ASTM E2368-04e1

(Practice)Standard Practice for Strain Controlled Thermomechanical Fatigue Testing

Standard Practice for Strain Controlled Thermomechanical Fatigue Testing

SIGNIFICANCE AND USE

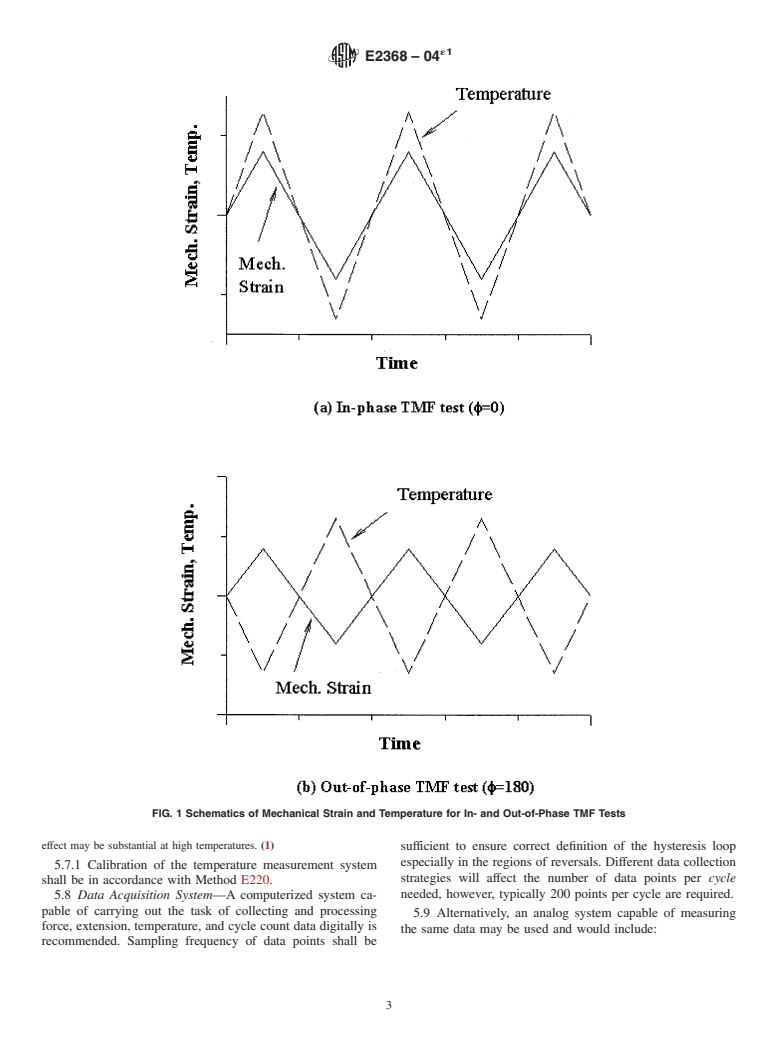

In the utilization of structural materials in elevated temperature environments, components that are susceptible to fatigue damage may experience some form of simultaneously varying thermal and mechanical forces throughout a given cycle. These conditions are often of critical concern because they combine temperature dependent and cycle dependent (fatigue) damage mechanisms with varying severity relating to the phase relationship between cyclic temperature and cyclic mechanical strain. Such effects can be found to influence the evolution of microstructure, micromechanisms of degradation, and a variety of other phenomenological processes that ultimately affect cyclic life. The strain-controlled thermomechanical fatigue test is often used to investigate the effects of simultaneously varying thermal and mechanical loadings under idealized conditions, where cyclic theoretically uniform temperature and strain fields are externally imposed and controlled throughout the gage section of the specimen.

SCOPE

1.1 This practice covers the determination of thermomechanical fatigue (TMF) properties of materials under uniaxially loaded strain-controlled conditions. A "thermomechanical" fatigue cycle is here defined as a condition where uniform temperature and strain fields over the specimen gage section are simultaneously varied and independently controlled. This practice is intended to address TMF testing performed in support of such activities as materials research and development, mechanical design, process and quality control, product performance, and failure analysis. While this practice is specific to strain-controlled testing, many sections will provide useful information for force-controlled or stress-controlled TMF testing.

