ASTM D7331-07

(Practice)Standard Practice for Sewn Products Marker Data Interchange

Standard Practice for Sewn Products Marker Data Interchange

SIGNIFICANCE AND USE

This practice is intended to allow marker data exchange between nesting software or CAM systems.

The pieces description, exported by a CAD system, is dedicated to CAM systems.

SCOPE

1.1 This practice describes a format for transferring marker data from a CAD marker software system to another or to a CAM software system.

1.2 This practice does not support curve interpolation or definitions. All curves are represented by discrete vectors and are dependent on the resolution of the CAD software

1.3 This practice is concerned in limiting differences when processing the same data on different CAD systems.

1.4 This practice is not intended to represent the dimension relationships between pattern pieces or between pattern sizes, or the correspondence between 2D or 3D sewn product pattern piece geometries.

1.5 This practice does not specify the file format for the marker data exchange.

1.6 A consistent XML implementation of this practice is recommended.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7331 – 07

Standard Practice for

Sewn Products Marker Data Interchange

This standard is issued under the fixed designation D7331; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3 The following terms are new terms related to Sewn

Products Automation:

1.1 This practice describes a format for transferring marker

3.3.1 absolute pattern matching, n—nesting specification

data from a CAD marker software system to another or to a

where the nested piece position shall have a specified position

CAM software system.

in regard to a repeat line.

1.2 This practice does not support curve interpolation or

3.3.2 bundle, n—set of nested pieces that are intended to be

definitions. All curves are represented by discrete vectors and

processed together because they are issued from the same

are dependent on the resolution of the CAD software

graded style and are parts of the same end user’s product.

1.3 This practice is concerned in limiting differences when

3.3.2.1 Discussion—All bundle pieces are to be cut on the

processing the same data on different CAD systems.

same material.

1.4 This practice is not intended to represent the dimension

3.3.3 bundle group, n—setofbundlesthatareusedtodefine

relationships between pattern pieces or between pattern sizes,

constraints.

or the correspondence between 2D or 3D sewn product pattern

3.3.3.1 Discussion—Abundlemaybepartofseveralbundle

piece geometries.

groups for several different constraints. Example: pockets from

1.5 This practice does not specify the file format for the

the jacket and the trousers of a suit may have a mutual rotation

marker data exchange.

constraint.

1.6 A consistent XML implementation of this practice is

3.3.4 constraint, n—description of the behavior that one or

recommended.

severalnestedpieceofthemarkershouldfollowduringmarker

1.7 This standard does not purport to address all of the

processing.

safety concerns, if any, associated with its use. It is the

3.3.5 effıciency, n—area of the produced pieces located on

responsibility of the user of this standard to establish appro-

the up side of the fabric, including blocking, versus area of the

priate safety and health practices and determine the applica-

marker, defined by its length and its width.

bility of regulatory limitations prior to use.

3.3.5.1 Discussion—Pieces area inside fusing blocks is

2. Referenced Documents

considered when calculating efficiency. Fusing blocks area is

not considered.

2.1 ASTM Standards:

3.3.6 fabric category, n—identifies the category to which

D6963 Terminology Relating to Sewn ProductsAutomation

the fabric belongs.

3. Terminology

3.3.6.1 Discussion—The category allows the definition of

fabric groups that will be used for pattern matching constraints

3.1 For all terminology related to Sewn Products Automa-

definitions.

tion, see Terminology D6963.

3.3.7 fabric type, n—characteristicofapatternpieceusedto

3.2 The following terms are relevant to this standard: drill

identify the material type the piece has to be made of.

hole, grainline, line, notch, style.

3.3.8 flip, n—transformation of a geometry that gives the

symmetryofthegradedpiecegeometryeitheracrosstheXaxis

or across the Y axis or across both, that is equivalent to a 180

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

degrees rotation.

is the direct responsibility of Subcommittee D13.66 on Sewn Product Automation.

3.3.8.1 Discussion—The X andYaxis to consider are those

Current edition approved Dec. 1, 2007. Published January 2008. DOI: 10.1520/

D7331-07.

from the graded piece referential.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.3.9 graded piece, n—explicit description of one or more

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

specificsizesofapatternpiece,andrelatedinformationusedto

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. produce it.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7331 – 07

FIG. 1 Absolute Matching

FIG. 2 Unflipped and Flipped Geometries

3.3.10 graded piece repetition, n—instance of a graded 3.3.16.1 Discussion—A nested piece is an instance of a

piece in a graded style. graded piece repetition and contains geometrical description

3.3.10.1 Discussion—A graded piece may have several and positioning parameters.

graded piece repetitions if its geometry is repeated several 3.3.17 pattern piece, n—design level description of an

times in the graded style. A graded piece repetition can be: elementary part of a sewn product.

