ASTM B344-14

(Specification)Standard Specification for Drawn or Rolled Nickel-Chromium and Nickel-Chromium-Iron Alloys for Electrical Heating Elements

Standard Specification for Drawn or Rolled Nickel-Chromium and Nickel-Chromium-Iron Alloys for Electrical Heating Elements

SCOPE

1.1 This specification covers annealed, drawn, or rolled shapes for electrical heating purposes, of alloys having the nominal compositions of 80 % nickel and 20 % chromium; 60 % nickel, 16 % chromium, and remainder iron; and 35 % nickel, 20 % chromium, and remainder iron; 38 % nickel, 21 % chromium, and remainder iron; and 35 % nickel, 20 % chromium remainder iron.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B344 −14

Standard Specification for

Drawn or Rolled Nickel-Chromium and Nickel-Chromium-

1

Iron Alloys for Electrical Heating Elements

This standard is issued under the fixed designation B344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4.2 Samples for Chemical Analysis—Specimens for chemi-

calanalysismaybetakenfromeitherthemeltorfromasample

1.1 This specification covers annealed, drawn, or rolled

of finished wire that is representative of the lot.

shapes for electrical heating purposes, of alloys having the

4.2.1 The lot size for determining compliance with the

nominal compositions of 80 % nickel and 20 % chromium;

requirements of this specification shall be one heat.

60 % nickel, 16 % chromium, and remainder iron; and 35 %

nickel,20 %chromium,andremainderiron;38 %nickel,21 %

4.3 Chemical Analysis—The chemical analysis shall be

chromium, and remainder iron; and 35 % nickel, 20 % chro-

made in accordance with Test Methods A751, or by other

mium remainder iron.

analytical methods approved by the purchaser.

1.2 The values stated in inch-pound units are to be regarded

4.4 Actual chemical analysis is not required for routine

as standard. The values given in parentheses are mathematical

acceptance.

conversions to SI units that are provided for information only

and are not considered standard.

5. Physical Requirements

2. Referenced Documents

5.1 The material shall be thoroughly and uniformly an-

2

2.1 ASTM Standards:

nealed.

A751 Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products 5.2 Wire shall conform to the following elongation require-

B63 Test Method for Resistivity of Metallically Conducting

ments:

Resistance and Contact Materials

Size Elongation in 10 in.,

B70 Test Method for Change of Resistance With Tempera- min, %

0.0035 in. (0.0889 mm) (No. 39 Awg) and larger 20

ture of Metallic Materials for Electrical Heating

0.0031 in. (0.0787 mm) to 0.002 in. 10

B76 Test Method for Accelerated Life of Nickel-Chromium

(0.0508 mm) (Nos. 40 to 44 Awg)

and Nickel-Chromium-Iron Alloys for Electrical Heating

5.3 Determination is not required for routine acceptance.

3. Significance and Use

6. Nominal Resistivity

3.1 This specification on nickel-chromium and nickel-

chromium-iron alloys contains the requirements for chemistry,

6.1 The nominal resistivity (Note 1) shall be the resistivity

electrical resistance, mechanical properties, and packaging.

of the wire as quenched from a temperature above 1450°F

(788°C). The numerical value of the nominal resistivity shall

4. Requirements

be as shown in Table 2.

4.1 The alloys shall conform to the requirements as to

6.2 Determination is not required for routine acceptance.

chemical composition prescribed in Table 1.

NOTE 1—The characteristics of these alloys are such that the actual

1

This specification is under the jurisdiction of ASTM Committee B02 on

resistivity of annealed wire may be as much as 6 % higher than the

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

nominal, depending on its method of manufacture.

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

Current edition approved Oct. 1, 2014. Published October 2014. Originally

7. Test for Resistivity

approved in 1959. Last previous edition approved in 2011 as B344 – 11. DOI:

10.1520/B0344-14.

2 7.1 The resistivity shall be determined in accordance with

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Test Method B63.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 7.2 Determination is not required for routine acceptance.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B344−14

