ASTM E2749-15a(2019)

(Practice)Standard Practice for Measuring the Uniformity of Furnace Exposure on Test Specimens

Standard Practice for Measuring the Uniformity of Furnace Exposure on Test Specimens

SIGNIFICANCE AND USE

5.1 This practice describes a procedure to gather data intended to measure the uniformity of exposure conditions upon test specimens for the fire test methods described in Test Methods E119, E814, E1529, E1725, E1966 and E2336. The collected data from furnaces are intended to form a basis for performance requirements for the furnaces described in the referenced standards.

5.2 This practice does not include requirements for furnace performance.

5.3 In this procedure, the standardized test specimen is subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this procedure to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire-test-exposure conditions described in this procedure.

5.4 The attention of all persons connected with the conduct of this practice is drawn to the fact that fire testing is hazardous and that there is a possibility that harmful smoke and gases are developed during the test. There is also a possibility that mechanical and operational hazards develop during the construction of the test specimen and the disposal of the test residues. An assessment of all potential hazards and risks to health shall be made and safety precautions shall be identified and provided. Written safety instructions shall be issued. Appropriate training shall be provided to relevant personnel. Laboratory personnel shall ensure that they follow written safety instructions at all times.

SCOPE

1.1 This standard provides general principles for measuring the uniformity of the furnace exposure on specimens tested in accordance with Test Methods E119, E814, E1529, E1725, E1966 and E2336.

1.2 This practice specifies the materials and the construction requirements for a standardized test specimen used to provide a mounting surface for the instrumentation that measures furnace exposure.

1.3 The instrumentation records temperatures, pressure differentials, and oxygen content near the surface of the test specimen.

1.4 The values stated in SI units are to be regarded as the standard. The units given in parentheses are for information only.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2749 − 15a (Reapproved 2019) An American National Standard

Standard Practice for

Measuring the Uniformity of Furnace Exposure on Test

Specimens

This standard is issued under the fixed designation E2749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This standard provides general principles for measuring

the uniformity of the furnace exposure on specimens tested in

2. Referenced Documents

accordance with Test Methods E119, E814, E1529, E1725,

E1966 and E2336.

2.1 ASTM Standards:

C1396/C1396M Specification for Gypsum Board

1.2 Thispracticespecifiesthematerialsandtheconstruction

E119 Test Methods for Fire Tests of Building Construction

requirements for a standardized test specimen used to provide

and Materials

a mounting surface for the instrumentation that measures

E176 Terminology of Fire Standards

furnace exposure.

E814 Test Method for Fire Tests of Penetration Firestop

1.3 The instrumentation records temperatures, pressure

Systems

differentials, and oxygen content near the surface of the test

E1529 Test Methods for Determining Effects of Large Hy-

specimen.

drocarbon Pool Fires on Structural Members and Assem-

blies

1.4 The values stated in SI units are to be regarded as the

E1725 Test Methods for Fire Tests of Fire-Resistive Barrier

standard. The units given in parentheses are for information

Systems for Electrical System Components

only.

E1966 Test Method for Fire-Resistive Joint Systems

1.5 This standard is used to measure and describe the

E2336 Test Methods for Fire Resistive Grease Duct Enclo-

response of materials, products, or assemblies to heat and

sure Systems

flame under controlled conditions, but does not by itself

2.2 ISO Technical Report:

incorporate all factors required for fire hazard or fire risk

ISO/TR 834-2 Fire resistance tests – Elements of building

assessment of the materials, products, or assemblies under

construction – Part 2: Guide on measuring uniformity of

actual fire conditions.

furnace exposure on test samples

1.6 Fire testing is inherently hazardous. Adequate safe-

guards for personnel and property shall be employed in

3. Terminology

conducting these tests.

3.1 Definitions—For definitions of terms used in this

1.7 This standard does not purport to address all of the

practice, refer to Terminology E176.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.2.1 effective area of the furnace opening—furnace open-

mine the applicability of regulatory limitations prior to use.

ing within the boundaries of the monitoring instrumentation.

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Practice

ization established in the Decision on Principles for the

4.1 This practice consists of preparing a standardized test

Development of International Standards, Guides and Recom-

specimen to represent test specimens described in Test Meth-

ods E119, E814, E1529, E1725, E1966 and E2336. The

This practice is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.11 on Fire

Resistance. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2019. Published March 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2010. Last previous edition approved in 2015 as E2749 – 15a. Standards volume information, refer to the standard’s Document Summary page on

DOI:10.1520/E2749-15AR19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2749 − 15a (2019)

standardized test specimen provides a low cost, easily con-

structed supporting construction for the mounting of instru-

mentation that measures the exposure imposed by the furnace

onto test specimens.

4.2 The standardized test specimen consists of two layers of

15.9 mm ( ⁄8 in.) thick Type X gypsum board on the surface

facing the furnace chamber attached to steel channels and a

single layer of structural panels (plywood or oriented strand

board) attached to the steel channels on the surface away from

the furnace chamber. The gypsum board provides a fire-

resistive surface for the mounting of the instrumentation. The

structural panels provide stability for the steel support chan-

nels.

4.3 Instrumentation to measure the thermal impact due to

exposure to the furnace upon the standardized test specimen is

installed at various locations on the exposed surface of the

standardized test specimen. Probes used to gather air samples

within the furnace chamber are also installed.

