ASTM D4007-11(2016)

(Test Method)Standard Test Method for Water and Sediment in Crude Oil by the Centrifuge Method (Laboratory Procedure)

Standard Test Method for Water and Sediment in Crude Oil by the Centrifuge Method (Laboratory Procedure)

SIGNIFICANCE AND USE

4.1 The water and sediment content of crude oil is significant because it can cause corrosion of equipment and problems in processing. A determination of water and sediment content is required to measure accurately net volumes of actual oil in sales, taxation, exchanges, and custody transfers. It is not anticipated that this test method, which is written with a dedicated laboratory facility in mind, is likely to be used in field test rooms or sample rooms due to safety concerns for proper ventilation and handling.

4.2 This test method may not be suitable for crude oils that contain alcohols that are soluble in water. In cases where the impact on the results may be significant, the user is advised to consider using another test method, such as Test Method D4928 (API MPMS Chapter 10.9).

SCOPE

1.1 This test method describes the laboratory determination of water and sediment in crude oils by means of the centrifuge procedure. This centrifuge method for determining water and sediment in crude oils is not entirely satisfactory. The amount of water detected is almost always lower than the actual water content. When a highly accurate value is required, the revised procedures for water by distillation, Test Method D4006 (API MPMS Chapter 10.2) (Note 1), and sediment by extraction, Test Method D473 (API MPMS Chapter 10.1), shall be used.

Note 1: Test Method D4006 (API MPMS Chapter 10.2) has been determined to be the preferred and most accurate method for the determination of water.

1.2 The values stated in SI units are to be regarded as standard.

1.2.1 Exception—The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements appear in 6.1, 8.3, and A1.5.4.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4007 − 11 (Reapproved 2016)

Manual of Petroleum Measurement Standards (MPMS), Chapter 10.3

Standard Test Method for

Water and Sediment in Crude Oil by the Centrifuge Method

(Laboratory Procedure)

This standard is issued under the fixed designation D4007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope BituminousMaterialsbyDistillation(API MPMSChapter

10.5)

1.1 This test method describes the laboratory determination

D473TestMethodforSedimentinCrudeOilsandFuelOils

of water and sediment in crude oils by means of the centrifuge

by the Extraction Method (API MPMS Chapter 10.1)

procedure. This centrifuge method for determining water and

D665Test Method for Rust-Preventing Characteristics of

sediment in crude oils is not entirely satisfactory. The amount

Inhibited Mineral Oil in the Presence of Water

of water detected is almost always lower than the actual water

D1796Test Method for Water and Sediment in Fuel Oils by

content. When a highly accurate value is required, the revised

the Centrifuge Method (Laboratory Procedure) (API

procedures for water by distillation, Test Method D4006 (API

MPMS Chapter 10.6)

MPMS Chapter 10.2) (Note 1), and sediment by extraction,

D4006Test Method for Water in Crude Oil by Distillation

Test Method D473 (API MPMS Chapter 10.1), shall be used.

(API MPMS Chapter 10.2)

NOTE 1—Test Method D4006 (API MPMS Chapter 10.2) has been

D4057Practice for Manual Sampling of Petroleum and

determined to be the preferred and most accurate method for the

Petroleum Products (API MPMS Chapter 8.1)

determination of water.

D4177Practice for Automatic Sampling of Petroleum and

1.2 The values stated in SI units are to be regarded as

Petroleum Products (API MPMS Chapter 8.2)

standard.

D4928Test Method forWater in Crude Oils by Coulometric

1.2.1 Exception—The values given in parentheses are for

Karl Fischer Titration (API MPMS Chapter 10.9)

information only.

D5854Practice for Mixing and Handling of Liquid Samples

1.3 This standard does not purport to address all of the

of Petroleum and Petroleum Products (API MPMS Chap-

safety concerns, if any, associated with its use. It is the

ter 8.3)

responsibility of the user of this standard to establish appro- E969Specification for Glass Volumetric (Transfer) Pipets

priate safety and health practices and determine the applica-

2.2 API Standards:

bility of regulatory limitations prior to use. Specific warning

MPMS Chapter 8.1Manual Sampling of Petroleum and

statements appear in 6.1, 8.3, and A1.5.4.

