ASTM A860/A860M-00

(Specification)Standard Specification for Wrought High-Strength Low-Alloy Steel Butt-Welding Fittings

Standard Specification for Wrought High-Strength Low-Alloy Steel Butt-Welding Fittings

SCOPE

1.1 This specification covers wrought high-strength low-alloy steel butt-welding fittings of seamless and electric fusion-welded construction covered by the latest revisions of ANSI B16.9, ANSI 16.28, and MSS-SP-75. Butt-welding fittings differing from these ASME and MSS standards shall be furnished in accordance with Supplementary Requirement S58 of Specification A960. These fittings are for use in high-pressure gas and oil transmission and distribution systems.

1.2 Optional supplementary requirements are provided for fittings when a greater degree of examination is desired. One or more of the supplementary requirements may be specified in the order.

1.3 This specification does not cover cast-welding fittings or fittings machined from castings.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification. Unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 860/A 860M – 00

Standard Specification for

Wrought High-Strength Low-Alloy Steel Butt-Welding

1

Fittings

ThisstandardisissuedunderthefixeddesignationA860/A860M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope AWS5.18 Specification for Carbon Steel Metals for Gas

3

Shielded Arc Welding

1.1 This specification covers wrought high-strength low-

4

2.3 ASME Boiler and Pressure Vessel Code:

alloysteelbutt-weldingfittingsofseamlessandelectricfusion-

Section V, Nondestructive Examination

welded construction covered by the latest revisions of ANSI

Section VIII, Division 1, Pressure Vessels

B16.9, ANSI 16.28, and MSS-SP-75. Butt-welding fittings

differing from these ASME and MSS standards shall be

3. Ordering Information

furnished in accordance with Supplementary Requirement S58

3.1 In addition to the requirements of Specification A960,

of Specification A960. These fittings are for use in high-

the following ordering information applies:

pressure gas and oil transmission and distribution systems.

3.1.1 Grade Symbol,

1.2 Optional supplementary requirements are provided for

3.1.2 Requirements for certification of test report.

fittingswhenagreaterdegreeofexaminationisdesired.Oneor

more of the supplementary requirements may be specified in

4. General Requirements

the order.

4.1 Product furnished to this specification shall conform to

1.3 Thisspecificationdoesnotcovercast-weldingfittingsor

the requirements of SpecificationA960, including any supple-

fittings machined from castings.

mentary requirements that are indicated in the purchase order.

1.4 The values stated in either inch-pound units or SI units

Failure to comply with the general requirements of Specifica-

are to be regarded separately as standard. Within the text, the

tionA960 constitutes nonconformance with this specification.

SI units are shown in brackets. The values stated in each

In case of conflict between the requirements of this specifica-

system are not exact equivalents; therefore, each system must

tion and Specification A960, this specification shall prevail.

beusedindependentlyoftheother.Combiningvaluesfromthe

two systems may result in nonconformance with this specifi-

5. Materials and Manufacture

cation. Unless the order specifies the applicable “M” specifi-

5.1 The material for fittings shall be fully killed fine-grain

cation designation (SI units), the material shall be furnished to

material made by a melting process that is intended to produce

inch-pound units.

rounded, well dispersed, fine sulphide inclusions, that promote

good notch toughness, assists in the resistance to hydrogen

2. Referenced Documents

induced cracking, and for weldability suitable for field weld-

2.1 ASTM Standards:

ing.

