ASTM D4425-97

(Test Method)Standard Test Method for Oil Separation From Lubricating Grease by Centrifuging (Koppers Method)

Standard Test Method for Oil Separation From Lubricating Grease by Centrifuging (Koppers Method)

SCOPE

1.1 This test method describes a procedure for determining the tendency of lubricating grease to separate oil when subjected to high centrifugal forces.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4425 – 97 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Oil Separation From Lubricating Grease by Centrifuging

1

(Koppers Method)

This standard is issued under the fixed designation D 4425; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

a 5 distance from top of grease surface to tube mouth

1.1 This test method describes a procedure for determining

(mm).

the tendency of lubricating grease to separate oil when sub-

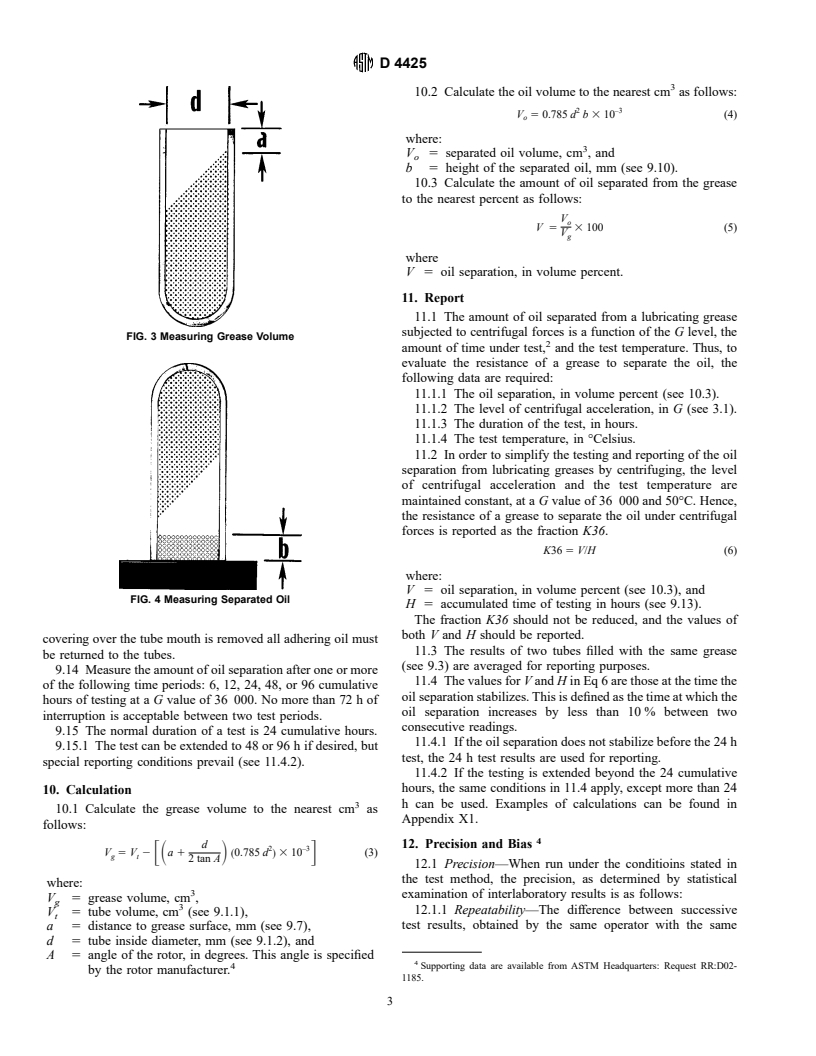

b 5 height of liquid column in an inverted test tube

jected to high centrifugal forces.

(mm).

1.2 This standard does not purport to address all of the

d 5 test tube inside diameter (mm).

safety concerns, if any, associated with its use. It is the

H 5 accumulated test time at a given reading (h).

responsibility of the user of this standard to establish appro-

K36 5 resistance to centrifugal separation (V/H).

priate safety and health practices and determine the applica-

r 5 measured at the maximum radius of rotation (mm).

bility of regulatory limitations prior to use.

rpm 5 rotational speed (r/min).

1.3 The values stated in SI units are to be regarded as the

V 5 volume of separated oil, as a percentage of the

standard.

original grease volume (%).

