ASTM D1541-97

(Test Method)Standard Test Method for Total Iodine Value of Drying Oils and Their Derivatives (Withdrawn 2006)

Standard Test Method for Total Iodine Value of Drying Oils and Their Derivatives (Withdrawn 2006)

SCOPE

1.1 This test method covers the determination of total iodine value.

1.2 This test method is applicable to oils, fatty acids, and bodied oils. While this test method is applicable to all oils and fatty acids and bodied oils, it is particularly useful for those drying oils or derivatives that have conjugated unsaturation.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Sections 6 and 7.

WITHDRAWN RATIONALE

This test method covers the determination of total iodine value and is applicable to oils, fatty acids, and bodied oils. While this test method is applicable to all oils and fatty acids and bodied oils, it is particularly useful for those drying oils or derivatives that have conjugated unsaturation.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in February 2006 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1541–97

Standard Test Method for

Total Iodine Value of Drying Oils and Their Derivatives

This standard is issued under the fixed designation D 1541; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of total 4.1 This test method measures the total amount of unsatura-

iodine value. tion including conjugated unsaturation by addition of bromine

1.2 This test method is applicable to oils, fatty acids, and in a catalyzed bromine solution to the double bonds. The

bodied oils. While this test method is applicable to all oils and amount of bromine absorbed is determined by back titration of

fatty acids and bodied oils, it is particularly useful for those the excess bromine, and then compared to a blank determina-

drying oils or derivatives that have conjugated unsaturation. tion.ThistestmethodispreferredoverTestMethodD 1959for

1.3 This standard does not purport to address all of the products containing conjugated unsaturation.

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of whoever uses this standard to consult and

5.1 Iodine Flasks, glass-stoppered, of 250-mL capacity.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

NOTE 2—The test may be run either in a photographic-type darkroom

Specific hazard statements are given in Sections 6 and 7. 5

under red safelight illumination or in a darkened laboratory in which the

light intensity is adjusted to 0.5 footcandle (5.4 1x) or less. The darkroom

2. Referenced Documents

with red safelights permits the use of clear flasks. If the test shall be run

in a darkened laboratory, low-actinic (amber) flasks, or clear flasks

2.1 ASTM Standards:

protected from light by covering as described below, must be used.

D 1193 Specification for Reagent Water

Alternative modes of using clear flasks in a darkened laboratory are

D 1959 Test Method for Iodine Value of Drying Oils and

described as follows. The type of covering is left to the discretion of the

Fatty Acids

analyst:

(1) Place the clear iodine flask in a suitable metal can so that the neck

3. Terminology

of the flask is level with the can rim. Over the top of the can, place a piece

3.1 Definitions: ofheavycardboard,withaholeprecutinthecentertojustfitovertheneck

of the flask; the top of the flask should just protrude out of the hole in the

3.1.1 total iodine value—a measure of the total unsaturation

cardboard cover. Then run the analysis as usual in a darkened laboratory.

present in fats and oils (Note 1), expressed as the number of

(2) Wrap heavy aluminum foil around the iodine flasks so as to cover

centigrams of iodine equivalent to the unsaturation present in 1

all but the top rim. The foil can be then removed at the latter stage of

g of sample (weight percent of absorbed iodine).

titration. Run the analysis in a darkened laboratory.

(3) Place the flask in an opaque bag that has a drawstring neck.The rim

NOTE 1—When the total iodine value is determined on oils having

of the iodine flask should just protrude from the bag to allow addition of

conjugated systems, the result is a measure of the total unsaturation. This

reagent.

is in contrast to the iodine value method described in Test Method D 1959

which determines only part of the total unsaturation of conjugated

5.2 Graduates, 5, 25, and 50-mL capacity.

systems.

5.3 Volumetric Pipets, 10, 20, and 50-mL capacity.

NOTE 3—The bulb of the 50-mL pipet should be covered with alumi-

1 num foil.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings and Materials and is the direct responsibility of Subcommittee

5.4 Buret, 50-mL capacity graduated in 0.1-mL divisions.

D01.32 on Drying Oils.

