ASTM D5493-93(1998)

(Test Method)Standard Test Method for Permittivity of Geotextiles Under Load

Standard Test Method for Permittivity of Geotextiles Under Load

SCOPE

1.1 This test method covers the determination of the water permittivity behavior of geotextiles in a direction normal to the plane of the geotextile when subjected to specific normal compressive loads.

1.2 Use of this test method is limited to geotextiles. This test method is not intended for application with geotextile-related products such as geogrids, geonets, geomembranes, and other geocomposites.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5493 – 93 (Reapproved 1998)

Standard Test Method for

Permittivity of Geotextiles Under Load

This standard is issued under the fixed designation D 5493; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 hydraulic gradient, i, n—the loss of hydraulic head

per unit distance of flow, dh/dL (see Test Method D 4716).

1.1 This test method covers the determination of the water

-1

3.1.3 permittivity, (c), (T ), n—of geotextiles, the volumet-

permittivity behavior of geotextiles in a direction normal to the

ric flow rate of water per unit cross-sectional area per unit head

plane of the geotextile when subjected to specific normal

under laminar flow conditions, in the normal direction through

compressive loads.

a geotextile (see Terminology D 4439).

1.2 Use of this test method is limited to geotextiles. This test

3.1.4 For the definitions of other terms relating to geotex-

method is not intended for application with geotextile-related

tiles, refer to Terminology D 4439. For the definitions of textile

products such as geogrids, geonets, geomembranes, and other

terms, refer to Terminology D 123. For the definitions of

geocomposites.

coeffıcient of permeability, refer to Terminology D 653.

1.3 The values stated in SI units are to be regarded as the

standard. The inch-pound units given in parentheses are for

4. Summary of Test Method

information only.

4.1 This test method provides a procedure for measuring the

1.4 This standard does not purport to address all of the

water flow, in the normal direction through a known cross

safety concerns, if any, associated with its use. It is the

section of a single layer of a geotextile at predetermined

responsibility of the user of this standard to establish appro-

constant hydraulic heads over a range of applied normal

priate safety and health practices and determine the applica-

compressive stresses.

bility of regulatory limitations prior to use.

4.2 The permittivity of a geotextile, c, can be determined by

2. Referenced Documents measuring the flow rate of water, in the normal direction,

through a known cross section of a geotextile at predetermined

2.1 ASTM Standards:

2 constant water heads.

D 123 Terminology Relating to Textile Materials

4.3 Water flow through geotextiles can be laminar, transient,

D 653 Terminology Relating to Soil, Rock, and Contained

or turbulent, and therefore permittivity cannot be taken as a

Fluids

constant.

D 4354 Practice for Sampling of Geosynthetics for Testing

D 4439 Terminology for Geosynthetics

5. Significance and Use

D 4491 Test Method for Water Permeability of Geotextiles

5.1 The thickness of a geotextile decreases with increase in

by Permittivity

the normal compressive stress. This decrease in thickness may

D 4716 Test Method for Determining the (in-plane) Flow

result in the partial closing or the opening of the voids of

Rate per Unit Width and Hydraulic Transmissivity of a

4 geotextile depending on its initial structure and the boundary

Geosynthetic Using a Constant Head

conditions.

3. Terminology 5.2 This test method measures the permittivity due to a

change of void structure of a geotextile as a result of an applied

3.1 Definitions:

compressive stress.

