ASTM F2414-04(2009)

(Practice)Standard Practice for Sealing Sewer Manholes Using Chemical Grouting

Standard Practice for Sealing Sewer Manholes Using Chemical Grouting

SIGNIFICANCE AND USE

This practice is used as a guide for the installation of chemical grout in the practice of sealing sewer manholes from leaks, cracks, and around penetrations. It is attended to assist sewer owners and engineer, owner’s representative, or authorized inspectors for installation method specification and for contractors to refer to during installations of chemical grout for manhole sealing.

SCOPE

1.1 This practice covers proposed selection of materials, installation techniques, and inspection required for sealing manholes using chemical grout. Manholes or sections of manholes with active leaks shall be repaired. Manholes to be grouted are of brick, block, cast-in-place concrete, precast concrete, or fiberglass construction. Manholes or sections of manholes with active leaks will be designated by the engineer, owner’s representative, or authorized inspector, for manhole grouting.

1.2 The contractor shall be responsible for furnishing all labor, supervision, materials, equipment, and inspection follow-up required for the completion of chemical grouting of manhole defects in accordance with the contract documents.

1.3 Materials, additives, mixture ratios, and procedures utilized for the grouting process shall be in accordance with manufacturer’s recommendations and shall be appropriate for the application.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2414 − 04(Reapproved 2009)

Standard Practice for

Sealing Sewer Manholes Using Chemical Grouting

This standard is issued under the fixed designation F2414; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.2 acrylate—a general term applied to various water-

soluble acrylic resinous materials.

1.1 This practice covers proposed selection of materials,

installation techniques, and inspection required for sealing 2.1.3 authorized inspector—the person(s) contracted or ap-

manholes using chemical grout. Manholes or sections of proved by the owner or owner’s representative to do inspec-

manholes with active leaks shall be repaired. Manholes to be tions.

grouted are of brick, block, cast-in-place concrete, precast

2.1.4 catalyst—substance which markedly speeds up the

concrete, or fiberglass construction. Manholes or sections of

cure of an adhesive when added in small quantities as

manholes with active leaks will be designated by the engineer,

compared to the amounts of primary reactants.

owner’s representative, or authorized inspector, for manhole

2.1.5 chemical grout—injection repair media other than

grouting.

cementitious grout that may be multi-component, with or

1.2 The contractor shall be responsible for furnishing all

without additives, and based on either polyurethane resin or

labor, supervision, materials, equipment, and inspection

acrylic resin.

follow-up required for the completion of chemical grouting of

2.1.6 control agent—substance added which controls the

manhole defects in accordance with the contract documents.

viscosity or flow properties of the material it is added to.

1.3 Materials, additives, mixture ratios, and procedures

2.1.7 engineer—an engineer registered in the state where

utilized for the grouting process shall be in accordance with

the work is to be done who has been contracted by or is acting

manufacturer’s recommendations and shall be appropriate for

on behalf of the owner or the owner’s representative.

the application.

2.1.8 exfiltration—leaking or weeping to the external areas

1.4 The values stated in inch-pound units are to be regarded

outside the barrier from a source inside the barrier.

