ASTM D5895-01

(Test Method)Standard Test Methods for Measuring Times of Drying or Curing During Film Formation of Organic Coatings Using Mechanical Recorders

Standard Test Methods for Measuring Times of Drying or Curing During Film Formation of Organic Coatings Using Mechanical Recorders

SCOPE

1.1 These test methods describe the determination of several stages and the rate of dry-film formation of organic coatings using straight line and circular mechanical drying-time recording devices.

1.2 The values stated in inch-pounds are to be regarded as the standard. The SI values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5895 – 01

Standard Test Methods for

Measuring Times of Drying or Curing During Film Formation

1

of Organic Coatings Using Mechanical Recorders

This standard is issued under the fixed designation D 5895; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods describe the determination of several

stages and the rate of dry-film formation of organic coatings

using straight line and circular mechanical drying-time record-

ing devices.

1.2 The values stated in SI are to be regarded as the

standard. The values given in parentheses are provided for

information only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

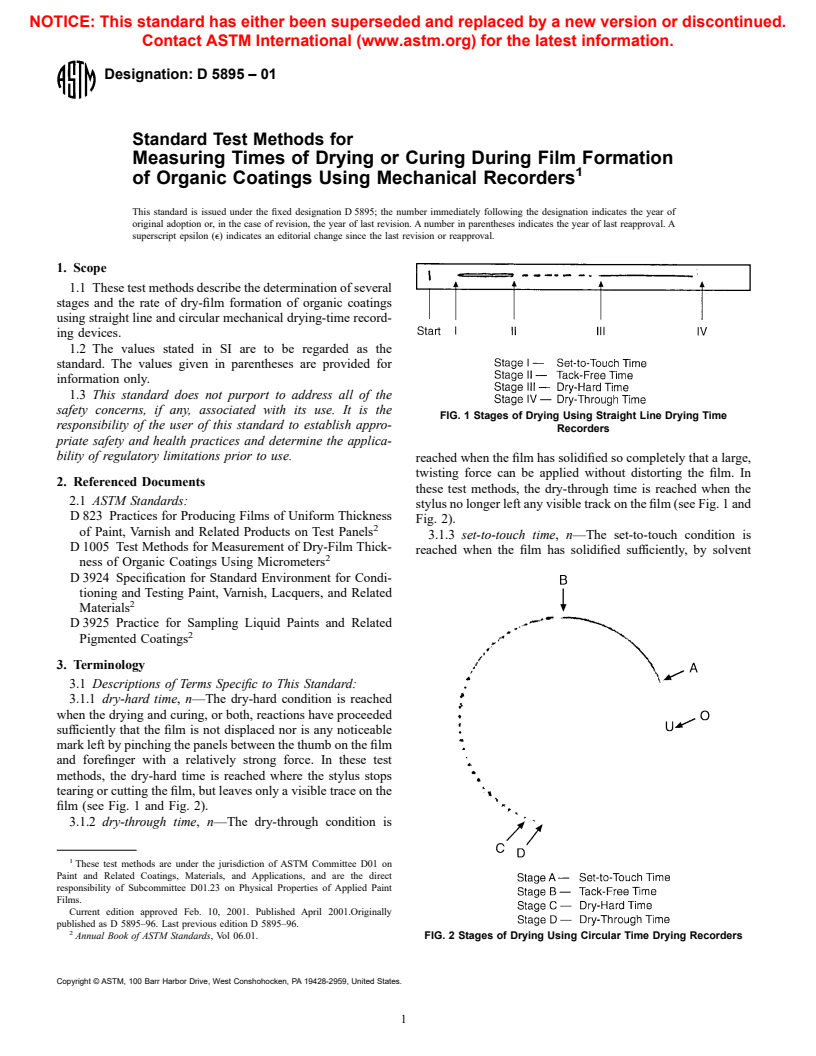

FIG. 1 Stages of Drying Using Straight Line Drying Time

responsibility of the user of this standard to establish appro-

Recorders

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

reached when the film has solidified so completely that a large,

twisting force can be applied without distorting the film. In

2. Referenced Documents

these test methods, the dry-through time is reached when the

2.1 ASTM Standards:

stylus no longer left any visible track on the film (see Fig. 1 and

D 823 Practices for Producing Films of Uniform Thickness

Fig. 2).

2

of Paint, Varnish and Related Products on Test Panels

3.1.3 set-to-touch time, n—The set-to-touch condition is

D 1005 Test Methods for Measurement of Dry-Film Thick-

reached when the film has solidified sufficiently, by solvent

2

ness of Organic Coatings Using Micrometers

D 3924 Specification for Standard Environment for Condi-

tioning and Testing Paint, Varnish, Lacquers, and Related

2

Materials

D 3925 Practice for Sampling Liquid Paints and Related

2

Pigmented Coatings

3. Terminology

3.1 Descriptions of Terms Specific to This Standard:

3.1.1 dry-hard time, n—The dry-hard condition is reached

when the drying and curing, or both, reactions have proceeded

sufficiently that the film is not displaced nor is any noticeable

mark left by pinching the panels between the thumb on the film

and forefinger with a relatively strong force. In these test

methods, the dry-hard time is reached where the stylus stops

tearing or cutting the film, but leaves only a visible trace on the

film (see Fig. 1 and Fig. 2).

3.1.2 dry-through time, n—The dry-through condition is

1

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications, and are the direct

responsibility of Subcommittee D01.23 on Physical Properties of Applied Paint

Films.

Current edition approved Feb. 10, 2001. Published April 2001.Originally

published as D 5895–96. Last previous edition D 5895–96.

2

Annual Book of ASTM Standards, Vol 06.01. FIG. 2 Stages of Drying Using Circular Time Drying Recorders

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5895

A

TABLE 1 Suggested Film Thickness of Materials to be Tested

evaporation or chemical reaction, or both, that it not longer

flows nor sticks to a finger that lightly touches it. In these test Material Dry Film Thickness

methods, the set-to-touch time is reached where a pear-shaped

Oil paints 45 6 2.5 μm (1.8 6 0.2 mil)

Enamels 25 6 2 μm (1.0 6 0.1 mil )

depression appears in the film when the film stops flowing over

Waterborne paints 25 6 2 μm (1.06 0.1 mil)

the path of the recorder’s stylus and leaves a track in the film

Drying oils 25 6 2 μm (1.0 6 0.1 mil)

(see Fig. 1 and Fig. 2).

Varnishes 20 6 2 μm (0.85 6 0.1 mil)

Resin solutions 20 6 2 μm ( 0.85 6 0.1mil )

3.1.4 tack-free time, n—The tack-free condition is reached

Lacquers 12.5 6 2 μm (0.5 6 0.1 mil)

when the film surface has dried or cured (see set-to-touch time)

A

This table is a general guide to be used when there is no specific agreement

so that the film does not adhere to very light objects placed on

between the purchaser and the seller.

it. In these test methods, the tack-free time is reached where the

continuous track in the film ceases and the stylus starts to tear which the coating can be applied at the proper film thickness

the film or leave a discontinuous cutting of the film (see Fig. 1

with resultant good flow and leveling properties.

and Fig. 2). 6.3 Films to be tested should have practical thicknesses

commensurate with those expected under actual usage for the

4. Summary of Test Methods

type under test.

4.1 In Test Method A (Straight Line Recorder), the coating

7. Test Conditions

is appli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.