ASTM F512-95(2001)

(Specification)Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and Fittings for Underground Installation

Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and Fittings for Underground Installation

SCOPE

1.1 This specification covers the requirements for smooth-wall poly(vinyl chloride) conduit and fittings for underground communication and electrical power wire and cables.

1.2 The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 512 – 95 (Reapproved 2001) An American National Standard

Standard Specification for

Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and

1

Fittings for Underground Installation

This standard is issued under the fixed designation F 512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4

1. Scope Poly(Vinyl Chloride) (PVC) Pipe and Fittings

4

F 412 Terminology Relating to Plastic Piping Systems

1.1 This specification covers the requirements for smooth-

wall poly(vinyl chloride) conduit and fittings for underground

3. Terminology

communication and electrical power wire and cables.

3.1 Definitions are in accordance with Terminology F 412

1.2 The values given in parentheses are for information

and abbreviations are in accordance with Terminology D 1600,

only.

unless otherwise specified. The abbreviation for poly(vinyl

1.3 The following safety hazards caveat pertains only to the

chloride) is PVC.

test method portion, Section 8, of this specification: This

standard does not purport to address all of the safety concerns,

4. Classification

if any, associated with its use. It is the responsibility of the user

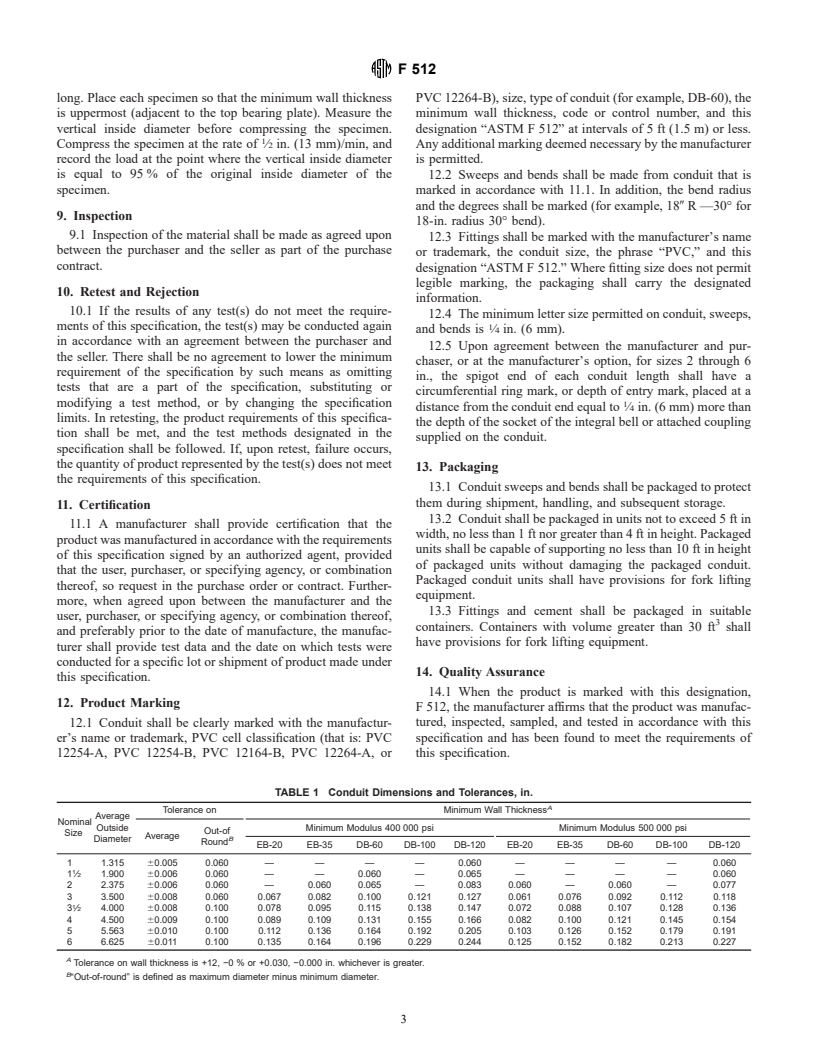

4.1 This specification covers four types of underground

of this standard to establish appropriate safety and health

conduit. There are two having lesser pipe stiffness values,

practices and determine the applicability of regulatory limita-

designed primarily for concrete encased burial (EB), and two

tions prior to use.

with greater pipe stiffness values, designed primarily for direct

burial (DB). The complete designations follow:

2. Referenced Documents

Type EB-20 — Designed to be encased in concrete.

2.1 ASTM Standards:

Type EB-35 — Designed to be encased in concrete.

2

D 618 Practice for Conditioning Plastics for Testing

Type DB-60 — Designed for direct burial without encasement in concrete.

D 1600 Terminology for Abbreviated Terms Relating to Type DB-100 — Designed for direct burial without encasement in concrete.

,

2 3

Type DB-120 — Designed for direct burial without encasement in concrete.

Plastics

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

4.2 This specification covers conduit with integral bells, or

Compounds and Chlorinated Poly(Vinyl Chloride)

with either separate or attached couplings.

4,3

(CPVC) Compounds

4.3 This specification covers molded and fabricated fittings

D 2122 Test Method for Determining Dimensions of Ther-

intended for use with all types of conduit.

4

moplastic Pipe and Fittings

5. Materials

D 2152 Test Method for Adequacy of Fusion of Extruded

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

5.1 Basic Materials—The conduit shall be made of virgin

4

Acetone Immersion

homopolymer PVC compound having a cell classification of

5

D 2412 Test Method for Determination of External Loading

12254-A or B, 12164-B (with a minimum tensile strength of

4

Characteristics of Plastic Pipe by Parallel-Plate Loading

4000 psi (28 MPa)), or 12264-A or B (with a minimum tensile

D 2444 Test Method for Determination of the Impact Re-

modulus of 500 000 psi) as defined in Specification D 1784.

sistance of Thermoplastic Pipe and Fittings by Means of a

Molded fittings shall be made from PVC compound having a

4

Tup (Falling Weight)

cell classification of 12234-B, 12234-C, or 13343-C as defined

D 2466 Specification for Poly(Vinyl Chloride) (PVC) Plas-

in Specification D 1784. Homopolymer PVC compounds must

4

tic Pipe Fittings, Schedule 40

equal or exceed the requirements of the listed cell classification

D 2564 Specification for Solvent Cements for Poly(Vinyl

numbers.

4

Chloride) (PVC) Plastic Piping Systems

5.2 Rework Materials—Rework material from the manufac-

D 2855 Practice for Making Solvent-Cemented Joints With

turer’s own conduit or fittings production may be used by the

same manufacturer, provided that the conduit or fittings pro-

duced meet all of the requirements of this specification.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

5.3 Solvent Cement—The solvent cement shall meet the

Piping and is the direct responsibility of Subcommittee F17.25 on Vinyl Based Pipe.

requirements of Specification D 2564.

Current edition approved Sept. 10, 1995. Published November 1995. Originally

published as F 512 – 77. Last previous edition F 512 – 93.

2

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 08.02.

4 5

Annual Book of ASTM Standards, Vol 08.04. Supporting data are available at ASTM Headquarters. Request RR:F17-1002.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.