ASTM D3885-07A(2019)e1

(Test Method)Standard Test Method for Abrasion Resistance of Textile Fabrics (Flexing and Abrasion Method)

Standard Test Method for Abrasion Resistance of Textile Fabrics (Flexing and Abrasion Method)

SIGNIFICANCE AND USE

5.1 This test method is not recommended for acceptance testing of commercial shipments because information on between-laboratory precision is known to be poor.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, the test samples to be used are as homogenous as possible, are drawn from the material from which the disparate test results were obtained, and are randomly assigned in equal numbers to each laboratory for testing. Other fabrics with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

5.2 The measurement of the resistance to abrasion of textile fabrics is very complex. The resistance to abrasion is affected by many factors that include the inherent mechanical properties of the fibers; the dimensions of the fibers; the structure of the yarns; the construction of the fabrics; the type, kind, and amount of treatment added to the fibers, yarns, or fabric; the nature of the abradant; the variable action of the abradant over the specimen area abraded; the tension on the specimen; the pressure between the specimen and the abradant; and the dimensional changes in the specimen.

5.3 The measurement of the relative amount of abrasion can be affected by the method of evaluation and is often influenced by the judgment of the operator. It is recognized that with this test method other means of evaluation besides cycles to rupture and breaking strength have been used by the industry, such as color change, appearance change, and so forth. Experience...

SCOPE

1.1 This test method2 covers the determination of the abrasion resistance of woven or nonwoven textile fabrics using the flexing and abrasion tester.

1.2 This test method applies to most woven and nonwoven fabrics providing they do not stretch excessively. It is not applicable to floor coverings.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: For other test methods for abrasion resistance of textiles refer to Test Methods D3884, D3886, D4157, D4158, D4966, and AATCC93.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D3885 − 07a (Reapproved 2019)

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Flexing and

Abrasion Method)

This standard is issued under the fixed designation D3885; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

7 1

ε NOTE—In 6.2, the last unit in parentheses was corrected from 6 ⁄16 in. to 6 ⁄16 in. editorially in May 2021.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of the

2.1 ASTM Standards:

abrasion resistance of woven or nonwoven textile fabrics using

D76 Specification for Tensile Testing Machines for Textiles

the flexing and abrasion tester.

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

1.2 This test method applies to most woven and nonwoven

fabrics providing they do not stretch excessively. It is not D2904 Practice for Interlaboratory Testing of a Textile Test

applicable to floor coverings. Method that Produces Normally Distributed Data (With-

drawn 2008)

1.3 The values stated in either SI units or inch-pound units

D2906 Practice for Statements on Precision and Bias for

are to be regarded separately as the standard. Within the text,

Textiles (Withdrawn 2008)

the inch-pound units are shown in parentheses. The values

D3884 Guide for Abrasion Resistance of Textile Fabrics

stated in each system may not be exact equivalents; therefore,

(Rotary Platform, Double-Head Method)

each system shall be used independently of the other. Combin-

D3886 Test Method for Abrasion Resistance of Textile

ingvaluesfromthetwosystemsmayresultinnonconformance

Fabrics (Inflated Diaphragm Apparatus)

with this test method.

D4157 Test Method for Abrasion Resistance of Textile

1.4 This standard does not purport to address all of the

Fabrics (Oscillatory Cylinder Method)

safety concerns, if any, associated with its use. It is the

D4158 Guide for Abrasion Resistance of Textile Fabrics

responsibility of the user of this standard to establish appro-

(Uniform Abrasion)

priate safety, health, and environmental practices and deter-

D4850 Terminology Relating to Fabrics and Fabric Test

mine the applicability of regulatory limitations prior to use.

Methods

NOTE 1—For other test methods for abrasion resistance of textiles refer

D4966 Test Method for Abrasion Resistance of Textile

to Test Methods D3884, D3886, D4157, D4158, D4966, and AATCC93.

