ASTM C749-92(2002)

(Test Method)Standard Test Method for Tensile Stress-Strain of Carbon and Graphite

Standard Test Method for Tensile Stress-Strain of Carbon and Graphite

SCOPE

1.1 This test method covers the testing of carbon and graphite in tension to obtain the tensile stress-strain behavior, to failure, from which the ultimate strength, the strain to failure, and the elastic moduli may be calculated as may be required for engineering applications. lists suggested sizes of specimens that can be used in the tests.

Note 1—The results of about 400 tests, on file at ASTM as RR:C05-1000, show the ranges of materials that have been tested, the ranges of specimen configurations, and the agreement between the testers.

Note 2—For safety considerations, it is recommended that the chains be surrounded by suitable members so that at failure all parts of the load train behave predictably and do not constitute a hazard for the operator.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:C 749–92(Reapproved 2002)

Standard Test Method for

Tensile Stress-Strain of Carbon and Graphite

This standard is issued under the fixed designation C 749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

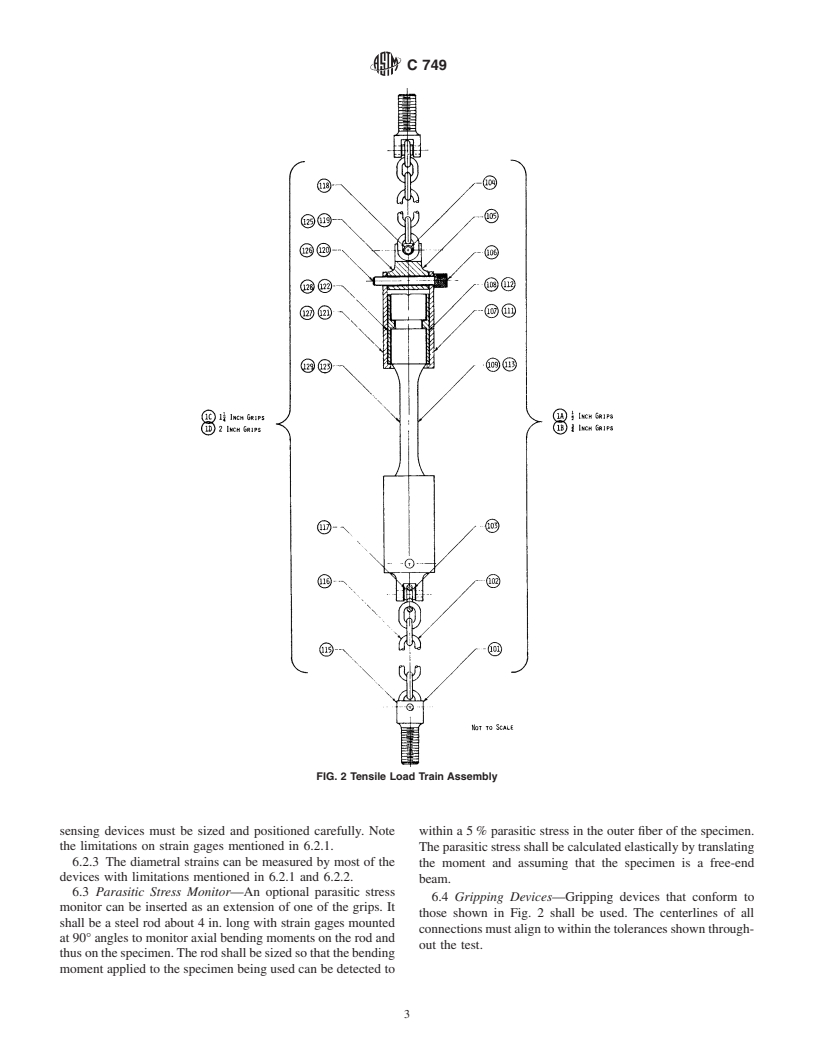

1.1 This test method covers the testing of carbon and 4.1 Atensile specimen (Fig. 1) is placed within a load train

graphite in tension to obtain the tensile stress-strain behavior, assembly made up of precision chains and other machined

to failure, from which the ultimate strength, the strain to parts (Fig. 2).Aload is applied to the specimen provided with

failure, and the elastic moduli may be calculated as may be means of measuring strain until it is caused to fracture. This

required for engineering applications. Table 1 lists suggested test yields the tensile strength, elastic constants, and strain to

sizes of specimens that can be used in the tests. failure of carbons and graphites.

