ASTM D3474-23

(Practice)Standard Practice for Calibration and Use of Torque Meters Used in Packaging Applications

Standard Practice for Calibration and Use of Torque Meters Used in Packaging Applications

SIGNIFICANCE AND USE

5.1 This practice can be used to check devices used to measure the application and removal torques of continuous or intermittent thread and lug closures.

5.2 This practice can be used to determine the amount of torque to either apply or remove a closure.

SCOPE

1.1 This practice covers the calibration and use of torque meters of the type normally used in packaging applications.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3474 − 23

Standard Practice for

Calibration and Use of Torque Meters Used in Packaging

1

Applications

This standard is issued under the fixed designation D3474; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Use—Torque values to apply or remove closures are

obtained by mounting containers on the platform and either

1.1 This practice covers the calibration and use of torque

applying or removing the closures. In some applications, the

meters of the type normally used in packaging applications.

closure is mounted on the platform and the container is rotated.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 This practice can be used to check devices used to

priate safety, health, and environmental practices and deter-

measure the application and removal torques of continuous or

mine the applicability of regulatory limitations prior to use.

intermittent thread and lug closures.

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5.2 This practice can be used to determine the amount of

ization established in the Decision on Principles for the

torque to either apply or remove a closure.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

6. Apparatus

Barriers to Trade (TBT) Committee.

6.1 Adapter—A circular plate that can be mounted concen-

trically on the platform of the tester. If the platform itself is

2. Referenced Documents

2 suitable, an adapter is not necessary. The adapter should be of

2.1 ASTM Standards:

such diameter that its radius multiplied by appropriate weights

D3198 Test Method for Application and Removal Torque of

1 1

3 will give torque values equal to ⁄4, ⁄2 , and full-scale meter

Threaded or Lug-Style Closures (Withdrawn 2016)

readings. (Typical devices for packaging applications have

3. Terminology

ranges from: 0 to 10, 0 to 25, 0 to 50, and 0 to 100 lbf-in. (0

to 1.13, 0 to 2.8, 0 to 5.7, and 0 to 11.3 N/m, respectively).

3.1 Definitions—For definitions of application torque and

removal torque, see Test Method D3198.

6.2 Connecting Means—A very flexible, thin filament, such

3.1.1 stripping torque—a force or system of forces acting in as a wire or fishing line that transmits the force of hanging

a tightening direction that causes overrunning of the threads or

weights to the circumference of the adapter.

rotation of a threaded or lug style closure system with respect

6.3 Pulley, low friction, used to change the direction of the

to its supporting member.

connecting means from horizontal to vertical.

4. Summary of Practice

6.4 Appropriate Dead Weights, for example: 2, 4, and 7-lb

(0.9, 1.8, and 3.2-kg) for a torque meter with a 7 in. (178 mm)

4.1 Calibration—Reference torque values are obtained by

diameter plate or platform and a range of 0 to 25 in.lb (0 to 2.8

means of vertically suspended dead weights acting at specific

N-m).

distances from the axis of the mounting platform of the tester.

1

7. Conditioning

This practice is under the jurisdiction of ASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.25 on Rigid

7.1 Prior to calibration, the torque meter and weights shall

Container Closure Systems.

be allowed to come to ambient room conditions.

Current edition approved Nov. 1, 2023. Published November 2023. Originally

approved in 1976. Last previous edition approved in 2018 as D3474 – 90 (2018).

DOI: 10.1520/D3474-23.

