ASTM C110-02a

(Test Method)Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone

Standard Test Methods for Physical Testing of Quicklime, Hydrated Lime, and Limestone

SCOPE

1.1 These test methods cover physical testing of quicklime and hydrated lime, and of limestone not otherwise covered in ASTM standards.

Note 1—Quicklime and hydrated lime have a high affinity for moisture and carbon dioxide. Caution should be taken to protect both hydrated and quicklime during sampling, storage, and testing (see Practice C 50).

1.2 The test procedures appear in the following order:SectionAir Entrainment 13Apparent Loose Density of Hydrated Lime, Pulverized Quicklime, and Limestone 16Apparent Packed Density of Hydrated Lime, Pulverized Quicklime, and Limestone 17Autoclave Expansion of Hydrated Lime 8Dry Brightness of Pulverized Limestone 15Dry Screening by Air Jet Sieve 19Fineness of Pulverized Quicklime and Hydrated Lime by Air Permeability18Limestone Grindability 20Particle Size of Pulverized Limestone 14Plasticity of Lime Putty 7Popping and Pitting of Hydrated Lime 9Residue and Sieve Analysis 5Settling Rate of Hydrated Lime11Slaking Rate of Quicklime 12Specific Gravity of Hydrated Lime Products21Standard Consistency of Lime Putty 6Water Retention of Hydrated Lime 10Wet Sieve Analysis of Agricultural Liming Materials22

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 110 – 02a

Standard Test Methods for

Physical Testing of Quicklime, Hydrated Lime, and

1

Limestone

This standard is issued under the fixed designation C 110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods cover physical testing of quicklime 2.1 ASTM Standards:

and hydrated lime, and of limestone not otherwise covered in C 25 Test Methods for Chemical Analysis of Limestone,

2 3

ASTM standards. Quicklime, and Hydrated Lime

3

C 28 Specification for Gypsum Plasters

NOTE 1—Quicklime and hydrated lime have a high affinity for moisture

C 50 Practice for Sampling, Inspection, Packaging, and

and carbon dioxide. Caution should be taken to protect both hydrated and

3

Marking of Lime and Limestone Products

quicklime during sampling, storage, and testing (see Practice C 50).

C 51 Terminology Relating to Lime and Limestone (as used

1.2 The test procedures appear in the following order:

3

by the Industry)

Section

3

C 91 Specification for Masonry Cement

C 109/C 109M Test Method for Compressive Strength of

Air Entrainment 13

Apparent Loose Density of Hydrated Lime, Pulverized

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Quicklime, and Limestone 16

3

Specimens)

Apparent Packed Density of Hydrated Lime, Pulverized

Quicklime, and Limestone 17 C 117 Test Method for Material Finer than 75–Micrometre

