ASTM E1725-95(2001)e1

(Test Method)Standard Test Methods for Fire Tests of Fire-Resistive Barrier Systems for Electrical System Components

Standard Test Methods for Fire Tests of Fire-Resistive Barrier Systems for Electrical System Components

SIGNIFICANCE AND USE

These fire-test-response test methods evaluate, under the specified test conditions, the ability of a fire-resistive barrier system to inhibit thermal transmission to the electrical system component within.

In these procedures, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it may not be possible by or from these test methods to predict changes in the fire test response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in these procedures.

These test methods provide a measurement of the transmission of heat to the electrical system components within the barrier system.

These test methods provide qualification of a fireresistive barrier system as one element of an electrical system designed to maintain continuous operation of critical functions and processes for a specific fire endurance rating.

4.4.1 In addition to the temperature data provided by these test methods, numerous other factors, such as referenced in 1.4 shall be considered in specifying such a system.

SCOPE

1.1 These test methods cover fire-test-response.

1.2 These fire-test-response test methods provide information on the temperatures recorded on the electrical system component within a fire-resistive barrier system during the period of exposure.

1.3 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions

1.4 Potentially important factors and fire characteristics not addressed by these test methods include, but are not limited to:

1.4.1 The performance of the fire-resistive barrier system constructed with components other than those tested.

1.4.2 An evaluation of the functionality of the electrical system within the fire-resistive barrier system.

1.4.3 An evaluation of the ampacity of the electrical system within the fire-resistive barrier system.

1.4.4 An evaluation of the smoke, toxic gases, corrosivity, or other products of heating.

1.4.5 A measurement of the flame spread characteristics over the surface of the fire-resistive barrier system.

1.4.6 An evaluation of through-penetration sealing methods.

1.4.7 Combustibility of materials in the fire-resistive barrier system or of the electrical system components.

1.4.8 The need for supports beyond those normally required.

1.4.9 Environmental conditions in the area of service.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:E1725–95 (Reapproved 2001)

Standard Test Methods for

Fire Tests of Fire-Resistive Barrier Systems for Electrical

System Components

This standard is issued under the fixed designation E 1725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—The fire-test-response caveat was updated in October 2004.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 These test methods cover fire-test-response.

1.2 These fire-test-response test methods provide informa-

2. Referenced Documents

tion on the temperatures recorded on the electrical system

2.1 ASTM Standards:

component within a fire-resistive barrier system during the

E 119 Test Methods for Fire Tests of Building Construction

period of exposure.

and Materials

1.3 This standard is used to measure and describe the

E 176 Terminology of Fire Standards

response of materials, products, or assemblies to heat and

E 1529 Test Methods for Determining Effects of Large

flame under controlled conditions, but does not by itself

Hydrocarbon Pool Fires on Structural Members and As-

incorporate all factors required for fire hazard or fire risk

semblies

assessment of the materials, products, or assemblies under

actual fire conditions.

3. Terminology

1.4 Potentially important factors and fire characteristics not

3.1 Definitions:

addressed by these test methods include, but are not limited to:

3.1.1 air drop—lengths of open run conductors or cables

1.4.1 The performance of the fire-resistive barrier system

supported only at each end.

constructed with components other than those tested.

3.1.2 electrical system components—cable trays, conduits

1.4.2 An evaluation of the functionality of the electrical

and other raceways, open run cables and conductors, cables,

system within the fire-resistive barrier system.

conductors, cabinets, and other components, as defined or used

1.4.3 An evaluation of the ampacity of the electrical system

in the National Electrical Code, and air drops as defined in

within the fire-resistive barrier system.

3.1.1.

1.4.4 An evaluation of the smoke, toxic gases, corrosivity,

3.1.3 fire-resistive barrier system—a specific construction

or other products of heating.

of devices, materials, or coatings installed around, or applied

1.4.5 A measurement of the flame spread characteristics

to, the electrical system components.

over the surface of the fire-resistive barrier system.

3.1.4 specimen—a construction consisting of electrical sys-

1.4.6 Anevaluationofthrough-penetrationsealingmethods.

tem components and a fire-resistive barrier system.