as standard. The values given in parentheses are mathematical

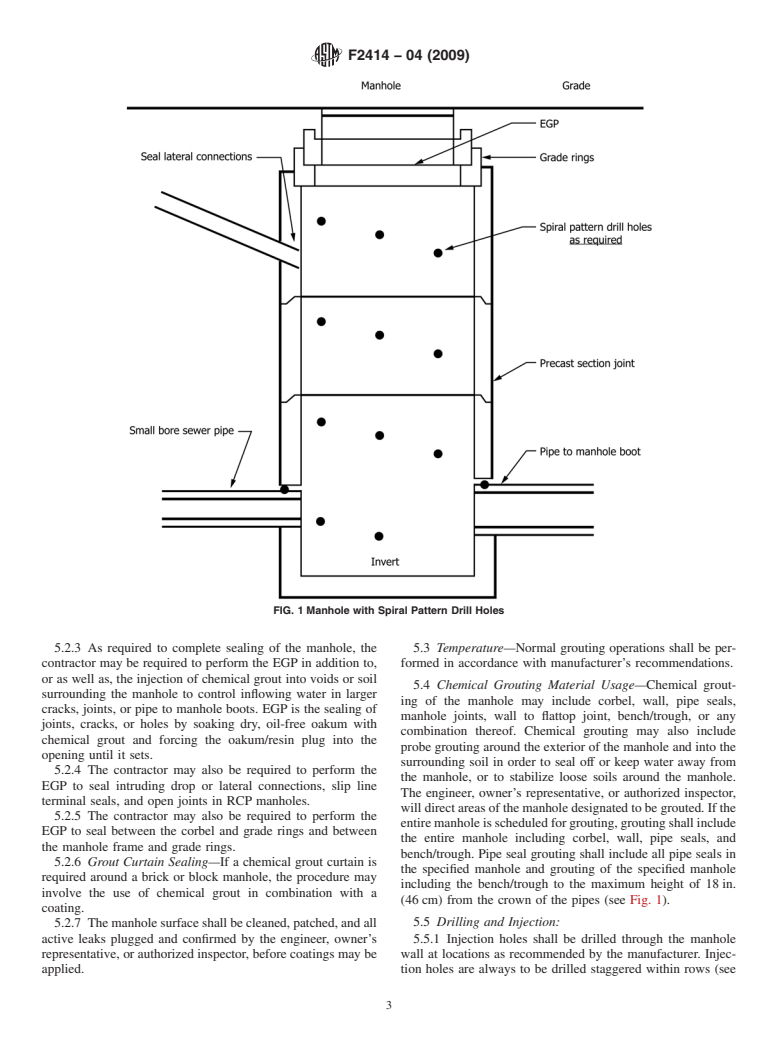

2.1.9 expanded gasket procedure (EGP)—the sealing of

conversions to SI units that are provided for information only

joints, cracks, or holes by soaking dry, oil-free oakum with

and are not considered standard.

chemical grout and forcing the oakum/resin plug into the

1.5 This standard does not purport to address all of the

opening until it sets.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 2.1.10 hydrophilic grout—hydrophilic grout will absorb and

priate safety and health practices and determine the applica- react with the water it comes into contact with.

bility of regulatory limitations prior to use.

2.1.11 hydrophobic grout—hydrophobic grout will repel

water and push it away.

2. Terminology

2.1.12 manhole—vertical shafts that intersect with sewers to

2.1 Definitions of Terms Specific to This Standard:

allow transitions in alignment and grade and to allow entry for

2.1.1 acrylamide—organic solid of white, odorless, acrylic

cleaning, inspection, and maintenance.

resinous material available in flake-like crystals and in liquid

2.1.13 oakum—loose hemp or jute fiber, sometimes treated

form. The greatest use of acrylamide is as a coagulant aid in

with resin or grout, used chiefly for caulking seams in

drinking water treatment. Other major uses of acrylamide are

structures and boats as well as packing pipe joints.

in soil stabilization, in grout for repairing sewers and in

acrylamide gels used in biotechnology laboratories.

2.1.14 owner’s representative—the individual who has been

contracted to act on behalf of the owner for project planning

and supervision.