Fabrics (Martindale Abrasion Tester Method)

1.5 This international standard was developed in accor-

D5035 Test Method for Breaking Force and Elongation of

dance with internationally recognized principles on standard-

Textile Fabrics (Strip Method)

ization established in the Decision on Principles for the

2.2 AATCC Test Method:

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical AATCC 93 Abrasion Resistance of Fabrics: Accelerotor

Barriers to Trade (TBT) Committee.

Method

1 3

This test method is under the jurisdiction ofASTM Committee D13 on Textiles For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Specific. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2019. Published July 2019. Originally approved the ASTM website.

in 1980. Last previous edition approved in 2015 as D3885 – 07a(2015). DOI: The last approved version of this historical standard is referenced on

10.1520/D3885-07AR19E01. www.astm.org.

2 5

This test method is based upon the development described by Stoll, R.G.,“ Available from American Association of Textile Chemists and Colorists

ImprovedMultipurposeAbrasionTesteranditsApplicationfortheEvaluationofthe (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709-2215, http://

Wear Resistance of Textiles,” Textile Research Journal, July, 1949, p. 394. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D3885 − 07a (2019)

3. Terminology breaking strength and cycles to rupture are the recommended

means of evaluation because they are considered the least

3.1 For all terminology related to D13.60, Fabric Test

variable and interlaboratory agreement is likely to be obtained

Methods, Specific, see Terminology D4850.

more easily.

3.2 The following terms are relevant to this standard:

5.4 Abrasiontestsaresubjecttovariationsduetochangesin

abrasion, abrasion cycle, breaking force, double-stroke,

the abradant bar during specific tests. The abradant bar is

flexibility, standard atmosphere for preconditioning textiles,

considered a permanent abradant that uses a hardened metal

standard atmosphere for testing textiles.

surface. It is assumed that the abradant will not change

3.3 For all other terminology related to textiles, see Termi-

appreciably in a specific series of tests, but obviously similar

nology D123.

abradantsusedindifferentlaboratorieswillnotlikelychangeat

the same rate due to differences in usage. Permanent abradants

4. Summary of Test Method

may also change due to pickup of treatments or other material

4.1 Abrasion resistance is measured by subjecting the speci-

from test fabrics and must accordingly be cleaned at frequent

men to unidirectional reciprocal folding and rubbing over a

intervals. Consequently, depending upon its usage, the abrad-

specificbarunderspecifiedconditionsofpressure,tension,and

ant bar must be checked periodically against a standard.

abrasive action. Resistance to abrasion is evaluated by either

5.5 The resistance of textile materials to abrasion as mea-

determining the percent loss in breaking force of an abraded

sured by this test method does not include all the factors which

specimen compared to an unabraded specimen or the cycles to

accountforwearperformanceordurabilityinactualuse.While

rupture, or both.

the abrasion resistance stated in terms of the number of cycles

and durability (defined as the ability to withstand deterioration

5. Significance and Use

or wearing out in use, including the effects of abrasion) are

5.1 This test method is not recommended for acceptance

frequently related, the relationship varies with different end

testing of commercial shipments because information on

uses. Different factors may be necessary in any calculation of

between-laboratory precision is known to be poor.

predicted durability from specific abrasion data.

5.1.1 If there are differences of practical significance be-

5.5.1 Laboratory tests may be reliable as an indication of

tween reported test results for two laboratories (or more),

relative end use in cases where the difference in abrasion

comparative tests should be performed to determine if there is

resistance of various materials is large, but they should not be

a statistical bias between them, using competent statistical

relied upon where differences in laboratory test findings are

assistance. As a minimum, the test samples to be used are as

small. In general, the results should not be relied upon for

homogenous as possible, are drawn from the material from

prediction of performance during actual wear life for specific

which the disparate test results were obtained, and are ran-

end uses unless there are data showing the specific relationship

domlyassignedinequalnumberstoeachlaboratoryfortesting.

