ASTM D6602-13(2022)e1

(Practice)Standard Practice for Sampling and Testing of Possible Carbon Black Fugitive Emissions or Other Environmental Particulate, or Both

Standard Practice for Sampling and Testing of Possible Carbon Black Fugitive Emissions or Other Environmental Particulate, or Both

SIGNIFICANCE AND USE

5.1 There are a variety of darkening agents that contribute to air and surface contamination in industrial, urban and rural environments. Biofilms (fungal and algal), soil minerals, plant fragments, rubber fragments, metal corrosion and soot are common darkening agents. Soot is formed as an unwanted by-product of combustion and consequently varies widely with the type of fuel and combustion conditions. Carbon black, on the other hand, is purposely produced under a controlled set of conditions. Therefore, it is important to be able to distinguish carbon black from soot, as well as other environmental contaminants.

SCOPE

1.1 This practice covers sampling and testing for distinguishing ASTM type carbon black, in the N100 to N900 series, from other environmental particulates.

1.2 This practice requires some degree of expertise on the part of the microscopist. For this reason, the microscopist must have adequate training and on-the-job experience in identifying the morphological parameters of carbon black and general knowledge of other particles that may be found in the environment. In support of this analysis, Donnet's book2 is highly recommended to be used as a technical reference for recognizing and understanding the microstructure of carbon black.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D6602 − 13 (Reapproved 2022)

Standard Practice for

Sampling and Testing of Possible Carbon Black Fugitive

Emissions or Other Environmental Particulate, or Both

This standard is issued under the fixed designation D6602; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected 6.2.1 editorially in February 2023.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers sampling and testing for distin-

D1619 Test Methods for Carbon Black—Sulfur Content

guishing ASTM type carbon black, in the N100 to N900 series,

D3053 Terminology Relating to Carbon Black

from other environmental particulates.

D3849 Test Method for Carbon Black—Morphological

1.2 This practice requires some degree of expertise on the

Characterization of Carbon Black Using Electron Micros-

part of the microscopist. For this reason, the microscopist must

copy

have adequate training and on-the-job experience in identifying

the morphological parameters of carbon black and general 3. Terminology

knowledge of other particles that may be found in the envi-

3.1 Definitions of Terms Specific to This Standard:

ronment. In support of this analysis, Donnet’s book is highly

3.1.1 aciniform—shaped like a cluster of grapes.

recommended to be used as a technical reference for recogniz-

3.1.1.1 Discussion—The spheroidal primary particles of

ing and understanding the microstructure of carbon black.

carbon black are fused into aggregates of colloidal dimension

forming an acinoform morphology.

1.3 The values stated in SI units are to be regarded as

3.1.2 aciniform carbon—colloidal carbon having a mor-

standard. No other units of measurement are included in this

phology consisting of spheroidal primary particles (nodules)

standard.

fused together in aggregates of colloidal dimension in a shape

1.4 This standard may involve hazardous materials,

having grape-like clusters or open branch-like structures

operations, and equipment. This standard does not purport to

3.1.3 carbon black, n—an engineered material, primarily

address all of the safety concerns, if any, associated with its

composed of elemental carbon, obtained from the partial

use. It is the responsibility of the user of this standard to

combustion or thermal decomposition of hydrocarbons, exist-

establish appropriate safety, health, and environmental prac-

ing in the form of aggregates of aciniform morphology which

tices and determine the applicability of regulatory limitations

are composed of spheroidal primary particles characterized by

prior to use.

uniformity of primary particle sizes within a given aggregate

1.5 This international standard was developed in accor- and turbostratic layering within the primary particles.

3.1.3.1 Discussion—Particle size and aggregate size (num-

dance with internationally recognized principles on standard-

ber of particles per aggregate) are distributional properties and

ization established in the Decision on Principles for the

vary depending on the carbon black grade. Transmission

Development of International Standards, Guides and Recom-

electron micrographs shown in Annex A2 demonstrate that

mendations issued by the World Trade Organization Technical

while particle and aggregate sizes vary greatly within a given

Barriers to Trade (TBT) Committee.

grade of carbon black, the primary particle size is essentially

uniform within an individual aggregate.