1.4.7 Combustibility of materials in the fire-resistive barrier

3.1.5 test assembly—horizontal or vertical construction on

system or of the electrical system components.

which test specimens are to be mounted together with associ-

1.4.8 The need for supports beyond those normally re-

ated instrumentation.

quired.

1.4.9 Environmental conditions in the area of service.

4. Significance and Use

1.5 The values stated in inch-pound units are to be regarded

4.1 Thesefire-test-responsetestmethodsevaluate,underthe

as the standard. The SI units given in parentheses are for

specified test conditions, the ability of a fire-resistive barrier

information only.

system to inhibit thermal transmission to the electrical system

1.6 This standard does not purport to address all of the

component within.

safety concerns, if any, associated with its use. It is the

4.2 In these procedures, the specimens are subjected to one

responsibility of the user of this standard to establish appro-

or more specific sets of laboratory test conditions. If different

1 2

These test methods are under the jurisdiction ofASTM Committee E05 on Fire For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Standards and are the direct responsibility of Subcommittee E05.11 on Construction contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Assemblies. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 15, 1995. Published October 1995. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E1725–95 (2001)

test conditions are substituted or the end-use conditions are an accuracy of 6 0.75 %. A minimum length of 20 diameters

changed, it may not be possible by or from these test methods (125 mm) of the sheathed junction end of the thermocouple

to predict changes in the fire test response characteristics shall be mounted parallel to the surface of the test specimen.

measured. Therefore, the results are valid only for the fire test

5.4 Furnace Thermocouple Locations—Positionthefurnace

exposure conditions described in these procedures.

control thermocouples before the start of the fire exposure test.

4.3 These test methods provide a measurement of the

It shall be permitted to move the thermocouple to avoid

transmissionofheattotheelectricalsystemcomponentswithin

touching the specimen as a result of its deflection during the

the barrier system.

test.

4.4 These test methods provide qualification of a fireresis-

5.4.1 Place the junction of each thermocouple 12 6 1 in.

tive barrier system as one element of an electrical system

(305 6 25 mm) from the surface of horizontal constructions or

designed to maintain continuous operation of critical functions

12 61in.fromthesurfaceofspecimensmountedinhorizontal

and processes for a specific fire endurance rating.

constructions.

4.4.1 In addition to the temperature data provided by these

5.4.2 Placethejunctionofeachthermocouple6 61in.(152

test methods, numerous other factors, such as referenced in 1.4

6 25 mm) from the surface of vertical constructions or 6 6 1

shall be considered in specifying such a system.

in.fromthesurfaceofspecimensmountedinverticalconstruc-

tions.

5. Control of Fire Test

5.4.3 Use a minimum of three thermocouples.

5.1 Fire Test Exposure Conditions:

5.4.3.1 For specimens mounted in horizontal constructions,

5.1.1 Time-Temperature Curve—Maintain the fire environ-

2 2

thereshallbenolessthanfivethermocouplesper100ft (9m )

ment within the furnace in accordance with the standard

of exposed area. Calculate the exposed area to be the sum of

time-temperature curve shown in Test Method E 119 or the

the exterior surface area of the fire-resistive barrier system plus

rapid temperature rise curve shown in Test Method E 1529.

the area of the horizontal construction exposed to the furnace

5.2 Furnace Temperatures:

fire.

5.2.1 The temperature fixed by the curve shall be the

5.4.3.2 For specimens mounted in vertical constructions,

average temperature obtained from readings of thermocouples

there shall be no less than nine thermocouples per 100 ft (9

distributed within the test furnace. Disperse the thermocouples

m ) of exposed area. Calculate the exposed area to be the sum

as symmetrically as possible within the furnace to measure the

of the exterior surface area of the fire resistive barrier system

temperature near all exterior surfaces of the specimen. Do not

plustheareaoftheverticalconstructionexposedtothefurnace

place the thermocouples at locations where temperature read-

fire.

ings would be effected by drafts within the furnace.

5.2.2 Measure and report the temperatures at intervals not 5.5 Furnace Control:

exceeding 1 min.

