ASTM D5160-95(2019)

(Guide)Standard Guide for Gas-Phase Adsorption Testing of Activated Carbon

Standard Guide for Gas-Phase Adsorption Testing of Activated Carbon

SIGNIFICANCE AND USE

5.1 Activated carbon is used extensively for removing gases and vapors from air or other gas streams. The physical and chemical characteristics of an activated carbon can strongly influence its suitability for a given application. The procedure in this guide allows the evaluation of the dynamic adsorption characteristics of an activated carbon for a particular adsorbate under conditions chosen by the user. It is necessary that the user choose test conditions that are meaningful for the application (see Section 9).

5.2 This guide can also be used to evaluate activated carbons that have been impregnated with materials to enhance their effectiveness at removing gases otherwise poorly adsorbed on activated carbon.

5.3 The procedure given in this guide is not generally applicable for evaluation of carbons used as catalysts for such purposes as decomposition of low levels of ozone or oxidation of SO2 to SO3.

5.4 The procedure given in this guide can be applied to reactivated or regenerated activated carbons.

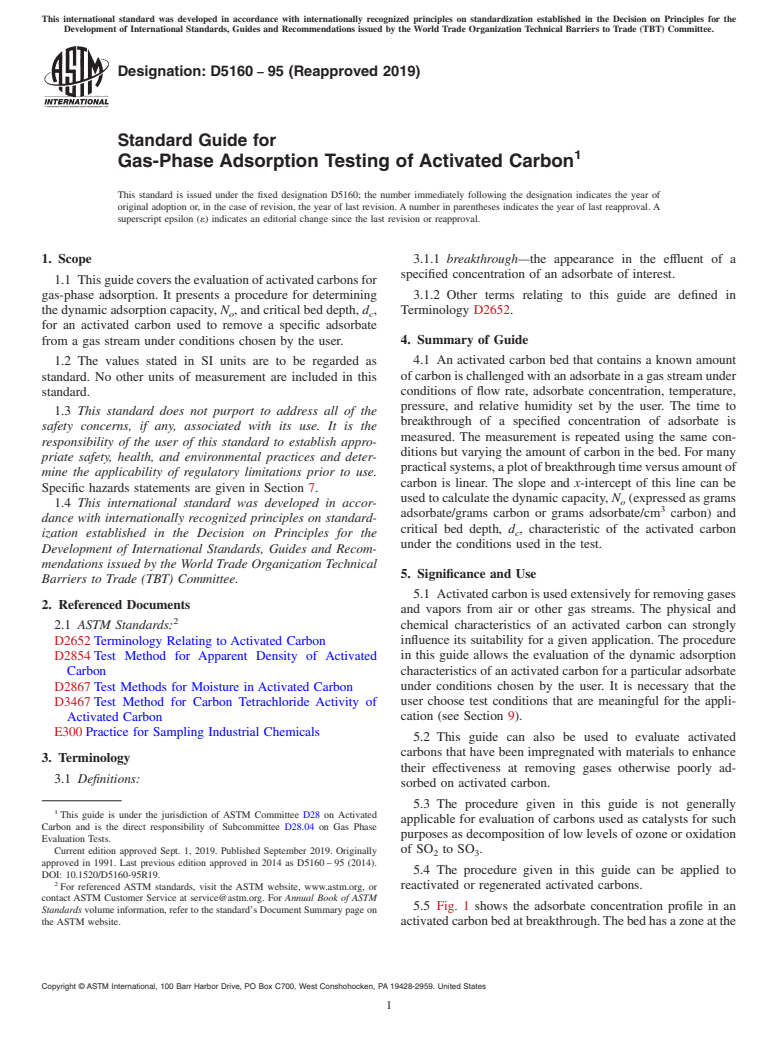

5.5 Fig. 1 shows the adsorbate concentration profile in an activated carbon bed at breakthrough. The bed has a zone at the inlet in which the adsorbate concentration is equal to the influent concentration. In this region the carbon is at equilibrium with adsorbate. The adsorbate concentration in the remainder of the bed drops until at the outlet it is equal to the breakthrough concentration. The shorter the length of this mass transfer zone (adsorption zone), the more effectively the carbon in the bed is utilized. A bed whose depth is less than the length of this zone will show immediate appearance of adsorbate in the effluent (breakpoint).