3.1.4 chain of custody—a document describing the condi-

This practice is under the jurisdiction of ASTM Committee D24 on Carbon

tion of a sample during its collection, analysis, and disposal.

Black and is the direct responsibility of Subcommittee D24.66 on Environment,

Health, and Safety.

Current edition approved June 1, 2022. Published July 2022. Originally approved

in 2000. Last previous edition approved in 2018 as D6602 – 13 (2018). DOI:

10.1520/D6602-13R22E01. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Hess, W.M. and Herd, C.R., Carbon Black Science and Technology, Edited by contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Donnet, J.B., Bansal, R.C., and Wang, M.J., Marcel Dekker, Inc., New York, NY, Standards volume information, refer to the standard’s Document Summary page on

1993, pp. 89–173. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6602 − 13 (2022)

3.1.5 char—a particulate larger than 1 μm made by incom- samples and identify the classes of particulate present includ-

plete combustion which may not deagglomerate or disperse by ing materials consistent or inconsistent with manufactured

ordinary techniques, may contain material which is not black, carbon black (referred to simply as carbon black). A semi-

and may contain some of the original material’s cell structure, quantitative estimate of the percentage of each type of surface

minerals, ash, cinders, and so forth. particulate component is determined using polarized light

microscopy (PLM). However, PLM analysis cannot differen-

3.1.6 fugitive dust—transitory, fleeting material comprised

tiate between carbon black and soots (black carbons) that may

of particulates foreign to the surface of deposition.

come from many sources in the environment. Therefore,

3.1.7 fungus, sooty mold, mildew, biofilm—particulates from

transmission electron microscopy (TEM) analysis is mandatory

a superficial growth that grows on living and decaying organic

in determining whether a sample contains carbon black.

matter.

Because the preparation steps for the TEM analysis eliminates

3.1.8 mineral dust—naturally occurring inorganic particu-

certain types of particles and concentrates only the fine (small)

lates inherent to the area such as soil minerals.

particles from the sample, the TEM analysis alone cannot be

3.1.9 pollen—particulates from a mass of microspores in a used to estimate the amount of carbon black or other particle

seed plant. type in the whole sample. Either the PLM or TEM analysis

may be done first.

3.1.10 rubber dust—finely divided soft particulates abraded

from rubber.

4.2 Section 6 provides guidelines for proper sampling and

handling of fugitive emission/environmental samples. Sections

3.1.11 sample—a small fractional part of a material or a

8 and 9 describe the analysis of the sample using polarized

specified number of objects that are selected for testing,

light microscopy (PLM) and transmission electron microscopy

inspection, or specific observations of particular characteris-

(TEM). The TEM analysis is critical in determining if the

tics.

collected sample is consistent or inconsistent with carbon

3.1.12 soot—a submicron black powder generally produced

black. Use of the TEM analysis is mandatory in determining

as an unwanted by-product of combustion or pyrolysis. It

whether a sample is positive for carbon black. The use of the

consists of various quantities of carbonaceous and inorganic

PLM analysis is not mandatory when the TEM analysis finds

solids in conjunction with adsorbed and occluded organic tars

no aciniform aggregates resembling carbon black. Section 9

and resins.

describes additional ancillary techniques that may be included

3.1.12.1 Discussion—The carbonaceous portion also is col-

in a sample analysis for purposes of providing supporting

loidal and often has the aciniform morphology. Soot may have

information as to the nature of the sample material. These are

several carbon morphologies. Examples of soot are carbon

situation-dependent methods and can provide critical identifi-

residues from diesel and gasoline engines, industrial flares,

cation information in certain cases.

sludge pits, burning tires, and so forth.

