ASTM D4389/D4389M-04(2010)e1

(Specification)Standard Specification for Finished Glass Fabrics Woven From Rovings

Standard Specification for Finished Glass Fabrics Woven From Rovings

ABSTRACT

This specification primarily covers glass fabrics woven from "E" electrical continuous glass fiber rovings that are intended primarily as a reinforcing material in laminated plastics for structural use. The basic designation for glass woven roving fabric is by mass per unit area and is given in grams per square metre. The roving shall be continuous filament fiber, free of any free alkali, such as sodium or potassium metal salts and foreign particles, dirt, and other impurities. For the given woven roving fabrics, the average fabric count, average size-free yarn numbers, filament diameter, average mass per unit area, and fabric length shall conform to the requirements specified. For woven roving fabrics, the roving designations, strand construction, and fabric width shall be agreed upon between the purchaser and the supplier. For the given woven roving fabrics, the weave type shall be plain weave. The woven roving fabric shall be generally uniform in quality and condition, clean, smooth, and free of foreign particles and defects detrimental to fabrication, appearance, or performance. Woven roving fabric shall be furnished in rolls and shall be wound on spiral tubes.

SCOPE

1.1 This specification primarily covers glass fabrics woven from “E” electrical continuous glass fiber rovings that are intended primarily as a reinforcing material in laminated plastics for structural use.

1.2 This specification specifies the terminology, definitions, general requirements, and physical requirements for woven roving glass fiber fabrics. This specification permits the application of sizing materials to the glass fiber roving during manufacture that helps facilitate weaving. When used as permitted in this specification, such materials are compatible with the resin matrix as specified in the contracting instrument.

Note 1—Sizing materials on glass fiber yarns, in most cases, are removed by various cleaning procedures as a first stage in preparing a finished fabric. When these yarn sizing materials are removed during a cleaning procedure, they need not be compatible with the subsequent resin matrix.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

Note 2—This specification is one of a series to provide a substitute for the following Military Specifications:

MIL-Y-1140H Yarn, Cord, Sleeving, Cloth, and Tape-Glass

MIL-C-9084C Cloth, Glass Finished for Resin Laminates

MIL-C-19663C Cloth, Glass, Woven Roving for Plastic Laminates

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D4389/D4389M −04(Reapproved 2010)

Standard Specification for

Finished Glass Fabrics Woven From Rovings

This standard is issued under the fixed designation D4389/D4389M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The units statement was updated and 3.1.1 and the last line of Table 2 were added editorially in August 2010.

1. Scope D578 Specification for Glass Fiber Strands

D1776 Practice for Conditioning and Testing Textiles

1.1 This specification primarily covers glass fabrics woven

D2408 Test Method for Finish Content of Woven Glass

from “E” electrical continuous glass fiber rovings that are

Fabric, Cleaned and After-Finished With Amino-Silane-

intended primarily as a reinforcing material in laminated

Type Finishes, for Plastic Laminates (Withdrawn 1988)

plastics for structural use.

D2409 Test Method for Finish Content of Woven Glass

1.2 This specification specifies the terminology, definitions,

Fabric, Cleaned and After-Finished With Vinyl-Silane

general requirements, and physical requirements for woven

Type Finishes, for Plastic Laminates (Withdrawn 1988)

roving glass fiber fabrics. This specification permits the appli-

D2410 Test Method for Finish Content of Woven Glass

cation of sizing materials to the glass fiber roving during

Fabric, Cleaned and After-Finished With Chrome

manufacture that helps facilitate weaving. When used as 3

Complexes, for Plastic Laminates (Withdrawn 1988)

permitted in this specification, such materials are compatible

D2660 Test Method for Finish Content of Woven Glass

with the resin matrix as specified in the contracting instrument.

Fabric, Cleaned and After-Finished with Acrylic-Silane-

Type Finishes, for Plastic Laminates (Withdrawn 1988)

NOTE 1—Sizing materials on glass fiber yarns, in most cases, are

removed by various cleaning procedures as a first stage in preparing a

D3098 Test Method for Finish Content of Woven Glass

finished fabric. When these yarn sizing materials are removed during a

Fabrics, Cleaned and After-Finished with Epoxy-

cleaningprocedure,theyneednotbecompatiblewiththesubsequentresin

Functionsl Silane Type Finishes for Plastic Laminates

matrix.