4.4 The standardized test specimen is exposed to the time-

temperature curve specified in referenced ASTM fire test

standards for a time period of 45 min during which time data

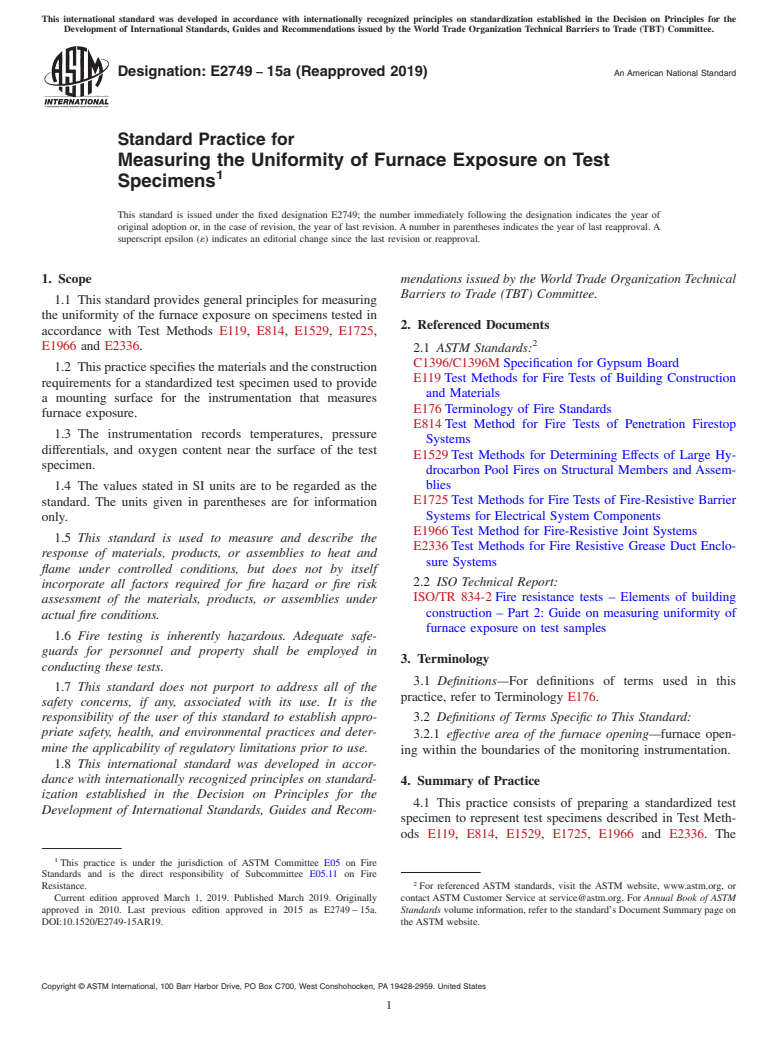

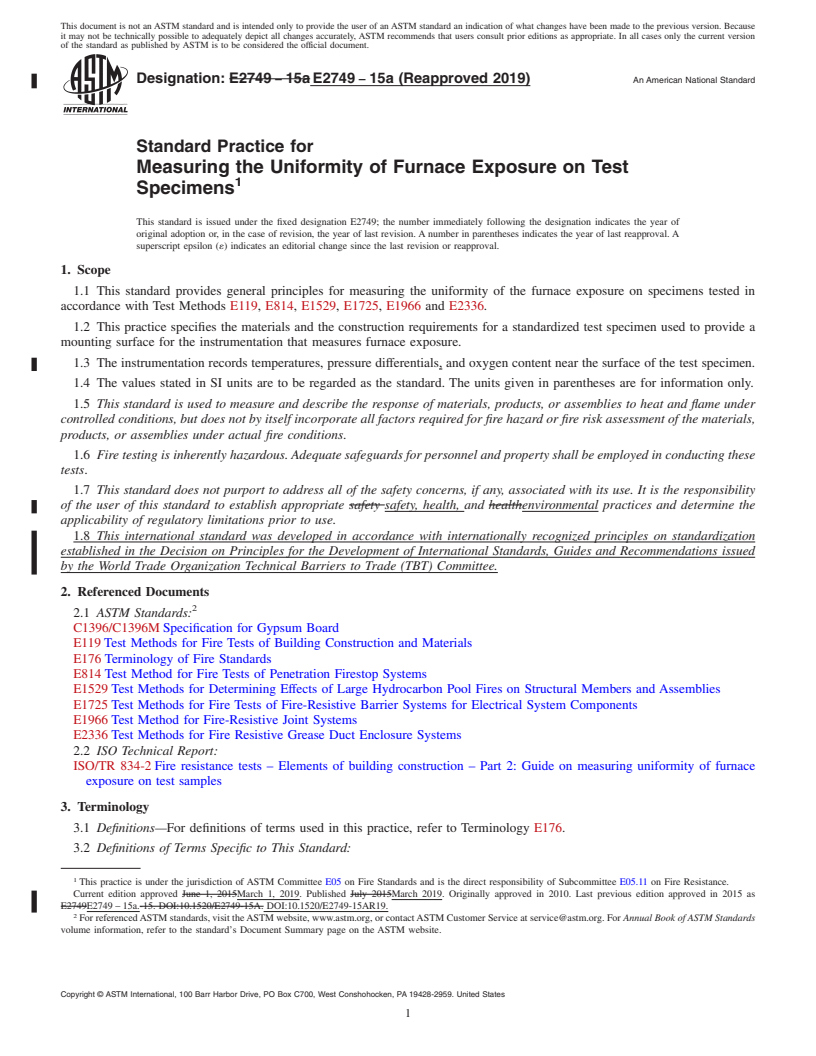

Dimensions in millimetres.

are recorded by the instrumentation mounted on the standard-

FIG. 1 Horizontal Standardized Test Specimen, Location of

ized test specimen.

Joists and Track Channels

4.5 The data provide a record of the conditions and unifor-

mityofthefurnaceexposureuponstandardizedtestspecimens.

The area bounded by the instrumentation installed on the

Appropriate training shall be provided to relevant personnel.

standardizedtestspecimenisdesignatedastheeffectiveareaof

Laboratory personnel shall ensure that they follow written

the furnace opening.

safety instructions at all times.

5. Significance and Use

6. Apparatus

5.1 This practice describes a procedure to gather data

6.1 The furnace(s) and restraining frame(s) used to conduct

intended to measure the uniformity of exposure conditions

tests in accordance with Test Methods E119, E814, E1529,

upon test specimens for the fire test methods described in Test

E1725, E1966 and E2336 shall be used.

Methods E119, E814, E1529, E1725, E1966 and E2336. The

collected data from furnaces are intended to form a basis for

6.2 Standardized Test Specimen:

performance requirements for the furnaces described in the

6.2.1 Materials—The materials used to construct the stan-

referenced standards.

dardized test specimen shall consist of the following: gypsum

board, structural panels, cold-formed steel supports and fasten-

5.2 This practice does not include requirements for furnace

ers.

performance.