Petroleum Products (ASTM Practice D4057)

MPMS Chapter 8.2Automatic Sampling of Petroleum and

2. Referenced Documents

Petroleum Products (ASTM Practice D4177)

2.1 ASTM Standards:

MPMSChapter8.3MixingandHandlingofLiquidSamples

D95Test Method for Water in Petroleum Products and

of Petroleum and Petroleum Products (ASTM Practice

D5854)

MPMS Chapter 10.1Determination of Sediment in Crude

This test method is under the jurisdiction of ASTM Committee D02 on

Oils and Fuel Oils by the Extraction Method (ASTMTest

Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on

Method D473)

Petroleum Measurement and is the direct responsibility of Subcommittee D02.02

/COMQ the joint ASTM-API Committee on Hydrocarbon Measurement for

MPMSChapter10.2DeterminationofWaterinCrudeOilby

Custody Transfer (Joint ASTM-API). This test method has been approved by the

Distillation (ASTM Test Method D4006)

sponsoring committees and accepted by the Cooperating Societies in accordance

MPMS Chapter 10.4Determination of Sediment and Water

with established procedures.

in Crude Oil by the Centrifuge Method (Field Procedure)

CurrenteditionapprovedJune1,2016.PublishedJuly2016.Originallyapproved

ɛ1

in 1981. Last previous edition approved in 2011 as D4007–11 . DOI: 10.1520/

MPMS Chapter 10.5Determination of Water in Petroleum

D4007-16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Petroleum Institute (API), 1220 L. St., NW,

the ASTM website. Washington, DC 20005-4070, www.api.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4007 − 11 (2016)

Products and Bituminous Materials by Distillation be capable of maintaining the temperature within these limits

(ASTM Test Method D95) and operate safely if there is a flammable atmosphere.

MPMS Chapter 10.6Determination of Water and Sediment

5.1.4 Electricpoweredandheatedcentrifugesmustmeetall

in Fuel Oils by the Centrifuge Method (Laboratory Pro-

safety requirements for use in hazardous areas.

cedures) (ASTM Test Method D1796)

5.1.5 Calculate the necessary minimum speed of the rotat-

MPMSChapter10.9TestMethodforWaterinCrudeOilsby

ing head in revolutions per minute (r/min) as follows:

Coulometric Karl Fischer Titration (ASTM Test Method

D4928) r/min 51335 =rcf/d (1)

2.3 IP Standard:

where:

Methods Book, Appendix BSpecification for Methylben-

rcf = relative centrifugal force and

zenes (Toluenes)

d = diameter of swing measured between tips of opposite

2.4 ISO Standard:

tubes when in rotating position, mm, or

ISO 5272:1979Toluene for Industrial Use—Specifications

r/min 5265 =rcf/d (2)

3. Summary of Test Method

where:

3.1 Equal volumes of crude oil and water-saturated toluene

rcf = relative centrifugal force and

are placed into a cone-shaped centrifuge tube. After

d = diameter of swing measured between tips of opposite

centrifugation, the volume of the higher density water and

tubes when in rotating position, in.

sediment layer at the bottom of the tube is read.

5.1.6 Calculate the relative centrifugal force from a mea-

4. Significance and Use

sured speed (r/min) as follows:

4.1 The water and sediment content of crude oil is signifi-

r/min

cantbecauseitcancausecorrosionofequipmentandproblems

rcf 5 d (3)

S D

inprocessing.Adeterminationofwaterandsedimentcontentis

required to measure accurately net volumes of actual oil in where:

sales, taxation, exchanges, and custody transfers. It is not

d = diameter of swing measured between tips of opposite

anticipated that this test method, which is written with a

tubes when in rotating position, mm, or

dedicated laboratory facility in mind, is likely to be used in

r/min

field test rooms or sample rooms due to safety concerns for

rcf 5 d (4)

S D

proper ventilation and handling.

where:

4.2 This test method may not be suitable for crude oils that

d = diameter of swing measured between tips of opposite

contain alcohols that are soluble in water. In cases where the

tubes when in rotating position, in.