(Withdrawn 1988)

1.3 Units—The values stated in either SI units or inch-

D3773 Test Methods for Length of Woven Fabric

pound units are to be regarded as standard.The values stated in

D3774 Test Method for Width of Textile Fabric

each system may not be exact equivalents; therefore, each

D3775 Test Method forWarp (End) and Filling (Pick) Count

system shall be used independently of the other. Combining

of Woven Fabrics

values from the two systems may result in nonconformance

D3776 Test Methods for Mass Per Unit Area (Weight) of

with the standard.

Fabric

D4029 Specification for Finished Woven Glass Fabrics

NOTE 2—This specification is one of a series to provide a substitute for

the following Military Specifications:

D4963 Test Method for Ignition Loss of Glass Strands and

MIL-Y-1140H Yarn, Cord, Sleeving, Cloth, and Tape-Glass

Fabrics

MIL-C-9084C Cloth, Glass Finished for Resin Laminates

D7018 Terminology Relating to Glass Fiber and Its Products

MIL-C-19663C Cloth, Glass, Woven Roving for Plastic Laminates

2.2 ANSI Standard:

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

2. Referenced Documents

Attributes

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

3. Terminology

3.1 For definitions of glass fiber and product terms used in

1 this specification refer to Terminology D7018.

This specification is under the jurisdiction of ASTM Committee D13 on

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and

3.1.1 The following terms are relevant to this standard:

its Products.

continuous filament yarn, roving.

Current edition approved June 1, 2010. Published August 2010. Originally

approved in 1984. Last previous edition approved in 2004 as D4389 – 04. DOI:

ε1

10.1520/D4389_D4389M-04R10 .

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute 11 W. 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D4389/D4389M−04 (2010)

3.2 For definitions of other textile terms used in this listed in Table 1, the average size-free yarn numbers shall be

specification, refer to Terminology D123. agreed upon between the purchaser and the supplier.

CLASSIFICATION 9. Filament Diameter

9.1 The range of values for the filament diameters are listed

4. Classification

in Table 2.The average filament diameter for the rovings in the

4.1 Designation of Woven Roving Fabric— The basic des-

woven roving fabric shall be within the interval listed in Table

ignationsforglasswovenrovingfabricisbymassperunitarea

2.

and is given in grams per square metre (ounces per square

10. Strand Construction

yard).Historically,anASTMtypenumberhasbeenusedbythe

industry. These numbers have been sequentially assigned as

10.1 The construction of the component strands shall be

new woven roving constructions as they were added to this

agreed upon between the purchaser and the supplier.

specification. Numbers, 1 through 10, are shown in Table 1

11. Weave Type

with the relationship to mass per unit area and fabric count.

11.1 For woven roving fabrics listed in Table 1, the weave

REQUIREMENTS

type shall be plain weave. For woven roving fabrics not listed

in Table 1, the weave type shall be agreed upon between the

5. Material

purchaser and the supplier.

5.1 The roving shall be continuous filament fiber, free of

any free alkali, such as sodium or potassium metal salts and

12. Mass per Unit Area

foreignparticles,dirt,andotherimpurities.ItshallbeanEtype

12.1 For woven roving fabrics listed in Table 1, the average

glass as defined in Specification D578.

mass per unit area shall conform to the requirements of Table

5.1.1 The fabric shall be uniformly woven, have uniform

1. For woven roving fabrics not listed in Table 1, the average

color, overall cleanness, and no objectionable odor.

mass per unit area shall be agreed upon between the purchaser

andthesupplier.Theaveragemassperunitareaforthelotshall

6. Fabric Count

be within the interval: specified mass per unit area 6 10 % of

6.1 For woven roving fabrics listed in Table 1, the average

the specified mass per unit area.

fabric count shall conform to the requirements of Table 1. For

woven roving fabrics not listed in Table 1, the average fabric 13. Width

count shall be agreed upon between the purchaser and the

13.1 Fabric width shall be agreed upon between the pur-

supplier.

chaser and the supplier. The fabric width, including both

selvages but excluding any feathered edges, shall not be less

7. Yarn Designations

than the specified width and no more than 13 mm (0.5 in.)

7.1 For woven roving fabrics, the roving designations shall

wider than the specified width.

be as agreed upon between the purchaser and the supplier. The

NOTE 3—During the processing of glass fabrics, the selvages may be

requirements of the individual elements of the designation are

slit to minimize tension influences. This slit distance is excluded when

specified in Sections 8-10.

measuring the fabric width unless otherwise agreed upon between the

purchaser and the supplier.