3

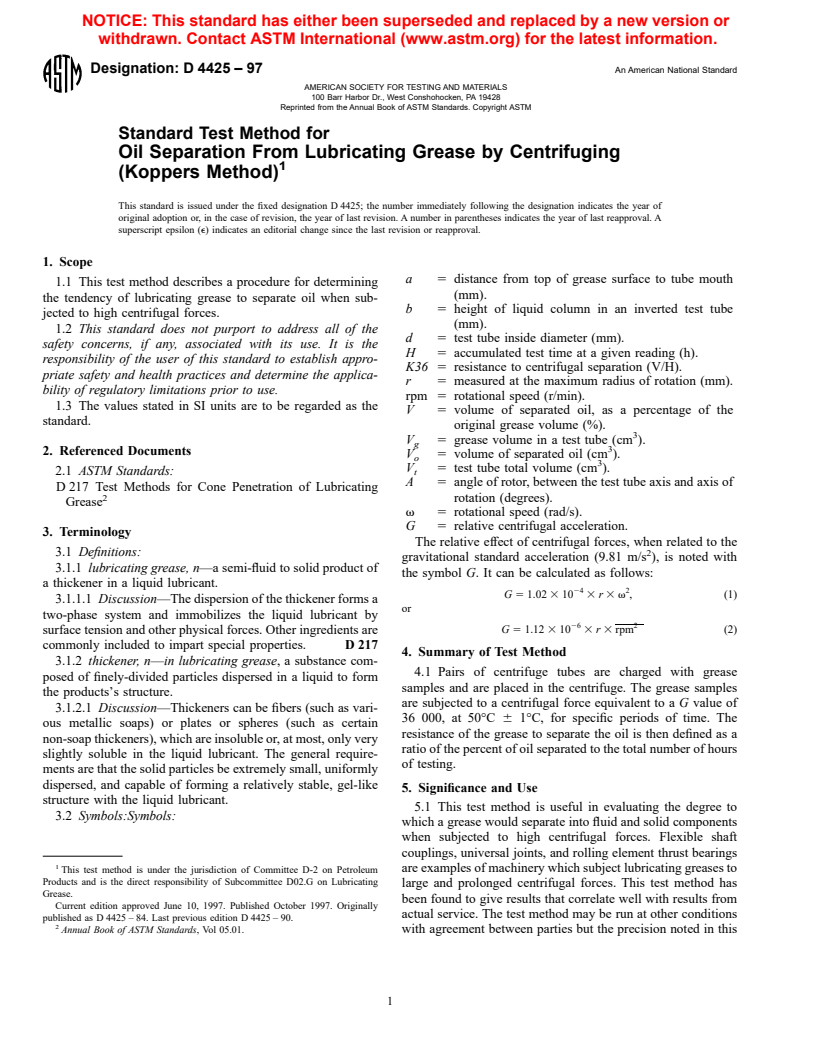

V 5 grease volume in a test tube (cm ).

g

3

2. Referenced Documents

V 5 volume of separated oil (cm ).

o

3

V 5 test tube total volume (cm ).

2.1 ASTM Standards: t

A 5 angle of rotor, between the test tube axis and axis of

D 217 Test Methods for Cone Penetration of Lubricating

2

rotation (degrees).

Grease

v5 rotational speed (rad/s).

G 5 relative centrifugal acceleration.

3. Terminology

The relative effect of centrifugal forces, when related to the

3.1 Definitions: 2

gravitational standard acceleration (9.81 m/s ), is noted with

3.1.1 lubricating grease, n—a semi-fluid to solid product of

the symbol G. It can be calculated as follows:

a thickener in a liquid lubricant.

24 2

G 5 1.02 3 10 3 r3v , (1)

3.1.1.1 Discussion—The dispersion of the thickener forms a

or

two-phase system and immobilizes the liquid lubricant by

26 2

G 5 1.12 3 10 3 r 3 rpm¯ (2)

surface tension and other physical forces. Other ingredients are

commonly included to impart special properties. D 217

4. Summary of Test Method

3.1.2 thickener, n—in lubricating grease, a substance com-

4.1 Pairs of centrifuge tubes are charged with grease

posed of finely-divided particles dispersed in a liquid to form

samples and are placed in the centrifuge. The grease samples

the products’s structure.

are subjected to a centrifugal force equivalent to a G value of

3.1.2.1 Discussion—Thickeners can be fibers (such as vari-

36 000, at 50°C 6 1°C, for specific periods of time. The

ous metallic soaps) or plates or spheres (such as certain

resistance of the grease to separate the oil is then defined as a

non-soap thickeners), which are insoluble or, at most, only very

ratio of the percent of oil separated to the total number of hours

slightly soluble in the liquid lubricant. The general require-

of testing.

ments are that the solid particles be extremely small, uniformly

dispersed, and capable of forming a relatively stable, gel-like

5. Significance and Use

structure with the liquid lubricant.

5.1 This test method is useful in evaluating the degree to

3.2 Symbols:Symbols:

which a grease would separate into fluid and solid components

when subjected to high centrifugal forces. Flexible shaft

couplings, universal joints, and rolling element thrust bearings

1

This test method is under the jurisdiction of Committee D-2 on Petroleum are examples of machinery which subject lubricating greases to

Products and is the direct responsibility of Subcommittee D02.G on Lubricating

large and prolonged centrifugal forces. This test method has

Grease.

been found to give results that correlate well with results from

Current edition approved June 10, 1997. Published October 1997. Originally

actual service. The test method may be run at other conditions

published as D 4425 – 84. Last previous edition D 4425 – 90.

2

Annual Book of ASTM Standards, Vol 05.01. with agreement between parties but the precision noted in this

1

---------------------- Page: 1 ----------------------

D 4425

3

test method will no longer apply.

6. Apparatus

6.1 High-Speed Centrifuge capable of developing a G value

of 36 000. Mount the unit on a flat level surface to allow

unrestricted air flow to the motor. This is essential for long

motor life. The centrifuge should be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.