ASTM E2459-05(2011)

(Guide)Standard Guide for Measurement of In-Duct Sound Pressure Levels from Large Industrial Gas Turbines and Fans

Standard Guide for Measurement of In-Duct Sound Pressure Levels from Large Industrial Gas Turbines and Fans

SIGNIFICANCE AND USE

All noise control features associated with the inlet or exhaust of large industrial fans and gas turbines are, or should be, based upon inlet or exhaust sound power levels in octave bands of frequency. Sound power levels are not directly measurable, however, so they must be calculated indirectly, using estimated or measured duct interior sound pressure levels.

Estimated in-duct sound pressure level may be obtained by measuring exterior airborne sound pressure levels and applying a transfer function representing the transmission loss of the duct wall. Significant uncertainties are associated with such a procedure, suggesting the need for this guide.

Estimated in-duct sound pressure level may be obtained by measuring exit plane sound pressure levels and applying a transfer function consisting of the insertion loss through the gas path, including the insertion loss of any silencers. Significant uncertainties are associated with such a procedure, suggesting the need for this guide.

This guide purports to measure the in-duct sound pressure level directly using type 1 instrumentation per ANSI S1.4 or S1.43. It is limited, however, to the determination of the sound pressure level at the location of the port only and will include the effects of duct acoustical modes, as well as an unknown degree of turbulence and other flow related effects. Methodologies may be devised by the user to minimize such effects. As a rule, the larger the number of test ports used, the better will be the averaged data. Although not prescribed by this guide, cross-channel coherence analysis is also available to the analyst, using ports at different locations along the duct axis, which may yield improvements in data quality.

This guide is intended for application to equipment in-situ, to be applied to large fans and gas turbines having inlet or exhaust ducts whose cross sectional areas are approximately four (4) square meters, or more, and are therefore not amenable to laboratory testing. Al...

SCOPE

1.1 This guide is intended to provide a simple and consistent procedure for the in-situ field measurement of in-duct sound pressure levels in large low pressure industrial air ducts, such as for gas turbines or fans, where considerations such as flow velocity, turbulence or temperature prevent the insertion of sound pressure sensors directly into the flow. This standard guide is intended for both ambient temperature intake air and hot exhaust gas flow in ducts having cross sections of four (4) square meters, or more.

1.2 The described procedure is intended to provide a repeatable and reproducible measure of the in-duct dynamic pressure level at the inlet or exhaust of the gas turbine, or fan. The guide is not intended to quantify the “true” sound pressure level or sound power level. Silencers, as well as Waste Heat Boilers, must be designed using the in-duct sound power level as the basis. Developing the true sound power level based on in-duct measurements of true sound pressure within a complete operating system is complex and procedures are developmental and often proprietary.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Extreme caution is mandatory when working near hot exhaust gas systems and appropriate safety precautions such as the installation of quick acting isolation valves are recommended.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2459 − 05(Reapproved 2011)

Standard Guide for

Measurement of In-Duct Sound Pressure Levels from Large

Industrial Gas Turbines and Fans

This standard is issued under the fixed designation E2459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standards:

S1.4Specification for Sound Level Meters

1.1 Thisguideisintendedtoprovideasimpleandconsistent

S1.43Specification for Integrating Averaging Sound Level

procedure for the in-situ field measurement of in-duct sound

Meters

pressure levels in large low pressure industrial air ducts, such

as for gas turbines or fans, where considerations such as flow

3. Terminology

velocity, turbulence or temperature prevent the insertion of

sound pressure sensors directly into the flow. This standard 3.1 Definitionsoftheacousticaltermsusedinthisguideare

guide is intended for both ambient temperature intake air and

given in Terminology C634.

hot exhaust gas flow in ducts having cross sections of four (4)

3.2 Definitions of Terms Specific to This Standard:

square meters, or more.