between laboratory abrasion tests and actual wear in the

Other fabrics with established test values may be used for this

intended end use.

purpose. The test results from the two laboratories should be

5.6 This test method is useful for pretreating material for

compared using a statistical test for unpaired data, at a

subsequent testing for strength or barrier performance.

probability level chosen prior to the testing series. If a bias is

5.7 The pressure and tension used is varied, depending on

found, either its cause must be found and corrected, or future

themassandnatureofthematerialandtheend-useapplication.

test results must be adjusted in consideration of the known

Whenever possible, all materials that are to be compared with

bias.

each other should be tested under the same pressure and

5.2 The measurement of the resistance to abrasion of textile

tension.

fabrics is very complex. The resistance to abrasion is affected

5.8 When abrasion tests are continued to total destruction,

bymanyfactorsthatincludetheinherentmechanicalproperties

abrasion resistance comparisons are not practical for fabrics

of the fibers; the dimensions of the fibers; the structure of the

having a different mass because the change in abrasion

yarns; the construction of the fabrics; the type, kind, and

resistance is not directly proportional to the change in the

amount of treatment added to the fibers, yarns, or fabric; the

fabric mass.

nature of the abradant; the variable action of the abradant over

the specimen area abraded; the tension on the specimen; the

5.9 All the test methods and instruments that have been

pressure between the specimen and the abradant; and the

developed for abrasion resistance may show a high degree of

dimensional changes in the specimen.

variability in results obtained by different operators and in

different laboratories, however, they represent the methods

5.3 The measurement of the relative amount of abrasion can

most widely used in the industry. Because there is a definite

be affected by the method of evaluation and is often influenced

need for measuring the relative resistance to abrasion, this test

by the judgment of the operator. It is recognized that with this

method is one of several standardized test methods that is

testmethodothermeansofevaluationbesidescyclestorupture

useful to help minimize the inherent variation that may occur

and breaking strength have been used by the industry, such as

in results.

color change, appearance change, and so forth. Experience has

shown these to be highly variable parameters and they are not 5.10 These general observations apply to most fabrics,

recommended without exact criteria identified in an applicable including woven and nonwoven fabrics that are used in

material specification or contract. Consequently, the criteria of automotive, household, and wearing apparel applications.

´1

D3885 − 07a (2019)

6. Apparatus 6.1.3 Thumb Screw, that allows moving the clamp to pro-

6 vide slack take-up of the specimen.