8. Yarn Number

14. Length

8.1 For woven roving fabrics listed in Table 1, the average

size-freeyarnnumbersoftheyarnsdesignatedshallconformto 14.1 For woven roving fabrics listed in Table 1, the fabric

the requirements of Table 1. For woven roving fabrics not length on each roll shall not be less than2m(2yd) below the

TABLE 1 Physical Properties of Generally Available “E” Glass Finished Woven Roving Fabrics

A

Roving

Construction

Nominal

Count Standard Roll

Nominal Roving Length Per Unit Mass

Mass Per

ASTM

25.4 mm Length

Weave

Unit Area

Type

Tex yd/lb

(1 in.) min

2 2

g/m oz/yd Warp Fill Warp Fill Warp Fill m yd

1 Plain 441 13.0 10 4 840 to 755 1065 to 925 590 to 655 465 to 535 91.5 100

2 Plain 542 16.0 10 4 840 to 755 1680 to 1505 590 to 655 295 to 330 91.5 100

3 Plain 831 24.5 5 4 2360 to 2065 2680 to 2255 210 to 240 185 to 220 68.5 75

4 Plain 831 24.5 5 3 2360 to 2065 3545 to 3105 210 to 240 140 to 160 68.5 75

5 Plain 915 27.0 5 2.5 2360 to 2065 4960 to 4725 210 to 240 100 to 105 59.5 65

6 Plain 610 18.0 7 6 1210 to 1835 1340 to 1155 410 to 270 370 to 430 68.5 75

7 Plain 745 22.0 5 4 2360 to 2065 2155 to 1910 210 to 240 230 to 260 68.5 75

8 Plain 610 18.0 4 4 2360 to 2065 1655 to 1505 210 to 240 300 to 330 68.5 75

9 Plain 559 16.5 5 4 1710 to 1525 1710 to 1525 290 to 325 290 to 325 91.5 100

10 Plain 711 21.0 4 4 2420 to 2155 2420 to 2155 205 to 230 205 to 230 82.5 90

A

In some cases, the fill yarn may be woven as 2 picks per shed and as 1 fill yarn. The basic roving length per unit area used to produce the above fill yarns should be

doubled.

´1

D4389/D4389M−04 (2010)

