ASTM F604-94

(Specification)Specification for Silicone Elastomers Used in Medical Applications (Withdrawn 2001)

Specification for Silicone Elastomers Used in Medical Applications (Withdrawn 2001)

SCOPE

1.1 This specification covers silicone elastomers intended for use as materials of construction for fabrication of medical devices.

1.2 Variations in ingredients, processing, and vulcanization (crosslinking/cure) systems of silicone elastomer are necessary to achieve the properties required in specific medical device applications.

1.2.1 An alphabetical/numerical code abbreviation is defined in this specification as what may be used to specify ingredients, crosslinking systems, processing conditions, and physical properties of many silicone elastomers used in medical device applications by a standard, abbreviated designation.

1.3 In all cases where the provisions of this specification are in conflict with those of the detailed specifications for a particular product, the latter shall take precedence.

1.3.1 When silicone elastomers are used in medical device applications where the materials requirements cannot be completely achieved by the technology prescribed in this specification, it may be necessary to adjust ingredients, processing, or cure systems to a greater extent to obtain the properties needed in these specific medical device applications.

1.3.1.1 When silicone elastomers are adjusted more extensively than prescribed in this specification, such adjustments shall be completely described and controlled in specifications for each specific material.

1.3.1.2 All sections of this specification that contain requirements pertinent to safety and effectiveness apply to all silicone elastomers used as materials of construction for medical devices, including those adjusted more broadly than defined in this specification.

1.4 While silicone elastomers have demonstrated excellent biocompatibility in medical device applications, the biocompatibility of silicone elastomers as a generic class has not been established. Many compositions and formulations are possible. Manufacturing practices, facilities, controls, process validation, and other considerations that ensure batch-to-batch duplication, assurance of identity, and quality of ingredients, as well as freedom from contamination or cross-contamination may vary widely within the silicone elastomer industry. Medical device manufacturers must ensure safety and effectiveness of each specific composition or formulation from each supplier in its intended applications. Historic, clinical, and biocompatibility data are pertinent prospectively only when all compounding, formulating, and fabrication are done in accordance with the provisions of Good Manufacturing Practice Regulations, which help ensure medical materials and devices are reasonably duplicated each time they are manufactured.

1.5 This specification is intended to assist in the development of specifications for formulated silicone elastomer compounds. It is also recommended for use in materials and finished device labeling to specify the type or types of silicone elastomers contained.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 604 – 94

Standard Specification for

Silicone Elastomers Used in Medical Applications

This standard is issued under the fixed designation F 604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope device manufacturers must ensure safety and effectiveness of

each specific composition or formulation from each supplier in

1.1 This specification covers silicone elastomers intended

its intended applications. Historic, clinical, and biocompatibil-

for use as materials of construction for fabrication of medical

ity data are pertinent prospectively only when all compound-

devices.

ing, formulating, and fabrication are done in accordance with

1.2 Variations in ingredients, processing, and vulcanization

the provisions of Good Manufacturing Practice Regulations,

(crosslinking/cure) systems of silicone elastomer are necessary

which help ensure medical materials and devices are reason-

to achieve the properties required in specific medical device

ably duplicated each time they are manufactured.

applications.

1.5 This specification is intended to assist in the develop-

1.2.1 An alphabetical/numerical code abbreviation is de-

ment of specifications for formulated silicone elastomer com-

fined in this specification as what may be used to specify

pounds. It is also recommended for use in materials and

ingredients, crosslinking systems, processing conditions, and

finished device labeling to specify the type or types of silicone

physical properties of many silicone elastomers used in medi-

elastomers contained.

cal device applications by a standard, abbreviated designation.

1.6 This standard does not purport to address all of the

1.3 In all cases where the provisions of this specification are

safety concerns, if any, associated with its use. It is the

in conflict with those of the detailed specifications for a

responsibility of the user of this standard to establish appro-

particular product, the latter shall take precedence.

priate safety and health practices and determine the applica-

1.3.1 When silicone elastomers are used in medical device

bility of regulatory limitations prior to use.

applications where the materials requirements cannot be com-

pletely achieved by the technology prescribed in this specifi-

2. Referenced Documents

cation, it may be necessary to adjust ingredients, processing, or

2.1 ASTM Standards:

cure systems to a greater extent to obtain the properties needed

D 149 Test Method for Dielectric Breakdown Voltage and

in these specific medical device applications.

