ASTM F2183-02

(Test Method)Standard Test Method for Small Punch Testing of Ultra-High Molecular Weight Polyethylene Used in Surgical Implants

Standard Test Method for Small Punch Testing of Ultra-High Molecular Weight Polyethylene Used in Surgical Implants

SIGNIFICANCE AND USE

Miniature specimen testing techniques are used to characterize the mechanical behavior of UHMWPE stock materials and surgical implants after manufacture, sterilization, shelf aging, radiation crosslinking, thermal treatment, and implantation (1). Furthermore, experimental UHMWPE materials can be evaluated after accelerated aging and hip or knee wear simulation. Consequently, the small punch test makes it possible to examine relationships between wear performance and mechanical behavior of UHMWPE. This test method can also be used to rank the mechanical behavior of UHMWPE relative to a reference control material (such as the NIST Ultra-High Molecular Weight Polyethylene Reference Material #8456).

Small punch testing results may vary with specimen preparation and with the speed and environment of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

SCOPE

1.1 This test method covers the determination of mechanical behavior of ultra-high molecular weight polyethylene (UHMWPE) by small punch testing of miniature disk specimens (0.5 mm in thickness and 6.4 mm in diameter). The test method has been established for characterizing UHMWPE surgical materials after ram extrusion or compression molding (1,2); for evaluating as-manufactured implants after radiation crosslinking and sterilization (3,4); as well as for testing of implants that have been retrieved (explanted) from the human body (5,6).

1.2 The parameters of the small punch test, namely the peak load, ultimate displacement, ultimate load, and work to failure, provide metrics of the yielding, ultimate strength, ductility, and toughness of UHMWPE under multiaxial loading conditions. Because the mechanical behavior of UHMWPE is different when loaded under uniaxial and multiaxial loading conditions (3), the small punch test provides a complementary mechanical testing technique to the uniaxial tensile testing specified for medical grade UHMWPE by Specification F 648.

1.3 In addition to its use as a research tool in implant retrieval analysis, the small punch test can be used as a laboratory screening test to evaluate new UHMWPE materials, such as those created by gamma or electron beam irradiation (1). The test method is also well suited for characterization of UHMWPE before and after accelerated aging (for example, Guide F 2003), and in that regard it can provide ranking of the mechanical degradation of different UHMWPE samples after oxidative degradation (4,7).

1.4 The small punch test has been applied to other polymers, including polymethyl methacrylate (PMMA) bone cement, polyacetal, and high density polyethylene (HDPE) (8,9). However, the small punch testing of polymers other than UHMWPE is beyond the scope of this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2183–02

Standard Test Method for

Small Punch Testing of Ultra-High Molecular Weight

Polyethylene Used in Surgical Implants

This standard is issued under the fixed designation F 2183; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 Thistestmethodcoversthedeterminationofmechanical

behavior of ultra-high molecular weight polyethylene (UHM-

2. Referenced Documents

WPE) by small punch testing of miniature disk specimens (0.5

2.1 ASTM Standards:

mm in thickness and 6.4 mm in diameter).The test method has

D 695 Method for Compressive Properties of Rigid Plas-

been established for characterizing UHMWPE surgical mate-

2 tics

rials after ram extrusion or compression molding (1,2) ; for

D 883 Terminology Relating to Plastics

evaluating as-manufactured implants after radiation crosslink-

E 4 Practices for Force Verification of Testing Machines

ingandsterilization (3,4);aswellasfortestingofimplantsthat

E 83 Practice for Verification and Classification of Exten-

have been retrieved (explanted) from the human body (5,6).

someters

1.2 The parameters of the small punch test, namely the peak

F 648 Specification of Ultra-High Molecular Weight Poly-

load, ultimate displacement, ultimate load, and work to failure,

ethylene Powder and Fabricated Forms for Surgical Im-

provide metrics of the yielding, ultimate strength, ductility, and

plants

toughness of UHMWPE under multiaxial loading conditions.

