ASTM D4239-14

(Test Method)Standard Test Method for Sulfur in the Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace Combustion

Standard Test Method for Sulfur in the Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace Combustion

SIGNIFICANCE AND USE

4.1 Sulfur is part of the ultimate analysis of coal and coke.

4.2 Results of the sulfur analysis are used for evaluation of coal preparation and cleaning, evaluation of potential sulfur emissions from coal and coke combustion or conversion processes, and evaluation of coal and coke quality in relation to contract specifications, as well as for scientific purposes.

4.3 The competency of laboratories with respect to use of this standard can be established through reference to Practice D7448.

SCOPE

1.1 This test method covers the determination of sulfur in samples of coal or coke by high-temperature tube furnace combustion.

1.1.1 Two analysis methods are described.

1.2 When automated equipment is used, either method can be classified as an instrumental method.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 All percentages are percent mass fractions unless otherwise noted.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4239 − 14

StandardTest Method for

Sulfur in the Analysis Sample of Coal and Coke Using High-

1

Temperature Tube Furnace Combustion

This standard is issued under the fixed designation D4239; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Analysis of Coal and Coke

D7582 Test Methods for Proximate Analysis of Coal and

1.1 This test method covers the determination of sulfur in

Coke by Macro Thermogravimetric Analysis

samples of coal or coke by high-temperature tube furnace

E691 Practice for Conducting an Interlaboratory Study to

combustion.

Determine the Precision of a Test Method

1.1.1 Two analysis methods are described.

3

2.2 ISO Standard:

1.2 When automated equipment is used, either method can

ISO 11722 Solid Mineral Fuels-Hard Coal – Determination

be classified as an instrumental method.

of Moisture in the general analysis test sample by drying

1.3 The values stated in SI units are to be regarded as in nitrogen

standard. No other units of measurement are included in this

3. Summary of Test Method

standard.

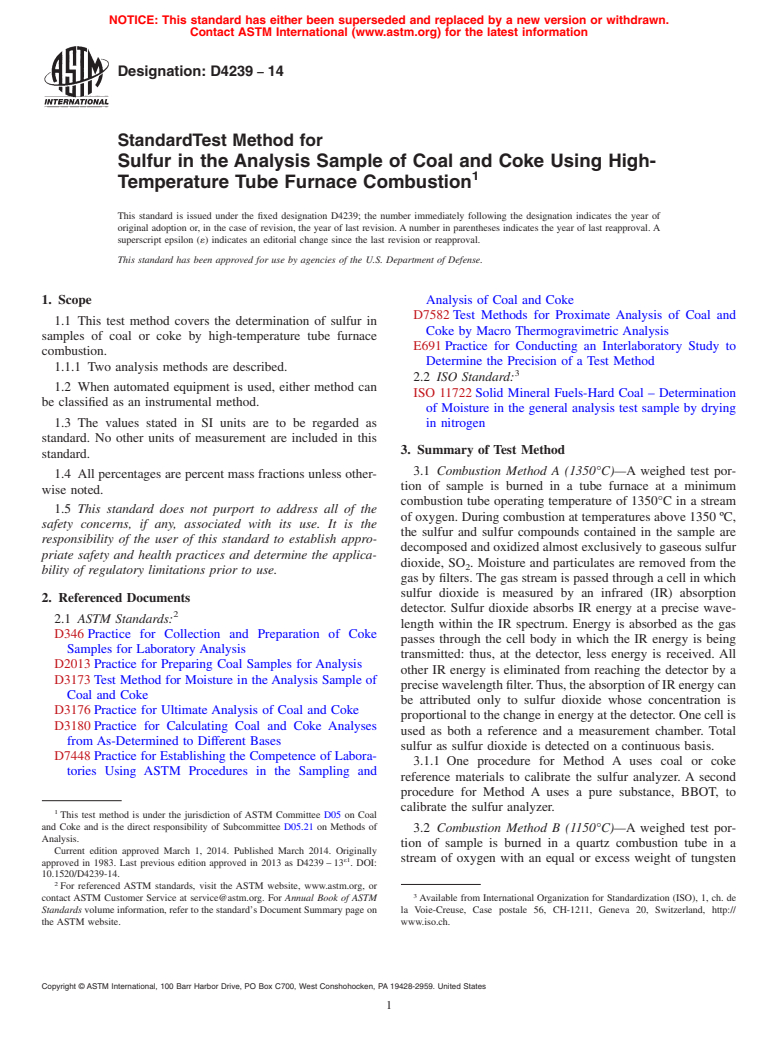

3.1 Combustion Method A (1350°C)—A weighed test por-

1.4 All percentages are percent mass fractions unless other-

tion of sample is burned in a tube furnace at a minimum

wise noted.

