ASTM E582-88(1999)

(Test Method)Standard Test Method for Minimum Ignition Energy and Quenching Distance in Gaseous Mixtures

Standard Test Method for Minimum Ignition Energy and Quenching Distance in Gaseous Mixtures

SCOPE

1.1 This method covers the determination of minimum energy for ignition (initiation of deflagration) and associated flat-plate ignition quenching distances. The complete description is specific to alkane or alkene fuels admixed with air at normal ambient temperature and pressure. This method is applicable to mixtures of the specified fuels with air, varying from the most easily ignitable mixture to mixtures near to the limit-of-flammability compositions.

1.2 Extensions to other fuel-oxidizer combinations, and to other temperatures and pressures can be accomplished with all the accuracy inherent in this method if certain additional conditions are met: (a) mixture stability and compatibility with bomb, seal, and other materials is established through time tests described in Section 9; (b) the expected peak pressure from the test is within the pressure rating of the bomb (established as required by the particular research laboratory); (c) spark breakdown within the bomb is consistent with Paschen's law for the distance being tested; (d) the temperature, including that of the discharge electrodes, is uniform; and (e) if the temperature is other than ambient, the energy storage capacitance required is less than about 9 pF.

1.3 This method is one of several being developed by Committee E-27 for determining the hazards of chemicals, including their vapors in air or other oxidant atmospheres. The measurements are useful in assessing fuel ignitability hazards due to static or other electrical sparks. However, the quenching distance data must be used with great prudence since they are primarily applicable to the ignition stage and therefore, represent values for initial pressure and not the smaller values existing at higher pressures.

1.4 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use .

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety precautions are listed in Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E582–88 (Reapproved 1999)

Standard Test Method for

Minimum Ignition Energy and Quenching Distance in

Gaseous Mixtures

This standard is issued under the fixed designation E582; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope should not be used to describe or appraise the fire hazard or

fire risk of materials, products, or assemblies under actual fire

1.1 This test method covers the determination of minimum

conditions. However, results of this test may be used as

energy for ignition (initiation of deflagration) and associated

2 elements of a fire risk assessment which takes into account all

flat-plate ignition quenching distances. The complete descrip-

of the factors which are pertinent to an assessment of the fire

tion is specific to alkane or alkene fuels admixed with air at

hazard of a particular end use.

normal ambient temperature and pressure. This method is

1.5 This standard does not purport to address all of the

applicable to mixtures of the specified fuels with air, varying

safety concerns, if any, associated with its use. It is the

from the most easily ignitable mixture to mixtures near to the

responsibility of the user of this standard to establish appro-

limit-of-flammability compositions.

priate safety and health practices and determine the applica-

1.2 Extensions to other fuel-oxidizer combinations, and to

bility of regulatory limitations prior to use. Specific safety

other temperatures and pressures can be accomplished with all

precautions are listed in Section 5.

the accuracy inherent in this method if certain additional

conditionsaremet:( a)mixturestabilityandcompatibilitywith

2. Summary of Method

bomb, seal, and other materials is established through time

2.1 Known quantities of stored electrical energy are dis-

tests described in Section 9; (b) the expected peak pressure

charged into a known fuel-air mixture at a known spark-gap

from the test is within the pressure rating of the bomb

length. Visual inspection indicates whether the mixture is

(established as required by the particular research laboratory);

ignited and flame propagates through the test reaction vessel.

(c) spark breakdown within the bomb is consistent with

Sufficient tests are conducted to determine the minimum

Paschen’s law for the distance being tested; (d) the tempera-

ignition energy versus stoichiometry and flat-plate ignition

ture, including that of the discharge electrodes, is uniform; and

quenching distance versus stoichiometry for the mixture under

(e) if the temperature is other than ambient, the energy storage

investigation.

capacitance required is less than about 9 pF.

1.3 This method is one of several being developed by

3. Significance and Use

Committee E-27 for determining the hazards of chemicals,

3.1 The minimum energies provide a basis for comparing

including their vapors in air or other oxidant atmospheres.The

the ease of ignition of gases. The flatplate ignition quenching

measurements are useful in assessing fuel ignitability hazards

distances provide an important verification of existing mini-

duetostaticorotherelectricalsparks.However,thequenching

mum ignition energy data and give approximate values of the

distance data must be used with great prudence since they are

propagation quenching distances of the various mixtures. It is

primarily applicable to the ignition stage and therefore, repre-

emphasized that maximum safe experimental gaps, as from

sent values for initial pressure and not the smaller values

“flame-proof” or “explosion-proof” studies, are less than the

existing at higher pressures.

flat-plate ignition quenching distances.