6.2.1.1 The gypsum board shall be minimum 15.9 mm ( ⁄8

5.3 In this procedure, the standardized test specimen is

in.) thick complying with the requirements of Type X as

subjected to one or more specific sets of laboratory test

defined in Specification C1396/C1396M.

conditions. If different test conditions are substituted or the

6.2.1.2 The structural panels shall be minimum 18 mm

end-use conditions are changed, it is not always possible by or

(nominal ⁄4 in.) thick. Typical materials include plywood and

from this procedure to predict changes in the fire-test-response

oriented strand boards.

characteristics measured. Therefore, the results are valid only

6.2.1.3 The cold-formed steel joists for horizontal speci-

for the fire-test-exposure conditions described in this proce-

mens shall be fabricated from minimum 1.4 mm thick (0.055

dure.

in.) steel. The cold formed steel joists shall be “C” shaped

5.4 The attention of all persons connected with the conduct having a minimum depth of 240 mm (9 ⁄2 in.), a minimum

of this practice is drawn to the fact that fire testing is hazardous flange width of 40 mm (1 ⁄8 in.) and a minimum lip length of

and that there is a possibility that harmful smoke and gases are 12 mm ( ⁄2 in.).

developed during the test. There is also a possibility that 6.2.1.4 The cold-formed steel wall studs for vertical speci-

mechanical and operational hazards develop during the con- mens shall be fabricated from minimum 0.9 mm thick (0.035

struction of the test specimen and the disposal of the test in.) steel.The cold-formed steel wall studs shall be “C” shaped

residues. An assessment of all potential hazards and risks to havingaminimumdepthof90mm(3 ⁄2in.),aminimumflange

health shall be made and safety precautions shall be identified width of 30 mm (1 ⁄4 in.) and a minimum folded back return

and provided. Written safety instructions shall be issued. flange legs of 5 mm ( ⁄4 in.).

E2749 − 15a (2019)

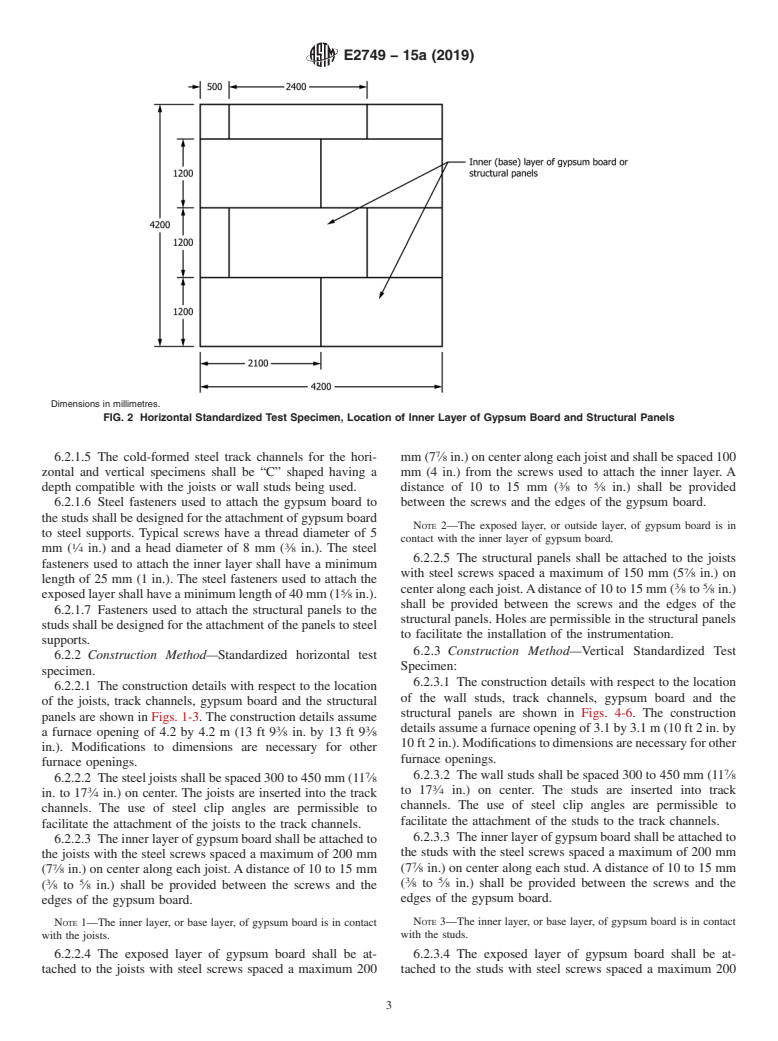

Dimensions in millimetres.

FIG. 2 Horizontal Standardized Test Specimen, Location of Inner Layer of Gypsum Board and Structural Panels

6.2.1.5 The cold-formed steel track channels for the hori- mm (7 ⁄8 in.) on center along each joist and shall be spaced 100

zontal and vertical specimens shall be “C” shaped having a mm (4 in.) from the screws used to attach the inner layer. A

3 5

depth compatible with the joists or wall studs being used. distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided

6.2.1.6 Steel fasteners used to attach the gypsum board to between the screws and the edges of the gypsum board.

the studs shall be designed for the attachment of gypsum board

NOTE 2—The exposed layer, or outside layer, of gypsum board is in

to steel supports. Typical screws have a thread diameter of 5

contact with the inner layer of gypsum board.

1 3

mm ( ⁄4 in.) and a head diameter of 8 mm ( ⁄8 in.). The steel

6.2.2.5 The structural panels shall be attached to the joists

fasteners used to attach the inner layer shall have a minimum

with steel screws spaced a maximum of 150 mm (5 ⁄8 in.) on

length of 25 mm (1 in.). The steel fasteners used to attach the

3 5

center along each joist.Adistance of 10 to 15 mm ( ⁄8 to ⁄8 in.)

exposed layer shall have a minimum length of 40 mm (1 ⁄8 in.).

shall be provided between the screws and the edges of the

6.2.1.7 Fasteners used to attach the structural panels to the

structural panels. Holes are permissible in the structural panels

studs shall be designed for the attachment of the panels to steel

to facilitate the installation of the instrumentation.

supports.

6.2.3 Construction Method—Vertical Standardized Test

6.2.2 Construction Method—Standardized horizontal test

Specimen:

specimen.

6.2.3.1 The construction details with respect to the location

6.2.2.1 The construction details with respect to the location

of the wall studs, track channels, gypsum board and the

of the joists, track channels, gypsum board and the structural

structural panels are shown in Figs. 4-6. The construction

panels are shown in Figs. 1-3. The construction details assume

3 3 details assume a furnace opening of 3.1 by 3.1 m (10 ft 2 in. by

a furnace opening of 4.2 by 4.2 m (13 ft 9 ⁄8 in. by 13 ft 9 ⁄8

10ft2in.).Modificationstodimensionsarenecessaryforother

in.). Modifications to dimensions are necessary for other

furnace openings.

furnace openings.

7 6.2.3.2 The wall studs shall be spaced 300 to 450 mm (11 ⁄8

6.2.2.2 The steel joists shall be spaced 300 to 450 mm (11 ⁄8

to 17 ⁄4 in.) on center. The studs are inserted into track

in. to 17 ⁄4 in.) on center. The joists are inserted into the track

channels. The use of steel clip angles are permissible to

channels. The use of steel clip angles are permissible to

facilitate the attachment of the studs to the track channels.

facilitate the attachment of the joists to the track channels.