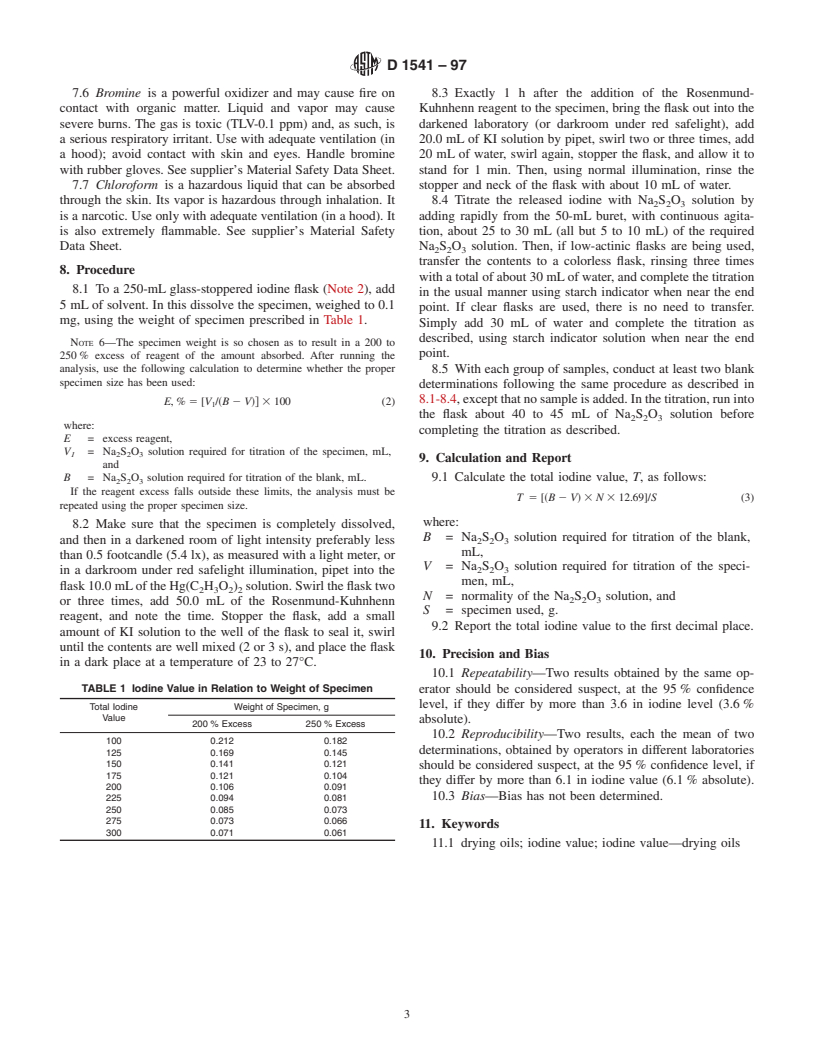

5.5 Weighing Device for Sample—A small, wide-mouth

Current edition approved Aug. 10, 1997. Published October 1997. Originally

e1

vial, fitted with a cork stopper and medicine dropper, may be

published as D 1541 – 58 T. Last previous edition D 1541 – 86 (1995) .

This procedure is essentially identical with that of Planck, R. W., Pack, F. C.,

and Goldblatt, L. A., as published in the Journal, Am. Oil Chemists’ Soc., Vol 30,

1953, p. 417, using the Rosenmund-Kuhnhenn reagent. Previously Benham, G. H., The sole source of supply of the red safelights Wratten No. 1 known to the

and Klee, L. J., published data on the use of this reagent for determining committee at this time is Eastman Kodak Co., 343 State St. Rochester, NY 14650.

unsaturation in the Journal, Am. Oil Chemists’ Soc., Vol 27, 1950, pp. 127–130. If you are aware of alternative suppliers, please provide this information to ASTM

Annual Book of ASTM Standards, Vol 11.01. International Headquarters. Your comments will receive careful consideration at a

4 1

Annual Book of ASTM Standards, Vol 06.03. meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1541–97

NOTE 4—The stock bottle containing the Rosenmund-Kuhnhenn re-

used to weigh the sample by difference. Alternatively, the

agent should be kept stoppered when it is not in use to minimize loss of

sample may be weighed directly into a 1-mLmicrobeaker, and

bromine.

carefully dropped into the iodine flask.

