185.

under load. The construction of such a fixture is shown in Fig.

8. Test Sample

2.

6.4 Keys—Differently sized keys, each for use with a 8.1 Size of Sample—The number of tile comprising a

different size range of tile, to be inserted between the edge of sample varies according to the size of the tile (see Table 1).

the bonded tile and the head of the compression testing 8.2 Selection and Preparation:

machine.TheirexactdimensionsareshowninFig.3.Specially 8.2.1 Tile in the number specified in 8.1 shall be selected at

dimensioned keys may be required for unusual tile thicknesses. random from the lot to be tested.

C482–81 (1996)

Metric Equivalents

Letter in. mm Letter in. mm

A ⁄8 9.5 H 9 229

3 1

B1 ⁄8 35 I ⁄4 6.4

3 1

C ⁄4 19 J ⁄8 3.2

D1 ⁄2 38 K 2 51

1 5

E ⁄2 13 L 1 ⁄16 33

F 7 178 M 2 ⁄16 59

G 8 203 N 4 ⁄2 114

FIG. 2 Fixture for Bond Strength Test

Metric Equivalents

Tile Size, in. (mm) A B C D E

1 3 1 3 1 3

1 ⁄16 (27) and smaller ⁄4 (19) 1 ⁄8 (29) ⁄16 (4.8) ⁄8 (3.2) ⁄8 (9.5)

1 9 1 1 3 1 3

1 ⁄8 (29) to 1 ⁄16 (40) 1 ⁄8 (29) 1 ⁄8 (29) ⁄16 (4.8) ⁄8 (3.2) ⁄8 (9.5)

5 1 5 3 3 1 3

2 ⁄8 (41) to 2 ⁄4 (57) 1 ⁄8 (41) 1 ⁄4 (44) ⁄16 (4.8) ⁄8 (3.2) ⁄8 (9.5)

5 1 1 3 3 1 3

2 ⁄16 (59) to 3 ⁄2 (88) 2 ⁄2 (64) 1 ⁄4 (44) ⁄16 (4.8) ⁄8 (3.2) ⁄8 (9.5)

9 1 1 3 1 1 1 1 3

3 ⁄16 (90) to 4 ⁄4 (108) ( ⁄4 (6.4) to ⁄8 (9.5) 4 ⁄4 2 ⁄2 (76) ⁄4 (6.4) ⁄8 (3.2) ⁄8 (9.5)

thick) (108)

3 1 3 1 1 3 1 3

3 ⁄4 (94) to 4 ⁄4 (108) (over ⁄8 (9.5) thick) 4 ⁄4 2 ⁄2 (76) ⁄8 (9.5) ⁄8 (3.2) ⁄8 (9.5)

(108)

FIG. 3 Key Detail for Fixture in Fig. 2

8.2.2 Mounted tile shall be separated from one another by 8.2.3 If any dimension between opposite edges of a tile

mechanical means, but water or other solvent shall not be used exceeds nominally 4 ⁄4 in. (108 mm), the tile shall be cut on a

to remove the mounting media, except as directed in 8.2.4. (It diamond or abrasive saw, so that the dimension is reduced to 4

is not necessary to remove mounting media completely, pro- in. (102 mm). Any tile that has lugs or other protuberances on

videditdoesnotinterferewiththemethodsprescribedineither its edges, or that does not have a straight, square edge, shall be

8.2.4 or Section 9.) trimmed with a saw ⁄4 in. (6.4 mm) in from an edge, and

C482–81 (1996)

TABLE 1 Number of Tile per Sample

will be vertical d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.