1.2 This practice allows for any maximum and minimum values of temperature and mechanical strain, and temperature-mechanical strain phasing, with the restriction being that such parameters remain cyclically constant throughout the duration of the test. No restrictions are placed on environmental factors such as pressure, humidity, environmental medium, and others, provided that they are controlled throughout the test, do not cause loss of or change in specimen dimensions in time, and are detailed in the data report.

1.3 The use of this practice is limited to specimens and does not cover testing of full-scale components, structures, or consumer products.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation:E2368–04

Standard Practice for

1

Strain Controlled Thermomechanical Fatigue Testing

This standard is issued under the fixed designation E2368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Editorial changes were made throughout in May 2005.

1. Scope E83 Practice for Verification and Classification of Exten-

someter Systems

1.1 This practice covers the determination of thermome-

E111 Test Method forYoung’s Modulus, Tangent Modulus,

chanicalfatigue(TMF)propertiesofmaterialsunderuniaxially

and Chord Modulus

loaded strain-controlled conditions. A “thermomechanical”

E112 Test Methods for Determining Average Grain Size

fatigue cycle is here defined as a condition where uniform

E220 Test Method for Calibration of Thermocouples By

temperature and strain fields over the specimen gage section

Comparison Techniques

are simultaneously varied and independently controlled. This

E467 Practice for Verification of Constant Amplitude Dy-

practice is intended to address TMF testing performed in

namic Forces in an Axial Fatigue Testing System

support of such activities as materials research and develop-

E606 Practice for Strain-Controlled Fatigue Testing

ment, mechanical design, process and quality control, product

E739 Practice for Statistical Analysis of Linear or Linear-

performance, and failure analysis. While this practice is spe-

ized Stress-Life ( S-N) and Strain-Life (e-N) Fatigue Data

cific to strain-controlled testing, many sections will provide

E1012 PracticeforVerificationofTestFrameandSpecimen

useful information for force-controlled or stress-controlled

Alignment Under Tensile and Compressive Axial Force

TMF testing.

Application

1.2 This practice allows for any maximum and minimum

E1823 Terminology Relating to Fatigue and Fracture Test-

values of temperature and mechanical strain, and temperature-

ing

mechanical strain phasing, with the restriction being that such

parameters remain cyclically constant throughout the duration

3. Terminology

of the test. No restrictions are placed on environmental factors

3.1 The definitions in this practice are in accordance with

such as pressure, humidity, environmental medium, and others,

definitions given in Terminology E1823 unless otherwise

provided that they are controlled throughout the test, do not

stated.

cause loss of or change in specimen dimensions in time, and

3.2 Additional definitions are as follows:

are detailed in the data report.

3.2.1 stress, s—stress is defined herein to be the engineer-

1.3 The use of this practice is limited to specimens and does

ing stress, which is the ratio of force, P, to specimen original

not cover testing of full-scale components, structures, or

cross sectional area, A:

consumer products.

s5 P/A (1)

2. Referenced Documents

The area, A, is that measured in an unloaded condition at

2

2.1 ASTM Standards:

room temperature. See 7.2 for temperature state implications.

E3 Guide for Preparation of Metallographic Specimens

3.2.2 coeffıcient of thermal expansion, a—the fractional

E4 Practices for Force Verification of Testing Machines

change in free expansion strain for a unit change in tempera-

ture, as measured on the test specimen.

1 3.2.3 total strain, ´—the strain component measured on the

t

This practice is under the jurisdiction ofASTM Committee E08 on Fatigue and

Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic test specimen, and is the sum of the thermal strain and the

Deformation and Fatigue Crack Formation.

mechanical strain.

Current edition approved May 1, 2004. Published June 2004. DOI: 10.1520/

3.2.4 thermal strain, ´ —the strain component resulting

th

E2368-04E01.

2

from a change in temperature under free expansion conditions

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(as measured on the test specimen).

Standards volume information, refer to the standard’s Document Summary page on

´ 5s · DT (2)

th

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

E2368–04

NOTE 1—For some materials, s may be nonlinear over the temperature

(test frame and associated fixtures) shall be in compliance with

range of interest.

the bending strain criteria specified in Practices E606, E1012,

and E467. The test system shall be able to independently

3.2.5 mechanical strain, ´ —thestraincomponentresulting

m

control both temperature and total strain. In addition it sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.