impact on the results may be significant, the user is advised to

consider using another test method, such as Test Method

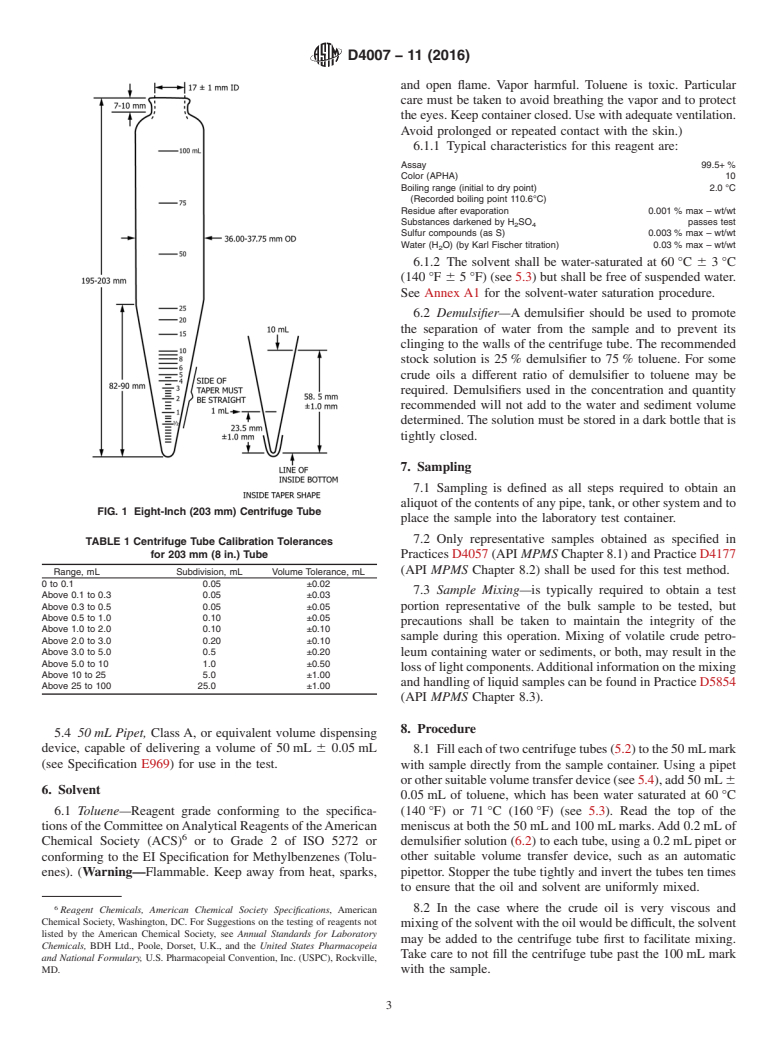

5.2 Centrifuge Tubes—Each centrifuge tube shall be a

D4928 (API MPMS Chapter 10.9).

203mm (8in.) cone-shaped tube, conforming to dimensions

given in Fig. 1 and made of thoroughly annealed glass. The

5. Apparatus

graduations, numbered as shown in Fig. 1, shall be clear and

5.1 Centrifuge:

distinct,andthemouthshallbeconstrictedinshapeforclosure

5.1.1 A centrifuge capable of spinning two or more filled

withacork.Scaleerrortolerancesandthesmallestgraduations

cone-shaped, 203mm (8in.) centrifuge tubes at a speed that

between various calibration marks are given in Table 1 and

can be controlled to give a relative centrifugal force (rcf) of a

applytocalibrationsmadewithair-freewaterat20°C(68°F),

minimumof600atthetipofthetubesshallbeused(see5.1.6).

whenreadingthebottomoftheshadedmeniscus.Theaccuracy

5.1.2 Therevolvinghead,trunnionrings,andtrunnioncups,

of the graduations on the centrifuge tube shall be volumetri-

including the cushions, shall be soundly constructed to with-

cally verified, before use of the tube. The verification shall

stand the maximum centrifugal force capable of being deliv-

include calibration at each mark up to the 0.25mL mark (as

eredbythepowersource.Thetrunnioncupsandcushionsshall

shown in Fig. 2), and at the 0.5mL, 1.0mL, 1.5mL, 2.0mL,

firmly support the tubes when the centrifuge is in motion. The

50.0mL, and 100mLmarks. The tube shall not be used if the

centrifuge shall be enclosed by a metal shield or case strong

scale error at any mark exceeds the applicable tolerance from

enough to eliminate danger if any breakage occurs.

Table 1.

