ASTM D3849-07(2011)

(Test Method)Standard Test Method for Carbon Black—Morphological Characterization of Carbon Black Using Electron Microscopy

Standard Test Method for Carbon Black—Morphological Characterization of Carbon Black Using Electron Microscopy

SIGNIFICANCE AND USE

Carbon black morphology significantly affects the transient and end-use properties of carbon black loaded polymer systems. A carbon black's particle size distribution is its single most important property, and it relates to degree of blackness and rubber reinforcement. For a given loading of carbon black, blackness and reinforcement increase with smaller particle size. Aggregate size and shape (structure) also affect a carbon black's end-use performance, as higher carbon black structure increases viscosity and improves dispersion. The stiffness (modulus) of elastomer systems becomes significantly higher with increasing structure. The preferred method for measuring these properties is transmission electron microscopy.

Carbon black aggregate dimensional and shape properties are dependent upon the nature of the system in which the sample is dispersed, as well as the mixing procedure.

SCOPE

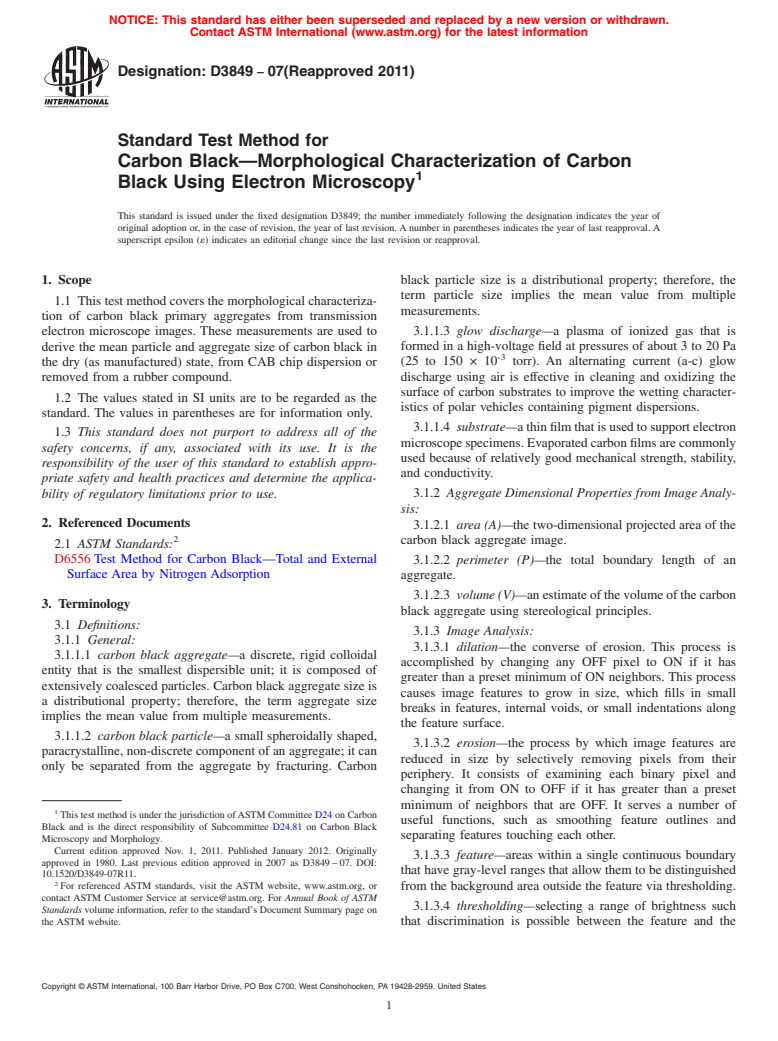

1.1 This test method covers the morphological characterization of carbon black primary aggregates from transmission electron microscope images. These measurements are used to derive the mean particle and aggregate size of carbon black in the dry (as manufactured) state, from CAB chip dispersion or removed from a rubber compound.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3849 − 07(Reapproved 2011)

Standard Test Method for

Carbon Black—Morphological Characterization of Carbon

1

Black Using Electron Microscopy

This standard is issued under the fixed designation D3849; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope black particle size is a distributional property; therefore, the

term particle size implies the mean value from multiple

1.1 Thistestmethodcoversthemorphologicalcharacteriza-

measurements.

tion of carbon black primary aggregates from transmission

electron microscope images. These measurements are used to 3.1.1.3 glow discharge—a plasma of ionized gas that is

derive the mean particle and aggregate size of carbon black in formed in a high-voltage field at pressures of about 3 to 20 Pa

-3

the dry (as manufactured) state, from CAB chip dispersion or (25 to 150 × 10 torr). An alternating current (a-c) glow

discharge using air is effective in cleaning and oxidizing the

removed from a rubber compound.

surface of carbon substrates to improve the wetting character-

1.2 The values stated in SI units are to be regarded as the

istics of polar vehicles containing pigment dispersions.

standard. The values in parentheses are for information only.

