ASTM D2684-95(2005)

(Test Method)Standard Test Method for Permeability of Thermoplastic Containers to Packaged Reagents or Proprietary Products

Standard Test Method for Permeability of Thermoplastic Containers to Packaged Reagents or Proprietary Products

SIGNIFICANCE AND USE

With the proper precautions and background experience, results can be useful for estimation of the loss of a packaged product through the walls of a container during shelf storage. The test is also useful for isolating the effects of a container design and materials, and is applicable for development and research and for specification purposes.

In the absence of adequate supporting data, extrapolations or correlations of results to conditions beyond those of the test are not recommended because of possible product alteration, solvency, or chemical effects on the plastic, etc.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method covers procedures for determining the permeability of thermoplastic containers to packaged reagents or proprietary products under specified conditions of exposure. The exposures used are intended to simulate the normal and elevated temperature-storage conditions that might be encountered in end-use application.

1.2 This test method is applicable only to those types of containers designed to allow positive, leakproof closure.

1.3 Two procedures are provided:

1.3.1 Procedure A is specific to testing only with a standard design container. This procedure provides for determinations of rate of weight loss (or gain) and for calculation of a permeability factor.

1.3.2 Procedure B applies to tests of all other container designs. Permeability data by this procedure are expressed only in terms of rate of weight loss (or gain) for the particular container tested.

1.4 The values stated in SI units are to be regarded as standard.

Note 1—There is no similar or equivalent ISO Standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2684–95 (Reapproved 2005)

Standard Test Method for

Permeability of Thermoplastic Containers to Packaged

Reagents or Proprietary Products

This standard is issued under the fixed designation D2684; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1505 Test Method for Density of Plastics by the Density-

Gradient Technique

1.1 This test method covers procedures for determining the

E145 Specification for Gravity-Convection and Forced-

permeability of thermoplastic containers to packaged reagents

Ventilation Ovens

orproprietaryproductsunderspecifiedconditionsofexposure.

The exposures used are intended to simulate the normal and

3. Terminology

elevated temperature-storage conditions that might be encoun-

3.1 Definitions:

tered in end-use application.

3.1.1 permeability factor, P —the permeability of a given

t

1.2 This test method is applicable only to those types of

plastic to a given product at temperature t, in degrees Celsius,

containers designed to allow positive, leakproof closure.

expressedinunitsofg·cm/day·m ,asdeterminedbyProcedure

1.3 Two procedures are provided:

A. The permeability factor under 23°C test conditions, for

1.3.1 Procedure A isspecifictotestingonlywithastandard

example, is signified by the notation P .

design container. This procedure provides for determinations

3.1.2 Determination of P is based on an averaged wall

t

of rate of weight loss (or gain) and for calculation of a

thickness over the entire area of the container and an assump-

permeability factor.

tion that permeation rate is inversely proportional to the

1.3.2 Procedure B applies to tests of all other container

thickness. Precaution in the extent of allowable variations of

designs.Permeabilitydatabythisprocedureareexpressedonly

these factors is recommended, and use of P should take into

t

in terms of rate of weight loss (or gain) for the particular

consideration that wall thickness of the containers varies, that

container tested.

the estimate of average thickness from density, area, and

1.4 The values stated in SI units are to be regarded as

weight is not exact, and that permeability of the product

standard.

throughtheplasticmaterialmaynotbedirectlyproportionalto

NOTE 1—There is no known ISO equivalent to this standard.

the thickness.

1.5 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 Test bottles are filled with the test product and, after

responsibility of the user of this standard to establish appro-

sealing, are exposed at 23°C (73.4°F) and 50°C (122°F)

priate safety and health practices and determine the applica-

conditions for 28 days or longer. Measurements of weight are

bility of regulatory limitations prior to use.

made at intervals to determine the average rate of weight

2. Referenced Documents

change.

2.1 ASTM Standards:

5. Significance and Use

D618 Practice for Conditioning Plastics for Testing

5.1 Withtheproperprecautionsandbackgroundexperience,

D4976 Specification for Polyethylene Plastics Molding and

results can be useful for estimation of the loss of a packaged

Extrusion Materials

product through the walls of a container during shelf storage.

The test is also useful for isolating the effects of a container

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

design and materials, and is applicable for development and

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

research and for specification purposes.

Current edition approved July 15, 2005. Published August 2005. Originally

approved in 1968. Last previous edition approved in 2001 as D2684-95 (2001). 5.2 In the absence of adequate supporting data, extrapola-

DOI: 10.1520/D2684-95R05.

tionsorcorrelationsofresultstoconditionsbeyondthoseofthe

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

test are not recommended because of possible product alter-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ation, solvency, or chemical effects on the plastic, etc.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2684–95 (2005)

5.3 Before proceeding with this test method, reference

shouldbemadetothespecificationofthematerialbeingtested.

Any test specimen preparation, conditioning, dimensions, or

testing parameters, or combination thereof, covered in the

materials specification shall take precedence over those men-

tioned in this test method. If there are no material specifica-

tions, then the default conditions apply.

6. Apparatus

6.1 Enclosure or room with provision for maintaining the

standard laboratory atmosphere of 23 6 2°C (73.4 6 3.6°F)

and 50 6 5% relative humidity, as defined by Practice D618.