FIG. 1 Concentration Profile of an Activated Carbon Bed at Breakthrough

5.6 From the standpoint of best carbon utilization, it is desirable to choose a carbon which will give as short a mass transfer zone as possible under use conditions. However, in many applications, high adsorptive capacity is more important th...

SCOPE

1.1 This guide covers the evaluation of activated carbons for gas-phase adsorption. It presents a procedure for determining the dynamic adsorption capacity, No, and critical bed depth, dc, for an activated carbon used to remove a specific adsorbate from a gas stream under conditions chosen by the user.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D5160 −95 (Reapproved 2019)

Standard Guide for

Gas-Phase Adsorption Testing of Activated Carbon

This standard is issued under the fixed designation D5160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 breakthrough—the appearance in the effluent of a

specified concentration of an adsorbate of interest.

1.1 Thisguidecoverstheevaluationofactivatedcarbonsfor

gas-phase adsorption. It presents a procedure for determining 3.1.2 Other terms relating to this guide are defined in

thedynamicadsorptioncapacity, N ,andcriticalbeddepth, d , Terminology D2652.

o c

for an activated carbon used to remove a specific adsorbate

from a gas stream under conditions chosen by the user. 4. Summary of Guide

4.1 An activated carbon bed that contains a known amount

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this ofcarbonischallengedwithanadsorbateinagasstreamunder

conditions of flow rate, adsorbate concentration, temperature,

standard.

pressure, and relative humidity set by the user. The time to

1.3 This standard does not purport to address all of the

breakthrough of a specified concentration of adsorbate is

safety concerns, if any, associated with its use. It is the

measured. The measurement is repeated using the same con-

responsibility of the user of this standard to establish appro-

ditions but varying the amount of carbon in the bed. For many

priate safety, health, and environmental practices and deter-

practicalsystems,aplotofbreakthroughtimeversusamountof

mine the applicability of regulatory limitations prior to use.

carbon is linear. The slope and x-intercept of this line can be

Specific hazards statements are given in Section 7.

usedtocalculatethedynamiccapacity, N (expressedasgrams

o

1.4 This international standard was developed in accor-

adsorbate/grams carbon or grams adsorbate/cm carbon) and

dance with internationally recognized principles on standard-

critical bed depth, d , characteristic of the activated carbon

c

ization established in the Decision on Principles for the

under the conditions used in the test.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 Activatedcarbonisusedextensivelyforremovinggases

2. Referenced Documents

and vapors from air or other gas streams. The physical and

2.1 ASTM Standards: chemical characteristics of an activated carbon can strongly

influence its suitability for a given application. The procedure

D2652Terminology Relating to Activated Carbon

D2854Test Method for Apparent Density of Activated in this guide allows the evaluation of the dynamic adsorption

characteristics of an activated carbon for a particular adsorbate

Carbon

D2867Test Methods for Moisture in Activated Carbon under conditions chosen by the user. It is necessary that the

user choose test conditions that are meaningful for the appli-

D3467Test Method for Carbon Tetrachloride Activity of

cation (see Section 9).

Activated Carbon

E300Practice for Sampling Industrial Chemicals

5.2 This guide can also be used to evaluate activated

carbons that have been impregnated with materials to enhance

3. Terminology

their effectiveness at removing gases otherwise poorly ad-

3.1 Definitions:

sorbed on activated carbon.

5.3 The procedure given in this guide is not generally

This guide is under the jurisdiction of ASTM Committee D28 on Activated

applicable for evaluation of carbons used as catalysts for such

Carbon and is the direct responsibility of Subcommittee D28.04 on Gas Phase

purposes as decomposition of low levels of ozone or oxidation

Evaluation Tests.

Current edition approved Sept. 1, 2019. Published September 2019. Originally of SO to SO .

