ASTM F982-86(1998)

(Specification)Standard Specification for Disclosure of Characteristics of Surgically Implanted Clamps for Carotid Occlusion

Standard Specification for Disclosure of Characteristics of Surgically Implanted Clamps for Carotid Occlusion

SCOPE

1.1 This specification covers requirements for the disclosure of specific characteristics of screw-type adjustable clamps that are designed for the gradual permanent occlusion of carotid arteries. These devices consist of an implantable portion and an externally projecting removable screwdriver (see Fig. 1).

1.2 The following precautionary caveat pertains only to the test method portion, Section 5, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 982 – 86 (Reapproved 1998)

Standard Specification for

Disclosure of Characteristics of Surgically Implanted

Clamps for Carotid Occlusion

This standard is issued under the fixed designation F 982; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

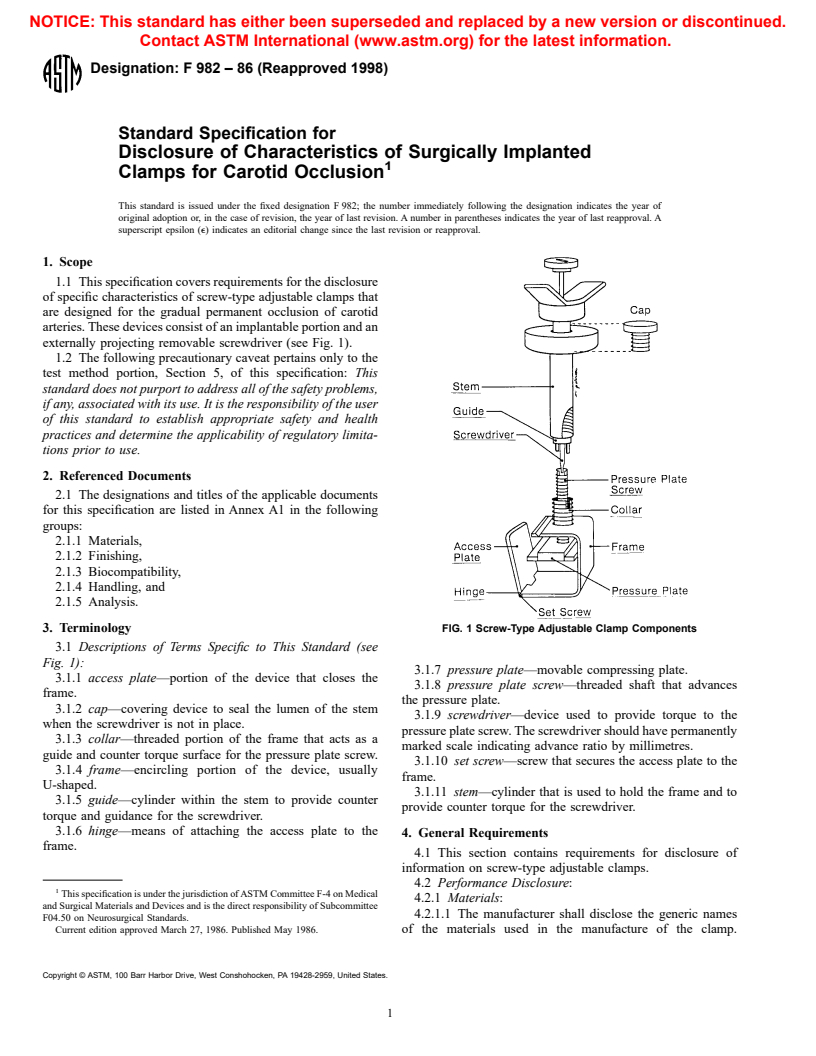

1.1 This specification covers requirements for the disclosure

of specific characteristics of screw-type adjustable clamps that

are designed for the gradual permanent occlusion of carotid

arteries. These devices consist of an implantable portion and an

externally projecting removable screwdriver (see Fig. 1).

1.2 The following precautionary caveat pertains only to the

test method portion, Section 5, of this specification: This

standard does not purport to address all of the safety problems,

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

tions prior to use.

2. Referenced Documents

2.1 The designations and titles of the applicable documents

for this specification are listed in Annex A1 in the following

groups:

2.1.1 Materials,

2.1.2 Finishing,

2.1.3 Biocompatibility,

2.1.4 Handling, and

2.1.5 Analysis.

3. Terminology FIG. 1 Screw-Type Adjustable Clamp Components

3.1 Descriptions of Terms Specific to This Standard (see

Fig. 1):

3.1.7 pressure plate—movable compressing plate.

3.1.1 access plate—portion of the device that closes the

3.1.8 pressure plate screw—threaded shaft that advances

frame.

the pressure plate.

3.1.2 cap—covering device to seal the lumen of the stem

3.1.9 screwdriver—device used to provide torque to the

when the screwdriver is not in place.

pressure plate screw. The screwdriver should have permanently

3.1.3 collar—threaded portion of the frame that acts as a

marked scale indicating advance ratio by millimetres.

guide and counter torque surface for the pressure plate screw.