A530/A530M Specification for General Requirements for

2 5.2 Starting materials shall consist of plate, sheet, forgings,

Specialized Carbon and Alloy Steel Pipe

forging quality bar, and seamless or fusion-welded tubular

A 960 Specification for Common Requirements for

2 products with filler metal added. The chemical composition

Wrought Steel Piping Fittings

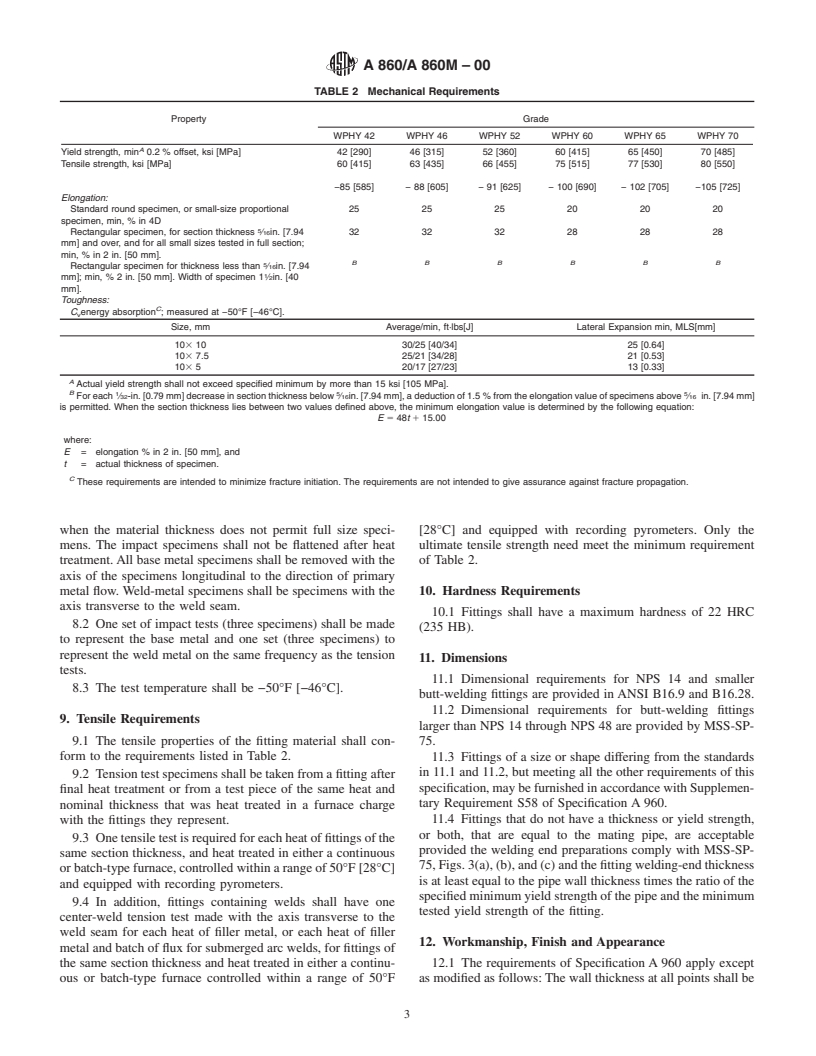

shall conform to Table 1.

2.2 AWS Standard:

5.3 Astartingmaterialthatspecificallyrequirestheaddition

of any element beyond those listed in Table 1 is not permitted.

1

This does not preclude the use of deoxidizers.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel, and RelatedAlloysand is the direct responsibility of Subcommittee

A01.22on Steel Forgings and Wrought Fittings for PipingApplications and Bolting

3

Materials for Piping and Special Purpose Applications. Available fromAmerican Welding Society, 550 N. W. Lajeune Rd., Miami, FL

Current edition approved Dec. 10, 2000. Published February 2001. Originally 33135.

4

published as A860/A860M–86. Last previous edition A860/A860M–96. Available from American Society of Mechanical Engineers, 345 E. 47th St.,

2

Annual Book of ASTM Standards, Vol 01.01. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 860/A 860M – 00

TABLE 1 Chemical Requirements

method.AcceptableteesshallbemarkedwiththesymbolPTor

Composition % MT, as applicable, to indicate compliance. NDE personnel

shall be qualified in accordance with SNT-TC-1A.

Heat

Analysis

5.9 All caps machined from bar stock shall be examined by

A

Carbon 0.20 liquid penetrant or magnetic particle in accordance with

Manganese 1.00–1.45 All values are

Supplementary Requirements S69 or S70 of Specification

Phosphorus 0.030 maximum unless

A960, and with p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.