ASTM D6783-05a(2017)

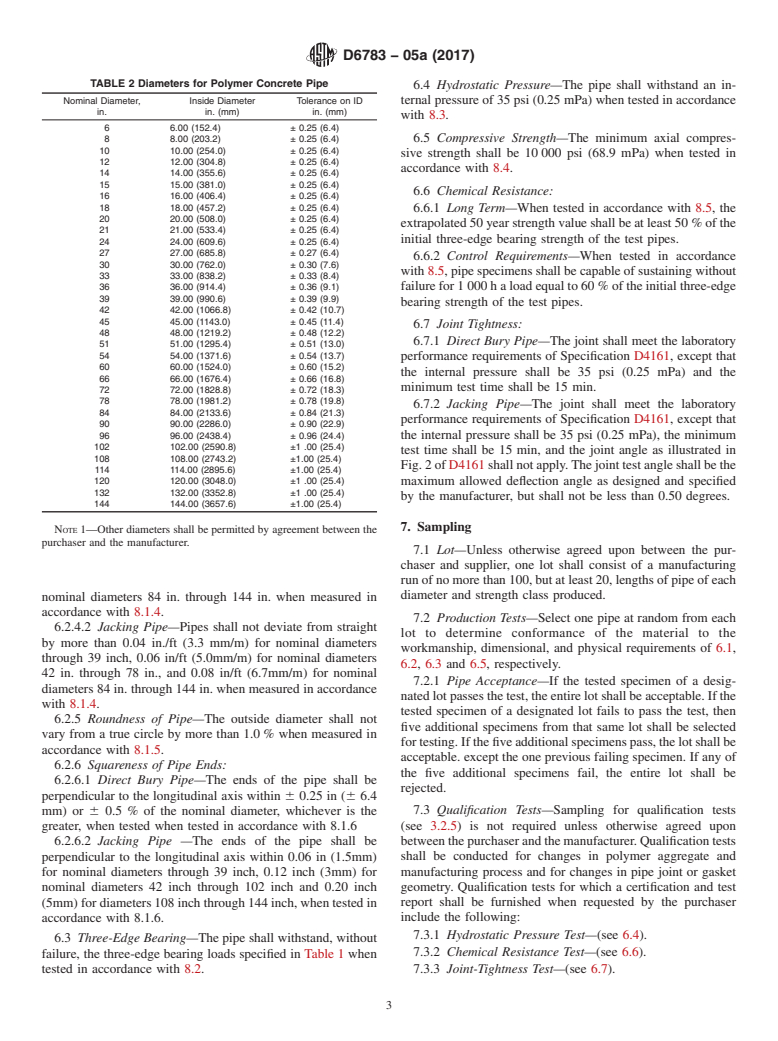

(Specification)Standard Specification for Polymer Concrete Pipe

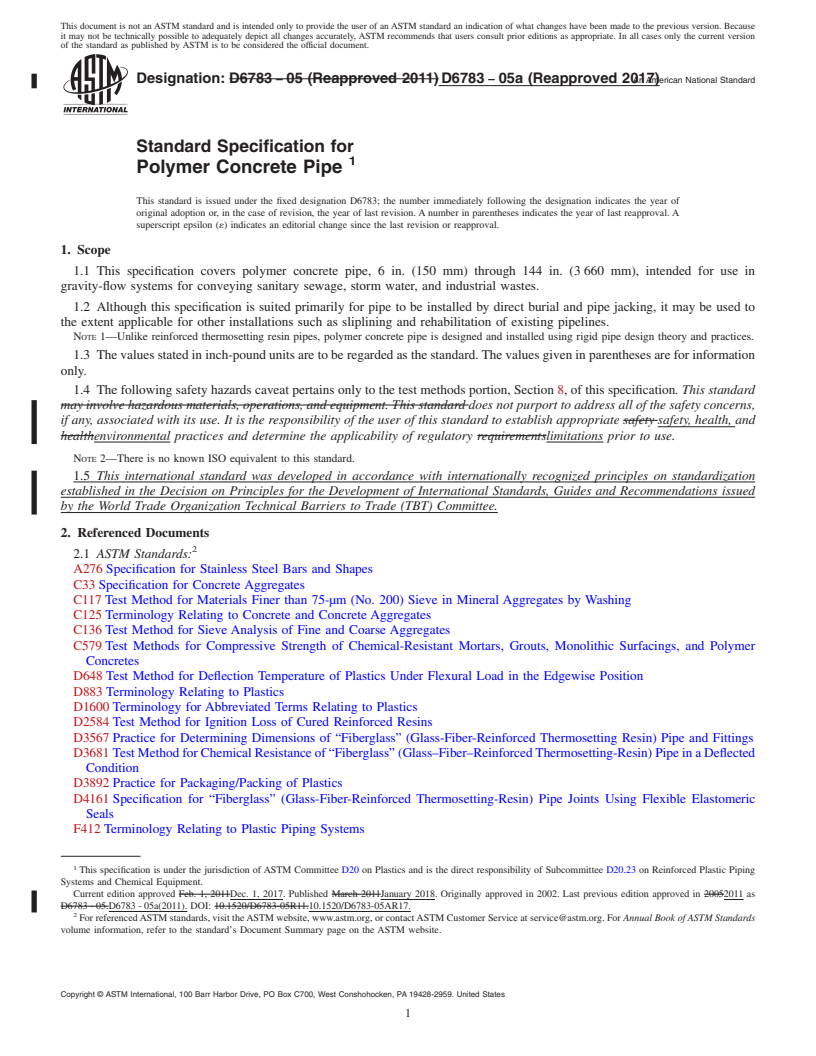

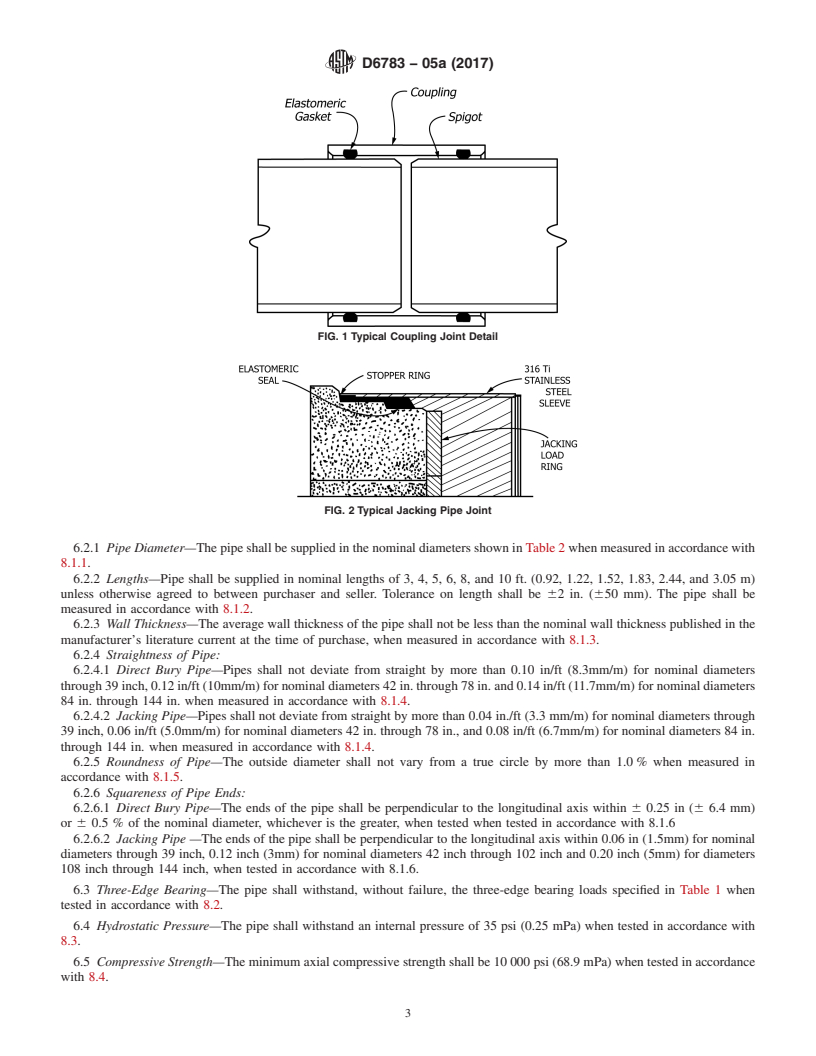

Standard Specification for Polymer Concrete Pipe

ABSTRACT

This specification covers the testing and requirements fof polymer concrete pipes of specified lengths, intended for use in gravity-flow systems for conveying sanitary sewage, storm water, and industrial wastes. Although this specification is suited primarily for pipes to be installed by direct burial and pipe jacking, it may be used to the extent applicable for other installations such as slip-lining and rehabilitation of existing pipelines. Materials shall be appropriately sampled for purposes of testing their conformance to such requirements as: workmanship; dimension (diameter, length, thickness, straightness, roundness, and squareness of ends); three-edge bearing; hydrostatic pressure; compressive strength; chemical resistance; and joint tightness.

SCOPE

1.1 This specification covers polymer concrete pipe, 6 in. (150 mm) through 144 in. (3 660 mm), intended for use in gravity-flow systems for conveying sanitary sewage, storm water, and industrial wastes.