3.1.1.4 substrate—athinfilmthatisusedtosupportelectron

1.3 This standard does not purport to address all of the

microscopespecimens.Evaporatedcarbonfilmsarecommonly

safety concerns, if any, associated with its use. It is the

used because of relatively good mechanical strength, stability,

responsibility of the user of this standard to establish appro-

and conductivity.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.1.2 Aggregate Dimensional Properties from Image Analy-

sis:

2. Referenced Documents

3.1.2.1 area (A)—the two-dimensional projected area of the

2

carbon black aggregate image.

2.1 ASTM Standards:

D6556Test Method for Carbon Black—Total and External

3.1.2.2 perimeter (P)—the total boundary length of an

Surface Area by Nitrogen Adsorption

aggregate.

3.1.2.3 volume (V)—anestimateofthevolumeofthecarbon

3. Terminology

black aggregate using stereological principles.

3.1 Definitions:

3.1.3 Image Analysis:

3.1.1 General:

3.1.3.1 dilation—the converse of erosion. This process is

3.1.1.1 carbon black aggregate—a discrete, rigid colloidal

accomplished by changing any OFF pixel to ON if it has

entity that is the smallest dispersible unit; it is composed of

greater than a preset minimum of ON neighbors. This process

extensively coalesced particles. Carbon black aggregate size is

causes image features to grow in size, which fills in small

a distributional property; therefore, the term aggregate size

breaks in features, internal voids, or small indentations along

implies the mean value from multiple measurements.

the feature surface.

3.1.1.2 carbon black particle—a small spheroidally shaped,

3.1.3.2 erosion—the process by which image features are

paracrystalline,non-discretecomponentofanaggregate;itcan

reduced in size by selectively removing pixels from their

only be separated from the aggregate by fracturing. Carbon

periphery. It consists of examining each binary pixel and

changing it from ON to OFF if it has greater than a preset

minimum of neighbors that are OFF. It serves a number of

1

This test method is under the jurisdiction ofASTM Committee D24 on Carbon

useful functions, such as smoothing feature outlines and

Black and is the direct responsibility of Subcommittee D24.81 on Carbon Black

separating features touching each other.

Microscopy and Morphology.

Current edition approved Nov. 1, 2011. Published January 2012. Originally

3.1.3.3 feature—areas within a single continuous boundary

approved in 1980. Last previous edition approved in 2007 as D3849–07. DOI:

that have gray-level ranges that allow them to be distinguished

10.1520/D3849-07R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or from the background area outside the feature via thresholding.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.3.4 thresholding—selecting a range of brightness such

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. that discrimination is possible between the feature and the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

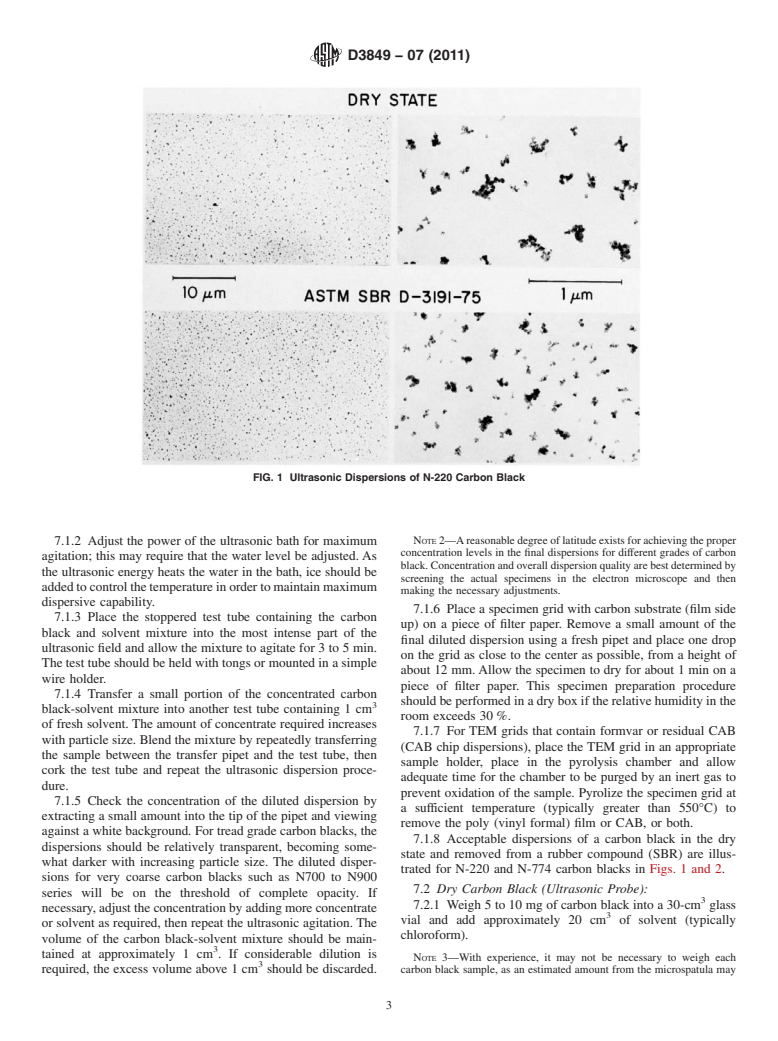

---------------------- Page: 1 ----------------------

D3849 − 07 (2011)

background. The gray levels within carbon black images ability to introduce and remove the sample boat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.