6.2 Circulating-Air Oven, consistent with ovens in accor-

dance with Specification E145, capable of maintaining a

temperature of 50 6 1°C (122 6 1.8°F) and an airflow rate of

3 3 3

8.5to17.0m /min(300to600ft /min).Thelimitationof25ft

on oven size can be overlooked, provided all other require-

ments are met.

NOTE 2—Only explosion-proof equipment with provision for adequate

exhaust of vapors should be used for tests with potentially hazardous or

toxic products.

NOTE 3—Relative humidity variation can significantly affect perme-

ability loss in many products, especially water-based products in various

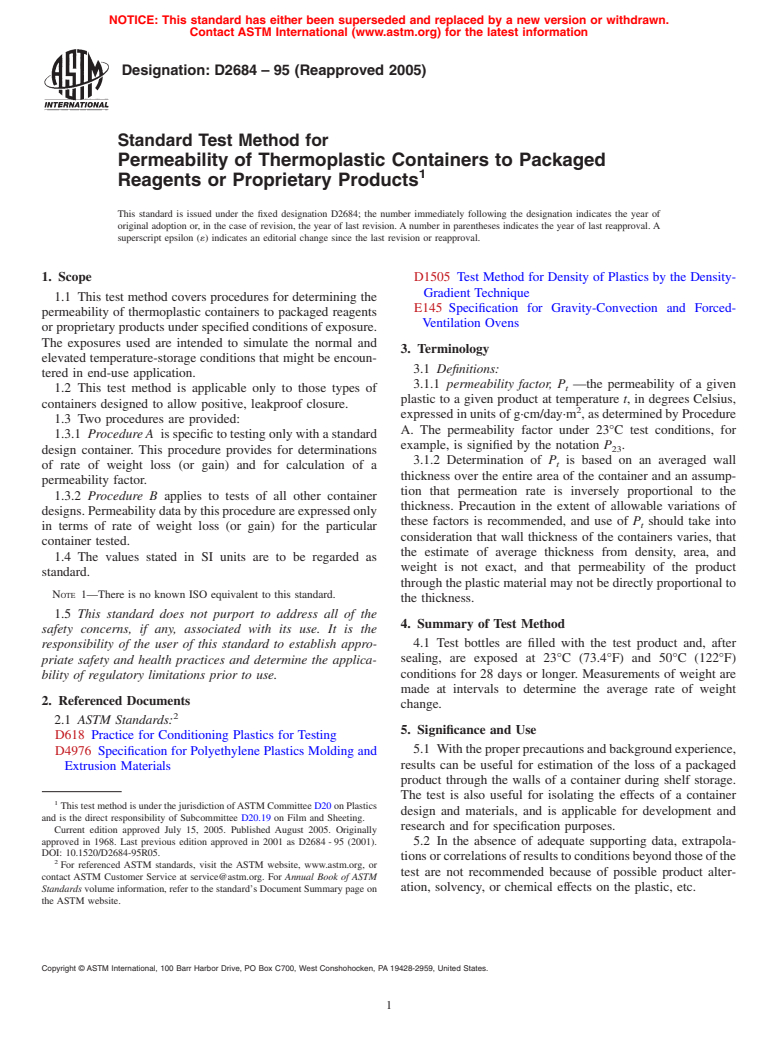

NOTE 1—Dimensions are in millimetres.

thermoplastics. Therefore, the user may find it useful to equip the oven

FIG. 1 Standard Container for Permeability Test

with a means to measure relative humidity and to record the same during

the period of test.

than 40 h prior to test in accordance with Procedure A of

6.3 Balance, accurate to 0.01% of the weight of test

Practice D618, for those tests where conditioning is required.

container and contents.

In cases of disagreement, the tolerances shall be 61°C

6.4 Container Seals, suitable heat-sealing laminate and

(61.8°F) and 62% relative humidity.

polyethylene or other suitably lined screw-type closures for

9.2 Test Conditions—Conduct tests in the standard labora-

sealing the containers.

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 65%

6.5 Heat Sealer.

relative humidity, unless otherwise specified in the test meth-

6.6 Torque Wrench.

ods. In cases of disagreements, the tolerances shall be 61°C

7. Reagents and Materials (61.8°F) and 62% relative humidity.

7.1 The reagent or proprietary product as specified for

10. Procedure A (Standard Container)

testing.

10.1 With specimens taken from the sidewalls of three of

8. Test Specimens

the containers, determine the average plastic density by Test

Method D1505, or by an alternative method of equivalent

8.1 The test specimen for Procedure A shall be the 4-oz

accuracy.

cylindrical bottle design as specified in Fig. 1, having a

2 2

10.2 For each test temperature, select a minimum of three

nominal external surface area of 154 cm (23.8 in. ).

containers. Weigh each when empty, without the closure.Also

8.2 The test specimen for Procedure B may be any thermo-

weigh the empty containers with their corresponding closures

plastic container, as specified or selected for test evaluation,

and appropriately sized laminate pieces.

provided it is designed to allow positive closure.

10.3 Fill the containers to nominal capacity with the test

8.3 Foreachprocedure,aminimumofthreespecimensshall

product.

be tested at each temperature. Three additional specimens are

10.4 Make a thorough check for any drippage or spill of

required for Procedure A for determination of the plastic

productontheoutsidesurfaceofthecontainers.Ifanyisnoted,

density.

replace the container with a new specimen.

NOTE 4—Trim and finish the containers, if needed, to ensure a smooth

10.5 Heat seal the containers with the laminate (plastic to

contacting surface for positive seal.

plastic), check for leaks, and then cap the co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.