Dielectric Strength of Solid Electrical Insulating Materials

1.3.1.1 When silicone elastomers are adjusted more exten-

at Commercial Power Frequencies

sively than prescribed in this specification, such adjustments

D 150 Test Methods for A-C Loss Characteristics and

shall be completely described and controlled in specifications

Permittivity (Dielectric Constant) of Solid Electrical Insu-

for each specific material.

lating Materials

1.3.1.2 All sections of this specification that contain require-

D 257 Test Methods for D-C Resistance or Conductance of

ments pertinent to safety and effectiveness apply to all silicone

Insulating Materials

elastomers used as materials of construction for medical

D 395 Test Methods for Rubber Property—Compression

devices, including those adjusted more broadly than defined in

Set

this specification.

D 412 Test Methods for Rubber Properties in Tension

1.4 While silicone elastomers have demonstrated excellent

D 430 Test Methods for Rubber Deterioration—Dynamic

biocompatibility in medical device applications, the biocom-

Fatigue

patibility of silicone elastomers as a generic class has not been

D 570 Test Method for Water Absorption of Plastics

established. Many compositions and formulations are possible.

D 624 Test Method for Tear Strength of Conventional

Manufacturing practices, facilities, controls, process valida-

Vulcanized Rubber and Thermoplastic Elastomers

tion, and other considerations that ensure batch-to-batch dupli-

D 792 Test Methods for Specific Gravity (Relative Density)

cation, assurance of identity, and quality of ingredients, as well

and Density of Plastics by Displacement

as freedom from contamination or cross-contamination may

D 813 Test Method for Rubber Deterioration—Crack

vary widely within the silicone elastomer industry. Medical

Growth

This specification is under the jurisdiction of ASTM Committee F-4 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee Federal Register, Vol 43, No. 141, Friday, July 21, 1978, Part II.

F04.11 on Polymeric Materials. Annual Book of ASTM Standards, Vol 10.01.

Current edition approved March 15, 1994. Published July 1994. Originally Annual Book of ASTM Standards, Vol 09.01.

published as F 604 – 78. Last previous edition F 604 – 87. Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 604

D 814 Test Method for Rubber Property—Vapor Transmis- 3.1.4 post cure—typically refers to heat processing of

sion of Volatile Liquids molded or fabricated silicone elastomer parts done in an air

D 865 Test Method for Rubber—Deterioration by Heating

circulating oven for a specified time and temperature. Post cure

in Air (Test Tube Enclosure) is generally necessary to complete the vulcanization/

D 926 Test Method for Rubber Property—Plasticity and

crosslinking chemistry, stabilize properties, and drive off any

Recovery (Parallel Plate Method) volatile materials such as residuals or break down products of

D 955 Test Method of Measuring Shrinkage from Mold

catalysts generated during vulcanization.

Dimensions of Molded Plastics

3.1.5 silicone compound—an unvulcanized, uniformly

D 991 Test Method for Rubber Property—Volume Resistiv-

blended formulation containing silicone polymers and fillers.

ity of Electrically Conductive and Antistatic Products

Silicone compounds may be one-part or two-part. One-part

D 1349 Practice for Rubber—Standard Temperatures for

compounds may be supplied either catalyzed and ready to

Testing

process, or uncatalyzed, requiring the addition of a catalyst

D 1418 Practice for Rubber and Rubber Latices—

prior to use. Two-part silicone compounds must be blended

Nomenclature

together prior to use and may have limited shelf life after

D 1566 Terminology Relating to Rubber

blending.

D 1898 Practice for Sampling of Plastics

3.1.6 silicone elastomer—an elastomer containing

D 2240 Test Method for Rubber Property—Durometer

crosslinked silicone polymer and filler, typically fumed silica.

Hardness

3.1.7 silicone polymer—polymer chains with chemical

D 3137 Test Method for Rubber Property—Hydrolytic Sta-

structure of repeating diorganosiloxy groups, typically repeat-

bility

ing dimethylsiloxy groups in elastomers used in medical device

F 619 Practice for Extraction of Medical Plastics

applications. Polymer chains contain repeating silicon and

F 748 Practice for Selecting Generic Biological Test Meth-

oxygen atoms.

ods for Materials and Devices

3.1.8 vulcanization—an irreversible process where covalent

F 813 Practice for Direct Contact Cell Culture Evaluation of

chemical crosslinks are formed between silicone polymers

Materials for Medical Devices

chains contained in silicone elastomer compounds. During

F 1251 Terminology Relating to Polymeric Biomaterials in

vulcanization the material changes from a flowable compound,

Medical and Surgical Devices

which can vary widely in viscosity, to an elastomeric material,

2.2 ANSI Standard:

which cannot again be reshaped except by its physical destruc-

Z1.8 General Requirements for a Quality Program

tion.