5.1.3 The centrifuge shall be heated and controlled thermo-

5.3 Bath—The bath shall be either a solid metal block bath

statically to avoid unsafe conditions. It shall be capable of

oraliquidbathofsufficientdepthforimmersingthecentrifuge

maintaining the sample temperature during the entire run at

tube in the vertical position to the 100mL mark. Means shall

60°C 6 3°C (140°F 6 5°F). The thermostatic control shall

be provided for maintaining the temperature at 60°C 63°C

(140°F 65°F).Forsomecrudeoils,temperaturesof71°C 6

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

3°C (160°F 6 5°F) may be required to melt wax crystals in

U.K., http://www.energyinst.org.uk.

crude oils. For these crude oils, the test temperature shall be

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. maintained high enough to ensure the absence of wax crystals.

D4007 − 11 (2016)

and open flame. Vapor harmful. Toluene is toxic. Particular

care must be taken to avoid breathing the vapor and to protect

theeyes.Keepcontainerclosed.Usewithadequateventilation.

Avoid prolonged or repeated contact with the skin.)

6.1.1 Typical characteristics for this reagent are:

Assay 99.5+ %

Color (APHA) 10

Boiling range (initial to dry point) 2.0 °C

(Recorded boiling point 110.6°C)

Residue after evaporation 0.001 % max – wt/wt

Substances darkened by H SO passes test

2 4

Sulfur compounds (as S) 0.003 % max – wt/wt

Water (H O) (by Karl Fischer titration) 0.03 % max – wt/wt

6.1.2 The solvent shall be water-saturated at 60°C 63°C

(140°F 6 5°F) (see 5.3) but shall be free of suspended water.

See Annex A1 for the solvent-water saturation procedure.

6.2 Demulsifier—A demulsifier should be used to promote

the separation of water from the sample and to prevent its

clinging to the walls of the centrifuge tube.The recommended

stock solution is 25% demulsifier to 75% toluene. For some

crude oils a different ratio of demulsifier to toluene may be

required. Demulsifiers used in the concentration and quantity

recommended will not add to the water and sediment volume

determined.The solution must be stored in a dark bottle that is

tightly closed.

7. Sampling

7.1 Sampling is defined as all steps required to obtain an

aliquotofthecontentsofanypipe,tank,orothersystemandto

FIG. 1 Eight-Inch (203 mm) Centrifuge Tube

place the sample into the laboratory test container.

7.2 Only representative samples obtained as specified in

TABLE 1 Centrifuge Tube Calibration Tolerances

for 203 mm (8 in.) Tube PracticesD4057(API MPMSChapter8.1)andPracticeD4177

(API MPMS Chapter 8.2) shall be used for this test method.

Range, mL Subdivision, mL Volume Tolerance, mL

0 to 0.1 0.05 ±0.02

7.3 Sample Mixing—is typically required to obtain a test

Above 0.1 to 0.3 0.05 ±0.03

Above 0.3 to 0.5 0.05 ±0.05 portion representative of the bulk sample to be tested, but

Above 0.5 to 1.0 0.10 ±0.05

precautions shall be taken to maintain the integrity of the

Above 1.0 to 2.0 0.10 ±0.10

sample during this operation. Mixing of volatile crude petro-

Above 2.0 to 3.0 0.20 ±0.10

Above 3.0 to 5.0 0.5 ±0.20

leum containing water or sediments, or both, may result in the

Above 5.0 to 10 1.0 ±0.50

lossoflightcomponents.Additionalinformationonthemixing

Above 10 to 25 5.0 ±1.00

andhandlingofliquidsamplescanbefoundinPracticeD5854

Above 25 to 100 25.0 ±1.00

(API MPMS Chapter 8.3).

8. Procedure

5.4 50 mL Pipet, Class A, or equivalent volume dispensing

device, capable of delivering a volume of 50mL 6 0.05mL

8.1 Filleachoftwocentrifugetubes(5.2)tothe50mLmark

(see Specification E969) for use in the test.

with sample directly from the sample container. Using a pipet

orothersuitablevolumetransferdevice(see5.4),add50mL 6

6. Solvent

0.05mL of toluene, which has been water saturated at 60°C

6.1 Toluene—Reagent grade conforming to the specifica- (140°F) or 71°C (160°F) (see 5.3). Read the top of the

tionsoftheCommitteeonAnalyticalReagentsoftheAmerican meniscusatboththe50mLand100mLmarks.Add0.2mLof

Chemical Society (ACS) or to Grade 2 of ISO 5272 or demulsifier solution (6.2) to each tube, using a 0.2mLpipet or

conforming to the EI Specification for Methylbenzenes (Tolu- other suitable volume transfer device, such as an automatic

enes). (Warning—Flammable. Keep away from heat, sparks, pipettor. Stopper the tube tightly and invert the tubes ten times

to ensure that the oil and solvent are uniformly mixed.