5.5.1 Test Method E 119 Time-Temperature Curve:

5.3 Furnace Thermocouples:

5.5.1.1 The control of the furnace control shall be such that

5.3.1 Test Method E 119—Enclose the thermocouples in

the area under the time-temperature curve, obtained by aver-

sealed protection tubes of such materials and dimensions that

aging the results from the furnace thermocouple readings, is

the time constant of the protected thermocouple assembly lies

within 10 % of the corresponding area under the standard

within the range from 300 to 400 s . The exposed length of the

time-temperature curve for fire tests of1hor less duration,

pyrometer tube and thermocouple in the furnace chamber shall

within 7.5 % for those over 1 h and not more than 2 h, and

be not less than 12 in. (305 mm).

within 5 % for tests exceeding2hin duration.

5.3.2 Test Methods E 1529—Measurethetemperatureofthe

5.5.2 Test Method E 1529 Time-Temperature Curve—The

gases adjacent to and impinging on the test specimens using

control of the furnace shall be such that the area under the

factory manufactured 0.25-in. (6-mm) outside diameter (OD),

time-temperature curve of the average of the gas temperature

4 4

Inconel -sheathed, Type K, chromel-alumel thermocouples.

measurements is within 10 % of the corresponding curve

The time constant, in air, of the thermocouple assemblies shall

developed in the furnace calibration for tests of 30 min or less

be less than 60 s. Use standard calibration thermocouples with

duration, within 7.5 % of those over 30 min and not more than

1 h, and within 5 % for tests exceeding 1 h.

5.5.3 If the indicated rating for the protection system is 60

A typical thermocouple meeting these time-constant requirements may be

fabricated by fusion-welding the twisted ends of No. 18 B&S gage, 0.040 in. (1.02 minormore,itshallbeincreasedordecreasedbythefollowing

mm),chromel-alumelwires,mountingtheleadsinporcelaininsulatorsandinserting

correction to compensate for significant variation of the mea-

the assembly so the thermocouple bead is 0.50 in. (13 mm) from the sealed end of

sured furnace temperature from the standard time-temperature

a standard weight, nominal ⁄2 in. iron, steel, or Inconel (a registered trademark of

curve. The correction is to be expressed by the following

INCO Alloys Inc., 3800 Riverside Dr., P.O. Box 1958, Huntingdon, WV 25720)

pipe. The time constant for this and for several other thermocouple assemblies was

formula:

measured in 1976. The time constant may also be calculated from knowledge of its

A 2 A

physical and thermal properties. See Research Report RR:E05-1001, available from s

C 5 2I (1)

ASTM Headquarters. 3~A 1 L!

s

Buchanan Splice Caps No. 2006S, crimped with a Buchanan C-24 pres-SURE-

tool have been found suitable for this purpose (Buchanan Construction Products,

where:

Inc., Hackettstown, NJ 07840). The cylindrical splice caps are constructed of thin

C = correction in the same units at I,

copper and result in a very secure and robust attachment with the addition of a

I = indicated fire resistance period,

minimal thermal mass.

e1

E1725–95 (2001)

the cold heat flux of 50 000 Btu/ft ·h within the first 5 min of

A = area under the curve of the average furnace tempera-

the test exposure; maintain this heat flux for the duration of the

ture for the first three fourths of the indicated period,

test.

A = areaunderthestandardtime-temperaturecurveforthe

s

5.6.4 The temperature of the environment that generates the

first three fourths of the indicated period, and

heat flux of 50 000 Btu/ft ·h shall be at least 1500°F (815°C)

L = lag correction in the same units asAandA 54°F·h or

s

30°C·h (3240°F·min or 1800°C·min). L is only appli- after the first 3 min of the test and shall be between 1850°F

(1010°C) and 2150°F (1180°C) at all times after the first 5 min

cable to thermocouples described in 5.3.1 and be-

comes zero for thermocouples described in 5.3.2. of the test.

5.7 Furnace Pressure—The furnace pressure control de-

5.6 Furnace Calibration—Test Method E 1529 contains a

calibration procedure, that is described in the following sec- scribed in the sections that follow pertain to tests performed

using either of the two time-temperature curves.

tions. Test Method E 119 does not contain a calibration

procedure. 5.7.1 Measure the pressure differential between the labora-

tory ambient air and the interior of the fire test furnace with a

5.6.1 Expose the test specimen to heat flux and temperature

conditions representative of total continuous engulfment in the minimum of two pressure probes.

