ASTM D6864-10

(Specification)Standard Specification for Color and Appearance Retention of Solid Colored Plastic Siding Products

Standard Specification for Color and Appearance Retention of Solid Colored Plastic Siding Products

ABSTRACT

This specification focuses on the requirements and test methods for the color and appearance retention of solid colored plastic siding products. Color retention testing provides a method for estimating the acceptability of color change in a siding product over a period of years of service. Calculation of ellipsoid values for indicating compliance with this specification are provided.

SCOPE

1.1 This specification establishes requirements and test methods for the color and appearance retention of solid colored plastic siding products.

1.2 Color retention testing provides a method for estimating the acceptability of color change in a siding product over a period of years of service.

1.3 Methods of indicating compliance with this specification are provided.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D6864 – 10

Standard Specification for

Color and Appearance Retention of Solid Colored Plastic

1

Siding Products

This standard is issued under the fixed designation D6864; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ance to these standards during a two year test program can be anticipated

1. Scope

to provide acceptable color retention properties for the expected life of the

1.1 This specification establishes requirements and test

product.

methodsforthecolorandappearanceretentionofsolidcolored

plastic siding products.

3. Terminology

1.2 Color retention testing provides a method for estimating

3.1 Definitions—Definitions are in accordance with Termi-

the acceptability of color change in a siding product over a

nologies D883 and D1600 unless otherwise noted.

period of years of service.

3.2 Definitions of Terms Specific to This Standard:

1.3 Methods of indicating compliance with this specifica-

3.2.1 color region—parameters that define the color space

tion are provided.

for a siding sample. Color is measured with Hunter Units,

sphere geometry (di:8), Illuminant C, 2° observer, specular

NOTE 1—There is no known ISO equivalent to this standard.

component included.

2. Referenced Documents

3.2.1.1 Discussion—Thecolorvaluesusedtoclassifycolors

2

by region were established by measuring the Hunter L, a, b

2.1 ASTM Standards:

D883 Terminology Relating to Plastics color values from the sample population, calculating the

average for Hunter L, a, b, and then choosing the integer from

D1435 Practice for Outdoor Weathering of Plastics

D1600 Terminology for Abbreviated Terms Relating to the corresponding L, a, b average values (that is, by truncating

any fractional result) to be used to classify colors by region.

Plastics

D2244 Practice for Calculation of Color Tolerances and Thusaveragevaluesgreaterthanzeroaretruncateddowntothe

next lowest integer, and average values less than zero are

Color Differences from Instrumentally Measured Color

truncated up to the next highest integer.All values greater than

Coordinates

D3679 Specification for Rigid Poly(Vinyl Chloride) (PVC) -1 and less than +1 truncate to 0.

3.2.2 color retention standards—predictive color regions

Siding

E805 Practice for Identification of Instrumental Methods of described by a three dimensional model, which constitutes

acceptable color retention levels resulting from weathering of

Color or Color-Difference Measurement of Materials

G147 Practice for Conditioning and Handling of Nonmetal- a specific product type and color. Color retention standards are

defined by equations that describe the three dimensional

lic Materials for Natural and Artificial Weathering Tests

2.2 Other Reference: ellipsoid value.

3.2.3 ellipsoid value—a mathematical calculation derived

Vinyl Siding Institute (VSI) Technical Research Report for

Weatherability of Vinyl Siding Products, VS2W by inserting the measured DL, Da, and Db values of a

weathered specimen into an ellipsoid equation.

NOTE 2—This report supports the conclusion that commercial vinyl

3.2.4 temperate northern climate—in weathering testing,a

siding products which demonstrate weathering behavior within conform-

North American metropolitan area testing site within 73 to

100°W longitude and 37 to 45°N latitude.

1

This specification is under the jurisdiction of ASTM Committee D20 on

4. Classification

Plastics and is the direct responsibility of Subcommittee D20.24 on Plastic Building

Products.

4.1 Definitions—Definitions are in accordance with Termi-

Current edition approved Oct. 1, 2010. Published November 2010. Originally

nologies D883 and D1600 unless otherwise noted.

´1

approved in 2003. Last previous addition approved in 2003 as D6864–03a . DOI:

4.2 Color Regions—The color region for a color is deter-

10.1520/D6864-10.

2

mined by measuring the Hunter L, a, b color values for a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

sample. Use the integer value (by truncating any fractional

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

result) to determine the color region for the color using the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. following region boundaries.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6864 – 10