3.1.10 set screw—screw that secures the access plate to the

3.1.4 frame—encircling portion of the device, usually

frame.

U-shaped.

3.1.11 stem—cylinder that is used to hold the frame and to

3.1.5 guide—cylinder within the stem to provide counter

provide counter torque for the screwdriver.

torque and guidance for the screwdriver.

3.1.6 hinge—means of attaching the access plate to the

4. General Requirements

frame.

4.1 This section contains requirements for disclosure of

information on screw-type adjustable clamps.

4.2 Performance Disclosure:

This specification is under the jurisdiction of ASTM Committee F-4 on Medical

4.2.1 Materials:

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

4.2.1.1 The manufacturer shall disclose the generic names

F04.50 on Neurosurgical Standards.

Current edition approved March 27, 1986. Published May 1986. of the materials used in the manufacture of the clamp.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 982

Whenever available, ASTM material specification nomencla- and connect it to the pulse duplicator system. Close the clamp

ture shall be used (Annex A1). If multiple components are to a gap of 2 mm. Turn on the pulse duplicator and measure the

used, the names of each component shall be disclosed. position of the pressure plate relative to the basis of the frame

4.2.1.2 The metals and alloys or other materials used in every 24 h for 72 h to determine if there has been any retreat

clamps that conform to this specification should be fabricated of the pressure plate. Perform a second test keeping the pulse

of approved materials in accordance with the ASTM specifi- duplicator functioning at the same setting but with the clamp

cations listed in A1.2.1. closed down to occlude the artery using the torque determined

4.2.2 Finishing—Surface cleanliness and characteristics safe as detailed in 5.2. Again, measure the position of the

should meet the requirements of the ASTM specifications listed pressure plate every 24 h for 72 h. A backoff of 0.2 mm (90°

in A1.2.2. There should be no debris visible at 20X and no turn) will be the maximum permitted. Measurement must be

imperfections visible to the naked eye. accurate to 60.35 mm.

4.2.3 Biocompatibility— Clamps should be biocompatible

6. Labeling Requirements

with the tissue in which they are intended to be implanted.

6.1 All labeling must be consistent with applicable Federal

Metal components shall meet ASTM biologic compatibility

requirements or equivalents listed in A1.2.3. Nonporous poly- Regulations. In addition, the labeling for carotid occlusive

clamps within the scope of this specification should comply

meric materials should conform to the ASTM requirements or

equivalents listed in the Annex. with the following requirements:

6.1.1 Package Label— The following information shall be

4.2.4 Handling—Handling procedures should be similar to

those suggested by several ASTM standards listed in A1.2.4. available with the unit package:

4.2.5 Analysis—Analysis of clips removed for any reason 6.1.1.1 Manufacturer’s name,

should resemble that specified for removal of orthopedic 6.1.1.2 Trade name,

implants (see A1.2.5). 6.1.1.3 Catalog number,

4.2.6 Reporting of Failures—All failures should be reported 6.1.1.4 Manufacturer’s identification or lot number,

both to the manufacturer and to the FDA. 6.1.1.5 Material(s),

4.2.7 Advance Ratio— The manufacturer shall disclose the 6.1.1.6 Magnetic properties,

distance (millimetres) advanced by the pressure plate for each 6.1.1.7 Advance ratio,

full revolution of the screwdriver (see also 5.1). 6.1.1.8 Torque which causes vessel laceration, and

4.2.8 Pressure Plate Induced Laceration of Vessel—The 6.1.1.9 Slip resistance.

6.1.2 Product Insert— The product insert should include the

manufacturer shall disclose the torque at which the pressure

plate will cause vessel laceration (see also 5.2). following information:

6.1.2.1 Manufacturer’s name,

4.2.9 Slip Resistance of the Clamp—The manufacturer shall

disclose whether the set screw will unwind and the pressure 6.1.2.2 Trade name,

6.1.2.3 Catalog number,

plate will retreat in the face of pulsatile pressure of 150/80 at

80 cpm applied to the pressure plate when it is 2 mm from 6.1.2.4 Manufacturer’s identification or lot number,

6.1.2.5 Size,

closure and when it is at the closed position (see also 5.3).

6.1.2.6 Length of compression plate,

5. Test Methods

6.1.2.7 Width of compression plate,

5.1 Advance Ratio— This measurement must be accurate to 6.1.2.8 Compression surface,

6 0.35 mm. 6.1.2.9 Advance ratio,

5.2 Vessel Damage— Implant the clamp aseptically around

6.1.2.10 Internal dimensions of clamp when fully opened,

a dog carotid artery and close using a torque wrench. Implant 6.1.2.11 Material(s),

several animals, each having their clamp tightened to a

6.1.2.12 Magnetic properties,

different torque. S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.