NOTE 1—The results of about 400 tests, on file at ASTM as RR:C05-

5. Significance and Use

1000, show the ranges of materials that have been tested, the ranges of

5.1 This test method is intended to be used for both carbons

specimen configurations, and the agreement between the testers.

and graphites whose particle sizes are of the order of 1 mil to

NOTE 2—For safety considerations, it is recommended that the chains

be surrounded by suitable members so that at failure all parts of the load

⁄4 in. (0.0254 to 6.4 mm) and larger. This wide range of

train behave predictably and do not constitute a hazard for the operator.

carbons and graphites can be tested with uniform gage diam-

eters with minimum parasitic stresses to provide quality data

1.2 This standard does not purport to address all of the

for use in engineering applications rather than simply for

safety concerns, if any, associated with its use. It is the

quality control. This test method can be easily adapted to

responsibility of the user of this standard to establish appro-

elevated temperature testing of carbons and graphites without

priate safety and health practices and determine the applica-

changingthespecimensizeorconfigurationbysimplyutilizing

bility of regulatory limitations prior to use.

elevated temperature materials for the load train. This test

1.3 The values stated in inch-pound units are to be regarded

method has been utilized for temperatures as high as 4352°F

as the standard. The values given in parentheses are for

(2400°C).Thedesignofthefixtures(Figs.2-9andTable2)and

information only.

description of the procedures are intended to bring about, on

2. Referenced Documents

the average, parasitic stresses of less than 5 %. The specimens

for the different graphites have been designed to ensure

2.1 ASTM Standards:

fracture within the gage section commensurate with experi-

E 4 Practices for Force Verification of Testing Machines

enced variability in machining and testing care at different

E 6 Terminology Relating to Methods of Mechanical Test-

facilities. The constant gage diameter permits rigorous analyti-

ing

cal treatment.

E 177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

6. Apparatus

E 691 Practice for Conducting an Interlaboratory Study to

6.1 Testing Machine—The machine used for tensile testing

Determine the Precision of a Test Method

shall conform to the requirements of Practices E 4. The testing

3. Terminology

machine shall have a load measurement capacity such that the

breaking load of the test specimen falls between 10 and 90 %

3.1 Definitions—The terms as related to tension testing as

of the scale capacity. This range must be linear to within 1 %

giveninTerminologyE 6shallbeconsideredasapplyingtothe

over 1 % increments either by design or by calibration.

terms used in this test method.

6.2 Strain Measurements:

6.2.1 The axial strain can be measured at room temperature

This test method is under the jurisdiction of ASTM Committee D02 on

by the use of strain gages, mechanical extensometers, Tucker-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.F on Manufactured Carbon and Graphite Products . man gages, optical systems, or other devices applied diametri-

Current edition approved Aug. 15, 1992. Published October 1992. Originally

cally opposite in the gage length portion of the specimen. Two

published as C 749 – 73. Last previous edition C 749 – 87.

opposing gages provide some compensation for bending and

Annual Book of ASTM Standards, Vol 03.01.

some assurance that it was not severe. Different graphites

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 749

A A

TABLE 1 Sample Sizes Used in Round-Robin Tests (Suggested Specimen Size )

B

Material Max Grain Sample, in. Specimen Recommended

Size, in. Size, in. Shank and

Maximum Gage,

in.

C

1 1 3

AXM-50 0.001 5 by 5 by 5, molded ⁄2 by 0.200 ⁄2 by ⁄16

3 1

⁄4 by ⁄4

1 1

9326 0.001 20 by 10 by 2, molded ⁄2 by ⁄4

⁄4 by 0.3

C

1 3

⁄2 by ⁄16

1 3

⁄2 by ⁄16

3 1

⁄4 by ⁄4

1 1 1 3

9326A 0.001 20 by 10 by 2, molded ⁄2 by ⁄4 ⁄2 by ⁄16

3 3

⁄4 by ⁄8

3 3

⁄4 by 0.3 ⁄4 by 0.3

3 3

⁄4 by ⁄8

1 1 1 1

ATJ 0.006 13, rounds, molded ⁄2 by ⁄4 ⁄2 by ⁄4

3 3 3 1

⁄4 by ⁄8 ⁄4 by ⁄4

3 3 3 1

⁄4 by ⁄8 ⁄4 by ⁄4

3 3

⁄4 by ⁄8

1 1 3 3

HLM 0.033 molded, 10 by 18 by 25 ⁄2 by ⁄4 ⁄4 by ⁄8

3 3

⁄4 by ⁄8

3 3

⁄4 by ⁄8

3 3

⁄4 by ⁄8

CS 0.030 10, rounds, extruded 2 by 1

3 3 3 3

⁄4 by ⁄8 ⁄4 by ⁄8

1 1

⁄2 by ⁄4

1 1

⁄2 by ⁄4

AGR 0.250 25, rounds, extruded 2 by 1 2 by 1

1 5

2by1 1 ⁄4 by ⁄8

2by1

1 5

1 ⁄4 by ⁄8

CGE 0.265 14, rounds, extruded 2 by 1 ⁄4

3 1

⁄4 by ⁄2 2by1

3 1 3 1

Graphitar . . . carbon-graphite, resin impregnated ⁄4 by ⁄4 ⁄4 by ⁄4

C

1 1 1

Grade 86 ⁄2 by ⁄4 ⁄2 by 0.2

1 1

⁄2 by ⁄4

3 1 3 1

Purebon P-59 . . . carbon-graphite, copper treated ⁄4 by ⁄4 ⁄4 by ⁄4

C

1 1 1 3

⁄2 by ⁄4 ⁄2 by ⁄16

1 1

⁄2 by ⁄4

A

Based on RR:C5-1000 (see Note 1).

