ASTM D4966-12e1

(Test Method)Standard Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method)

Standard Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method)

SIGNIFICANCE AND USE

5.1 Acceptance Testing—this test method is not considered satisfactory for acceptance testing of commercial shipments of fabric. The between-laboratory precision of this test method is poor and, because of the nature of abrasion testing itself, technicians frequently fail to obtain results in agreement on the same type of testing instrument, both within and between laboratories. Although this test method is not recommended for acceptance testing, it is useful because it is used widely, especially outside the United States.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens then should be assigned randomly in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Students t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in light of the known bias.

5.2 The resistance to abrasion also is affected greatly by the conditions of the tests, such as the nature of abradant; variable action of the abradant over the area of specimen abraded, the tension on the specimen, the pressure between the specimen and abradant, and the dimensional changes in the specimen.

5.3 Abrasion tests are all subject to variation due to changes in the abradant during specific tests. The abradant must be changed accordingly at freque...

SCOPE

1.1 This test method covers the determination of the abrasion resistance of textile fabrics using the Martindale abrasion tester. Fabrics of all types may be tested by this method but difficulties may arise with fabrics with a pile depth greater than 0.08 in. (2 mm).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1—For other current test methods of testing the abrasion resistance of textiles refer to Test Methods D3884, D3885, D3886, D4157, D4158, and AATCC Test Method 93.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4966 − 12

StandardTest Method for

Abrasion Resistance of Textile Fabrics (Martindale Abrasion

1

Tester Method)

This standard is issued under the fixed designation D4966; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—In Section 10.6, the referenced paragraphs for Options 1 and 2 were corrected to 11.1 and 11.2 in February

2013.

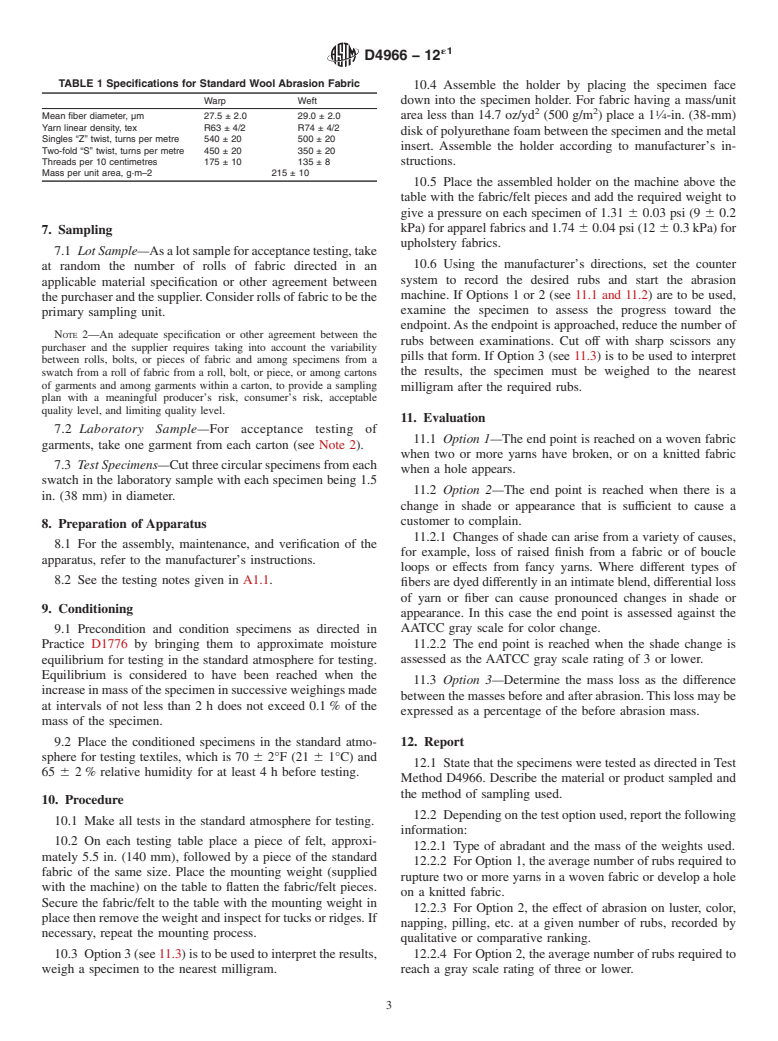

1. Scope D4157 Test Method for Abrasion Resistance of Textile

Fabrics (Oscillatory Cylinder Method)

1.1 This test method covers the determination of the abra-

D4158 Guide for Abrasion Resistance of Textile Fabrics

sion resistance of textile fabrics using the Martindale abrasion

(Uniform Abrasion)

tester. Fabrics of all types may be tested by this method but

D4850 Terminology Relating to Fabrics and Fabric Test

difficulties may arise with fabrics with a pile depth greater than

Methods

0.08 in. (2 mm).

2.2 AATCC Methods and Procedures:

1.2 The values stated in inch-pound units are to be regarded 3

Evaluation Procedure 1 Gray Scale for Color Change

as standard. The values given in parentheses are mathematical

Test Method 93 Abrasion Resistance of Fabrics:Accelerator

conversions to SI units that are provided for information only 3

Method

and are not considered standard.

3. Terminology

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1 For all terminology relating to D13.60, Fabric Test

responsibility of the user of this standard to establish appro-

Methods, Specific, refer to Terminology D4850.

priate safety and health practices and determine the applica-

3.1.1 The following terms are relevant to this standard:

bility of regulatory limitations prior to use.

abrasion, abrasion cycle, Lissajous figure, rub, standard atmo-

sphere for preconditioning textiles, standard atmosphere for

NOTE 1—For other current test methods of testing the abrasion

resistanceoftextilesrefertoTestMethodsD3884,D3885,D3886,D4157, testing, in textiles.

D4158, and AATCC Test Method 93.

3.2 For all other terms related to textiles, refer to Terminol-

ogy D123.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Summary of Test Method

D123 Terminology Relating to Textiles

4.1 Abrasion resistance is measured by subjecting the speci-

D1776 Practice for Conditioning and Testing Textiles

men to rubbing motion in the form of a geometric figure, that

D3884 Guide for Abrasion Resistance of Textile Fabrics

is, a straight line, which becomes a gradually widening ellipse,

(Rotary Platform, Double-Head Method)

until it forms another straight line in the opposite direction and

D3885 Test Method for Abrasion Resistance of Textile

traces the same figure again under known conditions of

Fabrics (Flexing and Abrasion Method)

pressure and abrasive action. Resistance to abrasion is evalu-

D3886 Test Method for Abrasion Resistance of Textile

ated by various means which are described in Section 11.

Fabrics (Inflated Diaphragm Apparatus)

5. Significance and Use

5.1 Acceptance Testing—this test method is not considered

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

satisfactory for acceptance testing of commercial shipments of

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific. fabric. The between-laboratory precision of this test method is

Current edition approved Feb. 1, 2012. Published February 2012. Originally

poor and, because of the nature of abrasion testing itself,

approved in 1989. Last previous edition approved in 2010 as D4966 – 10. DOI:

technicians frequently fail to obtain results in agreement on the

10.1520/D4966-12E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the American Association of Textile Chemists and Colorists,

the ASTM website. P.O. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D4966 − 12

intervals. The measurement of the relative amount of abrasion

also may be affected by the method of evaluation and may be

influenced by the judgment of the operator.

5.4 The resistance of textile materials to abrasion as mea-

sured on a testing machine in the laboratory is generally only

one of several factors contributing to wear performance or

durability as experienced in the actual use of the mate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.