1.4 This standard should be used to measure and describe

the properties of materials, products, or assemblies in response

4. Apparatus

to heat and flame under controlled laboratory conditions and

4.1 Reaction Vessel—The recommended reaction vessel is

manufactured according to the specifications of Fig. 1 and Fig.

2. This is a spherical vessel, manufactured of Type 304

ThistestmethodisunderthejurisdictionofASTMCommitteeE-27onHazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

stainless steel, and passivated after machining. The spherical

Flammability and Ignitability of Chemicals.

geometry maximizes the useable spark-gap length for a given

Current edition approved Jan. 29, 1988. Published March 1988. Originally

vessel volume. The reaction vessel provides for opposed

published as E582–76. Last previous edition E582–76(1981).

mounting of the spark electrodes which permits rapid and

Litchfield, E. L., Hay, M. H., Kubala, T. S., and Monroe, J. S.,“ Minimum

Ignition Energy and Quenching Distance in Gaseous Mixtures,’’ BuMines, R. L.

convenientvariationofthegaplengthwithoutthenecessityfor

7009, August 1967, 11 pp.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E582

NOTE 1—Tolerance is 6 0.010 in., unless noted.

NOTE 2—Break all sharp edges.

NOTE 3—Material is Type 304 stainless steel.

NOTE 4—Thread depth is 75 to 80%.

NOTE 5—1 in. 525.4 mm.

FIG. 1 Electrode Assembly (I)

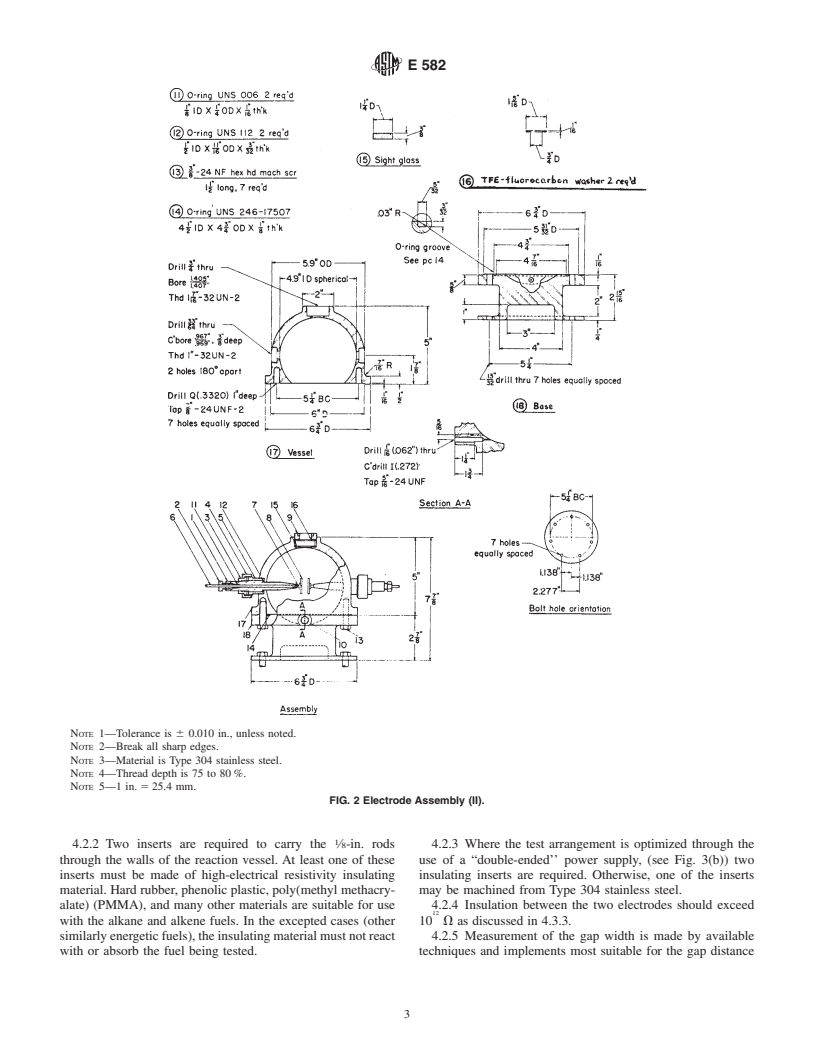

opening the vessel. The input orifice (Fig. 2, Section A-A)is which extend through inserts in the bomb walls to permit