combustion tube operating temperature of 1350°C in a stream

1.5 This standard does not purport to address all of the

of oxygen. During combustion at temperatures above 1350 ºC,

safety concerns, if any, associated with its use. It is the

the sulfur and sulfur compounds contained in the sample are

responsibility of the user of this standard to establish appro-

decomposed and oxidized almost exclusively to gaseous sulfur

priate safety and health practices and determine the applica-

dioxide, SO . Moisture and particulates are removed from the

2

bility of regulatory limitations prior to use.

gas by filters. The gas stream is passed through a cell in which

sulfur dioxide is measured by an infrared (IR) absorption

2. Referenced Documents

detector. Sulfur dioxide absorbs IR energy at a precise wave-

2

2.1 ASTM Standards:

length within the IR spectrum. Energy is absorbed as the gas

D346 Practice for Collection and Preparation of Coke

passes through the cell body in which the IR energy is being

Samples for Laboratory Analysis

transmitted: thus, at the detector, less energy is received. All

D2013 Practice for Preparing Coal Samples for Analysis

other IR energy is eliminated from reaching the detector by a

D3173 Test Method for Moisture in the Analysis Sample of

precisewavelengthfilter.Thus,theabsorptionofIRenergycan

Coal and Coke

be attributed only to sulfur dioxide whose concentration is

D3176 Practice for Ultimate Analysis of Coal and Coke

proportional to the change in energy at the detector. One cell is

D3180 Practice for Calculating Coal and Coke Analyses

used as both a reference and a measurement chamber. Total

from As-Determined to Different Bases

sulfur as sulfur dioxide is detected on a continuous basis.

D7448 Practice for Establishing the Competence of Labora-

3.1.1 One procedure for Method A uses coal or coke

tories Using ASTM Procedures in the Sampling and

reference materials to calibrate the sulfur analyzer. A second

procedure for Method A uses a pure substance, BBOT, to

calibrate the sulfur analyzer.

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke and is the direct responsibility of Subcommittee D05.21 on Methods of