3.3.10.2 unflipped—the repetition geometry is the graded 3.3.17.1 Discussion—The Pattern piece is a design entity,

piece geometry. not suited for production. It is not included in the marker.

3.3.10.3 X flipped—the repetition geometry is obtained by 3.3.18 plaid fabric, n—fabric which has repeat lines in both

an X flip of the graded piece geometry. the X and Y directions.

3.3.10.4 Y flipped—the repetition geometry is obtained by a 3.3.19 plot line, n—internal line intended to be plot.

Y flip of the graded piece geometry.

3.3.20 repeat line, n—line that is a characteristic of a

3.3.10.5 XY flipped—the repetition geometry is obtained by structured fabric and that is periodically repeated at a known

a Y flip and an X flip of the graded piece geometry. increment throughout the whole material.

3.3.11 graded style, n—explicit description of one or more 3.3.20.1 Discussion—An X repeat line is parallel to the X

specific sizes of a style, and related information used for axis and is repeated along theYdirection. Similarly, aYrepeat

production. line is parallel to the Y axis and is repeated along the X

3.3.11.1 Discussion—Agraded style is composed of graded direction.

pieces.

3.3.21 relative pattern matching, n—nesting specification

3.3.12 marker, n—main object that can be exchanged using where nested pieces positions are mutually constrained to have

this practice and that contains all the theoretical information the same offset (non-symmetrical matching) or opposite offset

needed to process nesting and production of a set of nested (symmetrical matching) in regard to a repeat line.

pieces on a flat material.

3.3.22 shrinkage, n—dimensional reduction that a material

3.3.13 markerOrder, n—set of data containing all necessary will undergo in the part of the processing that will follow the

information to nest a set of bundles. cutting phase.

3.3.14 material, n—description of the material structure. It 3.3.22.1 Discussion—Two-dimensional anisotropic shrink-

includes material geometric information and optional repeat age is modeled by two one-dimensional coefficients (X shrink-

lines description. age and Y shrinkage) that represent respectively the reduction

3.3.15 mutual constraint, n—constraint that applies to sev- factorthatwilllaterapplyalongeachoftheXandYdirections.

eral nested pieces in such way that all these nested pieces must

3.3.23 splice mark, n—geometrical information requested

respect this constraint in the same way. to start the spreading process over again at correct position

3.3.16 nested piece, n—the smallest entity that can be after it has been interrupted due to material physical defect

nested. Can be nested or not. processing.