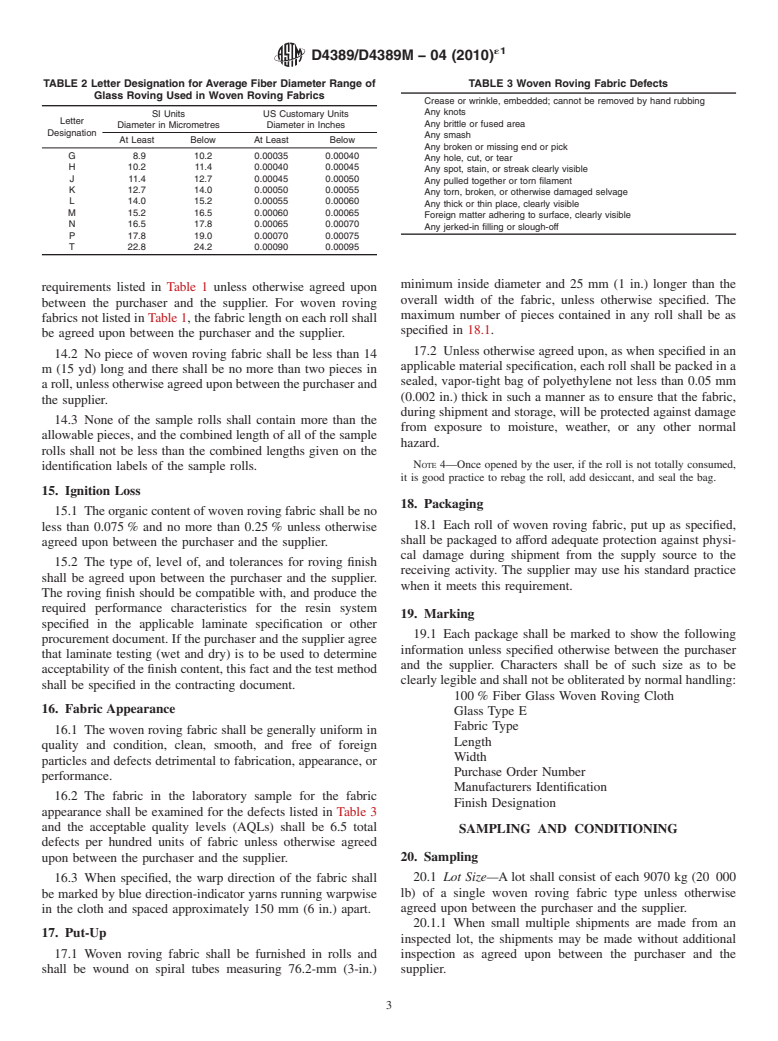

TABLE 2 Letter Designation for Average Fiber Diameter Range of TABLE 3 Woven Roving Fabric Defects

Glass Roving Used in Woven Roving Fabrics

Crease or wrinkle, embedded; cannot be removed by hand rubbing

Any knots

SI Units US Customary Units

Letter

Any brittle or fused area

Diameter in Micrometres Diameter in Inches

Designation

Any smash

At Least Below At Least Below

Any broken or missing end or pick

G 8.9 10.2 0.00035 0.00040

Any hole, cut, or tear

H 10.2 11.4 0.00040 0.00045

Any spot, stain, or streak clearly visible

J 11.4 12.7 0.00045 0.00050

Any pulled together or torn filament

K 12.7 14.0 0.00050 0.00055

Any torn, broken, or otherwise damaged selvage

L 14.0 15.2 0.00055 0.00060

Any thick or thin place, clearly visible

M 15.2 16.5 0.00060 0.00065

Foreign matter adhering to surface, clearly visible

N 16.5 17.8 0.00065 0.00070

Any jerked-in filling or slough-off

P 17.8 19.0 0.00070 0.00075

T 22.8 24.2 0.00090 0.00095

minimum inside diameter and 25 mm (1 in.) longer than the

requirements listed in Table 1 unless otherwise agreed upon

overall width of the fabric, unless otherwise specified. The

between the purchaser and the supplier. For woven roving

maximum number of pieces contained in any roll shall be as

fabrics not listed in Table 1, the fabric length on each roll shall

specified in 18.1.

be agreed upon between the purchaser and the supplier.

17.2 Unless otherwise agreed upon, as when specified in an

14.2 No piece of woven roving fabric shall be less than 14

applicable material specification, each roll shall be packed in a

m (15 yd) long and there shall be no more than two pieces in

sealed, vapor-tight bag of polyethylene not less than 0.05 mm

a roll, unless otherwise agreed upon between the purchaser and

(0.002 in.) thick in such a manner as to ensure that the fabric,

the supplier.

during shipment and storage, will be protected against damage

14.3 None of the sample rolls shall contain more than the

from exposure to moisture, weather, or any other normal

allowable pieces, and the combined length of all of the sample

hazard.

rolls shall not be less than the combined lengths given on the

NOTE 4—Once opened by the user, if the roll is not totally consumed,

identification labels of the sample rolls.

it is good practice to rebag the roll, add desiccant, and seal the bag.

15. Ignition Loss

18. Packaging

15.1 The organic content of woven roving fabric shall be no

18.1 Each roll of woven roving fabric, put up as specified,

less than 0.075 % and no more than 0.25 % unless otherwise

shall be packaged to afford adequate protection against physi-

agreed upon between the purchaser and the supplier.

cal damage during shipment from the supply source to the

15.2 The type of, level of, and tolerances for roving finish

receiving activity. The supplier may use his standard practice

shall be agreed upon between the purchaser and the supplier.

when it meets this requirement.

The roving finish should be compatible with, and produce the

required performance characteristics for the resin system

19. Marking

specified in the applicable laminate specification or other

19.1 Each package shall be marked to show the following

procurement document. If the purchaser and the supplier agree

information unless specified otherwise between the purchaser

that laminate testing (wet and dry) is to be used to determine

and the supplier. Characters shall be of such size as to be

acceptability of the finish content, this fact and the test method

clearly legible and shall not be obliterated by normal handling:

shall be specified in the contracting document.

100 % Fiber Glass Woven Roving Cloth

16. Fabric Appearance

Glass Type E

Fabric Type

16.1 The woven roving fabric shall be generally uniform in

Length

quality and condition, clean, smooth, and free of foreign

Width

particles and defects detrimental to fabrication, appearance, or

Purchase Order Number

performance.

