ASTM D4014-03(2018)

(Specification)Standard Specification for Plain and Steel-Laminated Elastomeric Bearings for Bridges

Standard Specification for Plain and Steel-Laminated Elastomeric Bearings for Bridges

ABSTRACT

This specification covers bearings, which consist of all elastomer or of alternate laminates of elastomer and steel, when the function of the bearings is to transfer loads or accommodate relative movement between a bridge superstructure and its supporting structure, or both. The bearings are furnished in four types as follows: plain elastomeric bearing pad; plain elastomeric sandwich bearing; steel-laminated elastomeric bearing; and steel-laminated elastomeric bearing with external load plate. The elastomer for the manufacture of the bearing is furnished in two types: Type CR and Type NR. The elastomer for the manufacture of the bearing is furnished in four grades of low-temperature properties: Grade 0; Grade 2; Grade 3; and Grade 5. The elastomeric compound used in the construction of a bearing shall contain only either natural rubber or chloroprene rubber as the raw polymer. Internal steel laminates shall be of rolled mild steel. Plain bearing pads shall be molded individually, or cut from previously molded strips or slabs, or extruded and cut to length. A steel-laminated bearing or a plain sandwich bearing shall be molded as a single unit under pressure and heat. All bonding of elastomer to steel laminates and to external load plates shall be carried out during molding. Bearing compression tests, compression stiffness, visual inspection, quality control properties, shear modulus, ozone resistance, and low-temperature grade tests shall be performed to conform to the specified requirements.

SCOPE

1.1 This specification covers bearings, which consist of all elastomer or of alternate laminates of elastomer and steel, when the function of the bearings is to transfer loads or accommodate relative movement between a bridge superstructure and its supporting structure, or both.

1.2 The values stated in SI units are to be regarded as the standard.

Note 1: The words “elastomer” or “elastomeric” will be used interchangeably with the word “rubber” in this specification.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

Designation: D4014 −03 (Reapproved 2018)

Standard Specification for

Plain and Steel-Laminated Elastomeric Bearings for

1

Bridges

This standard is issued under the fixed designation D4014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope Cracking (Withdrawn 2007)

D573Test Method for Rubber—Deterioration in an Air

1.1 This specification covers bearings, which consist of all

Oven

elastomer or of alternate laminates of elastomer and steel,

D832Practice for Rubber Conditioning For Low Tempera-

when the function of the bearings is to transfer loads or

ture Testing

accommodate relative movement between a bridge superstruc-

D1149TestMethodsforRubberDeterioration—Crackingin

ture and its supporting structure, or both.

an Ozone Controlled Environment

1.2 The values stated in SI units are to be regarded as the

D1415Test Method for Rubber Property—International

standard.

Hardness

NOTE 1—The words “elastomer” or “elastomeric” will be used inter- D1418 Practice for Rubber and Rubber Latices—

changeably with the word “rubber” in this specification.

Nomenclature

1.3 The following safety hazards caveat pertains only to the D2000Classification System for Rubber Products in Auto-

test methods portion, Section 8, of this specification: This

motive Applications

standarddoesnotpurporttoaddressallofthesafetyconcerns,

D2137TestMethodsforRubberProperty—BrittlenessPoint

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

of Flexible Polymers and Coated Fabrics

of this standard to establish appropriate safety, health, and

D2240TestMethodforRubberProperty—DurometerHard-

environmental practices and determine the applicability of

ness

regulatory limitations prior to use.

D3183Practice for Rubber—Preparation of Pieces for Test

1.4 This international standard was developed in accor-

Purposes from Products

dance with internationally recognized principles on standard-

E4Practices for Force Verification of Testing Machines

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

3.1 Definitions:

Barriers to Trade (TBT) Committee.

3.1.1 design load—the mean compressive stress applied to

the area of the steel laminate.

2. Referenced Documents

2

3.1.2 external load plate—a steel plate bonded to the top or

2.1 ASTM Standards:

bottom elastomeric surface of a bearing, or both.

A36/A36MSpecification for Carbon Structural Steel

D395Test Methods for Rubber Property—Compression Set

3.1.3 lot—unless otherwise specified in the contract or

D412TestMethodsforVulcanizedRubberandThermoplas-

purchaseorder,alotshallconsistofasingletypeofbearing,of

tic Elastomers—Tension

the same design and material, submitted for inspection at the

D518 Test Method for Rubber Deterioration—Surface

same time.

