ASTM B828-02

(Practice)Standard Practice for Making Capillary Joints by Soldering of Copper and Copper Alloy Tube and Fittings

Standard Practice for Making Capillary Joints by Soldering of Copper and Copper Alloy Tube and Fittings

SIGNIFICANCE AND USE

The techniques described herein are used to produce leak-tight soldered joints between copper and copper alloy tube and fittings, either in shop operations or in the field. Skill and knowledge on the part of the operator or mechanic are required to obtain a satisfactorily soldered joint.

SCOPE

1.1 This practice describes a procedure for making capillary joints by soldering of copper and copper alloy tube and fittings.

1.2 This procedure is applicable to pressurized systems such as plumbing, heating, air conditioning, refrigeration, mechanical, fire sprinkler, and other similar systems. ASME B31.5 and B31.9 reference the techniques used for satisfactory joint preparation. It is also used in the assembly of nonpressurized systems such as drainage, waste, and vent.

1.3 It is not applicable to the assembly of electrical or electronic systems.

1.4 Tube and fittings are manufactured within certain tolerances to provide for the small variations in dimensions associated with manufacturing practice. Applicable specifications are listed in Appendix X1.

1.5 A variety of solders are available that will produce sound, leak-tight joints. Choice of solder will depend upon the type of application and on local codes. For potable water systems, only lead-free solders shall be used, some of which are described in Specification B 32.

1.6 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statements, see the warning statements in 6.4.1, 6.6.1, and 6.6.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B828 – 02

Standard Practice for

Making Capillary Joints by Soldering of Copper and Copper

1

Alloy Tube and Fittings

This standard is issued under the fixed designation B828; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B68 Specification for Seamless Copper Tube, Bright An-

nealed

1.1 This practice describes a procedure for making capillary

B68M Specification for Seamless Copper Tube, Bright

jointsbysolderingofcopperandcopperalloytubeandfittings.

Annealed (Metric)

1.2 Thisprocedureisapplicabletopressurizedsystemssuch

B75 Specification for Seamless Copper Tube

as plumbing, heating, air conditioning, refrigeration, mechani-

B75M Specification for Seamless Copper Tube (Metric)

cal, fire sprinkler, and other similar systems.ASME B31.5 and

B88 Specification for Seamless Copper Water Tube

B31.9 reference the techniques used for satisfactory joint

B88M Specification for Seamless CopperWaterTube (Met-

preparation. It is also used in the assembly of nonpressurized

ric)

systems such as drainage, waste, and vent.

B280 Specification for Seamless Copper Tube for Air Con-

1.3 It is not applicable to the assembly of electrical or

ditioning and Refrigeration Field Service

electronic systems.

B306 Specification for Copper Drainage Tube (DWV)

1.4 Tube and fittings are manufactured within certain toler-

B447 Specification for Welded Copper Tube

ances to provide for the small variations in dimensions

B640 Specification for Welded Copper Tube forAir Condi-

associated with manufacturing practice. Applicable specifica-

tioning and Refrigeration Service

tions are listed in Appendix X1.

B641 Specification for Seamless and Welded Copper Dis-

1.5 A variety of solders are available that will produce

tribution Tube (Type D)

sound, leak-tight joints. Choice of solder will depend upon the

B716 Specification for Welded Copper Water Tube

type of application and on local codes. For potable water

B716M Specification for Welded Copper Water Tube [Met-

systems, only lead-free solders shall be used, some of which

ric]

are described in Specification B32.

B813 Specification for Liquid and Paste Fluxes for Solder-

1.6 The values stated in inch-pound units are to be regarded

ing of Copper and Copper Alloy Tube

as the standard. The values given in parentheses are for

B846 Terminology for Copper and Copper Alloys

information purposes only.