Manufacturers Identification

16.2 The fabric in the laboratory sample for the fabric

Finish Designation

appearance shall be examined for the defects listed in Table 3

and the acceptable quality levels (AQLs) shall be 6.5 total

SAMPLING AND CONDITIONING

defects per hundred units of fabric unless otherwise agreed

upon between the purchaser and the supplier. 20. Sampling

20.1 Lot Size—A lot shall consist of each 9070 kg (20 000

16.3 When specified, the warp direction of the fabric shall

be marked by blue direction-indicator yarns running warpwise lb) of a single woven roving fabric type unless otherwise

agreed upon between the purchaser and the supplier.

in the cloth and spaced approximately 150 mm (6 in.) apart.

20.1.1 When small multiple shipments are made from an

17. Put-Up

inspected lot, the shipments may be made without additional

17.1 Woven roving fabric shall be furnished in rolls and inspection as agreed upon between the purchaser and the

shall be wound on spiral tubes measuring 76.2-mm (3-in.) supplier.

´1

D4389/D4389M−04 (2010)

20.2 Lot Sample—Unless otherwise agreed upon, as when 25. Filament Diameter

specified in an applicable order or contract, take at random as

25.1 Determine the filament diameter for both the warp and

a lot sample the number of rolls of woven roving fabric

filling yarns as directed in Specification D578 by using 50

specified in ANSI/ASQC Z1.4 and a single

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D4389–04 Designation: D4389/D4389M – 04 (Reapproved 2010)

Standard Specification for

Finished Glass Fabrics Woven From Rovings

This standard is issued under the fixed designation D4389; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard is issued under the fixed designation D4389/D4389M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement was updated and 3.1.1 and the last line of Table 2 were added editorially in August 2010.

1. Scope

1.1 This specification primarily covers glass fabrics woven from “E” electrical continuous glass fiber rovings that are intended

primarily as a reinforcing material in laminated plastics for structural use.

1.2 This specification specifies the terminology, definitions, general requirements, and physical requirements for woven roving

glass fiber fabrics. This specification permits the application of sizing materials to the glass fiber roving during manufacture that

helps facilitate weaving. When used as permitted in this specification, such materials are compatible with the resin matrix as

specified in the contracting instrument.

NOTE 1—Sizing materials on glass fiber yarns, in most cases, are removed by various cleaning procedures as a first stage in preparing a finished fabric.

When these yarn sizing materials are removed during a cleaning procedure, they need not be compatible with the subsequent resin matrix.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in nonconformance with the standard.

NOTE 2—This specification is one of a series to provide a substitute for the following Military Specifications:

MIL-Y-1140H Yarn, Cord, Sleeving, Cloth, and Tape-Glass

MIL-C-9084C Cloth, Glass Finished for Resin Laminates

MIL-C-19663C Cloth, Glass, Woven Roving for Plastic Laminates

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D578 Specification for Glass Fiber Strands

D1776 Practice for Conditioning and Testing Textiles

D2408 Test Method for Finish Content of Woven Glass Fabric, Cleaned andAfter-Finished withAmino-Silane-Type Finishes,

for Plastic Laminates

D2409 Test Method for Finish Content of Woven Glass Fabric, Cleaned and After-Finished with Vinyl-Silane-Type Finishes,

for Plastic Laminates

D2410 TestMethodforFinishContentofWovenGlassFabric,CleanedandAfter-FinishedwithChromeComplexes,forPlastic

Laminates

D2660 Test Method for Finish Content of Woven Glass Fabric, Cleaned andAfter-Finished withAcrylic-Silane-Type Finishes,

for Plastic Laminates

D3098 TestMethodforFinishContentofWovenGlassFabric,CleanedandAfterFinishedwithEpoxy–FunctionalSilane-Type

Finishes for Plastic Laminates Method of Test for Finish Content of Woven Glass Fabrics, Cleaned and After-Finished with

This specification is under the jurisdiction ofASTM Committee D13 onTextiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and Its Products.

Current edition approved Dec. 1, 2004. Published January 2005. Originally approved in 1984. Last previous edition approved in 1999 as D4389–99. DOI:

10.1520/D4389-04.on Glass Fiber and its Products.