6.2.3.3 The inner layer of gypsum board shall be attached to

6.2.2.3 The inner layer of gypsum board shall be attached to

the studs with the steel screws spaced a maximum of 200 mm

the joists with the steel screws spaced a maximum of 200 mm

(7 ⁄8 in.) on center along each stud.Adistance of 10 to 15 mm

(7 ⁄8 in.) on center along each joist.Adistance of 10 to 15 mm

3 5

3 5

( ⁄8 to ⁄8 in.) shall be provided between the screws and the

( ⁄8 to ⁄8 in.) shall be provided between the screws and the

edges of the gypsum board.

edges of the gypsum board.

NOTE 3—The inner layer, or base layer, of gypsum board is in contact

NOTE 1—The inner layer, or base layer, of gypsum board is in contact

with the studs.

with the joists.

6.2.2.4 The exposed layer of gypsum board shall be at- 6.2.3.4 The exposed layer of gypsum board shall be at-

tached to the joists with steel screws spaced a maximum 200 tached to the studs with steel screws spaced a maximum 200

E2749 − 15a (2019)

Dimensions in millimetres.

FIG. 3 Horizontal Standardized Test Specimen, Location of Outer Layer of Gypsum Board

3 5

15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and

the edges of the structural panels. Holes are permissible in the

structural panels to facilitate the installation of the instrumen-

tation.

6.3 Furnace Limitations—Furnaces with dedicated

applications, such as testing of ceiling assemblies, typically

have specific horizontal or vertical assemblies for this purpose

and therefore do not include open restraining frames.

6.3.1 It is permissible to modify the standardized test

specimen to account for these limitations.

6.4 Instrumentation—The instrumentation installed on the

standardized test specimen shall include plate thermometers, a

directional flame thermometer, bi-directional probes, Type K

thermocouples and air sampling probes.

6.4.1 The plate thermometers (1) shall be constructed as

shown in Fig. 7.

6.4.1.1 The plate part of the plate thermometer shall be

constructedfrom150 61mmlongby100 61mmwideby0.7

6 0.1 mm thick nickel alloy plate strips folded to the design

shown in Fig. 7.

Dimensions in millimetres.

6.4.1.2 A Type K ungrounded Inconel sheathed thermo-

FIG. 4 Vertical Standardized Test Specimen, Location of Wall

couple having a maximum diameter of 1 mm shall be fixed to

Studs and Track Channels

the geometric center of the plate in the position shown in Fig.

7 by a steel strip made from the same material as the plate.The

steel strip shall be welded or screwed to the plate. The strip

mm (7 ⁄8 in.) on center along each stud and shall be spaced 100

shall be 18 61mmby6 6 1 mm when it is spot welded to the

mm (4 in.) from the screws used to attach the inner layer. A

3 5

plate (Fig. 7) and 25 61mmby6 6 1 mm when it is to be

distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided

screwed to the plate. The

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2749 − 15a (Reapproved 2019) An American National Standard

Standard Practice for

Measuring the Uniformity of Furnace Exposure on Test

Specimens

This standard is issued under the fixed designation E2749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This standard provides general principles for measuring

the uniformity of the furnace exposure on specimens tested in

2. Referenced Documents

accordance with Test Methods E119, E814, E1529, E1725,

E1966 and E2336.

2.1 ASTM Standards:

C1396/C1396M Specification for Gypsum Board

1.2 This practice specifies the materials and the construction

E119 Test Methods for Fire Tests of Building Construction

requirements for a standardized test specimen used to provide

and Materials

a mounting surface for the instrumentation that measures

E176 Terminology of Fire Standards

furnace exposure.

E814 Test Method for Fire Tests of Penetration Firestop

1.3 The instrumentation records temperatures, pressure

Systems

differentials, and oxygen content near the surface of the test

E1529 Test Methods for Determining Effects of Large Hy-

specimen.

drocarbon Pool Fires on Structural Members and Assem-

blies

1.4 The values stated in SI units are to be regarded as the

E1725 Test Methods for Fire Tests of Fire-Resistive Barrier

standard. The units given in parentheses are for information

Systems for Electrical System Components

only.

E1966 Test Method for Fire-Resistive Joint Systems

1.5 This standard is used to measure and describe the

E2336 Test Methods for Fire Resistive Grease Duct Enclo-

response of materials, products, or assemblies to heat and

sure Systems

flame under controlled conditions, but does not by itself

2.2 ISO Technical Report:

incorporate all factors required for fire hazard or fire risk

ISO/TR 834-2 Fire resistance tests – Elements of building

assessment of the materials, products, or assemblies under

construction – Part 2: Guide on measuring uniformity of

actual fire conditions.

furnace exposure on test samples

1.6 Fire testing is inherently hazardous. Adequate safe-

guards for personnel and property shall be employed in

3. Terminology

conducting these tests.

3.1 Definitions—For definitions of terms used in this

1.7 This standard does not purport to address all of the

practice, refer to Terminology E176.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.2.1 effective area of the furnace opening—furnace open-

mine the applicability of regulatory limitations prior to use.

ing within the boundaries of the monitoring instrumentation.

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Practice

ization established in the Decision on Principles for the

4.1 This practice consists of preparing a standardized test

Development of International Standards, Guides and Recom-

specimen to represent test specimens described in Test Meth-

ods E119, E814, E1529, E1725, E1966 and E2336. The

This practice is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.11 on Fire

Resistance. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2019. Published March 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2010. Last previous edition approved in 2015 as E2749 – 15a. Standards volume information, refer to the standard’s Document Summary page on

DOI:10.1520/E2749-15AR19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2749 − 15a (2019)

standardized test specimen provides a low cost, easily con-

structed supporting construction for the mounting of instru-

mentation that measures the exposure imposed by the furnace

onto test specimens.

4.2 The standardized test specimen consists of two layers of

15.9 mm ( ⁄8 in.) thick Type X gypsum board on the surface

facing the furnace chamber attached to steel channels and a

single layer of structural panels (plywood or oriented strand

board) attached to the steel channels on the surface away from

the furnace chamber. The gypsum board provides a fire-

resistive surface for the mounting of the instrumentation. The

structural panels provide stability for the steel support chan-

nels.

4.3 Instrumentation to measure the thermal impact due to

exposure to the furnace upon the standardized test specimen is

installed at various locations on the exposed surface of the

standardized test specimen. Probes used to gather air samples

within the furnace chamber are also installed.