3.2.1 anechoic tube—a constant diameter tube of sufficient

1.2 Thedescribedprocedureisintendedtoprovidearepeat- length that a sound wave reflected from the far end of the tube

ableandreproduciblemeasureofthein-ductdynamicpressure

termination arrives at the microphone position sufficiently

levelattheinletorexhaustofthegasturbine,orfan.Theguide attenuated that it will not appreciably affect the microphone

is not intended to quantify the “true” sound pressure level or

reading.

sound power level. Silencers, as well as Waste Heat Boilers,

3.2.2 dynamic pressure—the total instantaneous pressure

must be designed using the in-duct sound power level as the

incident upon the opening of the test port, including the

basis. Developing the true sound power level based on in-duct

influence of convective turbulence, local tangential modes,

measurements of true sound pressure within a complete oper-

localized boundary layer effects at the test port and the

atingsystemiscomplexandproceduresaredevelopmentaland

indeterminate effects of all duct acoustical modes.

often proprietary.

3.2.3 fixture—the apparatus containing the microphone fit-

1.3 This standard does not purport to address all of the

ting which locates the microphone flush with the inside

safety concerns, if any, associated with its use. It is the

diameteroftheanechoictube,thenecessaryfittingspermitting

responsibility of the user of this standard to establish appro-

airtight connection of the fixture and anechoic tube to the test

priate safety and health practices and determine the applica-

port, and the anechoic tube.

bility of regulatory limitations prior to use. Extreme caution is

3.2.4 probe microphone—a commercially available micro-

mandatory when working near hot exhaust gas systems and

diameter microphone probe that is inserted into the anechoic

appropriate safety precautions such as the installation of quick

termination near the test port connection. Some probes require

acting isolation valves are recommended.

a pressure compensation connection. Use and installation shall

2. Referenced Documents follow manufacturer’s procedures/instructions.

3.2.5 test port—the hole in the duct wall to which the

2.1 ASTM Standards:

anechoic tube is connected and whose diameter is equal to the

C634Terminology Relating to Building and Environmental

inside diameter of the anechoic tube. In general the term test

Acoustics

port,asusedherein,willusuallyincludeanysemi-permanently

installed hardware in the wall of the duct permitting closure of

This guide is under the jurisdiction ofASTM Committee E33 on Building and

EnvironmentalAcousticsandisthedirectresponsibilityofSubcommitteeE33.08on

the test port when not in use (ball valve and threaded pipe cap,

Mechanical and Electrical System Noise.

or both) as well as the pipe elements permitting attachment of

Current edition approved April 1, 2011. Published August 2011. Originally

the fixture and the anechoic tube.

approved in 2005. Last previous edition approved in 2005 as E2459–05. DOI:

10.1520/E2459-05R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2459 − 05 (2011)

4. Summary of Guide mount a protective screen covering the inside duct wall

opening, such screen shall not materially influence the sound

4.1 Key features of this guide:

pressure measurements, or a means of quantifying and ac-

4.1.1 Athrough-walltestportopening,25.4mm(nominally,

counting for such influence shall be included in the test

1 in.) or less, to which is connected the fixture, having a

protocol. (Be aware that such screens can become fouled with

constant inside diameter tube, to which the anechoic tube is

particles.)

connected.Thetestportopeningisflushwiththeinsidesurface

4.1.9 The inner duct wall opening shall be the same inside

of the duct wall. No apparatus are inserted into the flow path.

diameter as the inside diameter of the anechoic tube. That is,

4.1.2 The microphone sensor is mounted in the fixture

thisguidedoesnotpermittheanechoictubetobeinsertedinto,

(3.2.3) outboard of the duct wall, with the microphone axis

or positioned within a duct wall port of larger size, unless

oriented normal to the centerline of the anechoic tube.

means are provided to ensure that the inner wall surface at the

4.1.3 The tip of the microphone, usually with a protective

test port is restored to a reasonable semblance of a smooth

grid, is positioned flush with, or more accurately tangential to,

continuous wall surface.

the inner wall of the fixture and as close to the duct wall as

temperature or access limitations permit.