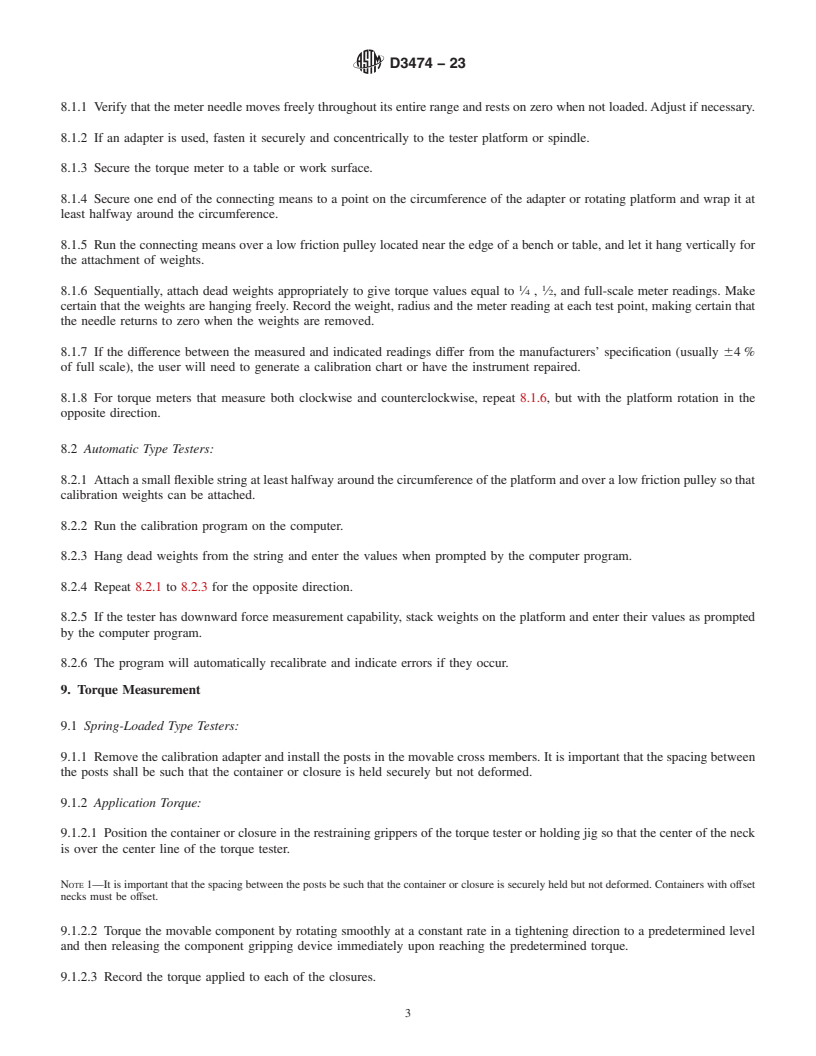

8. Calibration Procedures (see Fig. 1)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1 Spring-Loaded Type Testers:

Standards volume information, refer to the standard‘s Document Summary page on

8.1.1 Verify that the meter needle moves freely throughout

the ASTM website.

3

its entire range and rests on zero when not loaded. Adjust if

The last approved version of this historical standard is referenced on

www.astm.org. necessary.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3474 − 23

FIG. 1 Torque Meter Calibration Set Up

8.1.2 If an

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3474 − 90 (Reapproved 2018) D3474 − 23

Standard Practice for

Calibration and Use of Torque Meters Used in Packaging

1

Applications

This standard is issued under the fixed designation D3474; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the calibration and use of torque meters of the type normally used in packaging applications.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

D3198 Test Method for Application and Removal Torque of Threaded or Lug-Style Closures (Withdrawn 2016)

3. Terminology

3.1 Definitions—For definitions of application torque and removal torque, see Test Method D3198.

3.1.1 stripping torque—a force or system of forces acting in a tightening direction that causes overrunning of the threads or

rotation of an overshell a threaded or lug style closure system with respect to its supporting member.

4. Summary of Practice

4.1 Calibration—Reference torque values are obtained by means of vertically suspended dead weights acting at specific distances

from the axis of the mounting platform of the tester.

4.2 Use—Torque values to apply or remove closures are obtained by mounting containers on the platform and either applying or

removing the closures. In some applications, the closure is mounted on the platform and the container is rotated.

1

This practice is under the jurisdiction of ASTM Committee F02 on Primary Barrier Packaging and is the direct responsibility of Subcommittee F02.25 on Rigid Container

Closure Systems.

Current edition approved April 15, 2018Nov. 1, 2023. Published June 2018November 2023. Originally approved in 1976. Last previous edition approved in 20122018

as D3474 – 90 (2018).(2012). DOI: 10.1520/D3474-90R18.10.1520/D3474-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard‘s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3474 − 23

5. Significance and Use

5.1 This practice can be used to check devices used to measure the application and removal torques of continuous or intermittent

thread and lug closures.

5.2 This practice can be used to determine the amount of torque to either apply or remove a closure.

6. Apparatus

6.1 Adapter—A circular plate that can be mounted concentrically on the platform of the tester. If the platform itself is suitable,

an adapter is not necessary. The adapter should be of such diameter that its radius multiplied by appropriate weights will give

1 1

torque values equal to ⁄4, ⁄2 , and full-scale meter readings. (Typical devices for packaging applications have ranges from: 0 to

10, 0 to 25, 0 to 50, and 0 to 100 lbf-in. (0 to 1.13, 0 to 2.8, 0 to 5.7, and 0 to 11.3 N/m, respectively).

6.2 Connecting Means—A very flexible, thin filament, such as a wire or fishing line that transmits the force of hanging weights

to the circumference of the adapter.

6.3 Pulley, low friction, used to change the direction of the connecting means from horizontal to vertical.

6.4 Appropriate Dead Weights, for example: 2, 4, and 7-lb (0.9, 1.8, and 3.2-kg) for a torque meter with a 7 in. (178 mm) diameter

plate or platform and a range of 0 to 25 in-lbsin.lb (0 to 2.8 N-m).

7. Conditioning

7.1 Prior to calibration, the torque meter and weights shall be allowed to come to ambient room conditions.

8. Calibration Procedures (see Fig. 1)

8.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.