1.2 Although this specification is suited primarily for pipe to be installed by direct burial and pipe jacking, it may be used to the extent applicable for other installations such as sliplining and rehabilitation of existing pipelines.

Note 1: Unlike reinforced thermosetting resin pipes, polymer concrete pipe is designed and installed using rigid pipe design theory and practices.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 2: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6783 −05a (Reapproved 2017)

Standard Specification for

1

Polymer Concrete Pipe

This standard is issued under the fixed designation D6783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C117 Test Method for Materials Finer than 75-µm (No. 200)

Sieve in Mineral Aggregates by Washing

1.1 This specification covers polymer concrete pipe, 6 in.

C125 Terminology Relating to Concrete and Concrete Ag-

(150 mm) through 144 in. (3 660 mm), intended for use in

gregates

gravity-flow systems for conveying sanitary sewage, storm

C136 Test Method for Sieve Analysis of Fine and Coarse

water, and industrial wastes.

Aggregates

1.2 Althoughthisspecificationissuitedprimarilyforpipeto

C579 Test Methods for Compressive Strength of Chemical-

be installed by direct burial and pipe jacking, it may be used to

Resistant Mortars, Grouts, Monolithic Surfacings, and

the extent applicable for other installations such as sliplining

Polymer Concretes

and rehabilitation of existing pipelines.

D648 Test Method for Deflection Temperature of Plastics

NOTE1—Unlikereinforcedthermosettingresinpipes,polymerconcrete

Under Flexural Load in the Edgewise Position

pipe is designed and installed using rigid pipe design theory and practices.

D883 Terminology Relating to Plastics

1.3 The values stated in inch-pound units are to be regarded

D1600 Terminology forAbbreviatedTerms Relating to Plas-

as the standard. The values given in parentheses are for

tics

information only.

D2584 Test Method for Ignition Loss of Cured Reinforced

1.4 The following safety hazards caveat pertains only to the Resins

test methods portion, Section 8, of this specification. This

D3567 Practice for Determining Dimensions of “Fiberglass”

standard does not purport to address all of the safety concerns, (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

if any, associated with its use. It is the responsibility of the user

Fittings

of this standard to establish appropriate safety, health, and D3681 Test Method for Chemical Resistance of “Fiberglass”

environmental practices and determine the applicability of

(Glass–Fiber–Reinforced Thermosetting-Resin) Pipe in a

regulatory limitations prior to use. Deflected Condition

D3892 Practice for Packaging/Packing of Plastics

NOTE 2—There is no known ISO equivalent to this standard.

