ASTM D581-07

(Specification)Standard Specification for Glass Fiber Greige Braided Tubular Sleeving

Standard Specification for Glass Fiber Greige Braided Tubular Sleeving

ABSTRACT

This specification covers the requirements for continuous glass filament greige braided tubular sleeving and is suitable for use as electrical insulation and for structural and mechanical applications. Ultimate users will be assisted by designating the types of these products that are typical in the industry. Glass fiber greige braided tubular sleeving is produced in one type and two styles within that type and uses yarns designated namely Type G, Style A, and Style B. All yarns for braided tubular sleeving shall be electrical classification, (E glass), continuous filament glass yarns, and shall fall within the chemical composition that is utilized for general applications as described. The fiber shall be free of any free alkali metal oxides, such as soda or potash, and foreign particles, dirt, and other impurities. The primary twist in the singles strands shall be “Z” twist and the final twist in the plied yarns shall be “S” twist. Other properties such as yarn number, strand construction, twist level, ends per carrier, carrier number, picks per unit length, inside diameter, wall thickness, length per unit mass, length per package, and ignition loss shall conform to the requirements specified. The braided tubular sleeving shall be generally uniform in quality and condition, clean, smooth, and free of foreign particles and defects detrimental to fabrication, appearance, or performance.

SCOPE

1.1 This specification covers the requirements for continuous glass filament greige braided tubular sleeving and is suitable for use as electrical insulation and for structural and mechanical applications.

1.2 This specification is intended to assist ultimate users by designating the types of these products that are typical in the industry.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D581 – 07

Standard Specification for

1

Glass Fiber Greige Braided Tubular Sleeving

This standard is issued under the fixed designation D581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3775 Test Method for Warp (End) and Filling (Pick)

Count of Woven Fabrics

1.1 This specification covers the requirements for continu-

D4963 Test Method for Ignition Loss of Glass Strands and

ous glass filament greige braided tubular sleeving and is

Fabrics

suitable for use as electrical insulation and for structural and

D7018 Terminology Relating to Glass Fiber and Its Prod-

mechanical applications.

ucts

1.2 This specification is intended to assist ultimate users by

2.2 ANSI Standard:

designating the types of these products that are typical in the

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

industry.

3

Attributes

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

3.1 For all terminology related to D13.18, Glass Fiber and

system shall be used independently of the other. Combining

Its Products, see Terminology D7018.

values from the two systems may result in nonconformance

3.1.1 The following terms are relevant to this standard”

with the standard.

braid, carrier, continuous filament yarn, greige goods, sleeving,

1.4 This standard does not purport to address all of the

and tubing.

safety concerns, if any, associated with its use. It is the

3.2 For all other terminology related to textiles, see Termi-

responsibility of the user of this standard to establish appro-

nology D123.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Tubing Classifications

2. Referenced Documents 4.1 Glass fiber greige braided tubular sleeving is produced

2 in one type and two styles within that type and uses yarns

2.1 ASTM Standards:

designated as directed in Specification D578. The standard

D123 Terminology Relating to Textiles

type and styles are:

D350 Test Methods for Flexible Treated Sleeving Used for

4.1.1 Type G—Glass fiber greige braided tubular sleeving.

Electrical Insulation

4.1.2 Style A—Glass fiber greige braided tubular sleeving

D578 Specification for Glass Fiber Strands

having a nominal wall thickness of 0.20 mm (0.008 in.).

D579 Specification for Greige Woven Glass Fabrics

4.1.3 Style B—Glass fiber greige braided tubular sleeving

D1059 Test Method for Yarn Number Based on Short-

having a nominal wall thickness of 0.15 mm (0.006 in.).

Length Specimens

D1423 Test Method for Twist in Yarns by Direct-Counting

REQUIREMENTS

D1776 Practice for Conditioning and Testing Textiles

D1907 Test Method for Linear Density of Yarn (Yarn

5. Material

Number) by the Skein Method

5.1 All yarns for braided tubular sleeving shall be electrical

D3773 Test Methods for Length of Woven Fabric

classification, (E glass), continuous filament glass yarns, and

shall fall within the chemical composition that is utilized for

1 general applications as described in Specification D578, Sec-

This specification is under the jurisdiction of ASTM Committee D13 on

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and tion 4.2.2. Filament size shall be agreed upon between pur-

its Products.

chaser and supplier and shall meet the requirements of Speci-

Current edition approved Jan. 1, 2007. Published January 2007. Originally

fication D578, Table 1 Letter Designations for Glass Strand

approved in 1940 T. Last previous edition approved in 1999 as D581 – 99. DOI:

Filament Diameters.