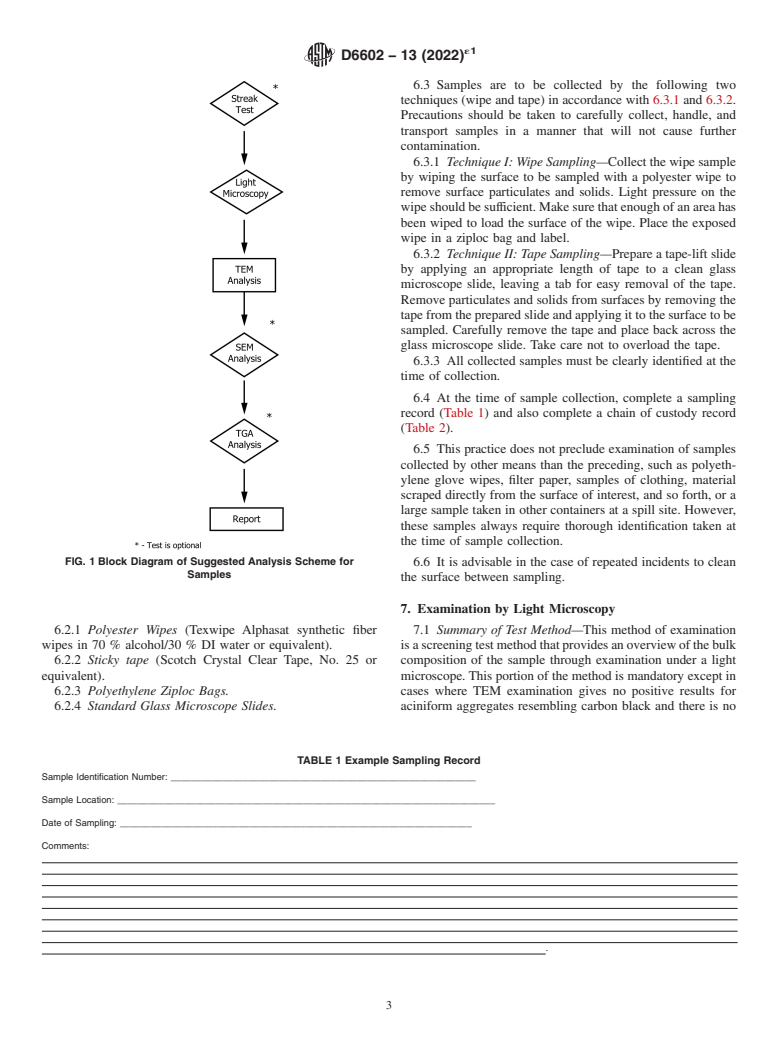

4.3 A block diagram is presented in Fig. 1 to give a possible

3.1.13 sticky tape—a section of tape with a sticky, solvent-

scheme to follow in performing this analysis. However, it

soluble adhesive used in the collection of particles from

should be noted that this diagram is a suggestion, not a

surfaces.

requirement. Either the PLM or TEM analysis may be per-

3.1.14 surface—the outer surface, facing, or exterior bound-

formed first.

ary of an object capable of supporting carbon and other fugitive

and natural occurring dusts and particulates.

5. Significance and Use

3.1.15 turbostratic—a type of graphitic crystallographic

5.1 There are a variety of darkening agents that contribute to

structure in which there is no symmetry along the z-axis.

air and surface contamination in industrial, urban and rural

3.2 Acronyms:

environments. Biofilms (fungal and algal), soil minerals, plant

3.2.1 EDS—energy dispersive spectroscopy associated with

fragments, rubber fragments, metal corrosion and soot are

SEM and TEM for the identification of elemental composition,

common darkening agents. Soot is formed as an unwanted

by-product of combustion and consequently varies widely with

3.2.2 LM—light microscope,

the type of fuel and combustion conditions. Carbon black, on

3.2.3 PLM—polarizing light microscope,

the other hand, is purposely produced under a controlled set of

3.2.4 SEM—scanning electron microscope,

conditions. Therefore, it is important to be able to distinguish

3.2.5 TEM—transmission electron microscope.

carbon black from soot, as well as other environmental

contaminants.

3.2.6 WDS—wavelength dispersive spectroscopy associated

with SEM and TEM for the identification of elemental com-

6. Sampling

position.

6.1 The area to be sampled should be representative of the

NOTE 1—Standard terminology relating to carbon black can be found in

contaminated area. For sampling, choose an area that appears

Terminology D3053.

to contain black particulates. In some situations, the same

4. Summary of Practice general surface can be used for gathering all test samples for

each property site location or area.

