ASTM D1003-00

(Test Method)Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics

Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics

SIGNIFICANCE AND USE

Light that is scattered upon passing through a film or sheet of a material can produce a hazy or smoky field when objects are viewed through the material. Another effect can be veiling glare, as occurs in an automobile windshield when driving into the sun.

Although haze measurements are made most commonly by the use of a hazemeter, a spectrophotometer may be used, provided that it meets the geometric and spectral requirements of Section 5. The use of a spectrophotometer for haze measurement of plastics can provide valuable diagnostic data on the origin of the haze,6 and Procedure B is devoted to the use of a spectrophotometer.

4.2.1 Procedure A (hazemeter) test values are normally slightly higher and less variable than Procedure B (spectrophotometer) test values.

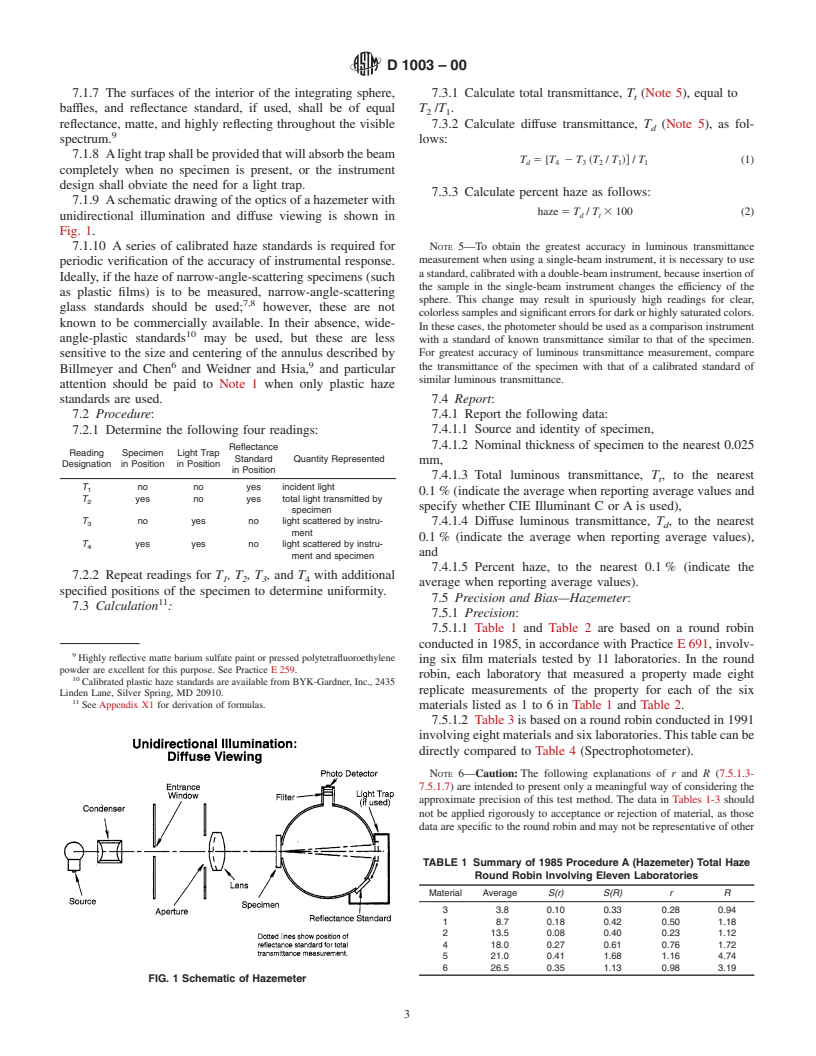

Regular luminous transmittance is obtained by placing a clear specimen at some distance from the entrance port of the integrating sphere. However, when the specimen is hazy, the total hemispherical luminous transmittance must be measured by placing the specimen at the entrance port of the sphere. The measured total hemispherical luminous transmittance will be greater than the regular luminous transmittance, depending on the optical properties of the sample. With this test method, the specimen is necessarily placed at the entrance port of the sphere in order to measure haze and total hemispherical luminous transmittance.

Haze data representative of the material may be obtained by avoiding heterogeneous surface or internal defects not characteristic of the material.

Haze and luminous-transmittance data are especially useful for quality control and specification purposes.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there...

