ASTM D850-11

(Test Method)Standard Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials

Standard Test Method for Distillation of Industrial Aromatic Hydrocarbons and Related Materials

SIGNIFICANCE AND USE

This test method is suitable for setting specifications, for use as an internal quality control tool, and for use in development or research work on industrial aromatic hydrocarbons and related materials.

This test method gives a broad indication of general purity and can also indicate presence of excessive moisture. It will not differentiate between products of similar boiling range.

SCOPE

1.1 This test method covers the distillation of industrial aromatic hydrocarbons and related materials of relatively narrow boiling ranges from 30 to 250°C.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following applies to all specified limits in this test method: for the purposes of determining conformance to this test method, an observed or calculated value shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

1.4 WarningMercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA's website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, 6.6.1 and Section 7.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D850 − 11

StandardTest Method for

Distillation of Industrial Aromatic Hydrocarbons and Related

1

Materials

This standard is issued under the fixed designation D850; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers the distillation of industrial 2.1 ASTM Standards:

aromatic hydrocarbons and related materials of relatively D1078 Test Method for Distillation Range of Volatile Or-

narrow boiling ranges from 30 to 250°C. ganic Liquids

D3437 Practice for Sampling and Handling Liquid Cyclic

1.2 The values stated in SI units are to be regarded as the

Products

standard. The values given in parentheses are for information

D4790 Terminology ofAromatic Hydrocarbons and Related

only.

Chemicals

1.3 The following applies to all specified limits in this test

E1 Specification for ASTM Liquid-in-Glass Thermometers

method: for the purposes of determining conformance to this

E29 Practice for Using Significant Digits in Test Data to

test method, an observed or calculated value shall be rounded

Determine Conformance with Specifications

off “to the nearest unit” in the last right-hand digit used in

E133 Specification for Distillation Equipment

expressing the specification limit, in accordance with the

E220 Test Method for Calibration of Thermocouples By

rounding-off method of Practice E29.

Comparison Techniques

1.4 Warning—Mercury has been designated by EPA and E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

many state agencies as a hazardous material that can cause

central nervous system, kidney and liver damage. Mercury, or 2.2 Other Document:

its vapor, may be hazardous to health and corrosive to OSHA Regulations, 29 CFR paragraphs 1910.1000 and

3

materials.Cautionshouldbetakenwhenhandlingmercuryand 1910.1200

mercury-containing products. See the applicable product Ma-

3. Terminology

terial Safety Data Sheet (MSDS) for details and EPA’s website

(http://www.epa.gov/mercury/faq.htm) for additional informa-

3.1 Definitions:

tion. Users should be aware that selling mercury or mercury-

3.1.1 See Terminology D4790 for definitions of terms used

containingproducts,orboth,inyourstatemaybeprohibitedby

in this test method.

state law.

4. Summary of Test Method

1.5 This standard does not purport to address all of the

4.1 The distillation of a 100-mL sample of industrial aro-

safety concerns, if any, associated with its use. It is the

matic hydrocarbons and related materials is carried out via a

responsibility of the user of this standard to establish appro-

carefully controlled distillation wherein temperature readings

priate safety and health practices and determine the applica-

are noted for the first drop of distillate and when 5, 10, and

bility of regulatory limitations prior to use. For specific hazard

statements, 6.6.1 and Section 7.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee D16 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee D16.04 on Instrumental Analysis. the ASTM website.