2 3

approved in 1991. Last previous edition approved in 2014 as D5160–95 (2014).

5.4 The procedure given in this guide can be applied to

DOI: 10.1520/D5160-95R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or reactivated or regenerated activated carbons.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Fig. 1 shows the adsorbate concentration profile in an

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. activatedcarbonbedatbreakthrough.Thebedhasazoneatthe

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5160−95 (2019)

mass transfer zone (small d ) when evaluated under the

c

operating conditions anticipated for the adsorber.

6. Apparatus

6.1 Sample Tube—This is often a vertically supported cy-

lindrical glass tube with diameter at least twelve times the

diameter of the largest carbon particles present or 16 times the

mean diameter. The lower end of the tube must have a flat

support for the carbon bed. Care should be taken to ensure

uniformity of flow profile across the bed. The support should

contribute as little as possible to the total pressure drop of the

bed. For this reason, fritted glass supports are often undesir-

able. Fine mesh stainless steel screens supported if necessary

by heavier screens may be used. Commercially available

spunbonded polyester nonwovens having both high strength

and very low pressure drop may also be used as very

convenient supports for tests in small tubes.

FIG. 1 Concentration Profile of an Activated Carbon Bed at

NOTE 1—Atest fixture in which the bed is held in place at both top and

Breakthrough

bottom requires less skill to obtain reproducible results. An 8.8 cm

diameter aluminum fixture with a perforated plate that screws down onto

the bed from above has been used successfully at bed depths from 1 to

inlet in which the adsorbate concentration is equal to the

3.5cm. A diagram of this fixture is shown in Fig. 2.

influent concentration. In this region the carbon is at equilib-

6.1.1 Flow should be downward through the sample to

rium with adsorbate. The adsorbate concentration in the

avoiddisturbingthebed.Fortestsonsmallamountsofcarbon,

remainder of the bed drops until at the outlet it is equal to the

a ground glass outer joint at the top of the tube allows easy

breakthroughconcentration.Theshorterthelengthofthismass

connection and disconnection from the challenge gas without

transferzone(adsorptionzone),themoreeffectivelythecarbon

disturbing the bed. It is very easy to disturb the packing of a

in the bed is utilized.Abed whose depth is less than the length

small bed. Preferably these should not be moved after loading.

of this zone will show immediate appearance of adsorbate in

6.1.2 The length of the sample tube must be several times

the effluent (breakpoint).

greaterthanthecriticalbeddepthoftheactivatedcarbonunder

5.6 From the standpoint of best carbon utilization, it is

the test conditions chosen.

desirable to choose a carbon which will give as short a mass

6.2 Fill Device—For small beds, the sample tube can be

transfer zone as possible under use conditions. However, in

loaded using the vibration feed device described in Test

many applications, high adsorptive capacity is more important

MethodD2854.Thebottomofthedeliveryfunnelshouldhave

than a short mass transfer zone. In almost every application,

the same diameter as the sample tube. It is desirable to allow

bed pressure drop is also a primary consideration.

thecarbontofallatleast10cmfromthebottomofthedelivery

5.7 Inafewsituationssuchasrespiratoryprotectionagainst

funnel to the top of the bed. For larger beds, the best packing

low levels of extremely toxic gases such as radioactive methyl

iodide, a short mass transfer zone (that is, high adsorption rate

coefficient) is more important than ultimate capacity. In other

cases such as solvent recovery, a high dynamic capacity is

more important.

5.8 Although the design of adsorber beds is beyond the

scope of this guide, the following points should be considered.

The bed diameter should be as large as possible in order to

lowerthepressuredropandtomaximizetheamountofcarbon

in the bed. Subject to pressure drop constraints, the deepest

possible carbon bed should be used. All else being equal, the

use of smaller particle size carbon will shorten the mass

transfer zone and improve bed efficiency at the expense of

higher pressure drop. If pressure drop considerations are

critical, some particle morphologies offer less resistance to

flow than others.