SCOPE

1.1 This test method covers the evaluation of specific light-transmitting and wide-angle-light-scattering properties of planar sections of materials such as essentially transparent plastic. A procedure is provided for the measurement of luminous transmittance and haze. Material having a haze value greater than 30% is considered diffusing and should be tested in accordance with Practice E167.

1.2 The values stated in SI units are to be regarded as the standard. Note 1-For greater discrimination among materials that scatter a high percent of light within a narrow forward angle, such as is the case with abraded transparent plastics, adjust the hazemeter and perform measurements in accordance with Test Method D1044.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 2-There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1003–00

Standard Test Method for

1

Haze and Luminous Transmittance of Transparent Plastics

This standard is issued under the fixed designation D 1003; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 259 Practice for Preparation of Reference White Reflec-

3

tance Standards

1.1 This test method covers the evaluation of specific

3

E 284 Terminology of Appearance

light-transmitting and wide-angle-light-scattering properties of

E 691 Practice for Conducting an Interlaboratory Test Pro-

planar sections of materials such as essentially transparent

4

gram to Determine the Precision of a Test Method

plastic. Two procedures are provided for the measurement of

5

2.2 ISO Standards:

luminous transmittance and haze. Procedure A uses a hazeme-

ISO 13468–1 Plastics—Determination of the Total Lumi-

ter as described in Section 5 and Procedure B uses a spectro-

nous Transmittance of Transparent Materials

photometer as described in Section 8. Material having a haze

ISO/DIS 14782 Plastics—Determination of Haze of Trans-

value greater than 30 % is considered diffusing and should be

parent Materials

tested in accordance with Practice E 167.

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard.

3.1 Definitions—Terms applicable to this test method are

NOTE 1—For greater discrimination among materials that scatter a high

defined in Terminologies D 883 and E 284.

percent of light within a narrow forward angle, such as is the case with

3.2 Definitions of Terms Specific to This Standard:

abraded transparent plastics, adjust the hazemeter and perform measure-

3.2.1 haze, n—in transmission, the scattering of light by a

ments in accordance with Test Method D 1044.

specimen responsible for the reduction in contrast of objects

1.3 This standard does not purport to address all of the

viewed through it. The percent of transmitted light that is

safety concerns, if any, associated with its use. It is the

scattered so that its direction deviates more than a specified

responsibility of the user of this standard to establish appro-

angle from the direction of the incident beam.

priate safety and health practices and determine the applica-

3.2.1.1 Discussion—In this test method, the specified angle

bility of regulatory limitations prior to use.

is 0.044 rad (2.5°).

3.2.2 luminous, adj—weighted according to the spectral

NOTE 2—This test method is not equivalent to ISO 13468–1 and

ISO/DIS 14782. luminous efficiency function V() of the CIE (1987).

3.2.3 luminous transmittance, n—the ratio of the luminous

2. Referenced Documents

flux transmitted by a body to the flux incident upon it.

2.1 ASTM Standards:

4. Significance and Use

D 618 Practice for Conditioning Plastics and Electrical

2

Insulating Materials for Testing

4.1 Light that is scattered upon passing through a film or

2

D 883 Terminology Relating to Plastics

sheet of a material can produce a hazy or smoky field when

D 1044 Test Method for Resistance of Transparent Plastics

objects are viewed through the material.Another effect can be

2

to Surface Abrasion

veiling glare, as occurs in an automobile windshield when

2

D 1898 Practice for Sampling of Plastics

driving into the sun.

E 167 Practice for Goniophotometry of Objects and Mate-

4.2 Although haze measurements are made most commonly

3

rials

by the use of a hazemeter, a spectrophotometer may be used,

provided that it meets the geometric and spectral requirements

of Section 5. The use of a spectrophotometer for haze mea-

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

surement of plastics can provide valuable diagnostic data on

and is the direct responsibility of Subcommittee D20.40 on Optical Properties.

This test method has been approved for use by agencies of the Department of

Defense to replace Method 3022 of Federal Test Method Standard 406.

Current edition approved June 10, 2000. Published July 2000. Originally

e1 4

published as D 1003 – 49 T. Last previous edition D 1003 – 97 . Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 08.01. Available from American National Standards Institute, 11 W. 42nd St., 13th

3

Annual Book of ASTM Standards, Vol 06.01. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1003–00

6

the origin of the haze, and Procedure B is devoted to the use 6.2 Test Conditions—Set up

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.