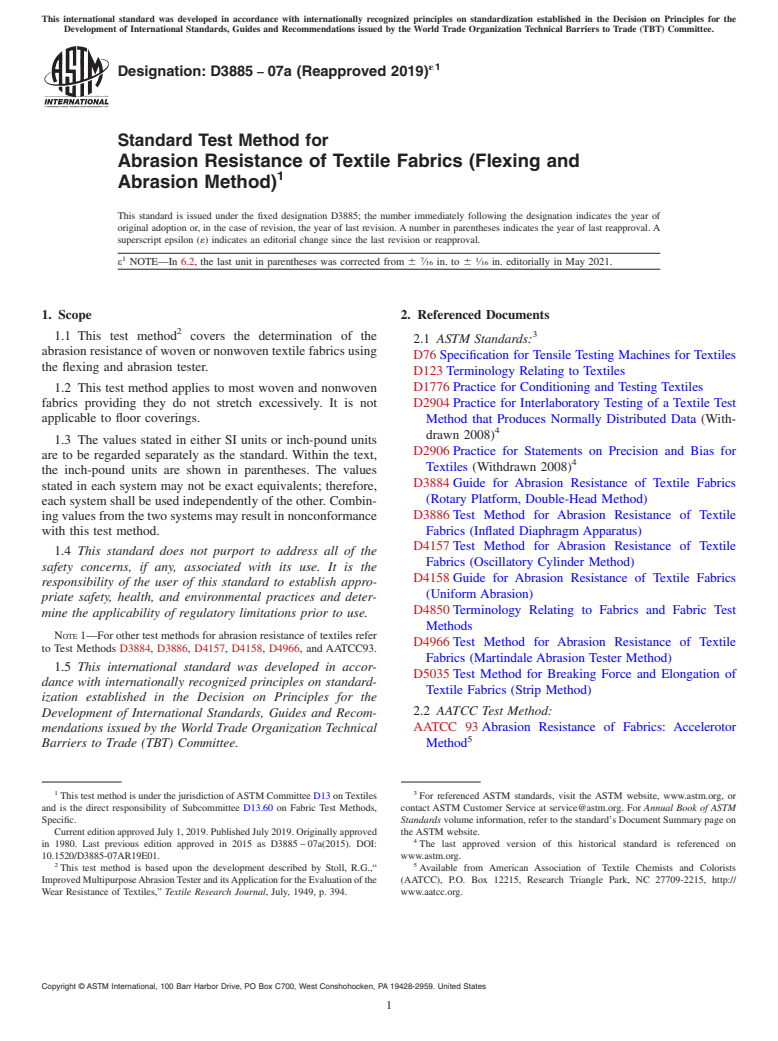

6.1 Flex Abrasion Testing Machine (see Figs. 1 and 2),

6.1.4 Machine Stopping Mechanism, a microswitch, or

consisting of the following:

equivalent, to stop the machine, actuated by the release of the

6.1.1 BalancedHeadandFlexBlockAssembly, that has two

tension on the specimen when it ruptures.

parallel, smooth plates.

6.1.5 Cycle Counter, to record the number of cycles (double

6.1.1.1 The balanced head is rigidly supported by a double-

strokes) and stop the machine at fabric failure.

lever assembly to provide free movement in a direction

6.1.6 Automatic Shutoff, as part of the cycle counter or

perpendicular to the plate of the flex block. This head must

in-line timer, or equivalent, with set and stop mechanism

remain stationary during the test and must be balanced to

capable of stopping the machine at a predetermined number of

maintain a uniform vertical pressure from the dead weights.

cycles.

6.1.1.2 The flex block is capable of reciprocating at 115 6

6.1.7 CalibratedTensionWeights, with individual masses of

10 double strokes per minute of 25 6 2-mm (1 6 0.1-in.)

250, 500, and 1000 g ( ⁄2, 1, and 2 lbf) that can provide up to

stroke length.

a total of 2500 g (5 lbf) that fit on a weight rack that is attached

6.1.1.3 Clamps are secured to the front of each plate of the

by cables to the yoke to adjust tension to the specimen.

head and flex-block assemblies to permit mounting of the

Individual weight tolerances are 61%.

specimen. The clamps have surfaces that prevent slippage of

6.1.8 Calibrated Head Weights, with individual masses of

the specimen and permit the specimen after it has been folded

250, 500, and 1000 g ( ⁄2, 1, and 2 lbf) that can provide up to

over the abradant bar to be centrally positioned and aligned

a total of 2500 g (5 lbf) that fits on the balanced head, to apply

with its long direction parallel to the reciprocating flex bar.

pressure to the specimen. Individual weight tolerances are

6.1.2 Flexing Bar Yoke, sufficiently rigid to prevent distor-

61%.

tion during the specimen loading and capable of applying

6.2 Working Flex Bar, used for testing, 1.6 6 0.4 by 11.2 6

tension to the rigidly secured flexing bar with the force acting

1 1 7 1

1.6mm( ⁄16 6 ⁄64by ⁄16 6 ⁄16in.)incrosssection,madewith

parallel to the surface of the head and block assembly plates

tool steel tipped with an edge of cemented carbide. The top,

and perpendicular to the fold of the specimen such that an

bottom,andedgeofthebarthatisincontactwiththespecimen

evenly distributed tension is provided across the fold of the

is finished by grinding and polishing, leveling off the micro-

specimen.