3.1.1 geotextile, n—any permeable textile material used

with foundation, soil, rock, earth, or any other geotechnical

6. Apparatus

engineering related material as an integral part of a manmade

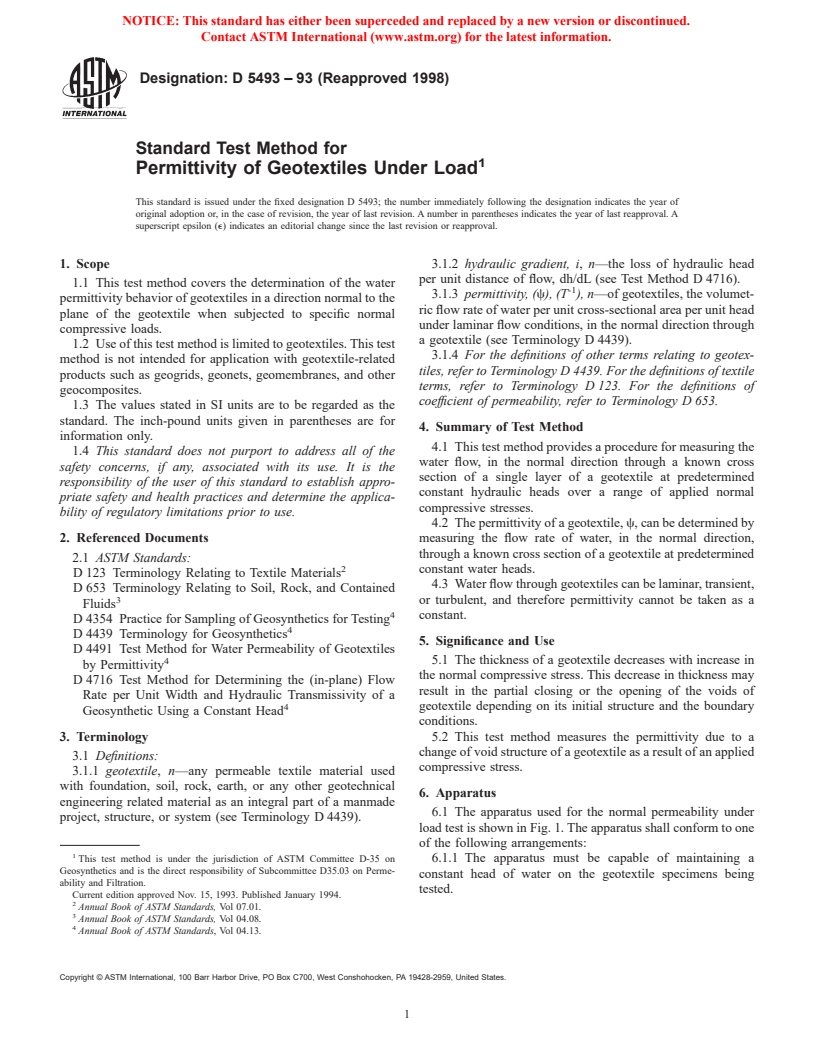

6.1 The apparatus used for the normal permeability under

project, structure, or system (see Terminology D 4439).

load test is shown in Fig. 1. The apparatus shall conform to one

of the following arrangements:

This test method is under the jurisdiction of ASTM Committee D-35 on 6.1.1 The apparatus must be capable of maintaining a

Geosynthetics and is the direct responsibility of Subcommittee D35.03 on Perme-

constant head of water on the geotextile specimens being

ability and Filtration.

tested.

Current edition approved Nov. 15, 1993. Published January 1994.

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 04.08.

Annual Book of ASTM Standards, Vol 04.13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5493 – 93 (1998)

6.6 Once the specimen, the balls, and the plates are secured

in the cylinder (3), remaining parts must be assembled on the

apparatus, that is:

6.6.1 Piezometers (14) are used to measure hydraulic head

losses at geotextile interfaces;

6.6.2 Part (15) allows setting of the load on the piston (4);

6.6.3 A valve (16) allows a constant flow of deaired water;

and

6.6.4 A graduated collection vessel (17) allows collecting of

the discharge water that flows through the specimen.

6.7 Certain required dimensions of the apparatus are shown

in Fig. 1.

7. Sampling

7.1 Lot Sample—As a lot sample for acceptance testing,

take at random the number of rolls of geotextile directed in an

applicable material specification or other agreement between

the purchaser and the supplier. Consider rolls of geotextile to

be the primary sampling units. If the specification requires

sampling during manufacture, select the rolls for the lot sample

at uniformly spaced time intervals throughout the production

period.

NOTE 1—An adequate specification or other agreement between the

purchaser and the supplier requires taking into account the variability

between rolls of geotextile and between specimens from a swatch from a

roll of geotextile so as to provide a sampling plan with a meaningful

producer’s risk, consumer’s risk, acceptable quality level, and limiting

quality level.