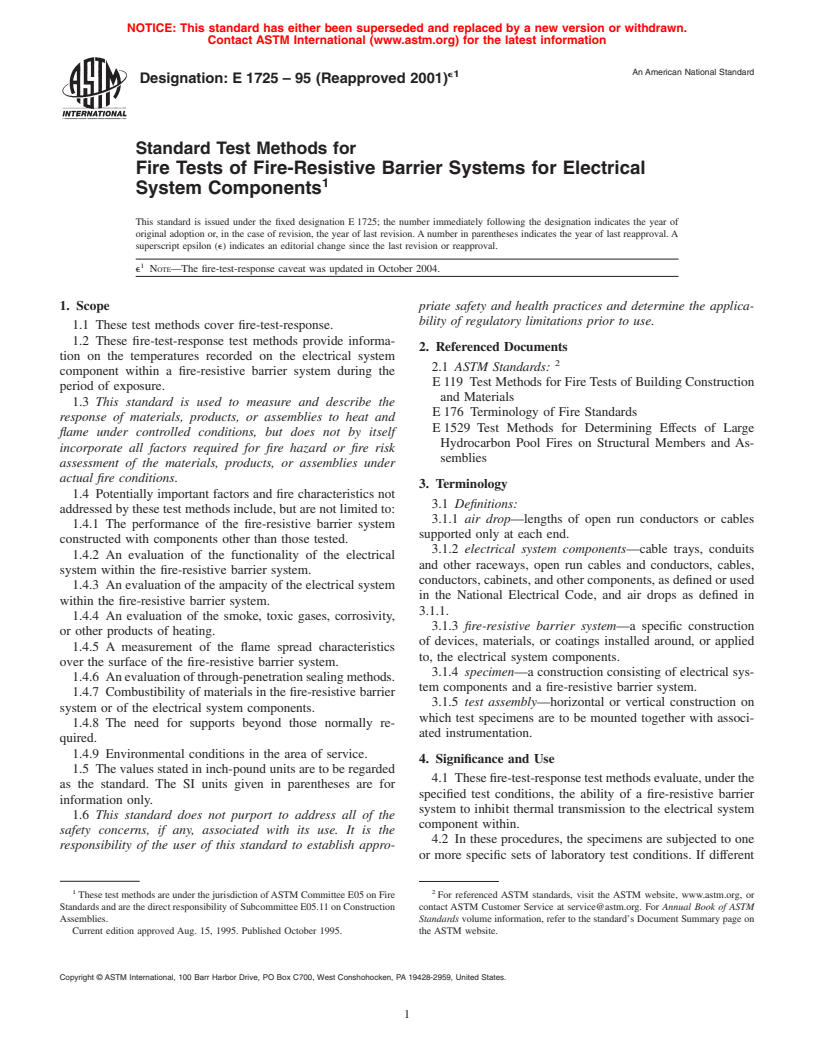

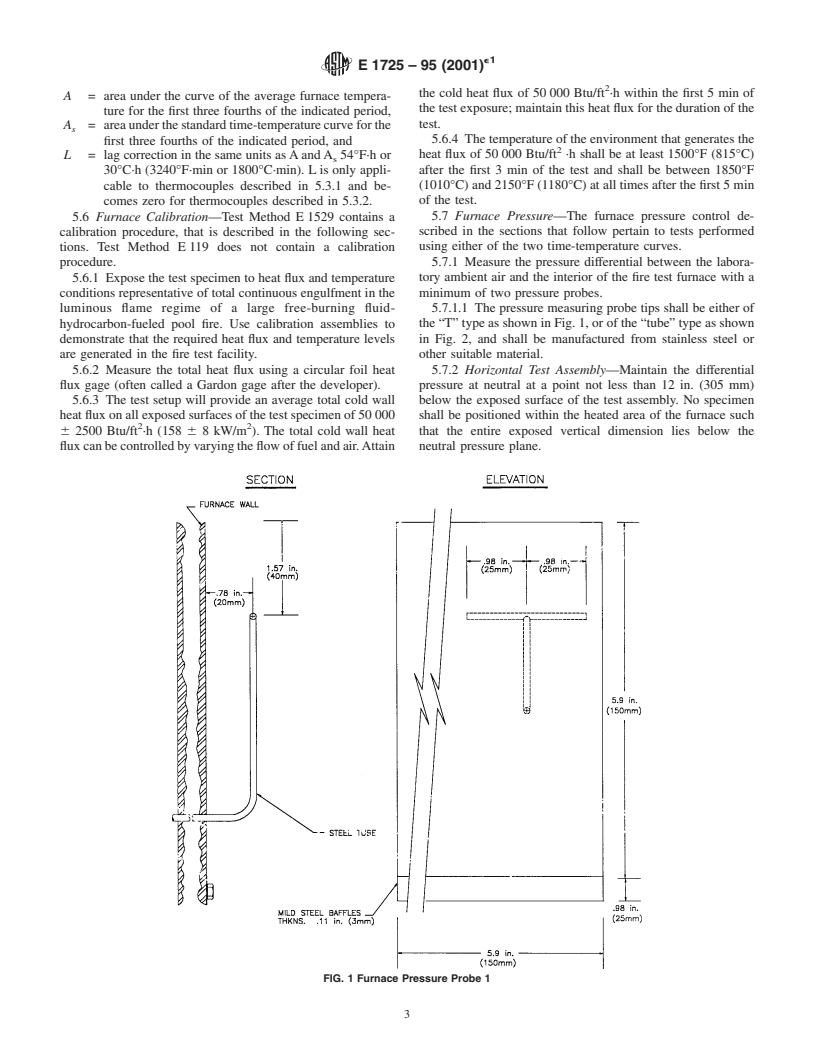

luminous flame regime of a large free-burning fluid- 5.7.1.1 The pressure measuring probe tips shall be either of

hydrocarbon-fueled pool fire. Use calibration assemblies to the “T” type as shown in Fig. 1, or of the “tube” type as shown

demonstrate that the required heat flux and temperature levels in Fig. 2, and shall be manufactured from stainless steel or

are generated in the fire test facility. other suitable material.

5.6.2 Measure the total heat flux using a circular foil heat 5.7.2 Horizontal Test Assembly—Maintain the differential

flux gage (often called a Gardon gage after the developer). pressure at neutral at a point not less than 12 in. (305 mm)

5.6.3 The test setup will provide an average total cold wall below the exposed surface of the test assembly. No specimen

heatfluxonallexposedsurfacesofthetestspecimenof50 000 shall be positioned within the heated area of the furnace such

2 2

6 2500 Btu/ft ·h (158 68kW/m ). The total cold wall heat that the entire exposed vertical dimension lies below the

fluxcanbecontrolledbyvaryingtheflowoffuelandair.Attain neutral pressure plane.

FIG. 1 Furnace Pressure Probe 1

e1

E1725–95 (2001)

FIG. 2 Furnace Pressure Probe 2

5.7.2.1 Locate the pressure measuring probe tips within 6 fire-resistive barrier systems and electrical system components

in. of the vertical centerline of the test specimen. Separate the shall be representative of actual end use.

probes by a minimum of one third of the longest inside 6.2 Electrical System Components—Test components at

dimension of the test furnace. Alternatively, separate the two their full size and linear dimensions for which evaluation is

probes by a minimum of 12 in. (305 mm) vertical distance desired. If the full-size component’s linear dimensions are

within the furnace, and the location of the neutral plane greater than those specified under each component type in this

calculated as a function of their vertical separation and their section, utilize the dimensions shown, unless data is required

pressure difference. for a unique design. Cable trays, conduits, and other raceways

5.7.3 Vertical Test Assembly—Position specimens within are tested without conductors, unless the test is for a unique

the heated area of the furnace such that at least one half of the design. Suggested arrangements are shown in Figs. 3 and 4.

vertical dimension lies above the neutral pressure plane. 6.2.1 Cable Trays, Raceways, and Open-Run Cables—

5.7.3.1 Separate at least two

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.