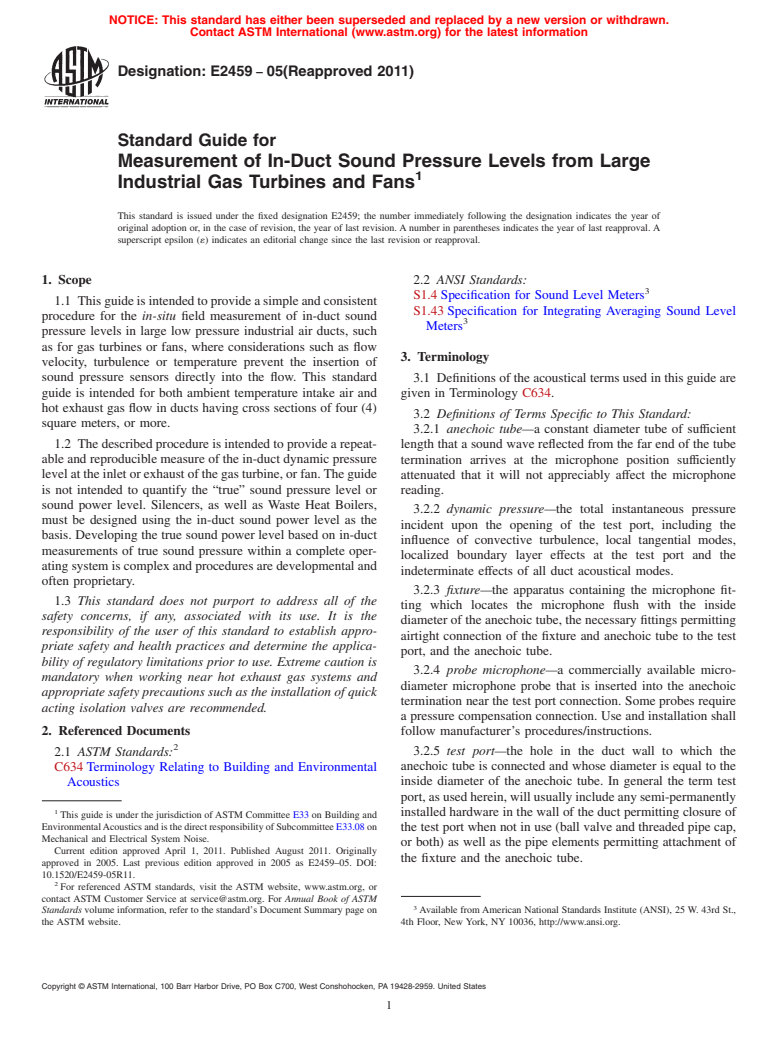

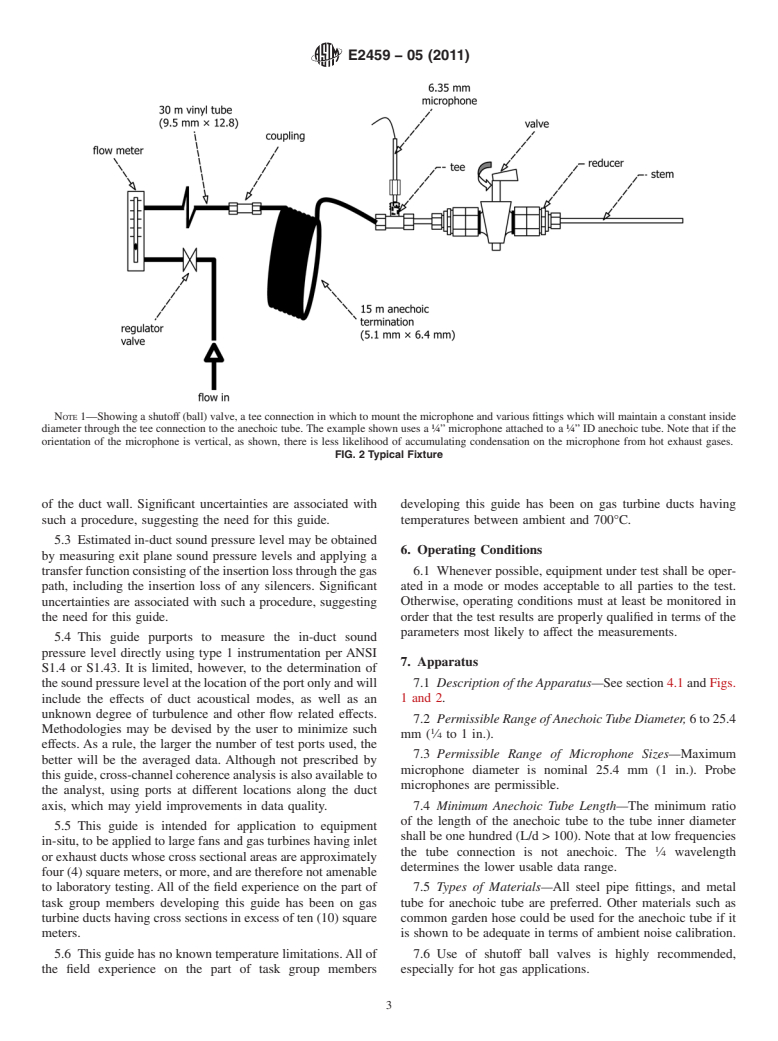

4.2 A sketch of a typical Test Port is shown in Fig. 1.A

4.1.4 The diameter of the microphone shall always be less

sketch of a typical Fixture is shown in Fig. 2. Only the initial

than or equal to the inside diameter of the anechoic tube.

portion of the otherwise very long Anechoic Tube is depicted

4.1.5 The position of the microphone is critical for high

in each figure.

temperature ducts, so as to limit the maximum temperature on

the microphone during testing.

5. Significance and Use

4.1.6 The anechoic tube shall have no inner wall disconti-

5.1 All noise control features associated with the inlet or

nuities or changes in diameter that might create reflections or

exhaust of large industrial fans and gas turbines are, or should

standing waves within the tube. It is important to avoid any

be, based upon inlet or exhaust sound power levels in octave

protrusion of the apparatus into the gas flow path.

bands of frequency. Sound power levels are not directly

4.1.7 The anechoic termination may be achieved by loosely

measurable, however, so they must be calculated indirectly,

packing the “cold” end of the tube with mineral wool or steel

using estimated or measured duct interior sound pressure

wool. The tube end should be sealed airtight unless forced air

levels.

is to be used to ensure adequate cooling of the anechoic tube.

4.1.8 The inner duct wall opening shall be as smooth as 5.2 Estimated in-duct sound pressure level may be obtained

practicable, with a minimum of turbulence producing discon- by measuring exterior airborne sound pressure levels and

tinuities at the duct wall inner surface. If the user chooses to applying a transfer function representing the transmission loss

NOTE 1—Showing a typical Fixture (see Fig. 2) installed in an insulated duct wall. Note the stem of the Fixture extends all the way to the inner duct