D7331 – 07

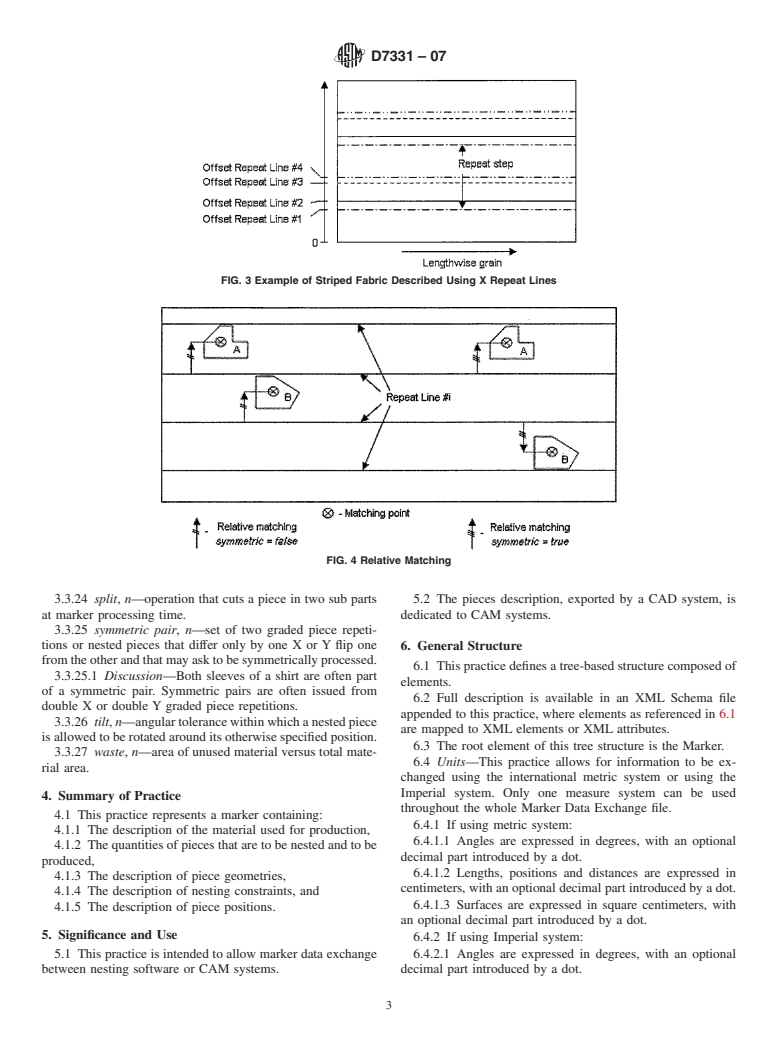

FIG. 3 Example of Striped Fabric Described Using X Repeat Lines

FIG. 4 Relative Matching

3.3.24 split, n—operation that cuts a piece in two sub parts 5.2 The pieces description, exported by a CAD system, is

at marker processing time. dedicated to CAM systems.

3.3.25 symmetric pair, n—set of two graded piece repeti-

tions or nested pieces that differ only by one X or Y flip one 6. General Structure

fromtheotherandthatmayasktobesymmetricallyprocessed.

6.1 This practice defines a tree-based structure composed of

3.3.25.1 Discussion—Both sleeves of a shirt are often part

elements.

of a symmetric pair. Symmetric pairs are often issued from

6.2 Full description is available in an XML Schema file

double X or double Y graded piece repetitions.

appended to this practice, where elements as referenced in 6.1

3.3.26 tilt, n—angulartolerancewithinwhichanestedpiece

are mapped to XML elements or XML attributes.

is allowed to be rotated around its otherwise specified position.

6.3 The root element of this tree structure is the Marker.

3.3.27 waste, n—area of unused material versus total mate-

6.4 Units—This practice allows for information to be ex-

rial area.

changed using the international metric system or using the

Imperial system. Only one measure system can be used

4. Summary of Practice

throughout the whole Marker Data Exchange file.

4.1 This practice represents a marker containing:

6.4.1 If using metric system:

4.1.1 The description of the material used for production,

6.4.1.1 Angles are expressed in degrees, with an optional

4.1.2 The quantities of pieces that are to be nested and to be

decimal part introduced by a dot.

produced,

6.4.1.2 Lengths, positions and distances are expressed in

4.1.3 The description of piece geometries,

centimeters, with an optional decimal part introduced by a dot.

4.1.4 The description of nesting constraints, and

6.4.1.3 Surfaces are expressed in square centimeters, with

4.1.5 The description of piece positions.

an optional decimal part introduced by a dot.

5. Significance and Use

6.4.2 If using Imperial system:

5.1 This practice is intended to allow marker data exchange 6.4.2.1 Angles are expressed in degrees, with an optional

between nesting software or CAM systems. decimal part introduced by a dot.

D7331 – 07

6.4.2.2 Lengths, positions and distances are expressed in 7.2.6 applicationVersion—(optional)Versionoftheapplica-

inches, with an optional decimal part introduced by a dot. tion that generated the marker file.

6.4.2.3 Surfaces are expressed in square inches, with an 7.3 Marker Attributes:

optional decimal part introduced by a dot. 7.3.1 units—Value is either “Metric” or “Imperial”.

7.3.2 effıciency—(optional) Value of the current efficiency

7. Marker

when at least one piece is nested.

7.3.3 waste—(optional) Value of the current waste when at

7.1 MarkerName—Name of the marker concerned by this

least one piece is nested.

practice.

7.3.4 cutDistance—(optional) Sum of all cut lines lengths.

7.2 Markerlnformation—Information about marker genera-

7.3.5 plotDistance—(optional) Sum of all plot lines lengths.

tion.

7.3.6 pieceArea—(optional)Area of all cut pieces including

7.2.1 userName—(optional) Name of the user who gener-

blocking.

ated the marker file.