2.3 AAMI Standard:

EOS-DE-O Sterilization Standard

4. Fabrication, Vulcanization, Postcure, and Physical

2.4 United States Pharmacopeia, XXII Edition, 1989

Properties

2.5 Federal Register, Title 21, Part 820

4.1 Fabrication and vulcanization conditions shall be desig-

nated by a letter code as listed in 4.1.1, followed by numerical

designations of time/temperature. Time shall be listed as h

3. Terminology

(hours), m (minutes), or s (seconds). Temperature shall be

3.1 Definitions:

defined as °C or °F.

3.1.1 catalyst/crosslinking agent—an ingredient contained

4.1.1 Fabrication Codes:

in a silicone elastomer formulation that either initiates or is a

CM compression molding

reactant in the crosslinking chemistry when the material is

TM transfer molding

vulcanized. E extrusion

D dispersion dipping

3.1.2 filler—a finely divided, solid material that is inti-

CA calendaring

mately blended with silicone polymers during mixing and

HL hand lay-up

Z other, to be specified

compounding to achieve specific properties. The filler used

with silicone elastomer is typically high surface area, amor-

4.2 Postcure shall be designated by the letters “PC” fol-

phous, fumed silica, an ingredient essential to high strength and

lowed by numerical designation of time/temperature (h/

elastomeric physical properties.

temperature° F or °C). (See Practice D 1349, Section 2.)

3.1.3 lot or batch—material with a fixed, specified formu-

Designate as “PC none” when no postcure has been used or

lation made in a single, continuous manufacturing run from

when none is recommended in material processing.

single lots of all ingredients and processed by the same

4.3 Physical Properties—Measurements of durometer, ten-

techniques at same conditions.

sile strength, and elongation are typically considered essential

for defining and controlling a silicone elastomer. Designate in

6 series as durometer/tensile strength/elongation as defined in

Annual Book of ASTM Standards, Vol 13.01.

Available from American National Standards Institute, 11 West 42nd St., 13th 4.3.1, 4.3.2, and 4.3.3, respectively.

Floor, New York, NY 10036.

4.3.1 Durometer (Hardness), Shore A—Measure in keeping

Available from Association for Advancement of Medical Instrumentation, 1500

with Test Method D 2240. Designate by D followed by a

Wilson Blvd., Suite 417, Arlington, VA 22209.

Available from Mack Publishing Co., Easton, PA. number as selected from the following:

F 604

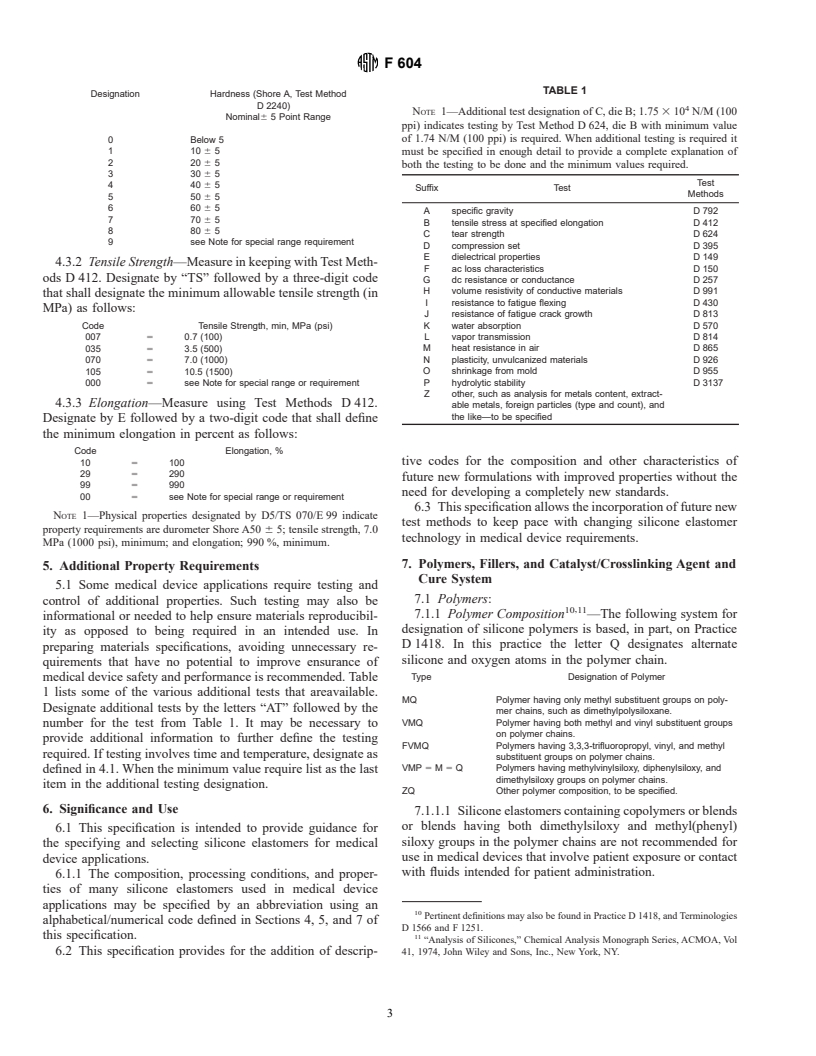

TABLE 1

Designation Hardness (Shore A, Test Method

D 2240)