8.2 In the case where the crude oil is very viscous and

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

mixingofthesolventwiththeoilwouldbedifficult,thesolvent

listed by the American Chemical Society, see Annual Standards for Laboratory

may be added to the centrifuge tube first to facilitate mixing.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Take care to not fill the centrifuge tube past the 100mL mark

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. with the sample.

D4007 − 11 (2016)

FIG. 2 Procedure for Reading Water and Sediment When Using an ASTM 100-mm Cone-Shaped Centrifuge Tube

D4007 − 11 (2016)

8.3 Loosen the stoppers slightly and immerse the tubes to 10. Precision and Bias

the 100mL mark for at least 15min in the bath maintained at

10.1 Precision—The precision of this test method, as deter-

60°C 6 3°C (140°F 6 5°F) (see 5.3). Secure the stoppers

mined by statistical examination of interlaboratory test results

and again invert the tubes ten times to ensure uniform mixing

in the range from 0.01% to 1.0%, is described in 10.1.1 and

of oil and solvent. (Warning—The vapor pressure at 60°C

10.1.2.

(140°F) is approximately double that at 40°C (104°F).)

10.1.1 Repeatability—The difference between two test

8.4 Placethetubesinthetrunnioncupsonoppositesidesof

results, obtained by the same operator with t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4007 − 11 D4007 − 11 (Reapproved 2016)

Manual of Petroleum Measurement Standards (MPMS), Chapter 10.3

Standard Test Method for

Water and Sediment in Crude Oil by the Centrifuge Method

(Laboratory Procedure)

This standard is issued under the fixed designation D4007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Referenced Documents and API information was editorially corrected in July 2013.

1. Scope*Scope

1.1 This test method describes the laboratory determination of water and sediment in crude oils by means of the centrifuge

procedure. This centrifuge method for determining water and sediment in crude oils is not entirely satisfactory. The amount of

water detected is almost always lower than the actual water content. When a highly accurate value is required, the revised

procedures for water by distillation, Test Method D4006 (API MPMS Chapter 10.2) (Note 1), and sediment by extraction, Test

Method D473 (API MPMS Chapter 10.1), shall be used.

NOTE 1—Test Method D4006 (API MPMS Chapter 10.2) has been determined to be the preferred and most accurate method for the determination of

water.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.2.1 Exception—The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements appear in 6.1, 8.3, and A1.5.4.

2. Referenced Documents

2.1 ASTM Standards:

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation (API MPMS Chapter 10.5)

D473 Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method (API MPMS Chapter 10.1)

D665 Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

D1796 Test Method for Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedure) (API MPMS Chapter

10.6)

D4006 Test Method for Water in Crude Oil by Distillation (API MPMS Chapter 10.2)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products (API MPMS Chapter 8.1)

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products (API MPMS Chapter 8.2)

D4928 Test Method for Water in Crude Oils by Coulometric Karl Fischer Titration (API MPMS Chapter 10.9)

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products (API MPMS Chapter 8.3)

E969 Specification for Glass Volumetric (Transfer) Pipets

2.2 API Standards:

MPMS Chapter 8.1 Manual Sampling of Petroleum and Petroleum Products (ASTM Practice D4057)

MPMS Chapter 8.2 Automatic Sampling of Petroleum and Petroleum Products (ASTM Practice D4177)

MPMS Chapter 8.3 Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products (ASTM Practice D5854)

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on Petroleum

Measurement and is the direct responsibility of Subcommittee D02.02 /COMQ the joint ASTM-API Committee on Hydrocarbon Measurement for Custody Transfer (Joint

ASTM-API). This test method has been approved by the sponsoring committees and accepted by the Cooperating Societies in accordance with established procedures.