3

Current edition approved July 1, 2011. Published July 2011. Originally approved AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

ε1

in 1945. Last previous edition approved in 2008 as D850 – 03 (2008) . DOI: 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

10.1520/D0850-11. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

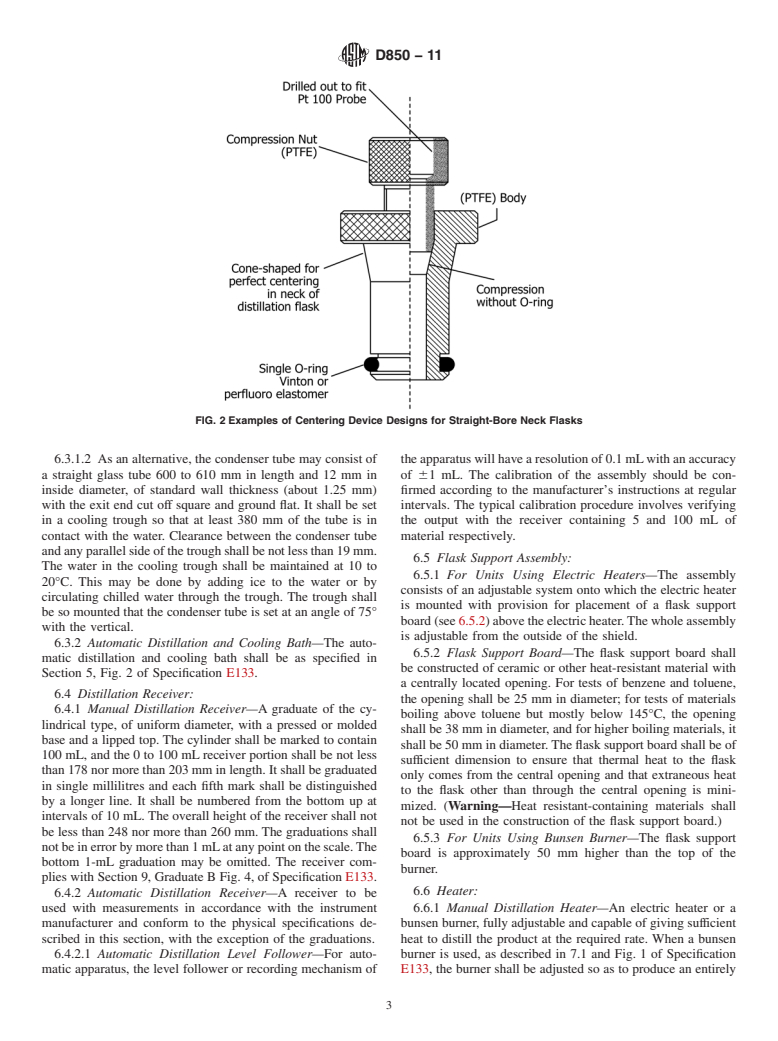

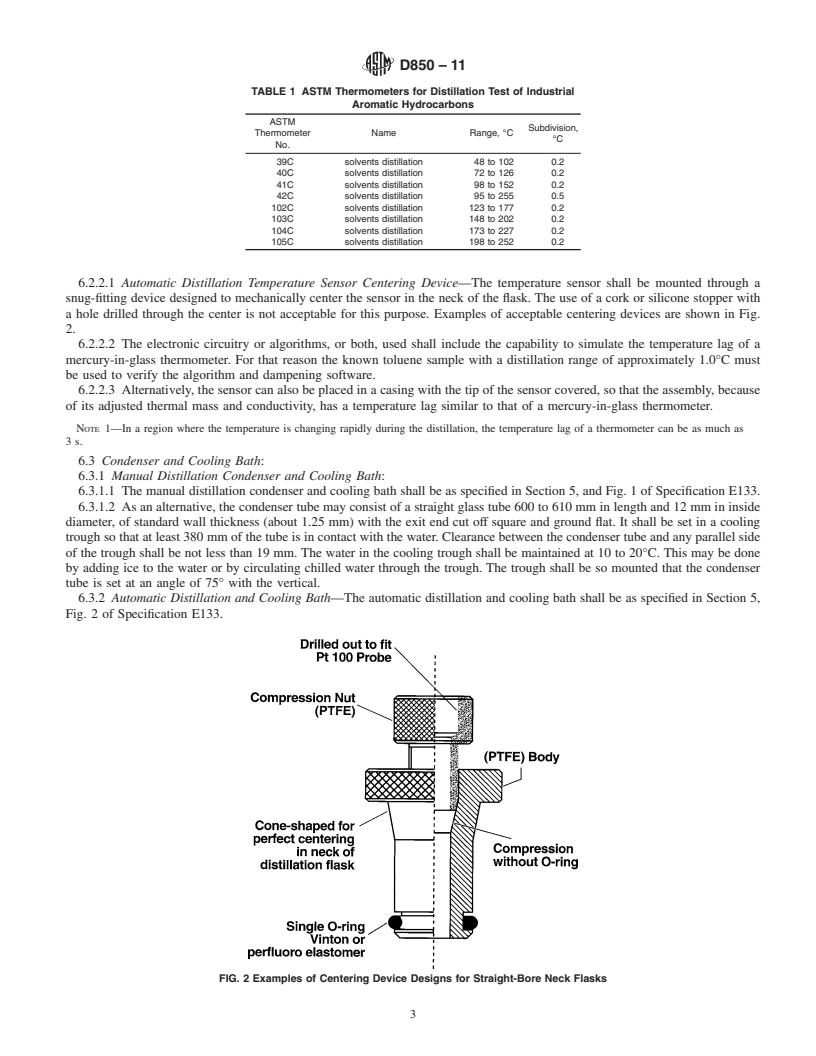

D850 − 11

TABLE 1 ASTM Thermometers for Distillation Test of Industrial

each additional 10 up to 90, and 95 % of the sample has

Aromatic Hydrocarbons

distilled over. The temperature corresponding to the dry point

ASTM

is also noted.

Subdivision,

Thermometer Name Range, °C

°C

No.

5. Significance and Use

39C solvents distillation 48 to 102 0.2

40C solvents distillation 72 to 126 0.2

5.1 Thistestmethodissuitableforsettingspecifications,for

41C solvents distillation 98 to 152 0.2

use as an internal quality control tool, and for use in develop-

42C solvents distillation 95 to 255 0.5

mentorresearchworkon

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D850–03(Reapproved2008) Designation:D850–11

Standard Test Method for

Distillation of Industrial Aromatic Hydrocarbons and Related

1

Materials

This standard is issued under the fixed designation D850; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Mercury warning was editorially added in June 2008.

1. Scope*

1.1 Thistestmethodcoversthedistillationofindustrialaromatichydrocarbonsandrelatedmaterialsofrelativelynarrowboiling

ranges from 30 to 250°C.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following applies to all specified limits in this test method: for the purposes of determining conformance to this test

method, an observed or calculated value shall be rounded off “to the nearest unit” in the last right-hand digit used in expressing