located so that the gases are introduced approximately tangen- externalelectricalconnections.Gassealsareprovidedbetween

tially to the vessel walls, thus providing a turbulent swirling the reaction vessel and the inserts and between the inserts and

motion that facilitates mixing. A sight glass permits direct the ⁄8-in. rods by O-ring seals (see Fig. 2, Assembly). The

observation of flame initiation and propagation throughout the glassflangematerialshouldbeeitherborosilicateorhighsilica

reaction volume. and the flanges should be fastened to the stainless steel tips

4.2 Electrode Assembly: with a thin layer of epoxy cement. The facing surfaces should

4.2.1 The electrodes (Fig. 1) have metal tips flanged with be planar and coplanar to 0.001 in. (0.025 mm) or 1% of the

glass plates. The tips screw into ⁄8-in. stainless steel rods intended test gap, whichever is larger.

E582

NOTE 1—Tolerance is 6 0.010 in., unless noted.

NOTE 2—Break all sharp edges.

NOTE 3—Material is Type 304 stainless steel.

NOTE 4—Thread depth is 75 to 80%.

NOTE 5—1 in. 525.4 mm.

FIG. 2 Electrode Assembly (II).

4.2.2 Two inserts are required to carry the ⁄8-in. rods 4.2.3 Where the test arrangement is optimized through the

through the walls of the reaction vessel. At least one of these use of a “double-ended’’ power supply, (see Fig. 3(b)) two

inserts must be made of high-electrical resistivity insulating insulating inserts are required. Otherwise, one of the inserts

material. Hard rubber, phenolic plastic, poly(methyl methacry- may be machined from Type 304 stainless steel.

alate) (PMMA), and many other materials are suitable for use 4.2.4 Insulation between the two electrodes should exceed

with the alkane and alkene fuels. In the excepted cases (other 10 V as discussed in 4.3.3.

similarlyenergeticfuels),theinsulatingmaterialmustnotreact 4.2.5 Measurement of the gap width is made by available

with or absorb the fuel being tested. techniques and implements most suitable for the gap distance

E582

NOTE 1—Distributed capacitance must be considered as part of the energy storage capacitance.

NOTE 2—See 4.3 for component value guidelines.

FIG. 3 Connections of Single and Double-Sided Power Supply in Circuit.

very highest quality data are required.

being measured. Calibrated leaf gages, inside micrometers, or

vernier calipers are suitable, depending upon the gap distance.

4.3.3 The output filter capacitors of the power supply must

The measurements should be made with a repeatability of

be isolated from the discharge energy storage capacitance by

60.001 in. (0.025 mm) or 1%, whichever is most conserva-

an isolating resistor. The resistive-capacitive time constant of

tive. To facilitate such measurements, it is helpful to have leaf

the charging circuit containing the energy storage capacitance

gages of known thicknesses for frequently used gap distances.

should be several seconds; 10 V is a desirable value for the

High-quality machinist’s micrometers will generally provide

most easily ignitable mixture (energy storage capacitance of 8

adequate accuracy.

to 12 pF) with the value reduced inversely as the energy

4.3 Power Supply and Electrical Circuit:

storage capacitance is increased for less easily ignitable mix-

4.3.1 The power supply should be of the oscillator type, so

tures. Two resistors should be used in series, four with the

that its filter condensers will be electrically small. The maxi-

double-ended supply. One resistor shall be immediately at the

mum output current should be about 1 mA.

power supply terminal, the other at the bomb energy storage

capacitance. Supply-line electrical insulation needs to be

NOTE 1—Caution:With such a power supply, the probability of lethal

14 12

greater than 10 V to be consistent with 10 V series

shock to the operator from the high-voltage circuits becomes negligible.

However, all usual and normal hazards to personnel will exist on the resistance. Such resistance is most easily achieved through air

60-Hz supply, main-side of the power supply.

insulationwithappropriatelyroundedcornerstoreducecorona

losses.

4.3.2 The power supply can be single-side with one high-

4.4 Measurement of Energy Storage Capacitance—The en-

voltageoutputterminalandonelow-voltage,neutral,orground

ergy storage capacitance may be measured with a high-quality

terminal(seeFig.3(a)).Alte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.