Current edition approved June 1, 2011June 1, 2016. Published August 2011July 2016. Originally approved in 1981. Last previous edition approved in 20082011 as

ɛ1

D4007D4007 – 11 –08. DOI: 10.1520/D4007-11E01.10.1520/D4007-16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Petroleum Institute (API), 1220 L. St., NW, Washington, DC 20005-4070, www.api.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4007 − 11 (2016)

MPMS Chapter 10.1 Determination of Sediment in Crude Oils and Fuel Oils by the Extraction Method (ASTM Test Method

D473)

MPMS Chapter 10.2 Determination of Water in Crude Oil by Distillation (ASTM Test Method D4006)

MPMS Chapter 10.4 Determination of Sediment and Water in Crude Oil by the Centrifuge Method (Field Procedure)

MPMS Chapter 10.5 Determination of Water in Petroleum Products and Bituminous Materials by Distillation (ASTM Test

Method D95)

MPMS Chapter 10.6 Determination of Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedures)

(ASTM Test Method D1796)

MPMS Chapter 10.9 Test Method for Water in Crude Oils by Coulometric Karl Fischer Titration (ASTM Test Method D4928)

2.3 IP Standard:

Methods Book, Appendix B Specification for Methylbenzenes (Toluenes)

2.4 ISO Standard:

ISO 5272:1979 Toluene for Industrial Use—Specifications

3. Summary of Test Method

3.1 Equal volumes of crude oil and water-saturated toluene are placed into a cone-shaped centrifuge tube. After centrifugation,

the volume of the higher density water and sediment layer at the bottom of the tube is read.

4. Significance and Use

4.1 The water and sediment content of crude oil is significant because it can cause corrosion of equipment and problems in

processing. A determination of water and sediment content is required to measure accurately net volumes of actual oil in sales,

taxation, exchanges, and custody transfers. It is not anticipated that this test method, which is written with a dedicated laboratory

facility in mind, is likely to be used in field test rooms or sample rooms due to safety concerns for proper ventilation and handling.

4.2 This test method may not be suitable for crude oils that contain alcohols that are soluble in water. In cases where the impact

on the results may be significant, the user is advised to consider using another test method, such as Test Method D4928 (API MPMS

Chapter 10.9).

5. Apparatus

5.1 Centrifuge:

5.1.1 A centrifuge capable of spinning two or more filled cone-shaped, 203-mm (8-in.)203 mm (8 in.) centrifuge tubes at a speed

that can be controlled to give a relative centrifugal force (rcf) of a minimum of 600 at the tip of the tubes shall be used (see 5.1.6).

5.1.2 The revolving head, trunnion rings, and trunnion cups, including the cushions, shall be soundly constructed to withstand

the maximum centrifugal force capable of being delivered by the power source. The trunnion cups and cushions shall firmly

support the tubes when the centrifuge is in motion. The centrifuge shall be enclosed by a metal shield or case strong enough to

eliminate danger if any breakage occurs.

5.1.3 The centrifuge shall be heated and controlled thermostatically to avoid unsafe conditions. It shall be capable of

maintaining the sample temperature during the entire run at 6060 °C 6 3°C (1403 °C (140 °F 6 5°F).5 °F). The thermostatic

control shall be capable of maintaining the temperature within these limits and operate safely if there is a flammable atmosphere.

5.1.4 Electric powered and heated centrifuges must meet all safety requirements for use in hazardous areas.

5.1.5 Calculate the necessary minimum speed of the rotating head in revolutions per minute (r/min) as follows:

r/min 5 1335 =rcf/d (1)

where:

rcf = relative centrifugal force and

d = diameter of swing measured between tips of opposite tubes when in rotating position, mm, or

r/min 5 265 =rcf/d (2)

where:

rcf = relative centrifugal force and

d = diameter of swing measured between tips of opposite tubes when in rotating position, in.

5.1.6 Calculate the relative centrifugal force from a measured speed (r/min) as follows:

r/min

rcf 5 d (3)

S D

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

D4007 − 11 (2016)

where:

d = diameter of swing measured between tips of opposite tubes when in rotating position, mm, or

r/min

rcf 5 d (4)

S D

where:

d = diameter of swing measured between tips of opposite tubes when in rotating position, in.