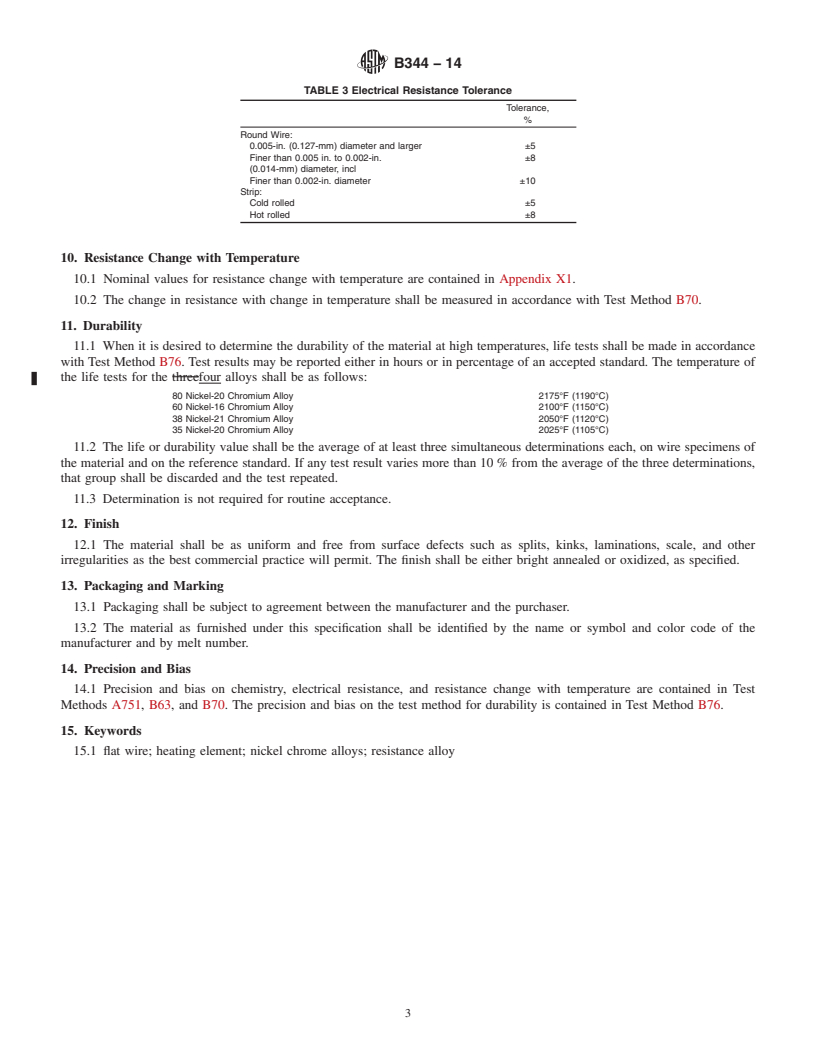

TABLE 1 Chemical Requirements

Composition, %

Element

80 Nickel-20 Chromium Alloy 60 Nickel-16 Chromium Alloy 38 Nickel-21 Chromium Alloy 35 Nickel-20 Chromium Alloy

A

Nickel remainder 57 min 36 to 39 34 to 37

Chromium 19 to 21 14 to 18 20 to 23 18 to 21

Manganese 1.0 max 1.0 max 1.0 max 1.0 max

Carbon 0.15 max 0.15 max 0.12 max 0.15 max

Silicon 0.75 to 1.75 0.75 to 1.75 1.3 to 2.2 1.0 to 3.0

Sulfur 0.01 max 0.01 max 0.03 max 0.01 max

Iron 1.0 max remainder remainder remainder

Phosphorus 0.03 max

Copper 0.5 max

Lanthanum 0.03 to 0.20

A

Quantities of less than 1 % cobalt included shall be r

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B344 − 11 B344 − 14

Standard Specification for

Drawn or Rolled Nickel-Chromium and Nickel-Chromium-

1

Iron Alloys for Electrical Heating Elements

This standard is issued under the fixed designation B344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers annealed, drawn, or rolled shapes for electrical heating purposes, of alloys having the nominal

compositions of 80 % nickel and 20 % chromium; 60 % nickel, 16 % chromium, and remainder iron; and 35 % nickel, 20 %

chromium, and remainder iron; 38 % nickel, 21 % chromium, and remainder iron; and 35 % nickel, 20 % chromium remainder

iron.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

B63 Test Method for Resistivity of Metallically Conducting Resistance and Contact Materials

B70 Test Method for Change of Resistance With Temperature of Metallic Materials for Electrical Heating

B76 Test Method for Accelerated Life of Nickel-Chromium and Nickel-Chromium-Iron Alloys for Electrical Heating

3. Significance and Use

3.1 This specification on nickel-chromium and nickel-chromium-iron alloys contains the requirements for chemistry, electrical

resistance, mechanical properties, and packaging.

4. Requirements

4.1 The alloys shall conform to the requirements as to chemical composition prescribed in Table 1.

4.2 Samples for Chemical Analysis—Specimens for chemical analysis may be taken from either the melt or from a sample of

finished wire that is representative of the lot.

4.2.1 The lot size for determining compliance with the requirements of this specification shall be one heat.

4.3 Chemical Analysis—The chemical analysis shall be made in accordance with Test Methods A751, or by other analytical

methods approved by the purchaser.

4.4 Actual chemical analysis is not required for routine acceptance.

5. Physical Requirements

5.1 The material shall be thoroughly and uniformly annealed.

5.2 Wire shall conform to the following elongation requirements:

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.10 on

Thermostat Metals and Electrical Resistance Heating Materials.

Current edition approved Oct. 1, 2011Oct. 1, 2014. Published November 2011October 2014. Originally approved in 1959. Last previous edition approved in 20012011

as B344 – 01B344 which was withdrawn May 2011 and reinstated in October 2011. DOI: 10.1520/B0344-11.– 11. DOI: 10.1520/B0344-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B344 − 14

TABLE 1 Chemical Requirements

Composition, %

Element

80 Nickel-20 Chromium Alloy 60 Nickel-16 Chromium Alloy 38 Nickel-21 Chromium Alloy 35 Nickel-20 Chromium Alloy

A

Nickel remainder 57 min 36 to 39 34 to 37

Chromium 19 to 21 14 to 18 20 to 23 18 to 21

Manganese 1.0 max 1.0 max 1.0 max 1.0 max

Carbon 0.15 max 0.15 max 0.12 max 0.15 max

Silicon 0.75 to 1.75 0.75 to 1.75 1.3 to 2.2 1.0 to 3.0

Sulfur 0.01 max 0.01 max 0.03 max 0.01 max

Iron 1.0 max remainder remainder remainder

Phosphorus 0.03 max

Copper 0.5 max

Lanthanum 0.03 to 0.20

A

Quantities of less than 1 % cobalt included shall be reported as nickel.

Size Elongation in 10 in.,

min, %

0.0035 in. (0.0889 mm) (No. 39 Awg) and larger 20

0.0031 in. (0.0787 mm) to 0.002 in. 10

(0.0508 mm) (Nos. 40 to 44 Awg)

5.3 Determination is not required for routine acceptance.

6. Nominal Resistivity

6.1 The nominal resistivity (Note 1) shall be the resistivity of the wire as quenched from a temperature above 1450°F (788°C).

The numerical value of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.