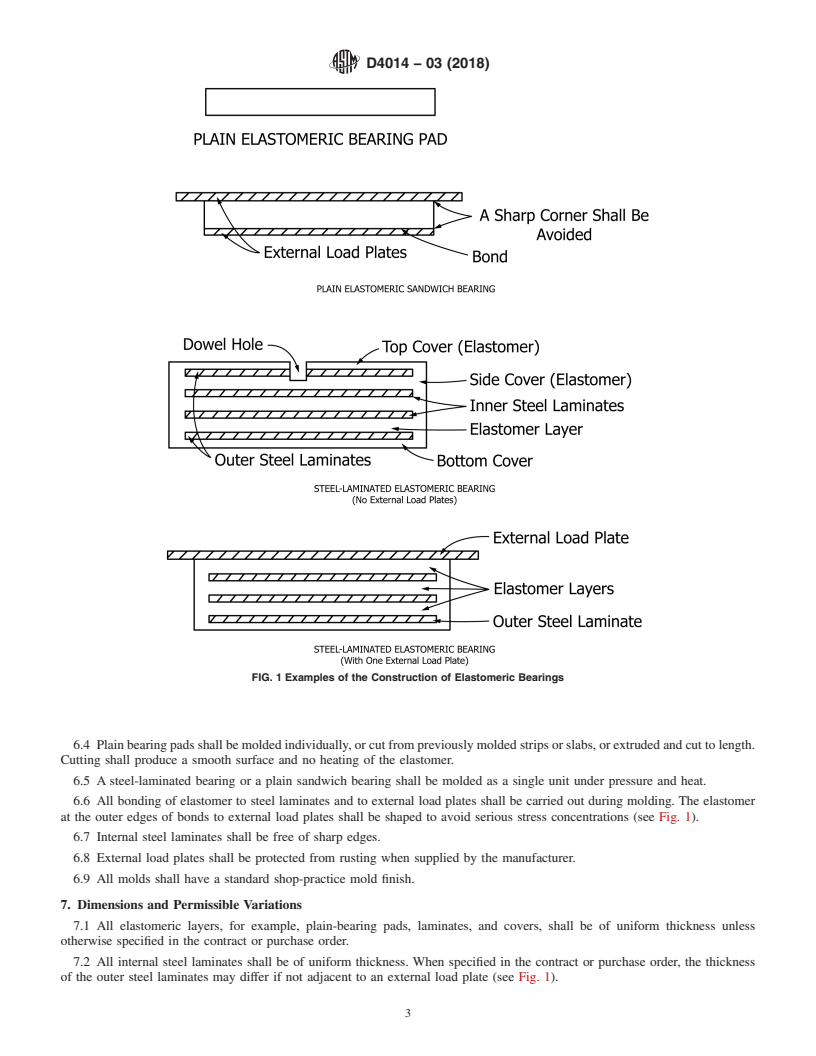

3.1.4 plainelastomericbearingpad—abearingthatconsists

only of elastomeric material.

1

This specification is under the jurisdiction ofASTM Committee D04 on Road

and Paving Materialsand is the direct responsibility of Subcommittee D04.32 on

3.1.5 plain elastomeric sandwich bearing—a bearing that

Bridges and Structures.

consistsofasinglelayerofelastomericmaterialbondedtoone

Current edition approved April 1, 2018. Published April 2018. Originally

or two external load plates (3.1.2).

approved in 1981. Last previous edition approved in 2012 as D4014–03 (2012).

DOI: 10.1520/D4014-03R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4014 − 03 (2018)

3.1.6 steel-laminated elastomeric bearing—a bearing 4.2.1 Type CR—Chloroprene rubber.

molded of elastomeric material with one or more steel lami- 4.2.2 Type NR—Natural rubber.

nates embedded in and bonded to it, and to which one or two

4.2.3 If none is specified, then the manufacturer shall use

external load plates (3.1.2) may be bonded. one of those types.

NOTE 4—Appendix X1 relates to elastomeric materials which do not

4. Classification

have fully documented in-service records or sufficiently widespread use,

4.1 The bearings are furnished in four types as follows:

or both.

4.1.1 Plain elastomeric bearing pad. NOTE 5—The abbreviations for the elastomer types are taken from

Practice D1418.

4.1.2 Plain elastomeric sandwich bearing.

4.1.3 Steel-laminated elastomeric bearing.

4.3 The elastomer for the

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4014 − 03 (Reapproved 2018)

Standard Specification for

Plain and Steel-Laminated Elastomeric Bearings for

1

Bridges

This standard is issued under the fixed designation D4014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope Cracking (Withdrawn 2007)

D573 Test Method for Rubber—Deterioration in an Air

1.1 This specification covers bearings, which consist of all

Oven

elastomer or of alternate laminates of elastomer and steel,

D832 Practice for Rubber Conditioning For Low Tempera-

when the function of the bearings is to transfer loads or

ture Testing

accommodate relative movement between a bridge superstruc-

D1149 Test Methods for Rubber Deterioration—Cracking in

ture and its supporting structure, or both.

an Ozone Controlled Environment

1.2 The values stated in SI units are to be regarded as the

D1415 Test Method for Rubber Property—International

standard.

Hardness

NOTE 1—The words “elastomer” or “elastomeric” will be used inter-

D1418 Practice for Rubber and Rubber Latices—

changeably with the word “rubber” in this specification.