5.9 The two parameters obtained by the procedure in this

guidecanbeusedasanaidinselectinganactivatedcarbonand

in sizing the adsorption bed in which this carbon will be used.

The best carbon for most applications should have a high

FIG. 2 Test Fixture for Gas-Phase Adsorption Testing of Acti-

dynamic capacity for the adsorbate N coupled with a short vated Carbon

o

D5160−95 (2019)

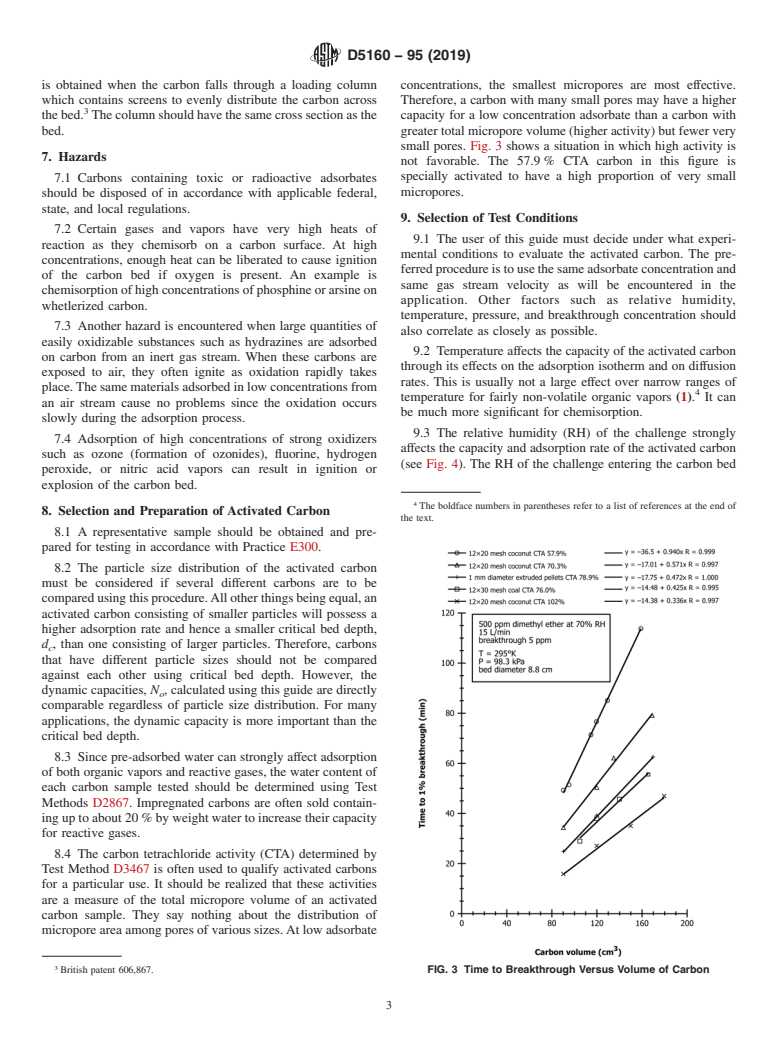

is obtained when the carbon falls through a loading column concentrations, the smallest micropores are most effective.

which contains screens to evenly distribute the carbon across Therefore, a carbon with many small pores may have a higher

thebed. Thecolumnshouldhavethesamecrosssectionasthe capacity for a low concentration adsorbate than a carbon with

bed. greatertotalmicroporevolume(higheractivity)butfewervery

small pores. Fig. 3 shows a situation in which high activity is

7. Hazards

not favorable. The 57.9% CTA carbon in this figure is

specially activated to have a high proportion of very small

7.1 Carbons containing toxic or radioactive adsorbates

micropores.

should be disposed of in accordance with applicable federal,

state, and local regulations.