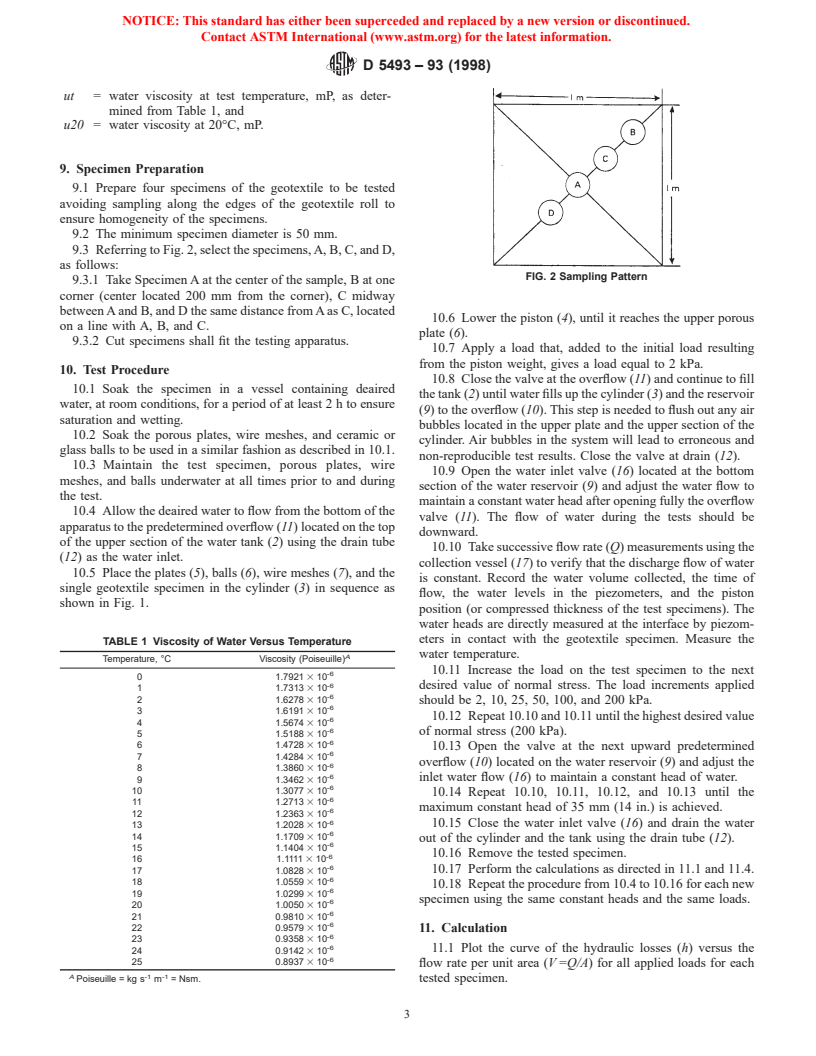

NOTE—Not at scale.

FIG. 1 Schematic View of the Apparatus

7.2 Laboratory Sample—Consider the units in the lot

sample as the units in the laboratory sample. Take a sample that

will exclude material from the outer wrap of the roll or the

6.1.2 The apparatus must not be the controlling factor for

inner wrap around the core unless the sample is taken at the

flow during the test. It will be necessary to establish a

production site, at which point the inner and outer wrap

calibration curve of flow rate versus hydraulic head for the

material may be used.

apparatus alone in order to establish compliance with this

requirement (see appendix).

8. Test Water Preparation

6.2 The apparatus consists of a stand (1) and a water tank

8.1 De-air the test water to provide reproducible test results.

(2) on which sits a vertical cylinder (3), a piston (4) used for

8.2 De-air the water used for saturation.

the application of the normal loads in the range from 2 to 200

8.3 De-air the water under a vacuum of 710 mm (28 in.) of

kPa (0.28 to 28 psig) with an accuracy of 62 μPa (60.28 psig),

mercury (Hg) for the period of time to bring the dissolved

two perforated plates used as water distributors (5), two glass

oxygen content down to a maximum of 6 ppm.

or ceramic balls layers (6), two layers of wire mesh (7), a water

8.4 Use dissolved oxygen meter or commercially available

inlet (8) connected to a reservoir containing deaired water (9),

chemical kits to determine the dissolved oxygen content.

overflow outlets at both the upper reservoir (10) and lower

8.5 The deaired system may be a commercially available

water tank (11), a drainage or discharge valve (12), a scale to

system, or one consisting of a vacuum pump capable of

measure changes of thickness of test specimen (13) and

removing a minimum of 150 L/min of air in connection with a

piezometers (14).

non-collapsible storage tank with a large enough storage

6.3 The overflow (11) located in the water tank (2) must be

capacity for the test series, or at least one specimen at a time.

located above the geotextile specimen installed in the cylinder

Allow the deaired water to stand in closed storage under a

(3). The recommended tubing diameter is 25 mm.

slight vacuum until room temperature is attained.

6.4 The reservoir (9) contains a number of overflow outlets

8.6 If water temperature other than 20°C is being used,

to enable setting of different hydraulic heads. The range of

make a temperature correction to the resulting value of

possible hydraulic heads should be between 20 to 350 mm. The

permittivity.

hydraulic head is defined as the difference between the water

8.7 Determine the temperature correction factor using the

level at overflow (10) and the water level at the outlet overflow

following equation:

(11).

Rt5ut/u20 (1)

6.5 The geotextile specimen is installed in the cylinder (3)

in between two wire meshes (7) and balls layers (6) and upper

where:

and lower perforated plates (5).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5493 – 93 (1998)

ut = water viscosity at test temper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.