4.4 The standardized test specimen is exposed to the time-

temperature curve specified in referenced ASTM fire test

standards for a time period of 45 min during which time data

Dimensions in millimetres.

are recorded by the instrumentation mounted on the standard-

FIG. 1 Horizontal Standardized Test Specimen, Location of

ized test specimen.

Joists and Track Channels

4.5 The data provide a record of the conditions and unifor-

mity of the furnace exposure upon standardized test specimens.

The area bounded by the instrumentation installed on the

Appropriate training shall be provided to relevant personnel.

standardized test specimen is designated as the effective area of

Laboratory personnel shall ensure that they follow written

the furnace opening.

safety instructions at all times.

5. Significance and Use

6. Apparatus

5.1 This practice describes a procedure to gather data

6.1 The furnace(s) and restraining frame(s) used to conduct

intended to measure the uniformity of exposure conditions

tests in accordance with Test Methods E119, E814, E1529,

upon test specimens for the fire test methods described in Test

E1725, E1966 and E2336 shall be used.

Methods E119, E814, E1529, E1725, E1966 and E2336. The

collected data from furnaces are intended to form a basis for

6.2 Standardized Test Specimen:

performance requirements for the furnaces described in the

6.2.1 Materials—The materials used to construct the stan-

referenced standards.

dardized test specimen shall consist of the following: gypsum

board, structural panels, cold-formed steel supports and fasten-

5.2 This practice does not include requirements for furnace

ers.

performance.

6.2.1.1 The gypsum board shall be minimum 15.9 mm ( ⁄8

5.3 In this procedure, the standardized test specimen is

in.) thick complying with the requirements of Type X as

subjected to one or more specific sets of laboratory test

defined in Specification C1396/C1396M.

conditions. If different test conditions are substituted or the

6.2.1.2 The structural panels shall be minimum 18 mm

end-use conditions are changed, it is not always possible by or

(nominal ⁄4 in.) thick. Typical materials include plywood and

from this procedure to predict changes in the fire-test-response

oriented strand boards.

characteristics measured. Therefore, the results are valid only

6.2.1.3 The cold-formed steel joists for horizontal speci-

for the fire-test-exposure conditions described in this proce-

mens shall be fabricated from minimum 1.4 mm thick (0.055

dure.

in.) steel. The cold formed steel joists shall be “C” shaped

5.4 The attention of all persons connected with the conduct having a minimum depth of 240 mm (9 ⁄2 in.), a minimum

of this practice is drawn to the fact that fire testing is hazardous flange width of 40 mm (1 ⁄8 in.) and a minimum lip length of

and that there is a possibility that harmful smoke and gases are 12 mm ( ⁄2 in.).

developed during the test. There is also a possibility that 6.2.1.4 The cold-formed steel wall studs for vertical speci-

mechanical and operational hazards develop during the con- mens shall be fabricated from minimum 0.9 mm thick (0.035

struction of the test specimen and the disposal of the test in.) steel. The cold-formed steel wall studs shall be “C” shaped

residues. An assessment of all potential hazards and risks to having a minimum depth of 90 mm (3 ⁄2 in.), a minimum flange

health shall be made and safety precautions shall be identified width of 30 mm (1 ⁄4 in.) and a minimum folded back return

and provided. Written safety instructions shall be issued. flange legs of 5 mm ( ⁄4 in.).

E2749 − 15a (2019)

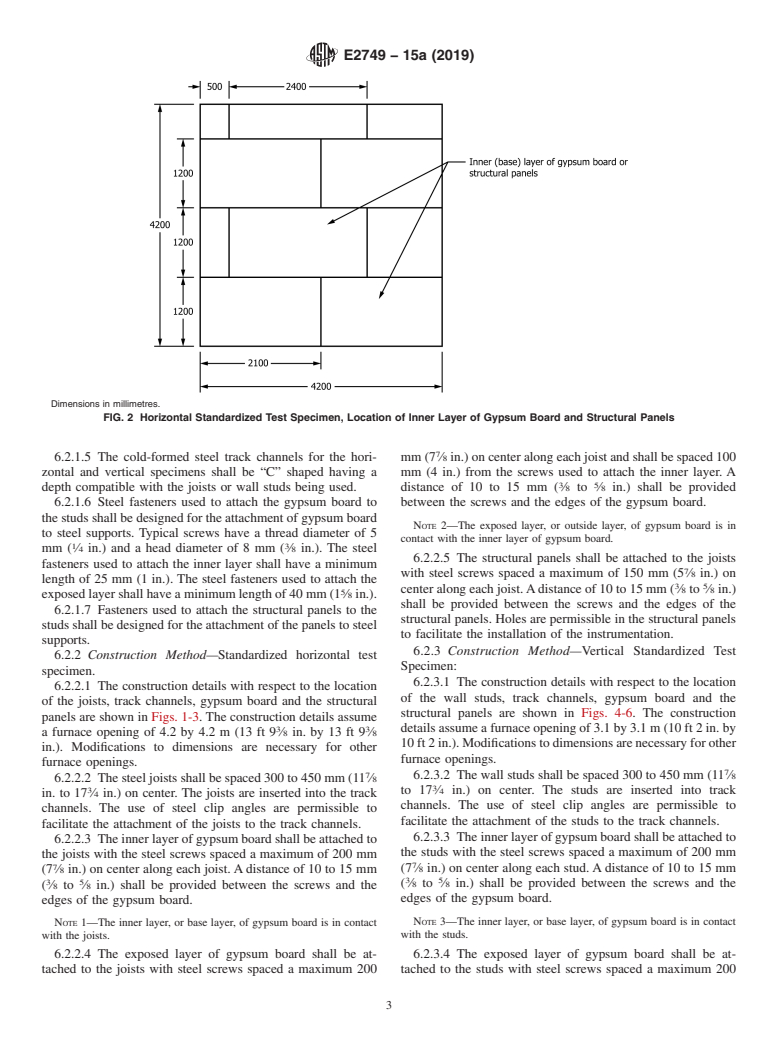

Dimensions in millimetres.

FIG. 2 Horizontal Standardized Test Specimen, Location of Inner Layer of Gypsum Board and Structural Panels

6.2.1.5 The cold-formed steel track channels for the hori- mm (7 ⁄8 in.) on center along each joist and shall be spaced 100

zontal and vertical specimens shall be “C” shaped having a mm (4 in.) from the screws used to attach the inner layer. A

3 5

depth compatible with the joists or wall studs being used. distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided

6.2.1.6 Steel fasteners used to attach the gypsum board to between the screws and the edges of the gypsum board.

the studs shall be designed for the attachment of gypsum board

NOTE 2—The exposed layer, or outside layer, of gypsum board is in

to steel supports. Typical screws have a thread diameter of 5

contact with the inner layer of gypsum board.