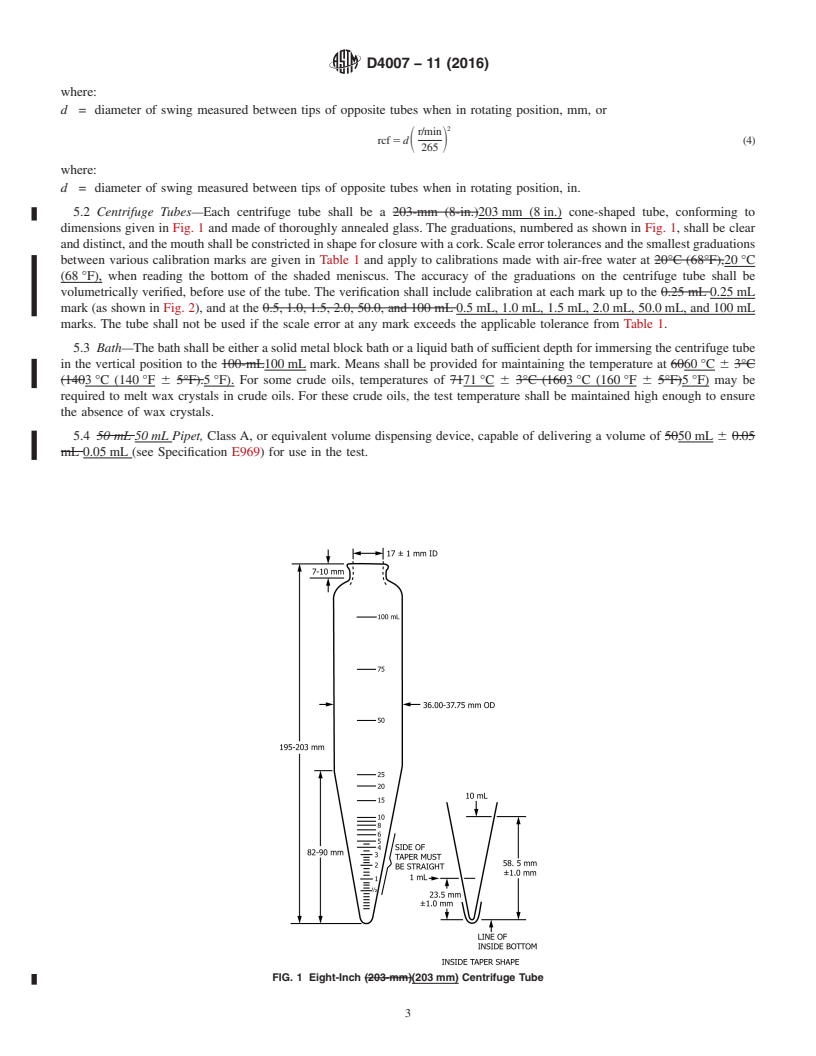

5.2 Centrifuge Tubes—Each centrifuge tube shall be a 203-mm (8-in.)203 mm (8 in.) cone-shaped tube, conforming to

dimensions given in Fig. 1 and made of thoroughly annealed glass. The graduations, numbered as shown in Fig. 1, shall be clear

and distinct, and the mouth shall be constricted in shape for closure with a cork. Scale error tolerances and the smallest graduations

between various calibration marks are given in Table 1 and apply to calibrations made with air-free water at 20°C (68°F),20 °C

(68 °F), when reading the bottom of the shaded meniscus. The accuracy of the graduations on the centrifuge tube shall be

volumetrically verified, before use of the tube. The verification shall include calibration at each mark up to the 0.25 mL 0.25 mL

mark (as shown in Fig. 2), and at the 0.5, 1.0, 1.5, 2.0, 50.0, and 100 mL 0.5 mL, 1.0 mL, 1.5 mL, 2.0 mL, 50.0 mL, and 100 mL

marks. The tube shall not be used if the scale error at any mark exceeds the applicable tolerance from Table 1.

5.3 Bath—The bath shall be either a solid metal block bath or a liquid bath of sufficient depth for immersing the centrifuge tube

in the vertical position to the 100-mL100 mL mark. Means shall be provided for maintaining the temperature at 6060 °C 6 3°C

(1403 °C (140 °F 6 5°F).5 °F). For some crude oils, temperatures of 7171 °C 6 3°C (1603 °C (160 °F 6 5°F)5 °F) may be

required to melt wax crystals in crude oils. For these crude oils, the test temperature shall be maintained high enough to ensure

the absence of wax crystals.