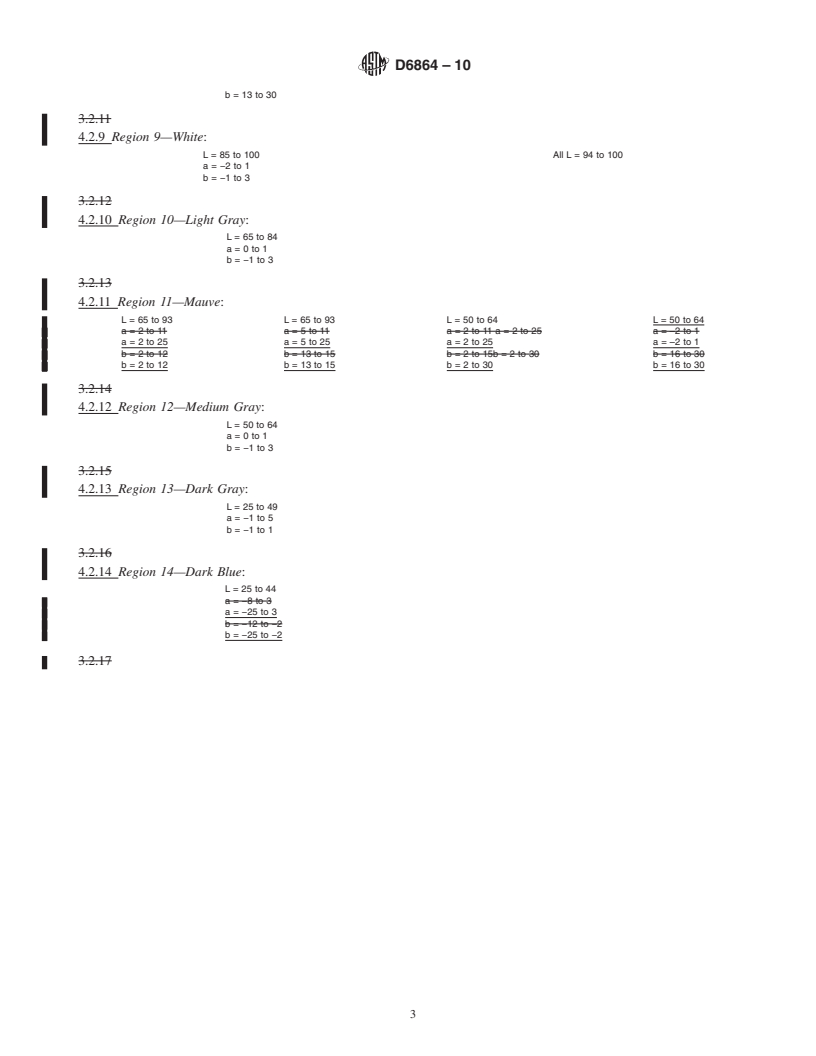

4.2.1 Region 1—Brown: 4.2.15 Region 15—Dark Green:

L = 20 to 49 L = 25 to 49 L = 25 to 49 L = 25 to 49

a=−1to5 a=−8to5 a = −25 to −2 a = −25

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D6864–03a Designation: D6864 – 10

Standard Specification for

Color and Appearance Retention of Solid Colored Plastic

1

Siding Products

This standard is issued under the fixed designation D6864; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Section X1.4 was editorially revised in February 2004.

1. Scope

1.1 This specification establishes requirements and test methods for the color and appearance retention of solid colored plastic

siding products.

1.2 Color retention testing provides a method for estimating the acceptability of color change in a siding product over a period

of years of service.

1.3 Methods of indicating compliance with this specification are provided.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1435 Practice for Outdoor Weathering of Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2244 Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

D3679 Specification for Rigid Poly(Vinyl Chloride) (PVC) Siding

E805 Practice for Identification of Instrumental Methods of Color or Color-Difference Measurement of Materials

G147 Practice for Conditioning and Handling of Nonmetallic Materials for Natural and Artificial Weathering Tests

2.2 Other Reference:

Vinyl Siding Institute (VSI) Technical Research Report for Weatherability of Vinyl Siding Products, VS2W

NOTE1—This 2—This report supports the conclusion that commercial vinyl siding products which demonstrate weathering behavior within

conformance to these standards during a two year test program can be anticipated to provide acceptable color retention properties for the expected life

of the product.

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminologies D883 and D1600 unless otherwise noted.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 color region—parameters that define the color space for a siding sample. Color is measured with Hunter Units, sphere

geometry (di:8), Illuminant C, 2° observer, specular component included.

3.2.1.1 Discussion—The color values used to classify colors by region will be established by measuring the Hunter L, a, b color

valuesfromthesamplepopulation,calculatingtheaverageforHunterL,a,b,andthenchoosingtheintegerfromthecorresponding

L, a, b average values (that is, no rounding up or down) to be used to classify colors by region. —The color values used to classify

colorsbyregionwereestablishedbymeasuringtheHunterL,a,bcolorvaluesfromthesamplepopulation,calculatingtheaverage

forHunterL,a,b,andthenchoosingtheintegerfromthecorrespondingL,a,baveragevalues(thatis,bytruncatinganyfractional

result) to be used to classify colors by region. Thus average values greater than zero are truncated down to the next lowest integer,

and average values less than zero are truncated up to the next highest integer.All values greater than -1 and less than +1 truncate

to 0.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.24 on Plastic Building Products.

Current edition approved Dec.Oct. 1, 2003.2010. Published January 2004.November 2010. Originally approved in 2003. Last previous addition approved in 2003 as

´1

D6864–03a . DOI: 10.1520/D6864-03AE01. DOI: 10.1520/D6864-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6864 – 10

3.2.2 color retention standards—predictive color regions described by a three dimensional model, which constitutes acceptable

color retention levels resulting from weathering of a specific product type and color. Color retention standards are defined by

equations that describe the three dimensional ellipsoid value.

3.2.3 ellipsoid value—a mathematical calculation derived by inserting the measured DL, Da, and Db values of a weathered

specimen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.