4.1 This practice describes the procedures and protocols to

follow in order to collect fugitive emission/environmental 6.2 Equipment:

´1

D6602 − 13 (2022)

6.3 Samples are to be collected by the following two

techniques (wipe and tape) in accordance with 6.3.1 and 6.3.2.

Precautions should be taken to carefully collect, handle, and

transport samples in a manner that will not cause further

contamination.

6.3.1 Technique I: Wipe Sampling—Collect the wipe sample

by wiping the surface to be sampled with a polyester wipe to

remove surface particulates and solids. Light pressure on the

wipe should be sufficient. Make sure that enough of an area has

been wiped to load the surface of the wipe. Place the exposed

wipe in a ziploc bag and label.

6.3.2 Technique II: Tape Sampling—Prepare a tape-lift slide

by applying an appropriate length of tape to a clean glass

microscope slide, leaving a tab for easy removal of the tape.

Remove particulates and solids from surfaces by removing the

tape from the prepared slide and applying it to the surface to be

sampled. Carefully remove the tape and place back across the

glass microscope slide. Take care not to overload the tape.

6.3.3 All collected samples must be clearly identified at the

time of collection.

6.4 At the time of sample collection, complete a sampling

record (Table 1) and also complete a chain of custody record

(Table 2).

6.5 This practice does not preclude examination of samples

collected by other means than the preceding, such as polyeth-

ylene glove wipes, filter paper, samples of clothing, material

scraped directly from the surface of interest, and so forth, or a

large sample taken in other containers at a spill site. However,

these samples always require thorough identification taken at

the time of sample collection.

FIG. 1 Block Diagram of Suggested Analysis Scheme for

6.6 It is advisable in the case of repeated incidents to clean

Samples

the surface between sampling.

7. Examination by Light Microscopy

6.2.1 Polyester Wipes (Texwipe Alphasat synthetic fiber 7.1 Summary of Test Method—This method of examination

wipes in 70 % alcohol/30 % DI water or equivalent). is a screening test method that provides an overview of the bulk

6.2.2 Sticky tape (Scotch Crystal Clear Tape, No. 25 or composition of the sample through examination under a light

equivalent). microscope. This portion of the method is mandatory except in

6.2.3 Polyethylene Ziploc Bags. cases where TEM examination gives no positive results for

6.2.4 Standard Glass Microscope Slides. aciniform aggregates resembling carbon black and there is no

TABLE 1 Example Sampling Record

Sample Identification Number: ___________________________________________________________

Sample Location: _________________________________________________________________________

Date of Sampling: ____________________________________________________________________

Comments:

.

´1

D6602 − 13 (2022)

TABLE 2 Example Chain of Custody Record

Sample ID Date Sampled Sampled By Comments

1.

2.

3.

4.

5.

Sample

Relinquished By Received By Time Date Reason for Change:

Number

1.

2.

3.

4.

5.

Comments:

request for a semi-quantitative analysis of the other compo- preserves the integrity of the particle aggregates without the

nents in the sample. In addition, there are special situations smearing that tends to occur when using the wipe sampler.

where other information such as a torn bag near a carbon black 7.3.3 Inspect the wipe sample with a stereobinocular micro-

manufacturing site strongly suggests that the black particulate scope. With a clean razor blade, cut out a small square section

being sampled is carbon black. In this case, a TEM analysis (~1 cm) of a representative portion of the wipe, including an

may be sufficient to confirm the presence of carbon black area of black staining if present. Using two clean tweezers,

without the mandatory PLM analysis. It is important to note agitate, twist, and scrape the square section of the wipe over a

that the results obtained by the light microscopy technique clean microscope slide to dislodge particle from the wipe and

cannot be considered as conclusive for identifying the presence on to the slide. If fine black particles coat some of the fibers of

of carbon black. the wipe, pull some of them out and mount them separately. It

may also be possible to transfer dark particulate from the wipe

7.2 Apparatus:

to a microscope slide using a tungsten needle. Add

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.