1 3

mm ( ⁄4 in.) and a head diameter of 8 mm ( ⁄8 in.). The steel

6.2.2.5 The structural panels shall be attached to the joists

fasteners used to attach the inner layer shall have a minimum

with steel screws spaced a maximum of 150 mm (5 ⁄8 in.) on

length of 25 mm (1 in.). The steel fasteners used to attach the

3 5

center along each joist. A distance of 10 to 15 mm ( ⁄8 to ⁄8 in.)

exposed layer shall have a minimum length of 40 mm (1 ⁄8 in.).

shall be provided between the screws and the edges of the

6.2.1.7 Fasteners used to attach the structural panels to the

structural panels. Holes are permissible in the structural panels

studs shall be designed for the attachment of the panels to steel

to facilitate the installation of the instrumentation.

supports.

6.2.3 Construction Method—Vertical Standardized Test

6.2.2 Construction Method—Standardized horizontal test

Specimen:

specimen.

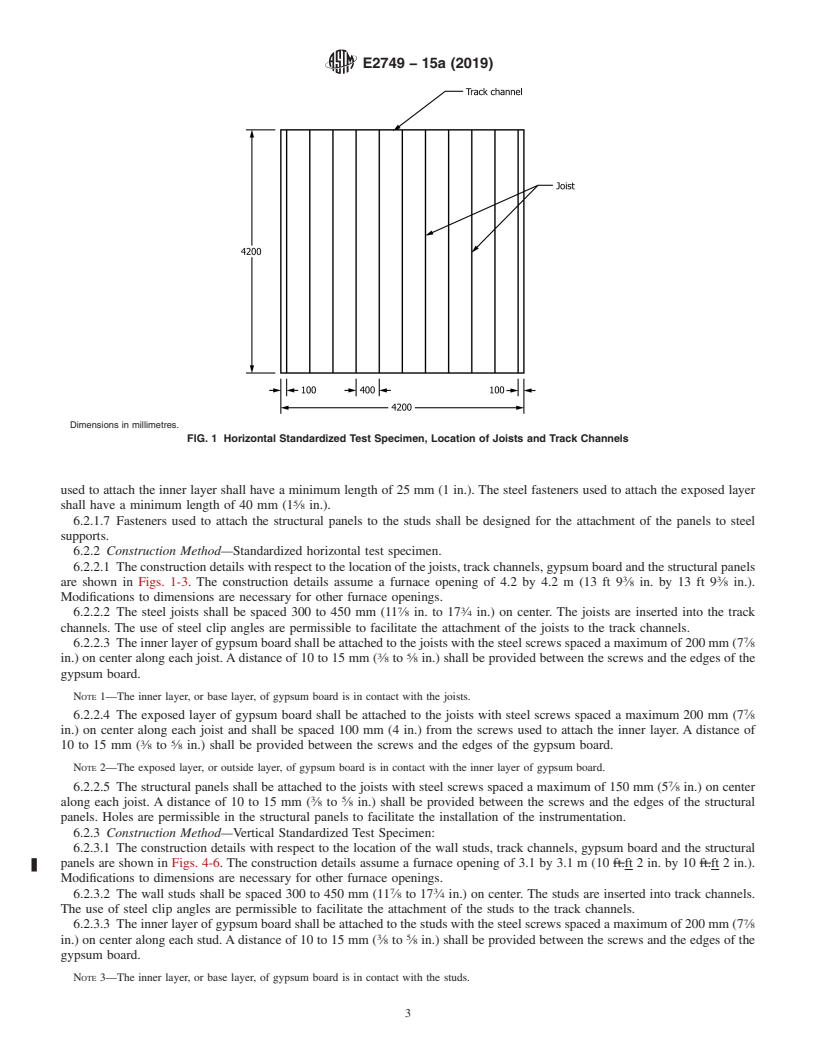

6.2.3.1 The construction details with respect to the location

6.2.2.1 The construction details with respect to the location

of the wall studs, track channels, gypsum board and the

of the joists, track channels, gypsum board and the structural

structural panels are shown in Figs. 4-6. The construction

panels are shown in Figs. 1-3. The construction details assume

3 3 details assume a furnace opening of 3.1 by 3.1 m (10 ft 2 in. by

a furnace opening of 4.2 by 4.2 m (13 ft 9 ⁄8 in. by 13 ft 9 ⁄8

10 ft 2 in.). Modifications to dimensions are necessary for other

in.). Modifications to dimensions are necessary for other

furnace openings.

furnace openings.

6.2.3.2 The wall studs shall be spaced 300 to 450 mm (11 ⁄8

6.2.2.2 The steel joists shall be spaced 300 to 450 mm (11 ⁄8

3 to 17 ⁄4 in.) on center. The studs are inserted into track

in. to 17 ⁄4 in.) on center. The joists are inserted into the track

channels. The use of steel clip angles are permissible to

channels. The use of steel clip angles are permissible to

facilitate the attachment of the studs to the track channels.

facilitate the attachment of the joists to the track channels.

6.2.3.3 The inner layer of gypsum board shall be attached to

6.2.2.3 The inner layer of gypsum board shall be attached to

the studs with the steel screws spaced a maximum of 200 mm

the joists with the steel screws spaced a maximum of 200 mm

(7 ⁄8 in.) on center along each stud. A distance of 10 to 15 mm

(7 ⁄8 in.) on center along each joist. A distance of 10 to 15 mm

3 5

3 5

( ⁄8 to ⁄8 in.) shall be provided between the screws and the

( ⁄8 to ⁄8 in.) shall be provided between the screws and the

edges of the gypsum board.

edges of the gypsum board.

NOTE 3—The inner layer, or base layer, of gypsum board is in contact

NOTE 1—The inner layer, or base layer, of gypsum board is in contact

with the studs.

with the joists.

6.2.2.4 The exposed layer of gypsum board shall be at- 6.2.3.4 The exposed layer of gypsum board shall be at-

tached to the joists with steel screws spaced a maximum 200 tached to the studs with steel screws spaced a maximum 200

E2749 − 15a (2019)

Dimensions in millimetres.