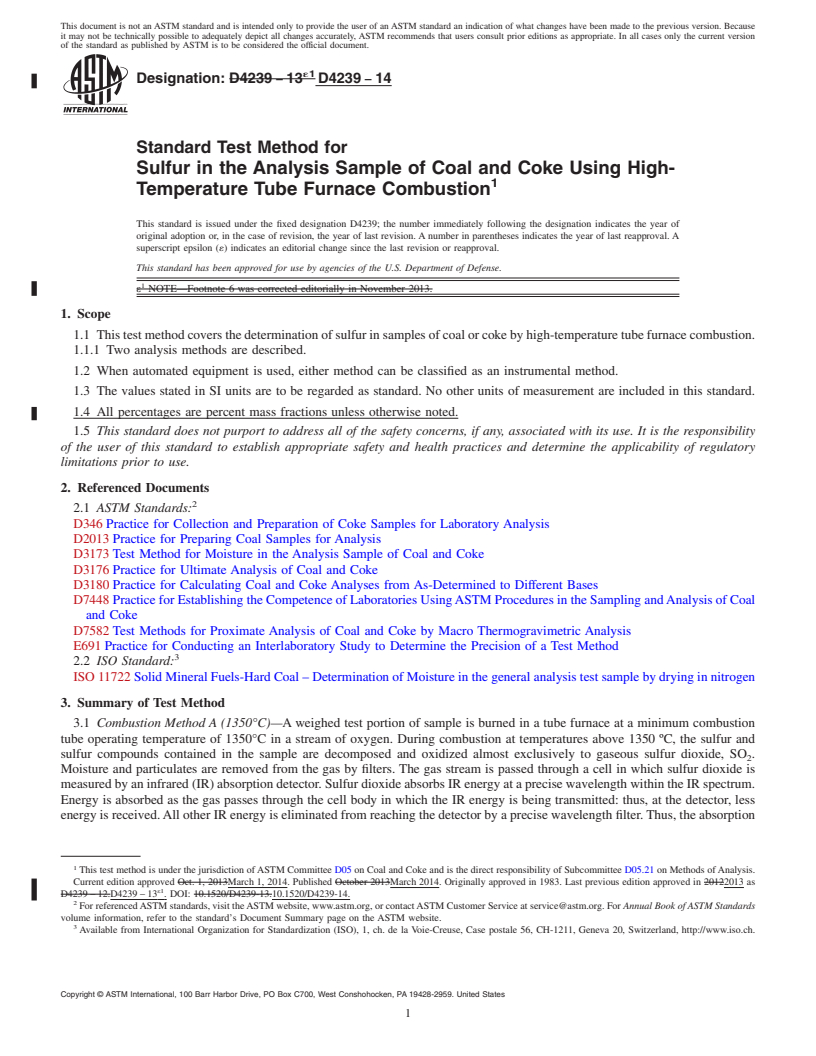

3.2 Combustion Method B (1150°C)—A weighed test por-

Analysis.

tion of sample is burned in a quartz combustion tube in a

Current edition approved March 1, 2014. Published March 2014. Originally

ε1

stream of oxygen with an equal or excess weight of tungsten

approved in 1983. Last previous edition approved in 2013 as D4239 – 13 . DOI:

10.1520/D4239-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), 1, ch. de

Standards volume information, refer to the standard’s Document Summary page on la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

the ASTM website. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4239 − 14

trioxide (WO ). Sulfur is oxidized during the reaction of the 5.2 Analyze a separate portion of the analysis sample for

3

samp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4239 − 13 D4239 − 14

Standard Test Method for

Sulfur in the Analysis Sample of Coal and Coke Using High-

1

Temperature Tube Furnace Combustion

This standard is issued under the fixed designation D4239; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Footnote 6 was corrected editorially in November 2013.

1. Scope

1.1 This test method covers the determination of sulfur in samples of coal or coke by high-temperature tube furnace combustion.

1.1.1 Two analysis methods are described.

1.2 When automated equipment is used, either method can be classified as an instrumental method.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 All percentages are percent mass fractions unless otherwise noted.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D346 Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

D2013 Practice for Preparing Coal Samples for Analysis

D3173 Test Method for Moisture in the Analysis Sample of Coal and Coke

D3176 Practice for Ultimate Analysis of Coal and Coke

D3180 Practice for Calculating Coal and Coke Analyses from As-Determined to Different Bases

D7448 Practice for Establishing the Competence of Laboratories Using ASTM Procedures in the Sampling and Analysis of Coal

and Coke

D7582 Test Methods for Proximate Analysis of Coal and Coke by Macro Thermogravimetric Analysis

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 ISO Standard:

ISO 11722 Solid Mineral Fuels-Hard Coal – Determination of Moisture in the general analysis test sample by drying in nitrogen

3. Summary of Test Method

3.1 Combustion Method A (1350°C)—A weighed test portion of sample is burned in a tube furnace at a minimum combustion

tube operating temperature of 1350°C in a stream of oxygen. During combustion at temperatures above 1350 ºC, the sulfur and

sulfur compounds contained in the sample are decomposed and oxidized almost exclusively to gaseous sulfur dioxide, SO .

2

Moisture and particulates are removed from the gas by filters. The gas stream is passed through a cell in which sulfur dioxide is

measured by an infrared (IR) absorption detector. Sulfur dioxide absorbs IR energy at a precise wavelength within the IR spectrum.

Energy is absorbed as the gas passes through the cell body in which the IR energy is being transmitted: thus, at the detector, less

energy is received. All other IR energy is eliminated from reaching the detector by a precise wavelength filter. Thus, the absorption

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal and Coke and is the direct responsibility of Subcommittee D05.21 on Methods of Analysis.

Current edition approved Oct. 1, 2013March 1, 2014. Published October 2013March 2014. Originally approved in 1983. Last previous edition approved in 20122013 as

ε1

D4239 – 12.D4239 – 13 . DOI: 10.1520/D4239-13.10.1520/D4239-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4239 − 14

of IR energy can be attributed only to sulfur dioxide whose concentration is proportional to the change in energy at the detector.

One cell is used as both a reference and a measurement chamber. Total sulfur as sulfur dioxide is detected on a continuous basis.

3.1.1 One procedure for Method A uses coal or coke reference materials to calibrate the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.