ASTM E582-04

(Test Method)Standard Test Method for Minimum Ignition Energy and Quenching Distance in Gaseous Mixtures

Standard Test Method for Minimum Ignition Energy and Quenching Distance in Gaseous Mixtures

SCOPE

1.1 This test method covers the determination of minimum energy for ignition (initiation of deflagration) and associated flat-plate ignition quenching distances. The complete description is specific to alkane or alkene fuels admixed with air at normal ambient temperature and pressure. This method is applicable to mixtures of the specified fuels with air, varying from the most easily ignitable mixture to mixtures near to the limit-of-flammability compositions.

1.2 Extensions to other fuel-oxidizer combinations, and to other temperatures and pressures can be accomplished with all the accuracy inherent in this method if certain additional conditions are met: ( a) mixture stability and compatibility with bomb, seal, and other materials is established through time tests described in Section 9; (b) the expected peak pressure from the test is within the pressure rating of the bomb (established as required by the particular research laboratory); (c) spark breakdown within the bomb is consistent with Paschen's law for the distance being tested; (d) the temperature, including that of the discharge electrodes, is uniform; and (e) if the temperature is other than ambient, the energy storage capacitance required is less than about 9 pF.

1.3 This method is one of several being developed by Committee E-27 for determining the hazards of chemicals, including their vapors in air or other oxidant atmospheres. The measurements are useful in assessing fuel ignitability hazards due to static or other electrical sparks. However, the quenching distance data must be used with great prudence since they are primarily applicable to the ignition stage and therefore, represent values for initial pressure and not the smaller values existing at higher pressures.

1.4 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety precautions are listed in Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E582–04

Standard Test Method for

Minimum Ignition Energy and Quenching Distance in

1

Gaseous Mixtures

This standard is issued under the fixed designation E582; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope should not be used to describe or appraise the fire hazard or

fire risk of materials, products, or assemblies under actual fire

1.1 This test method covers the determination of minimum

conditions. However, results of this test may be used as

energy for ignition (initiation of deflagration) and associated

2 elements of a fire risk assessment which takes into account all

flat-plate ignition quenching distances. The complete descrip-

of the factors which are pertinent to an assessment of the fire

tion is specific to alkane or alkene fuels admixed with air at

hazard of a particular end use.

normal ambient temperature and pressure. This method is

1.5 This standard does not purport to address all of the

applicable to mixtures of the specified fuels with air, varying

safety concerns, if any, associated with its use. It is the

from the most easily ignitable mixture to mixtures near to the

responsibility of the user of this standard to establish appro-

limit-of-flammability compositions.

priate safety and health practices and determine the applica-

1.2 Extensions to other fuel-oxidizer combinations, and to

bility of regulatory limitations prior to use. Specific safety

other temperatures and pressures can be accomplished with all

precautions are listed in Section 5.

the accuracy inherent in this method if certain additional

conditionsaremet:( a)mixturestabilityandcompatibilitywith

2. Summary of Method

bomb, seal, and other materials is established through time

2.1 Known quantities of stored electrical energy are dis-

tests described in Section 9;(b) the expected peak pressure

charged into a known fuel-air mixture at a known spark-gap

from the test is within the pressure rating of the bomb

length. Visual inspection indicates whether the mixture is

(established as required by the particular research laboratory);

ignited and flame propagates through the test reaction vessel.

(c) spark breakdown within the bomb is consistent with

Sufficient tests are conducted to determine the minimum

Paschen’s law for the distance being tested; (d) the tempera-

ignition energy versus stoichiometry and flat-plate ignition

ture, including that of the discharge electrodes, is uniform; and

quenching distance versus stoichiometry for the mixture under

(e) if the temperature is other than ambient, the energy storage

investigation.

capacitance required is less than about 9 pF.