FIG. 3 Horizontal Standardized Test Specimen, Location of Outer Layer of Gypsum Board

3 5

15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and

the edges of the structural panels. Holes are permissible in the

structural panels to facilitate the installation of the instrumen-

tation.

6.3 Furnace Limitations—Furnaces with dedicated

applications, such as testing of ceiling assemblies, typically

have specific horizontal or vertical assemblies for this purpose

and therefore do not include open restraining frames.

6.3.1 It is permissible to modify the standardized test

specimen to account for these limitations.

6.4 Instrumentation—The instrumentation installed on the

standardized test specimen shall include plate thermometers, a

directional flame thermometer, bi-directional probes, Type K

thermocouples and air sampling probes.

6.4.1 The plate thermometers (1) shall be constructed as

shown in Fig. 7.

6.4.1.1 The plate part of the plate thermometer shall be

constructed from 150 61 mm long by 100 6 1 mm wide by 0.7

6 0.1 mm thick nickel alloy plate strips folded to the design

shown in Fig. 7.

Dimensions in millimetres.

6.4.1.2 A Type K ungrounded Inconel sheathed thermo-

FIG. 4 Vertical Standardized Test Specimen, Location of Wall

couple having a maximum diameter of 1 mm shall be fixed to

Studs and Track Channels

the geometric center of the plate in the position shown in Fig.

7 by a steel strip made from the same material as the plate. The

steel strip shall be welded or screwed to the plate. The strip

mm (7 ⁄8 in.) on center along each stud and shall be spaced 100

shall be 18 6 1 mm by 6 6 1 mm when it is spot welded to the

mm (4 in.) from the screws used to attach the inner layer. A

3 5

plate (Fig. 7) and 25 6 1 mm by 6 6 1 mm when it is to be

distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided

screwed to the plate. The screw shall be a maximum 2 mm in

between the screws a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2749 − 15a E2749 − 15a (Reapproved 2019) An American National Standard

Standard Practice for

Measuring the Uniformity of Furnace Exposure on Test

Specimens

This standard is issued under the fixed designation E2749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard provides general principles for measuring the uniformity of the furnace exposure on specimens tested in

accordance with Test Methods E119, E814, E1529, E1725, E1966 and E2336.

1.2 This practice specifies the materials and the construction requirements for a standardized test specimen used to provide a

mounting surface for the instrumentation that measures furnace exposure.

1.3 The instrumentation records temperatures, pressure differentials, and oxygen content near the surface of the test specimen.

1.4 The values stated in SI units are to be regarded as the standard. The units given in parentheses are for information only.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C1396/C1396M Specification for Gypsum Board

E119 Test Methods for Fire Tests of Building Construction and Materials

E176 Terminology of Fire Standards

E814 Test Method for Fire Tests of Penetration Firestop Systems

E1529 Test Methods for Determining Effects of Large Hydrocarbon Pool Fires on Structural Members and Assemblies

E1725 Test Methods for Fire Tests of Fire-Resistive Barrier Systems for Electrical System Components

E1966 Test Method for Fire-Resistive Joint Systems

E2336 Test Methods for Fire Resistive Grease Duct Enclosure Systems

2.2 ISO Technical Report:

ISO/TR 834-2 Fire resistance tests – Elements of building construction – Part 2: Guide on measuring uniformity of furnace

exposure on test samples

3. Terminology

3.1 Definitions—For definitions of terms used in this practice, refer to Terminology E176.

3.2 Definitions of Terms Specific to This Standard:

This practice is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.11 on Fire Resistance.

Current edition approved June 1, 2015March 1, 2019. Published July 2015March 2019. Originally approved in 2010. Last previous edition approved in 2015 as

E2749E2749 – 15a.-15. DOI:10.1520/E2749-15A. DOI:10.1520/E2749-15AR19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2749 − 15a (2019)

3.2.1 effective area of the furnace opening—furnace opening within the boundaries of the monitoring instrumentation.

4. Summary of Practice

4.1 This practice consists of preparing a standardized test specimen to represent test specimens described in Test Methods E119,

E814, E1529, E1725, E1966 and E2336. The standardized test specimen provides a low cost, easily constructed supporting

construction for the mounting of instrumentation that measures the exposure imposed by the furnace onto test specimens.

4.2 The standardized test specimen consists of two layers of 15.9 mm ( ⁄8 in.) thick Type X gypsum board on the surface facing

the furnace chamber attached to steel channels and a single layer of structural panels (plywood or oriented strand board) attached

to the steel channels on the surface away from the furnace chamber. The gypsum board provides a fire-resistive surface for the

mounting of the instrumentation. The structural panels provide stability for the steel support channels.

4.3 Instrumentation to measure the thermal impact due to exposure to the furnace upon the standardized test specimen is

installed at various locations on the exposed surface of the standardized test specimen. Probes used to gather air samples within

the furnace chamber are also installed.

4.4 The standardized test specimen is exposed to the time-temperature curve specified in referenced ASTM fire test standards

for a time period of 45 min during which time data are recorded by the instrumentation mounted on the standardized test specimen.

4.5 The data provide a record of the conditions and uniformity of the furnace exposure upon standardized test specimens. The

area bounded by the instrumentation installed on the standardized test specimen is designated as the effective area of the furnace

opening.

5. Significance and Use

5.1 This practice describes a procedure to gather data intended to measure the uniformity of exposure conditions upon test

specimens for the fire test methods described in Test Methods E119, E814, E1529, E1725, E1966 and E2336. The collected data

from furnaces are intended to form a basis for performance requirements for the furnaces described in the referenced standards.

5.2 This practice does not include requirements for furnace performance.

5.3 In this procedure, the standardized test specimen is subjected to one or more specific sets of laboratory test conditions. If

different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this procedure

to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire-test-exposure

conditions described in this procedure.

5.4 The attention of all persons connected with the conduct of this practice is drawn to the fact that fire testing is hazardous and

that there is a possibility that harmful smoke and gases are developed during the test. There is also a possibility that mechanical

and operational hazards develop during the construction of the test specimen and the disposal of the test residues. An assessment

of all potential hazards and risks to health shall be made and safety precautions shall be identified and provided. Written safety

instructions shall be issued. Appropriate training shall be provided to relevant personnel. Laboratory personnel shall ensure that

they follow written safety instructions at all times.

6. Apparatus

6.1 The furnace(s) and restraining frame(s) used to conduct tests in accordance with Test Methods E119, E814, E1529, E1725,

E1966 and E2336 shall be used.

6.2 Standardized Test Specimen:

6.2.1 Materials—The materials used to construct the standardized test specimen shall consist of the following: gypsum board,

structural panels, cold-formed steel supports and fasteners.