Current edition approved June 1, 2010. Published August 2010. Originally approved in 1984. Last previous edition approved in 2004 as D4389 – 04. DOI:

´1

10.1520/D4389-04R10 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute 11 W. 42nd St., 13th Floor, New York, NY 10036.

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4389/D4389M – 04 (2010)

Epoxy-Functions Silane Type Finishes for Plastic Laminates

D3773 Test Methods for Length of Woven Fabric

D3774 Test Method for Width of Textile Fabric

D3775 Test Method for Warp (End) and Filling (Pick) Count of Woven Fabrics

D3776 Test Methods for Mass Per Unit Area (Weight) of Fabric

D4029 Specification for Finished Woven Glass Fabrics

D4963 Test Method for Ignition Loss of Glass Strands and Fabrics

D7018 Terminology Relating to Glass Fiber and Its Products

2.2 ANSI Standard:

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by Attributes

3. Terminology —

3.1For all terminology under the jurisdiction of Subcommittee D13.18 (continuous filament yarn, roving), refer to Terminology

3.1 For definitions of glass fiber and product terms used in this specification refer to Terminology D7018.

3.1.1 The following terms are relevant to this standard: continuous filament yarn, roving.

3.2 For definitions of other textile terms used in this specification, refer to Terminology D123.

CLASSIFICATION

4. Classification

4.1 Designation of Woven Roving Fabric— The basic designations for glass woven roving fabric is by mass per unit area and

is given in grams per square metre (ounces per square yard). Historically, an ASTM type number has been used by the industry.

These numbers have been sequentially assigned as new woven roving constructions as they were added to this specification.

Numbers, 1 through 10, are shown in Table 1 with the relationship to mass per unit area and fabric count.

REQUIREMENTS

5. Material

5.1 The roving shall be continuous filament fiber, free of any free alkali, such as sodium or potassium metal salts and foreign

particles, dirt, and other impurities. It shall be an E type glass as defined in Specification D578.

5.1.1 The fabric shall be uniformly woven, have uniform color, overall cleanness, and no objectionable odor.

6. Fabric Count

6.1 For woven roving fabrics listed inTable 1, the average fabric count shall conform to the requirements ofTable 1. For woven

roving fabrics not listed in Table 1, the average fabric count shall be agreed upon between the purchaser and the supplier.

7. Yarn Designations

7.1 For woven roving fabrics, the roving designations shall be as agreed upon between the purchaser and the supplier. The

requirements of the individual elements of the designation are specified in Sections 8-10.

Available from American National Standards Institute 11 W. 42nd St., 13th Floor, New York, NY 10036.

TABLE 1 Physical Properties of Generally Available “E” Glass Finished Woven Roving Fabrics

A

Roving

Construction

Nominal

Count Standard Roll

Nominal Roving Length Per Unit Mass

Mass Per

ASTM

25.4 mm Length

Weave

Unit Area

Type

Tex yd/lb

(1 in.) min

2 2

g/m oz/yd Warp Fill Warp Fill Warp Fill m yd

1 Plain 441 13.0 10 4 840 to 755 1065 to 925 590 to 655 465 to 535 91.5 100

2 Plain 542 16.0 10 4 840 to 755 1680 to 1505 590 to 655 295 to 330 91.5 100

3 Plain 831 24.5 5 4 2360 to 2065 2680 to 2255 210 to 240 185 to 220 68.5 75

4 Plain 831 24.5 5 3 2360 to 2065 3545 to 3105 210 to 240 140 to 160 68.5 75

5 Plain 915 27.0 5 2.5 2360 to 2065 4960 to 4725 210 to 240 100 to 105 59.5 65

6 Plain 610 18.0 7 6 1210 to 1835 1340 to 1155 410 to 270 370 to 430 68.5 75

7 Plain 745 22.0 5 4 2360 to 2065 2155 to 1910 210 to 240 230 to 260 68.5 75

8 Plain 610 18.0 4 4 2360 to 2065 1655 to 1505 210 to 240 300 to 330 68.5 75

9 Plain 559 16.5 5 4 1710 to 1525 1710 to 1525 290 to 325 290 to 325 91.5 100

10 Plain 711 21.0 4 4 2420 to 2155 2420 to 2155 205 to 230 205 to 230 82.5 90

A

In some cases, the fill yarn may be woven as 2 picks per shed and as 1 fill yarn. The basic roving length per unit area used to produce the above fill yarns should

be doubled.