scopicprojectionwithoutbreakingtheedgesofthebar.Thebar

6.1.2.1 A positioning device is provided to position the

is capable of firmly attaching to the yoke.

flexingbarandyokeassemblywhileloadingthespecimensuch

that the edge of the flexing bar is parallel to the fold of the

6.3 Standardized Master Flex Bar, to standardize the work-

specimen during the test. The positioning device is capable of

ing flex bar, including storage container to prevent bar damage,

moving into contact with the yoke prior to loading the

available from the manufacturer.

specimen and moving away from contact with the yoke just

6.4 CalibrationRibbon ,fusedacetateribbon,25mm(1in.)

prior to starting the test machine.

wide, available from the manufacturer.

6.5 TensileTestingMachine, of the CRE, CRL, or CRTtype

conforming to Specification D76, with respect to force

Apparatus and accessories are commercially available.

FIG. 1 Schematic Diagram of Flexing and Abrasion Tester

´1

D3885 − 07a (2019)

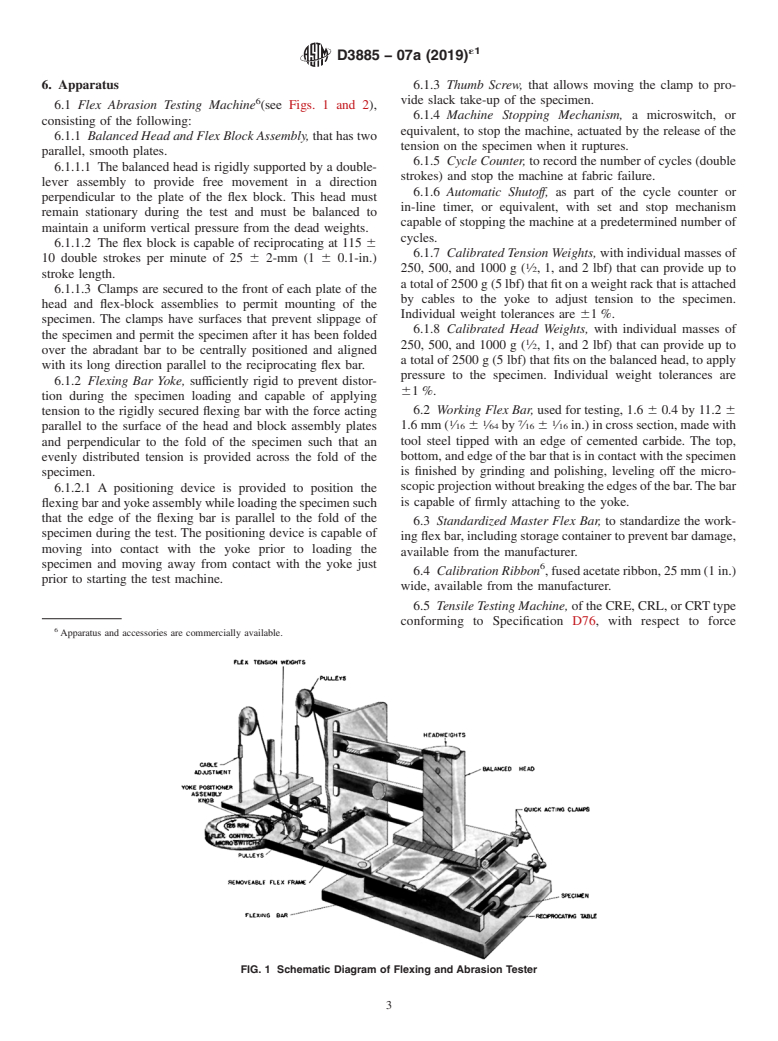

FIG. 2 Commercial Flexing and Abrasion Tester

indication, working range, capacity, and elongation indicator abrasion and parallel to the filling yarns for widthwise abra-

and designed for operation at a speed of 300 6 10 mm/min (12 sion. For nonwoven

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.