1.3 This method is one of several being developed by

3. Significance and Use

Committee E-27 for determining the hazards of chemicals,

3.1 The minimum energies provide a basis for comparing

including their vapors in air or other oxidant atmospheres.The

the ease of ignition of gases. The flatplate ignition quenching

measurements are useful in assessing fuel ignitability hazards

distances provide an important verification of existing mini-

duetostaticorotherelectricalsparks.However,thequenching

mum ignition energy data and give approximate values of the

distance data must be used with great prudence since they are

propagation quenching distances of the various mixtures. It is

primarily applicable to the ignition stage and therefore, repre-

emphasized that maximum safe experimental gaps, as from

sent values for initial pressure and not the smaller values

“flame-proof” or “explosion-proof” studies, are less than the

existing at higher pressures.

flat-plate ignition quenching distances.

1.4 This standard should be used to measure and describe

the properties of materials, products, or assemblies in response

4. Apparatus

to heat and flame under controlled laboratory conditions and

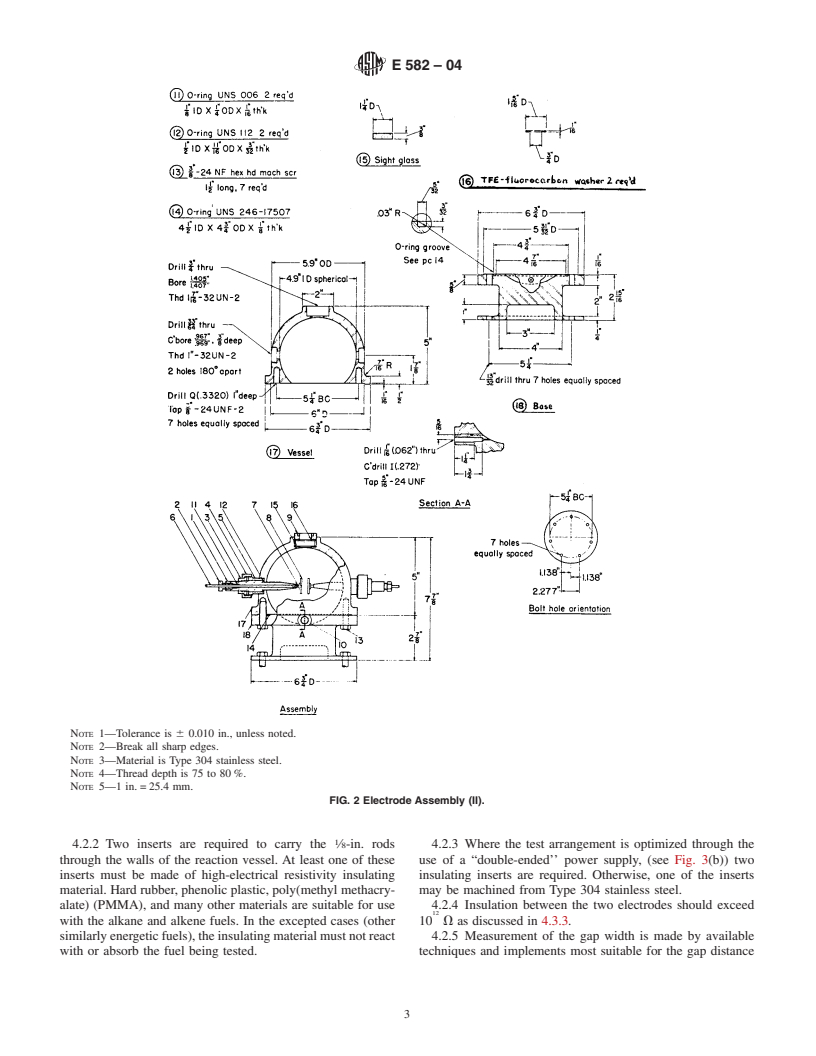

4.1 Reaction Vessel—The recommended reaction vessel is

manufactured according to the specifications of Fig. 1 and Fig.

1

2. This is a spherical vessel, manufactured of Type 304

This test method is under the jurisdiction ofASTM Committee E27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

stainless steel, and passivated after machining. The spherical

Flammability and Ignitability of Chemicals.

geometry maximizes the useable spark-gap length for a given

Current edition approved Dec. 1, 2004. Published January 2005. Originally

vessel volume. The reaction vessel provides for opposed

approved in 1976. Last previous edition approved in 1999 as E582–88(1999).

2

mounting of the spark electrodes which permits rapid and

Litchfield, E. L., Hay, M. H., Kubala,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.