5.4 50 mL 50 mL Pipet, Class A, or equivalent volume dispensing device, capable of delivering a volume of 5050 mL 6 0.05

mL 0.05 mL (see Specification E969) for use in the test.

FIG. 1 Eight-Inch (203-mm)(203 mm) Centrifuge Tube

D4007 − 11 (2016)

TABLE 1 Centrifuge Tube Calibration Tolerances

for 203-mm (8-in.)203 mm (8 in.) Tube

Range, mL Subdivision, mL Volume Tolerance, mL

0 to 0.1 0.05 ±0.02

Above 0.1 to 0.3 0.05 ±0.03

Above 0.3 to 0.5 0.05 ±0.05

Above 0.5 to 1.0 0.10 ±0.05

Above 1.0 to 2.0 0.10 ±0.10

Above 2.0 to 3.0 0.20 ±0.10

Above 3.0 to 5.0 0.5 ±0.20

Above 5.0 to 10 1.0 ±0.50

Above 10 to 25 5.0 ±1.00

Above 25 to 100 25.0 ±1.00

6. Solvent

6.1 Toluene—Reagent grade conforming to the specifications of the Committee on Analytical Reagents of the American

Chemical Society (ACS) or to Grade 2 of ISO 5272 or conforming to the EI Specification for Methylbenzenes (Toluenes).

(Warning—Flammable. Keep away from heat, sparks, and open flame. Vapor harmful. Toluene is toxic. Particular care must be

taken to avoid breathing the vapor and to protect the eyes. Keep container closed. Use with adequate ventilation. Avoid prolonged

or repeated contact with the skin.)

6.1.1 Typical characteristics for this reagent are:

Assay 99.5+ %

Color (APHA) 10

Boiling range (initial to dry point) 2.0°C

(Recorded boiling point 110.6°C)

Boiling range (initial to dry point) 2.0 °C

(Recorded boiling point 110.6°C)

Residue after evaporation 0.001 % max – wt/wt

Substances darkened by H SO passes test

2 4

Sulfur compounds (as S) 0.003 % max – wt/wt

Water (H O) (by Karl Fischer titration) 0.03 % max – wt/wt

6.1.2 The solvent shall be water-saturated at 6060 °C 6 3°C (1403 °C (140 °F 6 5°F)5 °F) (see 5.3) but shall be free of

suspended water. See Annex A1 for the solvent-water saturation procedure.

6.2 Demulsifier—A demulsifier should be used to promote the separation of water from the sample and to prevent its clinging

to the walls of the centrifuge tube. The recommended stock solution is 25 % demulsifier to 75 % toluene. For some crude oils a

different ratio of demulsifier to toluene may be required. Demulsifiers used in the concentration and quantity recommended will

not add to the water and sediment volume determined. The solution must be stored in a dark bottle that is tightly closed.

7. Sampling

7.1 Sampling is defined as all steps required to obtain an aliquot of the contents of any pipe, tank, or other system and to place

the sample into the laboratory test container.

7.2 Only representative samples obtained as specified in Practices D4057 (API MPMS Chapter 8.1) and Practice D4177 (API

MPMS Chapter 8.2) shall be used for this test method.

7.3 Sample Mixing—is typically required to obtain a test portion representative of the bulk sample to be tested, but precautions

shall be taken to maintain the integrity of the sample during this operation. Mixing of volatile crude petroleum containing water

or sediments, or both, may result in the loss of light components. Additional information on the mixing and handling of liquid

samples can be found in Practice D5854 (API MPMS Chapter 8.3).

8. Procedure

8.1 Fill each of two centrifuge tubes (5.2)(5.2) to the 50-mL50 mL mark with sample directly from the sample container. Using

a pipet or other suitable volume transfer device (see 5.4), add 5050 mL 6 0.05 mL 0.05 mL of toluene, which has been water

saturated at 60°C (140°F) or 71°C (160°F)60 °C (140 °F) or 71 °C (160 °F) (see 5.3). Read the top of the meniscus at both the

5050 mL and 100-mL100 mL marks. Add 0.2 mL 0.2 mL of demulsifier solution (6.2) to each tube, using a 0.2-mL0.2 mL pipet

or other suitable volume transfer device, such as an automatic pipettor. Stopper the tube tightly and invert the tubes ten times to

ensure that the oil and solvent are uniformly mixed.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.