2.2 Other Documents:

1.7 This standard does not purport to address all of the

3

ASME B31.5 Refrigeration Piping

safety concerns, if any, associated with its use. It is the

3

ASME B31.9 Building Services Piping

responsibility of the user of this standard to establish appro-

ASME B16.18 Cast Copper Alloy Solder Joint Pressure

priate safety and health practices and determine the applica-

3

Fittings

bility of regulatory limitations prior to use. For hazard state-

ASME B16.22 Wrought Copper and Copper Alloy Solder

ments, see the warning statements in 6.4.1, 6.6.1, and 6.6.3.

3

Joint Pressure Fittings

2. Referenced Documents ASME B16.23 Cast Copper Alloy Solder Joint Drainage

3

2

Fittings—DWV

2.1 ASTM Standards:

ASME B16.29 Wrought Copper and Copper Alloy Solder

B32 Specification for Solder Metal

3

Joint Drainage Fittings—DWV

4

ANSI/ASC Z49.1 Safety in Welding and Cutting

1

This practice is under the jurisdiction ofASTM Committee B05 on Copper and

CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 10, 2002. Published November 2002. Originally

3

approved as B828 – 92. Last previous edition B828 – 00. DOI: 10.1520/B0828-02. Available from American Society of Mechanical Engineers (ASME), ASME

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B828 – 02

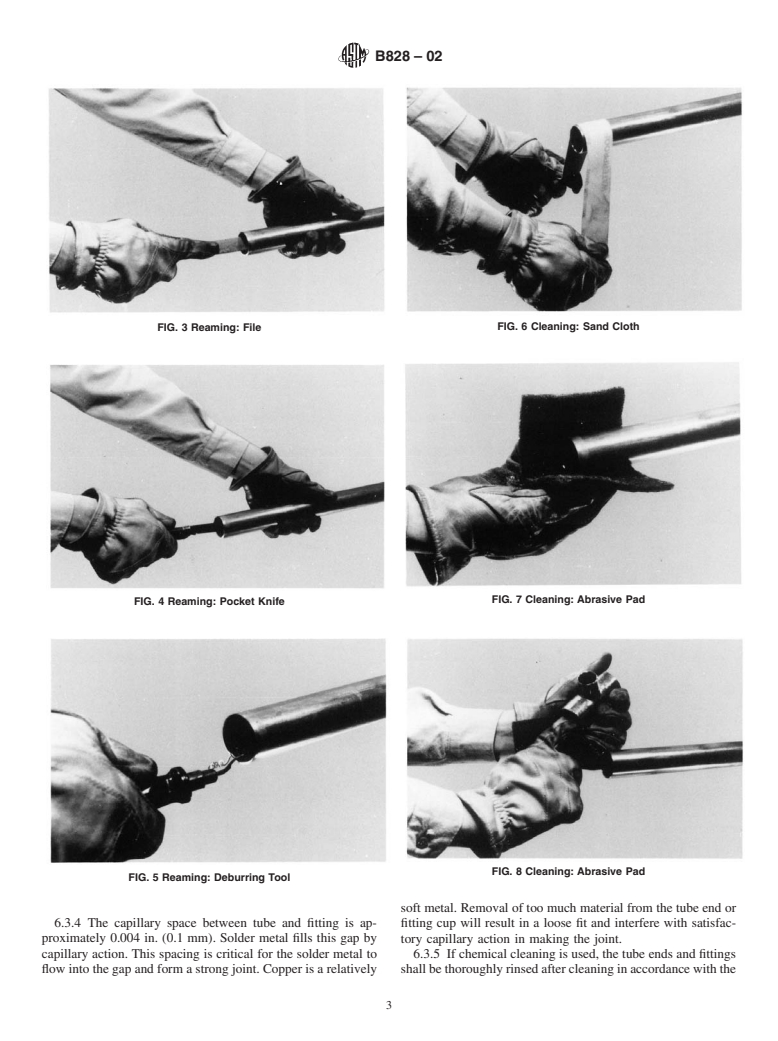

3. Terminology cannot be made. If the tube segment is too long, the possibility

exists that system strain that negatively affects service life will

3.1 For terms related to copper and copper alloys, refer to

be introduced.

Terminology B846 for term

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.