ASTM D2854-96(2004)

(Test Method)Standard Test Method for Apparent Density of Activated Carbon

Standard Test Method for Apparent Density of Activated Carbon

SIGNIFICANCE AND USE

This test method provides a method for determining the packed density of a bed of granular activated carbon. Determination of the packed density is essential when designing vessels to hold the material and for ordering purposes when procuring materials to fill existing vessels.

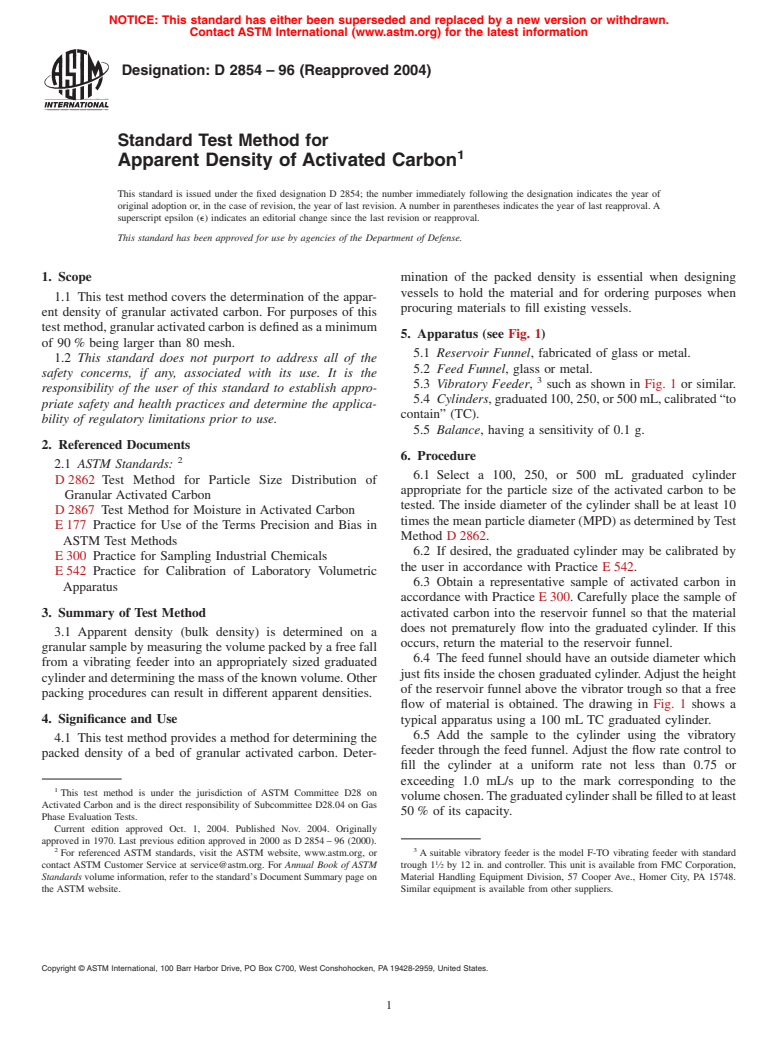

FIG. 1 Assembly of Apparatus

SCOPE

1.1 This test method covers the determination of the apparent density of granular activated carbon. For purposes of this test method, granular activated carbon is defined as a minimum of 90% being larger than 80 mesh.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 2854–96 (Reapproved 2004)

Standard Test Method for

Apparent Density of Activated Carbon

This standard is issued under the fixed designation D 2854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope mination of the packed density is essential when designing

vessels to hold the material and for ordering purposes when

1.1 This test method covers the determination of the appar-

procuring materials to fill existing vessels.

ent density of granular activated carbon. For purposes of this

test method, granular activated carbon is defined as a minimum

5. Apparatus (see Fig. 1)

of 90 % being larger than 80 mesh.

5.1 Reservoir Funnel, fabricated of glass or metal.

1.2 This standard does not purport to address all of the

5.2 Feed Funnel, glass or metal.

safety concerns, if any, associated with its use. It is the

5.3 Vibratory Feeder, such as shown in Fig. 1 or similar.

responsibility of the user of this standard to establish appro-

5.4 Cylinders,graduated100,250,or500mL,calibrated“to

priate safety and health practices and determine the applica-

contain” (TC).

bility of regulatory limitations prior to use.

5.5 Balance, having a sensitivity of 0.1 g.

2. Referenced Documents

6. Procedure

2.1 ASTM Standards:

6.1 Select a 100, 250, or 500 mL graduated cylinder

D 2862 Test Method for Particle Size Distribution of

appropriate for the particle size of the activated carbon to be

Granular Activated Carbon

tested. The inside diameter of the cylinder shall be at least 10

D 2867 Test Method for Moisture in Activated Carbon

times the mean particle diameter (MPD) as determined by Test

E 177 Practice for Use of the Terms Precision and Bias in

Method D 2862.

ASTM Test Methods

6.2 If desired, the graduated cylinder may be calibrated by

E 300 Practice for Sampling Industrial Chemicals

the user in accordance with Practice E 542.

E 542 Practice for Calibration of Laboratory Volumetric

6.3 Obtain a representative sample of activated carbon in

Apparatus

accordance with Practice E 300. Carefully place the sample of

3. Summary of Test Method activated carbon into the reservoir funnel so that the material

does not prematurely flow into the graduated cylinder. If this

3.1 Apparent density (bulk density) is determined on a

occurs, return the material to the reservoir funnel.

granular sample by measuring the volume packed by a free fall

6.4 The feed funnel should have an outside diameter which

from a vibrating feeder into an appropriately sized graduated

just fits inside the chosen graduated cylinder.Adjust the height

cylinder and determining the mass of the known volume. Other

of the reservoir funnel above the vibrator trough so that a free

packing procedures can result in different apparent densities.

flow of material is obtained. The drawing in Fig. 1 shows a

4. Significance and Use

typical apparatus using a 100 mL TC graduated cylinder.

6.5 Add the sample to the cylinder using the vibratory

4.1 This test method provides a method for determining the

feeder through the feed funnel. Adjust the flow rate control to

packed density of a bed of granular activated carbon. Deter-

fill the cylinder at a uniform rate not less than 0.75 or

exceeding 1.0 mL/s up to the mark corresponding to the

This test method is under the jurisdiction of ASTM Committee D28 on

volumechosen.Thegraduatedcylindershallbefilledtoatleast

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas

50 % of its capacity.

Phase Evaluation Tests.

Current edition approved Oct. 1, 2004. Published Nov. 2004. Originally

approved in 1970. Last previous edition approved in 2000 as D 2854 – 96 (2000).

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.