This practice is under the jurisdiction ofASTM Committee F36 on Technology

and Underground Utilitiesand is the direct responsibility of Subcommittee F36.20

2.1.15 polyurethane resin—any of various polymer resins

on Inspection and Renewal of Water and Wastewater Infrastructure.

containing the urethane radical; a wide variety of synthetic

Current edition approved May 1, 2009. Published June 2009. Originally

forms are made and used as adhesives, plastics, foams, paints,

approved in 2004. Last previous edition approved in 2004 as F2414 – 04. DOI:

10.1520/F2414-04R09. or rubber-like materials.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2414 − 04 (2009)

2.1.16 RCP—reinforced concrete pipe. 4.2.7 Careful consideration of current or potential wet-dry

cycles, ground pressures, and thermal conditions and applica-

2.1.17 rehabilitated manhole—a manhole restored to its

tion requirements must be thoroughly reviewed by the contrac-

intended capacity or use per the specifications.

tor or engineer when choosing or approving the appropriate

2.1.18 repaired or sealed manhole—a manhole that has

type of chemical grout.

been sealed from detected infiltration or exfiltrations, but not

4.2.8 Careful consideration of water type (storm water

necessarily restored to its original designed capacity.

versus waste water) is to be considered when choosing or

2.1.19 sewer—waste water sewer or storm drain sewer.

approving the appropriate type of materials.

4.3 Additives—The chemical grout must be applied so as to

3. Significance and Use

have the grout material flow freely into the defects. To avoid

3.1 This practice is used as a guide for the installation of

any wasting of the material flowing through the defects gel

chemical grout in the practice of sealing sewer manholes from

control agent may be added. Grout additions may also be used

leaks, cracks, and around penetrations. It is attended to assist

forcatalyzingthereaction,inhibitingthereaction,bufferingthe

sewer owners and engineer, owner’s representative, or autho-

solution, lowering the freezing temperature of the solution,

rized inspectors for installation method specification and for

acting as filler, providing strength, or inhibition of root growth.

contractors to refer to during installations of chemical grout for

4.3.1 Additivesmustnotalterotherintendedfinalproperties

manhole sealing.

and characteristics of the original material other than the

properties targeted for improvement.

4. Materials

4.4 Material Identification—The contractor shall com-

4.1 Grouting Materials—Chemical grout sealing material:

pletely identify the types of grout, sealant, root control

4.1.1 Acrylamide base gel,

chemicals, or any combination thereof, used and provide case

4.1.2 Acrylic base gel,

histories of successful use or defend the choice of grouting

4.1.3 Hydrophilic polyurethane foam or gel,

materials based on chemical and tested physical properties,

4.1.4 Hydrophobic polyurethane foam or gel, and

ease of application, and expected performance to the satisfac-

4.1.5 Oil-free, oakum-soaked polyurethane resin.

tion of the engineer, owner’s representative, or authorized

4.2 Grouting Materials Characteristics—Specific character-

inspector. The grout materials’Technical Data Sheets, Material

istics that pertain to the application requirements are to be

Safety Data Sheets, and the manufacturer’s application instruc-

defined and approved by the owner’s representative or project

tions are to be submitted for approval by the engineer, owner’s

engineer of record. The following general characteristics or

representative, or authorized inspector.

properties shall be exhibited by the chemical grout:

4.5 Mixing and Handling:

4.2.1 The chemical grout shall have documented service of

4.5.1 Hazards—Mixing and handling of chemical grout,

satisfactory performance in similar usage and should have a

which may be toxic under certain conditions, shall be in

manufacturer’s written guarantee of performance for the appli-

accordance with the recommendations of the manufacturer and

cation of sewer manhole sealing under intended conditions and

in such a manner as to minimize hazard to personnel. It is the

when installed per the manufacturer’s instructions.

responsibility of the contractor to provide appropriate protec-

4.2.2 The chemical grout shall have controllable reaction

tive measures to ensure that the chemicals are handled by

times and minimal shrinkage, as specified by the owner,

authorized personnel and in the proper manner.

owner’s representative, or engineer, through the use of chemi-

4.5.2 All equipment shall be subject to the approval of the

cals supplied by the same manufacturer.The minimum set time

engineer, owner’s representative, or authorized inspector. Only

shall be established so that adequate grout travel is achieved.

personnel thoroughly familiar with the handling of the grout

4.2.3 The chemical grout shall have resistance to chemicals,

material and add

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.