the specification limit, in accordance with the rounding-off method of Practice E29.

1.4 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, 6.6.1 and Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D1078 Test Method for Distillation Range of Volatile Organic Liquids

D3437 Practice for Sampling and Handling Liquid Cyclic Products

D4790 Terminology of Aromatic Hydrocarbons and Related Chemicals

E1 Specification for ASTM Liquid-in-Glass Thermometers

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E133 Specification for Distillation Equipment

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Other Document:

3

OSHA Regulations, 29 CFR paragraphs 1910.1000 and 1910.1200

3. Terminology

3.1 Definitions:

3.1.1 See Terminology D4790 for definitions of terms used in this test method.

1

This test method is under the jurisdiction ofASTM Committee D16 onAromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Subcommittee

D16.04 on Instrumental Analysis.

Current edition approved June 1, 2008. Published June 2008. Originally approved in 1945. Last previous edition approved in 2003 as D850–03. DOI:

10.1520/D0850-03R08E01.

´1

Current edition approved July 1, 2011. Published July 2011. Originally approved in 1945. Last previous edition approved in 2008 as D850 – 03 (2008) . DOI:

10.1520/D0850-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D850–11

4. Summary of Test Method

4.1 The distillation of a 100-mL sample of industrial aromatic hydrocarbons and related materials is carried out via a carefully

controlled distillation wherein temperature readings are noted for the first drop of distillate and when 5, 10, and each additional

10 up to 90, and 95 % of the sample has distil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.