9. Selection of Test Conditions

7.2 Certain gases and vapors have very high heats of

9.1 The user of this guide must decide under what experi-

reaction as they chemisorb on a carbon surface. At high

mental conditions to evaluate the activated carbon. The pre-

concentrations, enough heat can be liberated to cause ignition

ferredprocedureistousethesameadsorbateconcentrationand

of the carbon bed if oxygen is present. An example is

same gas stream velocity as will be encountered in the

chemisorptionofhighconcentrationsofphosphineorarsineon

application. Other factors such as relative humidity,

whetlerized carbon.

temperature, pressure, and breakthrough concentration should

7.3 Another hazard is encountered when large quantities of

also correlate as closely as possible.

easily oxidizable substances such as hydrazines are adsorbed

9.2 Temperature affects the capacity of the activated carbon

on carbon from an inert gas stream. When these carbons are

through its effects on the adsorption isotherm and on diffusion

exposed to air, they often ignite as oxidation rapidly takes

rates. This is usually not a large effect over narrow ranges of

place.Thesamematerialsadsorbedinlowconcentrationsfrom

temperature for fairly non-volatile organic vapors (1). It can

an air stream cause no problems since the oxidation occurs

be much more significant for chemisorption.

slowly during the adsorption process.

9.3 The relative humidity (RH) of the challenge strongly

7.4 Adsorption of high concentrations of strong oxidizers

affects the capacity and adsorption rate of the activated carbon

such as ozone (formation of ozonides), fluorine, hydrogen

(see Fig. 4). The RH of the challenge entering the carbon bed

peroxide, or nitric acid vapors can result in ignition or

explosion of the carbon bed.

The boldface numbers in parentheses refer to a list of references at the end of

8. Selection and Preparation of Activated Carbon

the text.

8.1 A representative sample should be obtained and pre-

pared for testing in accordance with Practice E300.

8.2 The particle size distribution of the activated carbon

must be considered if several different carbons are to be

comparedusingthisprocedure.Allotherthingsbeingequal,an

activated carbon consisting of smaller particles will possess a

higher adsorption rate and hence a smaller critical bed depth,

d , than one consisting of larger particles. Therefore, carbons

c

that have different particle sizes should not be compared

against each other using critical bed depth. However, the

dynamic capacities, N , calculated using this guide are directly

o

comparable regardless of particle size distribution. For many

applications, the dynamic capacity is more important than the

critical bed depth.

8.3 Since pre-adsorbed water can strongly affect adsorption

of both organic vapors and reactive gases, the water content of

each carbon sample tested should be determined using Test

Methods D2867. Impregnated carbons are often sold contain-

inguptoabout20%byweightwatertoincreasetheircapacity

for reactive gases.

8.4 The carbon tetrachloride activity (CTA) determined by

Test Method D3467 is often used to qualify activated carbons

for a particular use. It should be realized that these activities

are a measure of the total micropore volume of an activated

carbon sample. They say nothing about the distribution of

microporeareaamongporesofvarioussizes.Atlowadsorbate

British patent 606,867. FIG. 3 Time to Breakthrough Versus Volume of Carbon

D5160−95 (2019)

scale-up may require thermal insulation of a small lab column.

Such considerations can be especially important in chemisorp-

tion.

9.4.2 Anotherandusuallybetterwayofacceleratingthetest

is to increase the flow rate through the bed while maintaining

the adsorbate concentration as close as possible to that in the

desired application. Although this will change the adsorption

rate (and hence d ), often the dynamic capacity, N,ofthe

c o

carbon changes very little (2, 3). This is illustrated by the data

shown in Fig. 5. In this experiment, beds containing 105 cm

of carbon were tested against a 1000 ppm carbon tetrachloride

challenge at flow rates from 11 to 100 L/min. Breakthrough

was taken as 5 ppm. The data are plotted as time to break-

throughversusbedresidencetime.Bedresidencetimeisequal

tothebeddepthdividedbythesuperficialvelocity(volumetric

flow rate/cross section of the adsorbent bed) and can be

expressed in terms of the volume of adsorbent V (cm ) and the

flow rate Q (L/min) as follows:

V

τ s 50.06

~ ! S D

Q

The almost linear characteristic implies a dynamic adsorp-

tion capacity nearly independent of flow rate under these

FIG. 4 Effect of Test Relative Humidity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.