NOTE 1—Additional test designation of C, die B; 1.75 3 10 N/M (100

Nominal6 5 Point Range

ppi) indicates testing by Test Method D 624, die B with minimum value

of 1.74 N/M (100 ppi) is required. When additional testing is required it

0 Below 5

110 6 5

must be specified in enough detail to provide a complete explanation of

220 6 5

both the testing to be done and the minimum values required.

330 6 5

Test

440 6 5

Suffix Test

Methods

550 6 5

660 6 5

A specific gravity D 792

770 6 5

B tensile stress at specified elongation D 412

880 6 5

C tear strength D 624

9 see Note for special range requirement

D compression set D 395

E dielectrical properties D 149

4.3.2 Tensile Strength—Measure in keeping with Test Meth-

F ac loss characteristics D 150

ods D 412. Designate by “TS” followed by a three-digit code

G dc resistance or conductance D 257

H volume resistivity of conductive materials D 991

that shall designate the minimum allowable tensile strength (in

I resistance to fatigue flexing D 430

MPa) as follows:

J resistance of fatigue crack growth D 813

Code Tensile Strength, min, MPa (psi) K water absorption D 570

007 5 0.7 (100) L vapor transmission D 814

035 5 3.5 (500) M heat resistance in air D 865

070 5 7.0 (1000) N plasticity, unvulcanized materials D 926

105 5 10.5 (1500) O shrinkage from mold D 955

000 5 see Note for special range or requirement P hydrolytic stability D 3137

Z other, such as analysis for metals content, extract-

4.3.3 Elongation—Measure using Test Methods D 412.

able metals, foreign particles (type and count), and

the like—to be specified

Designate by E followed by a two-digit code that shall define

the minimum elongation in percent as follows:

Code Elongation, %

tive codes for the composition and other characteristics of

10 5 100

29 5 290

future new formulations with improved properties without the

99 5 990

need for developing a completely new standards.

00 5 see Note for special range or requirement

6.3 This specification allows the incorporation of future new

NOTE 1—Physical properties designated by D5/TS 070/E 99 indicate

test methods to keep pace with changing silicone elastomer

property requirements are durometer Shore A50 6 5; tensile strength, 7.0

technology in medical device requirements.

MPa (1000 psi), minimum; and elongation; 990 %, minimum.

7. Polymers, Fillers, and Catalyst/Crosslinking Agent and

5. Additional Property Requirements

Cure System

5.1 Some medical device applications require testing and

7.1 Polymers:

control of additional properties. Such testing may also be

10,11

7.1.1 Polymer Composition —The following system for

informational or needed to help ensure materials reproducibil-

designation of silicone polymers is based, in part, on Practice

ity as opposed to being required in an intended use. In

D 1418. In this practice the letter Q designates alternate

preparing materials specifications, avoiding unnecessary re-

silicone and oxygen atoms in the polymer chain.

quirements that have no potential to improve ensurance of

medical device safety and performance is recommended. Table Type Designation of Polymer

1 lists some of the various additional tests that areavailable.

MQ Polymer having only methyl substituent groups on poly-

Designate additional tests by the letters “AT” followed by the

mer chains, such as dimethylpolysiloxane.

VMQ Polymer having both methyl and vinyl substituent groups

number for the test from Table 1. It may be necessary to

on polymer chains.

provide additional information to further define the testing

FVMQ Polymers having 3,3,3-trifluoropropyl, vinyl, and methyl

required. If testing involves time and temperature, designate as

substituent groups on polymer chains.

VMP 5 M 5 Q Polymers having methylvinylsiloxy, diphenylsiloxy, and

defined in 4.1. When the minimum value require list as the last

dimethylsiloxy groups on polymer chains.

item in the additional testing designation.

ZQ Other polymer composition, to be specified.

6. Significance and Use

7.1.1.1 Silicone elastomers containing copolymers or blends

or blends having both dimethylsiloxy and methyl(phenyl)

6.1 This specification is intended to provide guidance for

siloxy groups in the polymer chains are not recommended for

the specifying and selecting silicone elastomers for medical

use in medical de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.