Nomenclature

1.3 The following safety hazards caveat pertains only to the

D2000 Classification System for Rubber Products in Auto-

test methods portion, Section 8, of this specification: This

motive Applications

standard does not purport to address all of the safety concerns,

D2137 Test Methods for Rubber Property—Brittleness Point

if any, associated with its use. It is the responsibility of the user

of Flexible Polymers and Coated Fabrics

of this standard to establish appropriate safety, health, and

D2240 Test Method for Rubber Property—Durometer Hard-

environmental practices and determine the applicability of

ness

regulatory limitations prior to use.

D3183 Practice for Rubber—Preparation of Pieces for Test

1.4 This international standard was developed in accor-

Purposes from Products

dance with internationally recognized principles on standard-

E4 Practices for Force Verification of Testing Machines

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

3.1 Definitions:

Barriers to Trade (TBT) Committee.

3.1.1 design load—the mean compressive stress applied to

the area of the steel laminate.

2. Referenced Documents

2

3.1.2 external load plate—a steel plate bonded to the top or

2.1 ASTM Standards:

bottom elastomeric surface of a bearing, or both.

A36/A36M Specification for Carbon Structural Steel

D395 Test Methods for Rubber Property—Compression Set

3.1.3 lot—unless otherwise specified in the contract or

D412 Test Methods for Vulcanized Rubber and Thermoplas-

purchase order, a lot shall consist of a single type of bearing, of

tic Elastomers—Tension

the same design and material, submitted for inspection at the

D518 Test Method for Rubber Deterioration—Surface

same time.

3.1.4 plain elastomeric bearing pad—a bearing that consists

only of elastomeric material.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

3.1.5 plain elastomeric sandwich bearing—a bearing that

Bridges and Structures.

consists of a single layer of elastomeric material bonded to one

Current edition approved April 1, 2018. Published April 2018. Originally

or two external load plates (3.1.2).

approved in 1981. Last previous edition approved in 2012 as D4014 – 03 (2012).

DOI: 10.1520/D4014-03R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4014 − 03 (2018)

3.1.6 steel-laminated elastomeric bearing—a bearing 4.2.1 Type CR—Chloroprene rubber.

molded of elastomeric material with one or more steel lami-

4.2.2 Type NR—Natural rubber.

nates embedded in and bonded to it, and to which one or two 4.2.3 If none is specified, then the manufacturer shall use

external load plates (3.1.2) may be bonded.

one of those types.

NOTE 4—Appendix X1 relates to elastomeric materials which do not

4. Classification

have fully documented in-service records or sufficiently widespread use,

4.1 The bearings are furnish

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4014 − 03 (Reapproved 2012) D4014 − 03 (Reapproved 2018)

Standard Specification for

Plain and Steel-Laminated Elastomeric Bearings for

1

Bridges

This standard is issued under the fixed designation D4014; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers bearings, which consist of all elastomer or of alternate laminates of elastomer and steel, when the

function of the bearings is to transfer loads or accommodate relative movement between a bridge superstructure and its supporting

structure, or both.

1.2 The values stated in SI units are to be regarded as the standard.

NOTE 1—The words “elastomer” or “elastomeric” will be used interchangeably with the word “rubber” in this specification.

NOTE 1—The words “elastomer” or “elastomeric” will be used interchangeably with the word “rubber” in this specification.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8B,, of this specification:This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability

of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

3

D518 Test Method for Rubber Deterioration—Surface Cracking (Withdrawn 2007)

D573 Test Method for Rubber—Deterioration in an Air Oven

D832 Practice for Rubber Conditioning For Low Temperature Testing

D1149 Test Methods for Rubber Deterioration—Cracking in an Ozone Controlled Environment

D1415 Test Method for Rubber Property—International Hardness

D1418 Practice for Rubber and Rubber Latices—Nomenclature

D2000 Classification System for Rubber Products in Automotive Applications

D2137 Test Methods for Rubber Property—Brittleness Point of Flexible Polymers and Coated Fabrics

D2240 Test Method for Rubber Property—Durometer Hardness

D3183 Practice for Rubber—Preparation of Pieces for Test Purposes from Products

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 Definitions:

3.1.1 design load—the mean compressive stress applied to the area of the steel laminate.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.32 on Bridges

and Structures.

Current edition approved July 15, 2012April 1, 2018. Published July 2012April 2018. Originally approved in 1981. Last previous edition approved in 20072012 as

D4014 – 03 (2012).(2007). DOI: 10.1520/D4014-03R12.10.1520/D4014-03R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4014 − 03 (2018)

3.1.2 external load plate—a steel plate bonded to the top or bottom elastomeric surface of a bearing, or both.

3.1.3 lot—unless otherwise specified in the contract or purchase order, a lot shall consist of a single type of bearing, of the same

design and material, submitted for inspection at the same time.

3.1.4 plain elastomeric bearing pad—a bearing that consists only of elastomeric material.

3.1.5 plain elastomeric sandwich bearing—a bearing that consists of a single layer of elastomeric material bonded to one or two

external load plates (3.1.2).

3.1.6 steel-laminated elastomeric bearing—a bearing molded of elastomeric mater

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.