B

Identity of suppliers available from ASTM Headquarters.

C

Gas-bearings.

NOTE 1—Standard Specimen:

r = r ,

1 2

A = A /1.2,

1 2

l = D /2, and

1 2

l = 2 in. (51 mm) or 8 D , whichever is greater.

2 1

FIG. 1 Double Reduction Used to Minimize Radii-Fractures

require different attachment procedures and extreme care is averages. If more than 20 % of the failures occur at the

necessary. A proven device for mounting the specimen with attachment location, change the strain monitoring system or

minimum damage and for enabling the specimen to receive attachment device.

different extensometers is shown in Fig. 10. When attaching 6.2.2 The circumferential strain can be measured at room

strain gages, the modification of the surface may result in a temperature by use of strain gages applied circumferentially.

glue-graphitecompositeattheskinandthustheresultingstrain Knowledge of the anisotropy in the billet and orientation of the

valuesmaybeerroneousandtypicallylow.Whenusingclip-on specimen is necessary in order to properly place the strain-

extensometers, the knife edges can initiate fracture. Record, measuring device. Generally, one can expect three values of

but do not include the fractures at the attachments in the Poisson’s ratio for a nonisotropic material. Hence, the strain

C 749

FIG. 2 Tensile Load Train Assembly

sensing devices must be sized and positioned carefully. Note within a 5 % parasitic stress in the outer fiber of the specimen.

the limitations on strain gages mentioned in 6.2.1.

Theparasiticstressshallbecalculatedelasticallybytranslating

6.2.3 The diametral strains can be measured by most of the

the moment and assuming that the specimen is a free-end

devices with limitations mentioned in 6.2.1 and 6.2.2.

beam.

6.3 Parasitic Stress Monitor—An optional parasitic stress

6.4 Gripping Devices—Gripping devices that conform to

monitor can be inserted as an extension of one of the grips. It

those shown in Fig. 2 shall be used. The centerlines of all

shall be a steel rod about 4 in. long with strain gages mounted

connectionsmustaligntowithinthetolerancesshownthrough-

at 90° angles to monitor axial bending moments on the rod and

out the test.

thusonthespecimen.Therodshallbesizedsothatthebending

moment applied to the specimen being used can be detected to

C 749

Dimensions, Item

in. (mm)

101 115

A 0.250 6 0.001 0.312 6 0.001

(6.35 6 0.03) (7.92 6 0.03)

B 0.500 6 0.001 0.625 6 0.001

(12.70 6 0.03) (15.88 6 0.03)

C 1.000 1.500

(25.40) (38.10)

3 3

D ⁄16 ⁄8

(4.76) (9.52)

NOTE 1—Refer to Fig. 2, Items 101 and 115.

FIG. 4 Crosshead Attachment Yoke

fracture stress. Either tool cutting or grinding is acceptable, but

the latter is preferred. Surface roughness should be no greater

than the maximum particle or void size, whichever is greater.

FIG. 3 Schematic of Tensile System for Carbon and Graphite

Usually, they are about equal.

7.3 The gage length of the specimen will be measured from

the axial center of the specimen. Gage marks can be applied

6.5 General Test Arrangement—The general arrangement with ink or layout dope but no scratching, punching, or

of the specimen, flexible linkages, and crossheads shall be as notching of the specimen is permissible. The gage length is to

shown in the schematic of Fig. 3. be used in referencing the point of fracture within 0.1 in. (2.5

mm). The total gage length is defined as that section with the

7. Test Specimens

smaller uniform diameter extending from radius tangent to

radius tangent plus 10 %. The additional 10 % is intended to

7.1 Test specimens shall be produced to the general con-

figurations shown in Fig. 9.The selection of the proper ratio of accommodate the normal statistics of fracture for a material

like graphite. However, at least 50 % of the specimens should

shank to gage diameter is important to prevent excessive

head-pops or fracture of the specimen at the groove in the fracture within the uniform diameter or the specimen should be

redesigned and the system checked. Acceptable fractured are

shanks. The ratios shown in Table 1 have been found satisfac-

tory for this use. It is acceptable to double reduce gage shown in Fig. 11.