5.6 Photoelectric Light Meter—Anysuitablemeterformea- 6.8 Sodium Thiosulfate, Standard Solution (0.1 N)

suring room illumination in footcandles. If a darkroom and red

(Precaution—See 7.1-7.7)—Dissolve 24.8 g of sodium thio-

safelight illumination are to be used, a meter is not required. sulfate (Na S O ·5H O) in water and dilute to 1 L. Add 0.5 g

2 2 3 2

5.7 Erlenmeyer Flasks, three, 250-mL. of sodium carbonate (Na CO ) and a few drops of chloroform,

2 3

5.8 Volumetric Flasks, four, 1-L, glass-stoppered. as a preservative. Standardize against potassium iodate (KIO )

5.9 Bottle, Amber, one, 4-L, glass-stoppered. primary standard as follows: Weigh, to the nearest 0.1 mg, into

a 250-mL Erlenmeyer flask about 0.12 to 0.17 g of the KIO

6. Reagents

and dissolve in 50 mL of water.Add2gofKI,andas soon as

6.1 Purity of Reagents—Reagent grade chemicals shall be this is dissolved, 1 mLof concentrated hydrochloric acid (HCl,

used in all tests. Unless otherwise indicated, it is intended that sp gr 1.19) diluted to 10 mL. Titrate the liberated iodine

all reagents shall conform to the specifications of the Commit- immediately with the Na S O solution, using starch indicator

2 2 3

tee onAnalytical Reagents of theAmerican Chemical Society, near the end point. Calculate the normality of the Na S O

2 2 3

where such specifications are available. Other grades may be solution as follows:

used, provided it is first ascertained that the reagent is of

Normality 5 W/~0.03567 3 V! (1)

sufficiently high purity to permit its use without lessening the

accuracy of the determination. where:

W = KIO used, g, and

6.2 Purity of Water—Unless otherwise indicated, references 3

V =Na S O solution required for titration of the KIO ,

to water shall be understood to mean reagent water conforming 2 2 3 3

mL.

to Type I of Specification D 1193.

6.3 Solvents: isooctane or fresh cyclohexane to replace long

NOTE 5—The Na S O may be standardized against potassium dichro-

2 2 3

used carbon tetrachloride now banned as hazardous

mate (K Cr O ), if desired, as described in Test Method D 1959.

2 2 7

(Precaution—See 7.1).

6.9 Starch Indicator Solution—Make a paste with 10 g of

)—(Precaution—See 7.1)

6.4 Carbon Tetrachloride (CCl

starch in cold water. Add to this 1 L of boiling water, stir

6.5 Mercuric Acetate Solution—Dissolve 25 g of mercuric

rapidly, and cool. Salicylic acid (1.25 g/L) may be added as a

acetate (Hg(C H O ) )(Precaution—See 7.2) in glacial acetic

2 3 2 2

preservative. If long storage is required, keep the solution in a

acid (CH COOH) and dilute to 1 L with glacial acetic acid.

refrigerator at 40 to 50°F (4 to 10°C). Prepare fresh indicator

(Precaution—See 7.3)

when the end point of the titration from blue to colorless fails

6.6 Potassium Iodide Solution (150 g/L)—Dissolve150gof

to be sharp.

potassium iodide (KI) in water and dilute to 1 L.

6.7 Rosenmund-Kuhnhenn Reagent—Place 40 mL of gla-

7. Hazards

cial acetic acid (CH COOH) in each of three 250-mL

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.