7.3.7 notchCount—(optional) Number of notches.

7.2.2 creationDate—(optional) Creation date of the marker.

7.2.3 modificationDate—(optional) Date of the last marker 7.3.8 drillCount—(optional) Number of drills.

7.3.9 styleCount—(optional) Number of styles.

modification.

7.2.4 platform—(optional) Vendor name of the application 7.3.10 bundleCount—(optional) Number of bundles.

that generated the marker file. 7.3.11 pieceCount—(optional) Number of pieces.

7.2.5 application—(optional) Application name that gener- 7.3.12 addedPieceCount—(optional) Number of added

ated the marker file. pieces.

FIG. 5 Marker High Level Schema

D7331 – 07

7.3.13 unplacedPieceCount—(optional) Number of un- 8.3.4.1 Discussion—In case of tubular or book fold spread-

placed pieces. ing, marker width represents the half of the fabric width.

7.3.14 placedPieceCount—(optional) Number of placed

8.3.5 xShrinkage—(optional) Percentage of shrinkage that

pieces.

the fabric would undergo along the X axis after being cut.

7.3.15 sizeCount—(optional) Number of different sizes.

8.3.6 yShrinkage—(optional) Percentage of shrinkage that

7.3.16 achievedLength—(optional) Marker length.

the fabric would undergo along the Y axis after being cut.

7.4 MarkerOrder (see Section 8).

8.3.7 spreadCharacteristic—(optional) Type of spreading.

7.5 GradedStyleList (see Section 9).

Only the following values are allowed: “SinglePly,” “FaceTo-

7.6 BundleList (see Section 11).

Face,”“BookFoldTop,”“BookFoldBottom”or“Tubular.”Ifno

7.7 NestedPieceList (see Section 12).

spreadCharacteristic is specified, “Single Ply” is assumed.

7.8 SpliceMarkList (see Section 13).

8.3.8 fabricCategory—Material fabric category.

7.9 NotchDefinition (see Section 14).

8.3.9 PrimaryRepeatLine—(optional) Description of one

7.10 DrillDefinition (see Section 15).

main repeat line. There are at most two main repeat lines.

7.11 ConstraintList (see Section 16).

8.3.9.1 step—Repetition length of the PrimaryRepeatLine,

8. MarkerOrder

perpendicular to it.

8.3.9.2 angle—Angle between x axis and the repeat line.

8.1 The MarkerOrder contains the specification of the ma-

terial,thedescriptionofthebundlesthataretobeproducedand 8.3.9.3 repeatName—Unique name of this repeat line.

their quantities.

8.3.9.4 x,y—Coordinates of a point that belongs to the

8.1.1 costingMarker—(optional) Boolean value indicating

PrimaryRepeatLine.

whether or not the marker is dedicated to cost evaluation.

8.3.9.5 RepeatLine—(optional)Repeatlinesthatareparallel

8.1.2 automaticMarker—(optional) Boolean value indicat-

to their associated PrimaryRepeatLine. They are defined from

ing whether or not the marker has been generated by an

the PrimaryRepeatLine.

automatic nesting engine.

8.3.9.6 offset—Shortest distance between the PrimaryRe-

8.1.3 effıciencyGoal—(optional) Value of the targeted effi-

peatLine and the repeat line.

ciency.

8.3.9.7 repeatName—Unique name of this repeat line.

8.1.4 lengthGoal—(optional) Value of the targeted marker

8.3.10 MaterialBuffering—(optional) Buffering values

length.

added on each edge of the material. These values modify the

8.2 OrderName—Name of the marker order.

nesting area dimensions.

8.3 MarkerMaterial—Description of the material.

8.3.10.1 upBuffer—(optional) Buffer value on up material

8.3.1 name—(optional) Name of the material.

edge.

8.3.2 description—(optional) Comment used to describe the

8.3.10.2 downBuffer—(optional) Buffer value on down ma-

material.

terial edge.

8.3.3 length—(optional) Maximum marker length.

8.3.4 width—Width of the marker in the crosswise grain 8.3.10.3 leftBuffer—(optional) Buffer value on left material

direction when the material is spread. edge.

FIG. 6 MarkerOrder Schema

D7331 – 07

8.3.10.4 rightBuffer—(optional) Buffer value on right ma- 9.2.5 PieceName—Name of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.