´1

D4389/D4389M – 04 (2010)

8. Yarn Number

8.1 For woven roving fabrics listed in Table 1, the average size-free yarn numbers of the yarns designated shall conform to the

requirements of Table 1. For woven roving fabrics not listed in Table 1, the average size-free yarn numbers shall be agreed upon

between the purchaser and the supplier.

9. Filament Diameter

9.1 The range of values for the filament diameters are listed in Table 2. The average filament diameter for the rovings in the

woven roving fabric shall be within the interval listed in Table 2.

10. Strand Construction

10.1 The construction of the component strands shall be agreed upon between the purchaser and the supplier.

11. Weave Type

11.1 ForwovenrovingfabricslistedinTable1,theweavetypeshallbeplainweave.ForwovenrovingfabricsnotlistedinTable

1, the weave type shall be agreed upon between the purchaser and the supplier.

12. Mass per Unit Area

12.1 For woven roving fabrics listed in Table 1, the average mass per unit area shall conform to the requirements of Table 1.

For woven roving fabrics not listed in Table 1, the average mass per unit area shall be agreed upon between the purchaser and the

supplier.Theaveragemassperunitareaforthelotshallbewithintheinterval:specifiedmassperunitarea 610 %ofthespecified

mass per unit area.

13. Width

13.1 Fabric width shall be agreed upon between the purchaser and the supplier. The fabric width, including both selvages but

excluding any feathered edges, shall not be less than the specified width and no more than 13 mm (0.5 in.) wider than the specified

width.

NOTE 3—During the processing of glass fabrics, the selvages may be slit to minimize tension influences.This slit distance is excluded when measuring

the fabric width unless otherwise agreed upon between the purchaser and the supplier.

14. Length

14.1 For woven roving fabrics listed in Table 1, the fabric length on each roll shall not be less than2m(2yd) below the

requirements listed in Table 1 unless otherwise agreed upon between the purchaser and the supplier. For woven roving fabrics not

listed in Table 1, the fabric length on each roll shall be agreed upon between the purchaser and the supplier.

14.2 No piece of woven roving fabric shall be less than 14 m (15 yd) long and there shall be no more than two pieces in a roll,

unless otherwise agreed upon between the purchaser and the supplier.

14.3 None of the sample rolls shall contain more than the allowable pieces, and the combined length of all of the sample rolls

shall not be less than the combined lengths given on the identification labels of the sample rolls.

15. Ignition Loss

15.1 Theorganiccontentofwovenrovingfabricshallbenolessthan0.075 %andnomorethan0.25 %unlessotherwiseagreed

upon between the purchaser and the supplier.

15.2 The type of, level of, and tolerances for roving finish shall be agreed upon between the purchaser and the supplier. The

roving finish should be compatible with, and produce the required performance characteristics for the resin system specified in the

applicable laminate specification or other procurement document. If the purchaser and the supplier agree that laminate testing (wet

and dry) is to be used to determine acceptability of the finish content, this fact and the test method shall be specified in the

contracting document.