6.2.1.1 The gypsum board shall be minimum 15.9 mm ( ⁄8 in.) thick complying with the requirements of Type X as defined in

Specification C1396/C1396M.

6.2.1.2 The structural panels shall be minimum 18 mm (nominal ⁄4 in.) thick. Typical materials include plywood and oriented

strand boards.

6.2.1.3 The cold-formed steel joists for horizontal specimens shall be fabricated from minimum 1.4 mm thick (0.055 in.) steel.

The cold formed steel joists shall be “C” shaped having a minimum depth of 240 mm (9 ⁄2 in.), a minimum flange width of 40

5 1

mm (1 ⁄8 in.) and a minimum lip length of 12 mm ( ⁄2 in.).

6.2.1.4 The cold-formed steel wall studs for vertical specimens shall be fabricated from minimum 0.9 mm thick (0.035 in.) steel.

The cold-formed steel wall studs shall be “C” shaped having a minimum depth of 90 mm (3 ⁄2 in.), a minimum flange width of

1 1

30 mm (1 ⁄4 in.) and a minimum folded back return flange legs of 5 mm ( ⁄4 in.).

6.2.1.5 The cold-formed steel track channels for the horizontal and vertical specimens shall be “C” shaped having a depth

compatible with the joists or wall studs being used.

6.2.1.6 Steel fasteners used to attach the gypsum board to the studs shall be designed for the attachment of gypsum board to

1 3

steel supports. Typical screws have a thread diameter of 5 mm ( ⁄4 in.) and a head diameter of 8 mm ( ⁄8 in.). The steel fasteners

E2749 − 15a (2019)

Dimensions in millimetres.

FIG. 1 Horizontal Standardized Test Specimen, Location of Joists and Track Channels

used to attach the inner layer shall have a minimum length of 25 mm (1 in.). The steel fasteners used to attach the exposed layer

shall have a minimum length of 40 mm (1 ⁄8 in.).

6.2.1.7 Fasteners used to attach the structural panels to the studs shall be designed for the attachment of the panels to steel

supports.

6.2.2 Construction Method—Standardized horizontal test specimen.

6.2.2.1 The construction details with respect to the location of the joists, track channels, gypsum board and the structural panels

3 3

are shown in Figs. 1-3. The construction details assume a furnace opening of 4.2 by 4.2 m (13 ft 9 ⁄8 in. by 13 ft 9 ⁄8 in.).

Modifications to dimensions are necessary for other furnace openings.

7 3

6.2.2.2 The steel joists shall be spaced 300 to 450 mm (11 ⁄8 in. to 17 ⁄4 in.) on center. The joists are inserted into the track

channels. The use of steel clip angles are permissible to facilitate the attachment of the joists to the track channels.

6.2.2.3 The inner layer of gypsum board shall be attached to the joists with the steel screws spaced a maximum of 200 mm (7 ⁄8

3 5

in.) on center along each joist. A distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and the edges of the

gypsum board.

NOTE 1—The inner layer, or base layer, of gypsum board is in contact with the joists.

6.2.2.4 The exposed layer of gypsum board shall be attached to the joists with steel screws spaced a maximum 200 mm (7 ⁄8

in.) on center along each joist and shall be spaced 100 mm (4 in.) from the screws used to attach the inner layer. A distance of

3 5

10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and the edges of the gypsum board.

NOTE 2—The exposed layer, or outside layer, of gypsum board is in contact with the inner layer of gypsum board.

6.2.2.5 The structural panels shall be attached to the joists with steel screws spaced a maximum of 150 mm (5 ⁄8 in.) on center

3 5

along each joist. A distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and the edges of the structural

panels. Holes are permissible in the structural panels to facilitate the installation of the instrumentation.

6.2.3 Construction Method—Vertical Standardized Test Specimen:

6.2.3.1 The construction details with respect to the location of the wall studs, track channels, gypsum board and the structural

panels are shown in Figs. 4-6. The construction details assume a furnace opening of 3.1 by 3.1 m (10 ft.ft 2 in. by 10 ft.ft 2 in.).

Modifications to dimensions are necessary for other furnace openings.

7 3

6.2.3.2 The wall studs shall be spaced 300 to 450 mm (11 ⁄8 to 17 ⁄4 in.) on center. The studs are inserted into track channels.

The use of steel clip angles are permissible to facilitate the attachment of the studs to the track channels.

6.2.3.3 The inner layer of gypsum board shall be attached to the studs with the steel screws spaced a maximum of 200 mm (7 ⁄8

3 5

in.) on center along each stud. A distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and the edges of the

gypsum board.

NOTE 3—The inner layer, or base layer, of gypsum board is in contact with the studs.

E2749 − 15a (2019)

Dimensions in millimetres.

FIG. 2 Horizontal Standardized Test Specimen, Location of Inner Layer of Gypsum Board and Structural Panels

Dimensions in millimetres.

FIG. 3 Horizontal Standardized Test Specimen, Location of Outer Layer of Gypsum Board

6.2.3.4 The exposed layer of gypsum board shall be attached to the studs with steel screws spaced a maximum 200 mm (7 ⁄8

in.) on center along each stud and shall be spaced 100 mm (4 in.) from the screws used to attach the inner layer. A distance of 10

3 5

to 15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and the edges of the gypsum board.

NOTE 4—The exposed layer, or outside layer, of gypsum board is in contact with the inner layer of gypsum board.

6.2.3.5 The structural panels shall be attached to the support channels with steel screws spaced a maximum of 150 mm (5 ⁄8

3 5

in.) on center along each support channel. A distance of 10 to 15 mm ( ⁄8 to ⁄8 in.) shall be provided between the screws and the

edges of the structural panels. Holes are permissible in the structural panels to facilitate the installation of the instrumentation.

6.3 Furnace Limitations—Furnaces with dedicated applications, such as testing of ceiling assemblies, typically have specific

horizontal or vertical assemblies for this purpose and therefore do not include open restraining frames.

E2749 − 15a (2019)

Dimensions in millimetres.

FIG. 4 Vertical Standardized Test Specimen, Location of Wall Studs and Track Channels

6.3.1 It is permissible to modify the standardized test specimen to account for these limitations.

6.4 Instrumentation—The instrumentation installed on the standardized test specimen shall include plate thermometers, a

directional flame thermometer, bi-directional probes, Type K thermocouples and air sampling probes.

6.4.1 The plate thermometers (1) shall be constructed as sho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.