D4161 Specification for “Fiberglass” (Glass-Fiber-

1.5 This international standard was developed in accor-

Reinforced Thermosetting-Resin) Pipe Joints Using Flex-

dance with internationally recognized principles on standard-

ible Elastomeric Seals

ization established in the Decision on Principles for the

F412 Terminology Relating to Plastic Piping Systems

Development of International Standards, Guides and Recom-

F477 Specification for Elastomeric Seals (Gaskets) for Join-

mendations issued by the World Trade Organization Technical

ing Plastic Pipe

Barriers to Trade (TBT) Committee.

3. Terminology

2. Referenced Documents

2

3.1 Definitions—Unless otherwise indicated, definitions are

2.1 ASTM Standards:

in accordance with Terminologies C125, D883, and F412, and

A276 Specification for Stainless Steel Bars and Shapes

abbreviations are in accordance with Terminology D1600.

C33 Specification for Concrete Aggregates

3.2 Definitions of Terms Specific to This Standard:

3.2.1 aggregate, n—a granular material, such as sand,

1

This specification is under the jurisdiction of ASTM Committee D20 on

gravel, or crushed stone, in accordance with to the require-

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

ments of Specification C33 except that the requirements for

Current edition approved Dec. 1, 2017. Published January 2018. Originally

gradation shall not apply.

approved in 2002. Last previous edition approved in 2011 as D6783 - 05a(2011).

DOI: 10.1520/D6783-05AR17.

3.2.2 pipe jacking, n—a system of directly installing pipes

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

behind a shield machine by hydraulic jacking from a drive

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shaft, such that the pipes form a continuous string in the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ground.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6783−05a (2017)

3.2.3 polymer concrete, n—a composite material that con-

sists essentially of a thermosetting resin within which

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6783 − 05 (Reapproved 2011) D6783 − 05a (Reapproved 2017)An American National Standard

Standard Specification for

1

Polymer Concrete Pipe

This standard is issued under the fixed designation D6783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers polymer concrete pipe, 6 in. (150 mm) through 144 in. (3 660 mm), intended for use in

gravity-flow systems for conveying sanitary sewage, storm water, and industrial wastes.

1.2 Although this specification is suited primarily for pipe to be installed by direct burial and pipe jacking, it may be used to

the extent applicable for other installations such as sliplining and rehabilitation of existing pipelines.

NOTE 1—Unlike reinforced thermosetting resin pipes, polymer concrete pipe is designed and installed using rigid pipe design theory and practices.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification. This standard

may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety safety, health, and

healthenvironmental practices and determine the applicability of regulatory requirementslimitations prior to use.

NOTE 2—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A276 Specification for Stainless Steel Bars and Shapes

C33 Specification for Concrete Aggregates

C117 Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing

C125 Terminology Relating to Concrete and Concrete Aggregates

C136 Test Method for Sieve Analysis of Fine and Coarse Aggregates

C579 Test Methods for Compressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer

Concretes

D648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

D3567 Practice for Determining Dimensions of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and Fittings

D3681 Test Method for Chemical Resistance of “Fiberglass” (Glass–Fiber–Reinforced Thermosetting-Resin) Pipe in a Deflected

Condition

D3892 Practice for Packaging/Packing of Plastics

D4161 Specification for “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Joints Using Flexible Elastomeric

Seals

F412 Terminology Relating to Plastic Piping Systems

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved Feb. 1, 2011Dec. 1, 2017. Published March 2011January 2018. Originally approved in 2002. Last previous edition approved in 20052011 as

D6783 - 05.D6783 - 05a(2011). DOI: 10.1520/D6783-05R11.10.1520/D6783-05AR17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6783 − 05a (2017)

F477 Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe

3. Terminology

3.1 Definitions—Unless otherwise indicated, definitions are in accordance with Terminologies C125, D883, and F412, and

abbreviations are in accordance with Terminology D1600.

3.2 Definitions of Terms Specific to This Standard:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.