wall surface, occupying a hole in the duct wall only slightly larger than the tube stem O.D.

FIG. 1 Typical Fixture

E2459 − 05 (2011)

NOTE 1—Showing a shutoff (ball) valve, a tee connection in which to mount the microphone and various fittings which will maintain a constant inside

diameter through the tee connection to the anechoic tube.The example shown uses a ¼” microphone attached to a ¼” ID anechoic tube. Note that if the

orientation of the microphone is vertical, as shown, there is less likelihood of accumulating condensation on the microphone from hot exhaust gases.

FIG. 2 Typical Fixture

of the duct wall. Significant uncertainties are associated with developing this guide has been on gas turbine ducts having

such a procedure, suggesting the need for this guide. temperatures between ambient and 700°C.

5.3 Estimated in-duct sound pressure level may be obtained

6. Operating Conditions

by measuring exit plane sound pressure levels and applying a

transferfunctionconsistingoftheinsertionlossthroughthegas 6.1 Whenever possible, equipment under test shall be oper-

ated in a mode or modes acceptable to all parties to the test.

path, including the insertion loss of any silencers. Significant

uncertainties are associated with such a procedure, suggesting Otherwise, operating conditions must at least be monitored in

order that the test results are properly qualified in terms of the

the need for this guide.

parameters most likely to affect the measurements.

5.4 This guide purports to measure the in-duct sound

pressure level directly using type 1 instrumentation per ANSI

7. Apparatus

S1.4 or S1.43. It is limited, however, to the determination of

7.1 Description of the Apparatus—Seesection4.1andFigs.

thesoundpressurelevelatthelocationoftheportonlyandwill

include the effects of duct acoustical modes, as well as an 1 and 2.

unknown degree of turbulence and other flow related effects.