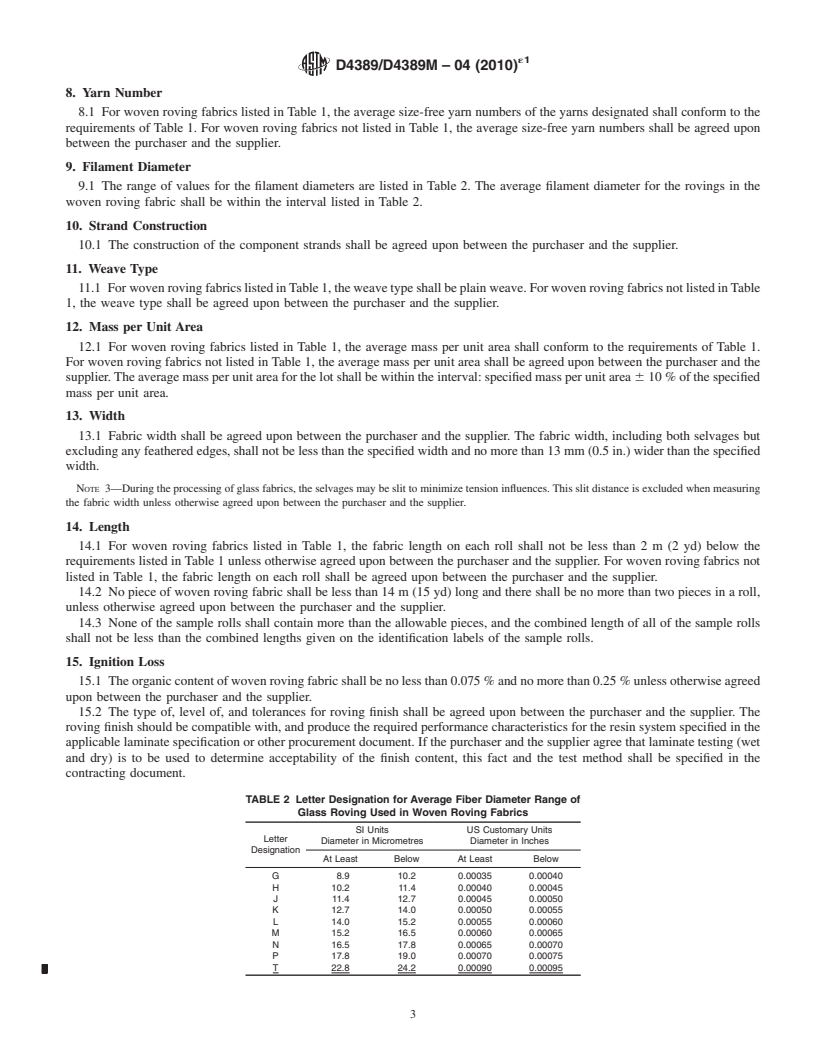

TABLE 2 Letter Designation for Average Fiber Diameter Range of

Glass Roving Used in Woven Roving Fabrics

SI Units US Customary Units

Letter

Diameter in Micrometres Diameter in Inches

Designation

At Least Below At Least Below

G 8.9 10.2 0.00035 0.00040

H 10.2 11.4 0.00040 0.00045

J 11.4 12.7 0.00045 0.00050

K 12.7 14.0 0.00050 0.00055

L 14.0 15.2 0.00055 0.00060

M 15.2 16.5 0.00060 0.00065

N 16.5 17.8 0.00065 0.00070

P 17.8 19.0 0.00070 0.00075

T 22.8 24.2 0.00090 0.00095

´1

D4389/D4389M – 04 (2010)

16. Fabric Appearance

16.1 The woven roving fabric shall be generally uniform in quality and condition, clean, smooth, and free of foreign particles

and defects detrimental to fabrication, appearance, or performance.

16.2 The fabric in the laboratory sample for the fabric appearance shall be examined for the defects listed in Table 3 and the

acceptable quality levels (AQLs) shall be 6.5 total defects per hundred units of fabric unless otherwise agreed upon between the

purchaser and the supplier.

16.3 When specified, the warp direction of the fabric shall be marked by blue direction-indicator yarns running warpwise in the

cloth and spaced approximately 150 mm (6 in.) apart.

17. Put-Up

17.1 Woven roving fabric shall be furnished in rolls and shall be wound on spiral tubes measuring 76.2-mm (3-in.) minimum

inside diameter and 25 mm (1 in.) longer than the overall width of the fabric, unless otherwise specified. The maximum number

of pieces contained in any roll shall be as specified in 18.1.

17.2 Unless otherwise agreed upon, as when specified in an applicable material specification, each roll shall be packed in a

sealed, vapor-tight bag of polyethylene not less than 0.05 mm (0.002 in.) thick in such a manner as to ensure that the fabric, during

shipment and storage, will be protected against damage from exposure to moisture, weather, or any other normal hazard.

NOTE 4—Once opened by the user, if the roll is not totally consumed, it is good practice to rebag the roll, add desiccant, and seal the bag.

18. Packaging

18.1 Each roll of woven roving fabric, put up as specified, shall be packaged to afford adequate protection against physical

damage during shipment from the supply source to the receiving activity.The supplier may use his standard practice when it meets

this requirement.

19. Marking

19.1 Each package shall be marked to show the following information unless specified otherwise between the purchaser and the

supplier. Characters shall be of such size as to be clearly legible and shall not be obliterated by normal handling:

100 % Fiber Glass Woven Roving Cloth

Glass Type E

Fabric Type

Length

Width

Purchase Order Number

Manufacturers Identification

Finish Designation

SAMPLING AND CONDITIONING

20. Sampling

20.1 Lot Size—A lot shall consist of each 90

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.