4

Autoclave Expansion of Hydrated Lime 8

(No. 200) Sieve in Mineral Aggregates by Washing

Dry Brightness of Pulverized Limestone 15

C 136 Test Method for Sieve Anlaysis of Fine and Coarse

Dry Screening by Air Jet Sieve 19

4

Fineness of Pulverized Quicklime and Hydrated Lime by Air Aggrgates

3

Permeability 18

C 150 Specification for Portland Cement

Limestone Grindability 20

C 185 Test Method for Air Content of Hydraulic Cement

Particle Size of Pulverized Limestone 14

3

Plasticity of Lime Putty 7

Mortar

3

Popping and Pitting of Hydrated Lime 9

C 188 Test Method for Density of Hydraulic Cement

Residue and Sieve Analysis 5

C 204 Test Method for Fineness of Hydraulic Cement by

Settling Rate of Hydrated Lime 11

3

Slaking Rate of Quicklime 12 Air Permeability Apparatus

Specific Gravity of Hydrated Lime Products 21

C 207 Specification for Hydrated Lime for Masonry Pur-

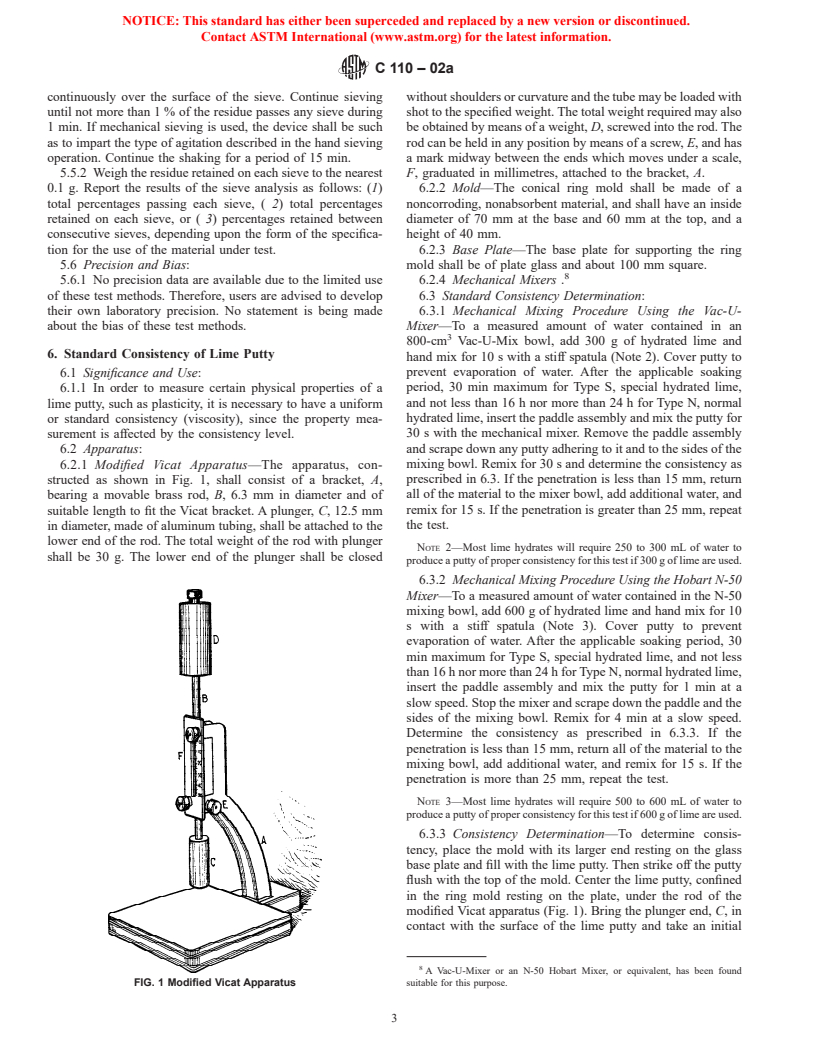

Standard Consistency of Lime Putty 6

3

poses

Water Retention of Hydrated Lime 10

Wet Sieve Analysis of Agricultural Liming Materials 22 C 230 Specification for Flow Table for Use in Tests of

3

Hydraulic Cement

1.3 The values stated in SI units are to be regarded as the

C 305 Practice for Mechanical Mixing of Hydraulic Cement

standard.

3

Pastes and Mortars of Plastic Consistency

1.4 This standard does not purport to address all of the

C 430 Test Method for Fineness of Hydraulic Cement by

safety concerns, if any, associated with its use. It is the

3

the 45-μm (No. 325) Sieve

responsibility of the user of this standard to establish appro-

C 472 Test Methods for Physical Testing of Gypsum, Gyp-

priate safety and health practices and determine the applica-

3

sum Plasters and Gypsum Concrete

bility of regulatory limitations prior to use.

C 670 Practice for Preparing Precision and Bias Statements

4

for Test Methods for Construction Materials

1

These test methods are under the jurisdiction of ASTM Committee C07 on C 702 Practice for Reducing Field Samples of Aggregate to

4

Lime and are the direct responsibility of Subcommittee C07.06 on Physical Tests.

Testing Size

Current edition approved Dec. 10, 2002. Published February 2003. Originally

approved in 1934. Last previous edition approved in 2002 as C 110–02.

2

For tests on limestone as aggregate, see Vol 04.02 of the Annual Book of ASTM

3

Standards. For tests on limestone as building stone, see Vol 04.05 of the Annual Annual Book of ASTM Standards, Vol 04.01.

4

Book of ASTM Standards. Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C110–02a

3

C 778 Specification for Standard Sand 5.2.3 Spray Nozzle conforming to the requirements of Test

7

Method C 430.

C 1005 Specification for Reference Masses and Devices for

5.2.4 Pressure Gage shall be 3-in. (75-mm) minimum

Determining Mass and Volume for Use in the Physical

3

diameter, and shall be g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.