7.2 Permissible Range ofAnechoic Tube Diameter,6to25.4

Methodologies may be devised by the user to minimize such

mm ( ⁄4 to 1 in.).

effects.As a rule, the larger the number of test ports used, the

7.3 Permissible Range of Microphone Sizes—Maximum

better will be the averaged data. Although not prescribed by

microphone diameter is nominal 25.4 mm (1 in.). Probe

thisguide,cross-channelcoherenceanalysisisalsoavailableto

microphones are permissible.

the analyst, using ports at different locations along the duct

axis, which may yield improvements in data quality. 7.4 Minimum Anechoic Tube Length—The minimum ratio

of the length of the anechoic tube to the tube inner diameter

5.5 This guide is intended for application to equipment

shall be one hundred (L/d > 100). Note that at low frequencies

in-situ,tobeappliedtolargefansandgasturbineshavinginlet

the tube connection is not anechoic. The ⁄4 wavelength

orexhaustductswhosecrosssectionalareasareapproximately

determines the lower usable data range.

four(4)squaremeters,ormore,andarethereforenotamenable

to laboratory testing.All of the field experience on the part of 7.5 Types of Materials—All steel pipe fittings, and metal

task group members developing this guide has been on gas tube for anechoic tube are preferred. Other materials such as

turbineductshavingcrosssectionsinexcessoften(10)square common garden hose could be used for the anechoic tube if it

meters. is shown to be adequate in terms of ambient noise calibration.

5.6 This guide has no known temperature limitations.All of 7.6 Use of shutoff ball valves is highly recommended,

the field experience on the part of task group members especially for hot gas applications.

E2459 − 05 (2011)

7.7 Guides for Creating Anechoic Terminations—Any L 5 L 1TF (1)

PId PMd

acoustically absorptive material such as mineral wool or steel

where:

wool is sufficient.The end of the anechoic tube shall be sealed

TF = L – L = the transfer function,

PRc PMc

airtight for all hot gas applications, or may be fitted with a

L = reference in-duct pressure level, cold,

PRc

pressurized air injection system.

L = measured pressure level, cold,

PMc

7.8 Guidelines for Forced Air Insertion into the Anechoic

L = in-duct pressure level, dynamic, and

PId

Tube—In the event pressurized air injection system is used, L = measured pressure level, dynamic.

PMd

additional tests shall be performed demonstrating no interfer-

8.2.1 If the object is to determine the transfer function

ence results from the sound of the injection system or flow

relative to the mean duct cross-sectional average sound pres-

velocity across the microphone.

surelevel,thenthereferencesoundpressurelevelmustconsist

7.9 Frequency Ranges of Interest—Unless otherwise agreed

of a spatially averaged sound pressure level measured in

tobythepartiestothetest,thefrequencyrangeofinterestshall

sufficient detail over the entire interior duct cross section.

be 16 Hz to 10000 Hz. For low frequency applications ensure

8.2.2 If the object is to determine the transfer function

thatthe ⁄4wavelengthoftheanechoicterminationisbelowthe

strictly in regard to the in-duct sound pressure level in the

range of interest. immediate vicinity of the test port, then the reference sound

pressure level will consist only of the level in the immediate

8. Procedure

vicinityofthetestportitself.Thedistancefromthetestportto

8.1 Selection of Measurement Positions—Location of test

the reference microphone must be specified and, if applicable,

ports shall be at the discretion of the user. To the maximum

the extent of any spatial averaging achieved by moving the

extent practicable, the plane of the duct at which test ports are

microphone while recording the reference signal.

installed should be a region of relatively uniform flow both

8.2.3 If the object is to determine the transfer function

upstream and downstream; that is, a straight portion of duct,

strictly in regard to the full at-wall sound pressure level at the

andlowvelocity.Ifthereareanumberofdiscontinuitiesinthe

port face, then the reference sound pressure is determined by

duct cross sectional area, it would be advisable to locate test

inserting a microphone into the test port so that the micro-

ports at midpoints between the discontinuities. For any given

phone’s protective grid, or probe opening, is flush with the

planeoftestportlocations,experiencehasshownbetterresults

inner wall surface.

when the ports are located away from duct corners. If strong

8.2.4 The artificial sound source used for any of the above

duct acoustical modes are present and the mode shapes are

transferfunctiondeterminationsmaybeahornorloudspeaker.

kn

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.