7.4 To determine the cross-sectional area, the diameter of

diameters as necessary (see Fig. 1) to eliminate head pops (or

out-of-gage fractures) or reduce them to an acceptable 20 % thespecimenatthesmallerorconstantdiameterregionshallbe

used. The dimension shall be recorded to the nearest 0.001 in.

maximum of the total fractures. However, the reducing radius

(0.254 mm).

must be maintained near the values shown or excessive radii

breaks will be obtained.Also, the gage diameter should not be

8. Procedure

reduced to less than three to five times the maximum particles

size in the material, or the failure mode may be atypical. 8.1 Calibration—Calibrate the micrometres that are to be

7.2 Improperly prepared test specimens often cause unsat- used for measurement of diameters by measuring the dimen-

isfactory test results. It is important, therefore, that care be sions of blocks provided by the NBS that are accurate within

exercised in the preparation of specimens both in minimizing 60.0001 in. (0.00254 mm). Calibrate all instrumentation and

endandsidethrustsandinprovidingaqualitysurface.Stresses establish shunt calibration for each recorded and each param-

induced during preparation should not exceed 10 % of ultimate eter. Zero all recorders.

C 749

Dimensions Item

in. (mm) 103 117

9 5

E ⁄16 ⁄8

(14.29) (15.88)

5 1

F ⁄16 ⁄2

(7.94) (12.7)

G 0.250 6 0.001 0.3126 0.001

(6.35 6 0.03) (7.92 6 0.03)

H 0.500 0.625

(12.70) (15.88)

3 3

J ⁄16 ⁄8

(4.76) (9.52)

1 3

K ⁄8 ⁄16

(3.18) (4.76)

NOTE 1—Refer to Fig. 2, Items 103 and 117.

FIG. 5 Chain Journal

8.2 Specimen—Adapt to the specimen the appropriate strain

where:

instrumentation by bonding strain gages to its surface, adapt-

s = tensile strength, psi (Pa),

ult

ing, or any other strain measuring system so that strain can be

P = maximum load, lbf (N), and

max

measured during the test. Place the specimen within the load A = cross-sectionalareaofthespecimenintheconstant

2 2

train. Make sure all instrumentation is properly calibrated and diameter region or gage section, in. (m ).

zeroed.

8.3 Loading—Apply the load at a predetermined constant

9.1.1 The cross-sectional area is given by the equation:

stress rate by following the appropriate load time curve either

pD

manually or automatically. Continuously apply the load until

A 5 (2)

fracture is induced.

8.4 Recording—During the entire load application duration,

where:

record the output of the load cell on the vertical axis of an X-Y D = average diameter of the constant diameter region (gage

recorder and the strain on the horizontal axis, and obtain a section) of the specimen, in. (m).

permanent record of the stress-strain curve for the specimen

9.2 Calculatemodulusofelasticityofthespecimenfromthe

being tested during the entire test.

stress-strain curve as follows:

8.5 Post Test—Observed the specimen fracture surface. If

Ds

E 5 initial slope of stress2strain curve 5 (3)

the specimen failed outside the gage length as defined in 6.3

De

(including head pops), the strength value measured must be

where:

reported but not included in the average.

E = modulus of elasticity, psi (Pa),

9. Calculation

Ds = incremental stress corresponding to the incremental

strain, psi (Pa), and

9.1 Calculate the strength as follows:

De = incremental strain corresponding to the incremental

P

max

s 5 (1) stress, in./in. (m/m).

ult

A

C 749

Dimensions, Item

in. (mm)

107 111 121 127

1 1 1 1

S ⁄4 ⁄4 ⁄2 ⁄2

(6.35) (6.35) (12.7) (12.7)

T 1.000 6 0.001 1.000 6 0.001 1.5006 0.001 2.2506 0.001

(25.40 6 0.03) (25.40 6 0.03) (38.10 6 0.03) (57.15 6 0.03)

U 1.500 1.500 1.875 2.750

(38.10) (38.10) (47.62) (69.85)

5 5 5 1

V2 ⁄16 2 ⁄16 3 ⁄8 5 ⁄2

(58.74) (58.74) (92.07) (139.70)

A

W 6–32 6–32 10–32 10–32

X 0.500 + 0.002 0.750 + 0.002 1.250 + 0.002 2.000 + 0.002

− 0.000 − 0.000 − 0.000 − 0.000

(12.70 + 0.05 (19.05 + 0.05 (31.75 + 0.05 (50.80 + 0.05

− 0.00) − 0.00) − 0.00) − 0.00)

A

Screw size.

NOTE 1—Refer to Fig. 2, Items 107, 111, 121, and 127.

FIG. 6 Grip Sleeve

9.3 Calculate the strain-to-failure from the stress-strain 10.1.8 A record of all specimens that broke during machin-

curveasthestrainwherethemaximumstresswasobtainedand ing or subsequent handling after they had been reduced

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.