10.1520/D0581-07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 11 W. 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

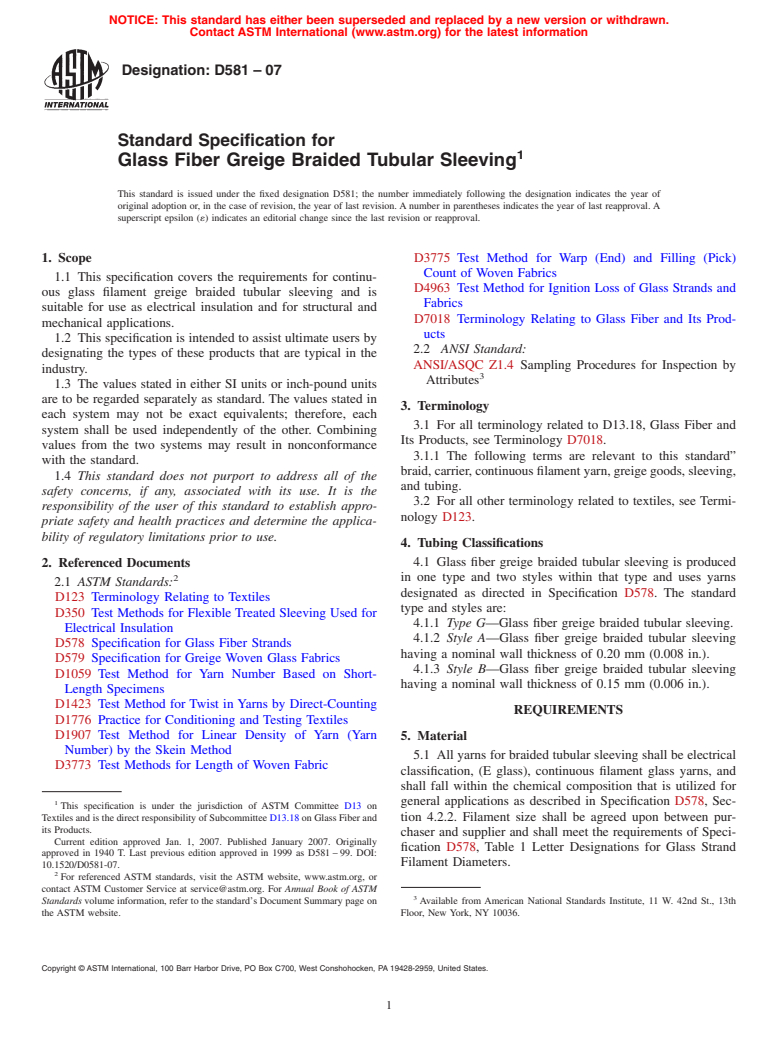

---------------------- Page: 1 ----------------------

D581 – 07

5.1.1 The fiber shall be free of any free alkali metal oxides, 13. Inside Diameter

such as soda or potash, and foreign particles, dirt, and other

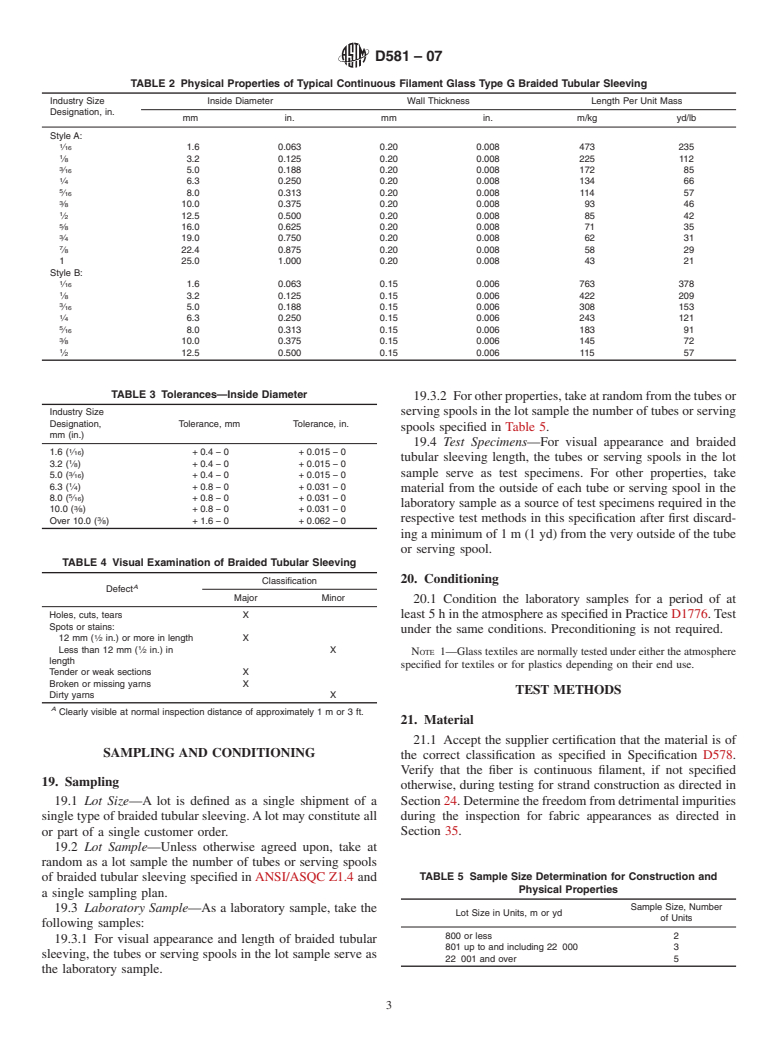

13.1 For braided tubular sleeving listed in Table 2, the

impurities.

nominal inside diameter shall conform to the requirements of

Table 2. For sleeving not listed in Table 2, the nominal inside

6. Yarn Number

diameter shall be agreed upon between the purchaser

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.