F 1714 Guide for Gravimetric Wear Assessment of Pros-

Because the mechanical behavior of UHMWPE is different

thetic Hip Designs in Simulator Devices

when loaded under uniaxial and multiaxial loading conditions

F 1715 Guide for Wear Assessment of Prosthetic Knee

(3),thesmallpunchtest provides a complementary mechanical

Designs in Simulator Devices

testing technique to the uniaxial tensile testing specified for

F 2003 Guide forAcceleratedAging of Ultra-High Molecu-

medical grade UHMWPE by Specification F 648.

lar Weight Polyethylene

1.3 In addition to its use as a research tool in implant

F 2102 Guide for Evaluating the Extent of Oxidation in

retrieval analysis, the small punch test can be used as a

Ultra-High-Molecular-Weight Polyethylene Fabricated

laboratory screening test to evaluate new UHMWPE materials,

Forms Intended for Surgical Implants

such as those created by gamma or electron beam irradiation

(1). The test method is also well suited for characterization of

3. Terminology

UHMWPE before and after accelerated aging (for example,

3.1 Definitions—The features of a typical small punch test

Guide F 2003), and in that regard it can provide ranking of the

loadversusdisplacementcurveforUHMWPEareillustratedin

mechanical degradation of different UHMWPE samples after

Fig. 1.

oxidative degradation (4,7).

3.1.1 peak load—an initial local maximum in the load

1.4 Thesmallpunchtesthasbeenappliedtootherpolymers,

versus displacement curve (Fig. 1). In certain radiation

including polymethyl methacrylate (PMMA) bone cement,

crosslinked UHMWPE materials, the load versus displacement

polyacetal, and high density polyethylene (HDPE) (8,9). How-

curve increases monotonically and a shoulder, rather than an

ever,thesmallpunchtestingofpolymersotherthanUHMWPE

initial peak load, may be observed.

is beyond the scope of this standard.

3.1.2 small punch test—a test wherein the specimen is of

1.5 This standard does not purport to address all of the

miniature size relative to conventional mechanical test speci-

safety concerns, if any, associated with its use. It is the

mens, is disk-shaped, and is loaded axisymmetrically in

responsibility of the user of this standard to establish appro-

bending by a hemispherical-head punch.

3.1.3 ultimate displacement—the displacement at rupture

(failure) of the specimen (Fig. 1).

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devicesand is the direct responsibility of Subcommittee

F04.15on Materials Test Methods.

Current edition approved April 10, 2002. Published June 2002. Annual Book of ASTM Standards, Vol 08.01.

2 4

The boldface numbers in parentheses refer to the list of references at the end of Annual Book of ASTM Standards, Vol 03.01.

this standard. Annual Book of ASTM Standards, Vol 13.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2183

FIG. 1 Features of the Small Punch Test Load Versus Displacement Curve for Unirradiated UHMWPE, Including the Peak Load, Ultimate

Load and Displacement, and Work to Failure

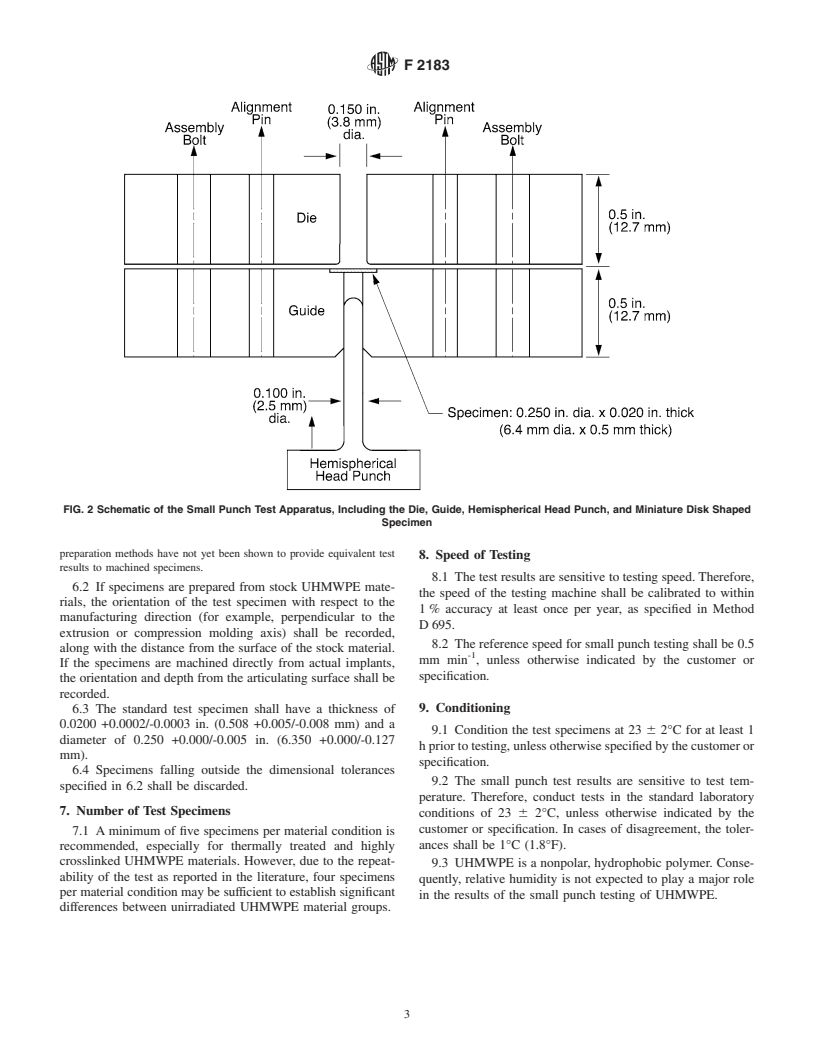

3.1.4 ultimate load—the load at rupture (failure) of the 5.1.2 Die—Thefunctionofthedieistoconstrainthesample

specimen (Fig. 1). during testing. The inner diameter of the die bore shall be

3.1.5 work to failure—the area under the load versus dis- 0.1500 6 0.0005 in. (3.810 6 0.013 mm).

placement curve (Fig. 1).

5.1.3 Punch—The hemispherical head punch shall have a

diameter of 0.1000 in. (2.540 mm), with a tolerance of

4. Significance and Use

+0.0000/-0.0002 in. (+0.000/-0.005 mm).

4.1 Miniature specimen testing techniques are used to char- 5.2 Testing Machine—Any suitable testing machine as de-

acterize the mechanical behavior of UHMWPE stock materials scribed in Method D 695, consisting of a drive mechanism and

and surgical implants after manufacture, sterilization, shelf a load indicator. The load indicator shall have a full range of

aging, radiation crosslinking, thermal treatment, and implanta- 250 N (56.2 lbs).The accuracy of the machine shall be verified

tion (1). Furthermore, experimental UHMWPE materials can at least once per year, as specified by Method D 695 and

be evaluated after accelerated aging and hip or knee wear Practice E 4.

simulation. Consequently, the small punch test makes it pos-

5.3 Compressometer—This instrument, described in Sec-

sible to examine relationships between wear performance and

tion 5.2 from Method D 695, can be used to determine the

mechanical behavior of UHMWPE. This test method can also

distance between the die and the punch during the test. If the

be used to rank the mechanical behavior of UHMWPE relative

actuator displacement of the testing machine can be shown to

to a reference control material (such as the NIST Ultra-High

determine punch displacement within 1 % of the value mea-

Molecular Weight Polyethylene Reference Material #8456).

sured by a suitably calibrated compressometer (as defined in

4.2 Small punch testing results may vary with specimen

Practice E 83), actuator displacement shall be used as refer-

preparation and with the speed and environment of testing.

ence.

Consequently, where precise comparative results are desired,

5.4 Compression Platen—The punch shall rest on a com-

these factors must be carefully controlled.

pression platen or tool for applying the load to the punch.

5.5 Micrometers—Suitable micrometers, reading to 0.0001

5. Apparatus

in. (0.0025 mm), shall be used to record the diameter and

5.1 Small Punch Test Apparatus —Asystem consisting of a

thickness of the specimens.

hemispherical head punch, a die, and a guide for the punch, as

5.6 Thermometer—A suitable thermometer or thermo-

shown in Fig. 2. The parts shall be fabricated from a hardened

couple, reading to 0.1°C, shall be used to record the test

steel.

temperature within the range 20 to 24°C.

5.1.1 Guide—Thefunctionoftheguideistoalignthepunch

relative to the specimen, which rests in a disk-shaped recess.

6. Test Specimens

The inner diameter of the guide bore shall be 0.1010 +0.0002/-

6.1 As the test results are known to be sensitive to prepa-

0.0000 in. (2.565 +0.005/-0.000 mm), and the specimen recess

ration technique, the specimens described in 6.2 and 6.3 shall

shall be 0.0200 +0.0004/-0.0000 in. (0.508 +0.010/-0.000 mm)

be used. The specimens may be prepared by machining

in depth and 0.2520 6 0.0005 in. (6.401 6 0.013 mm) in

operations from materials in sheet, rod, plate, or implant form.

diameter.

All machining operations shall be done carefully so that

smooth surfaces result. Great care shall be taken in machining

the faces so that smooth, parallel surfaces result.

Small punch testers suitable for use and meeting the requirements of this test

NOTE 1—Althoughspecimenfabricationmethodsotherthanmachining

method are available from Exponent, Inc., 2300 Chestnut St., Suite 150, Philadel-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.