ASTM F1839-08e1

(Specification)Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopedic Devices and Instruments

Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopedic Devices and Instruments

ABSTRACT

This specification covers rigid polyurethane foam blocks or sheets recommended for use as a standard material for mechanical testing using orthopedic devices and instruments. Although the physical properties of the foam are in the order of those reported for human cancellous bones, these materials are not intended for implantation into the human body. All materials should conform to the specified quality of appearance, dimensional stability, and composition, and values of void content, compressive strength, compressive modulus, shear strength, shear modulus, and screw pullout.

SIGNIFICANCE AND USE

This specification describes the compositional requirements, physical requirements, mechanical requirements, and test methods for rigid unicellular polyurethane foam for use in testing orthopaedic devices or instruments.

This foam described in this specification is not intended to replicate the mechanical properties of human or animal bone. The requirements of this specification are intended to provide a consistent and uniform material with properties on the order of human cancellous bone to use as a test medium when testing various orthopaedic devices, such as bone screws.

SCOPE

1.1 This specification covers rigid unicellular polyurethane foam for use as a standard material for performing mechanical tests utilizing orthopaedic devices or instruments. The specification is applicable to sheets or blocks of foam, or foam that is made by the user using a two-part liquid mixture.

1.2 This specification covers polyurethane foam material that is used in the laboratory for mechanical testing, as described in 1.1. These materials are not intended for implantation into the human body.

1.3 The foam described herein possesses mechanical properties which are on the order of those reported for human cancellous bone. See Appendix X1 Rationale for further information regarding the appropriateness of using the specified foam as a model for human cancellous bone.

1.4 This specification covers compositional requirements, physical requirements, mechanical requirements, and test methods for rigid polyurethane foam in the solid final form.

1.5 This specification provides qualification criteria for vendor or end-user processes and acceptance criteria for individual material lots.

1.6 This specification provides mechanical properties of five different grades of foam in the solid final form. A foam that does not meet the specified mechanical properties shall be identified as an ungraded foam.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 The following precautionary statement pertains to the test method portion only, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1839 – 08

Standard Specification for

Rigid Polyurethane Foam for Use as a Standard Material for

1

Testing Orthopaedic Devices and Instruments

This standard is issued under the fixed designation F1839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information was editorially corrected in August 2009.

1. Scope 2. Referenced Documents

2

1.1 This specification covers rigid unicellular polyurethane 2.1 ASTM Standards:

foam for use as a standard material for performing mechanical C273 Test Method for Shear Properties of Sandwich Core

tests utilizing orthopaedic devices or instruments. The specifi- Materials

cation is applicable to sheets or blocks of foam, or foam that is D1621 Test Method for Compressive Properties Of Rigid

made by the user using a two-part liquid mixture. Cellular Plastics

1.2 This specification covers polyurethane foam material D1622 Test Method forApparent Density of Rigid Cellular

that is used in the laboratory for mechanical testing, as Plastics

described in 1.1. These materials are not intended for implan- E4 Practices for Force Verification of Testing Machines

tation into the human body. F543 Specification and Test Methods for Metallic Medical

1.3 The foam described herein possesses mechanical prop- Bone Screws

erties which are on the order of those reported for human

3. Terminology

cancellous bone. See Appendix X1 Rationale for further

information regarding the appropriateness of using the speci- 3.1 Definitions:

3.1.1 final form—the condition of the foam product when

fied foam as a model for human cancellous bone.

1.4 This specification covers compositional requirements, used by the end user to perform tests of orthopaedic devices or

instruments.

physical requirements, mechanical requirements, and test

methods for rigid polyurethane foam in the solid final form. 3.1.1.1 Discussion—This is the condition of the foam prod-

uct of which all physical and mechanical tests required by this

1.5 This specification provides qualification criteria for

specification are performed.

vendor or end-user processes and acceptance criteria for

individual material lots. 3.1.1.2 solid—the foam is in a uniform solid form, such as

a slab, plate, or block.

1.6 Thisspecificationprovidesmechanicalpropertiesoffive

different grades of foam in the solid final form. A foam that 3.1.2 foam rise direction—the nominal direction that the

foam rises during the polymerization (“foaming”) process,

does not meet the specified mechanical properties shall be

identified as an ungraded foam. either at the supplier’s production facilities for the solid

supplied foam, or at the end-user’s facilities for foam produced

1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this from the liquid supplied form. The foam rise direction shall be

marked on the foam block or indicated in the shipping

standard.

1.8 The following precautionary statement pertains to the documentation for foam that is supplied in the solid form.

3.1.3 grades—The grade designation refers to the nominal

test method portion only, Section 8, of this specification: This

standard does not purport to address all of the safety concerns, density of the foam, in its solid final form, expressed in units

3

of kg/m . Ten grades of foam have been defined in this

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health specification. Their nominal densities are:

3

practices and determine the applicability of regulatory limita- Grade 5: 80.1 kg/m

3

Grade 10: 160.2 kg/m

tions prior to use.

3

Grade 12: 192.2 kg/m

3

Grade 15: 240.3 kg/m

1

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

2

Subcommittee F04.21 on Osteosynthesis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2008. Published December 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1997. Last previous edition approved in 2007 as F1839 – 01(2007). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1839-08E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F1839 – 08

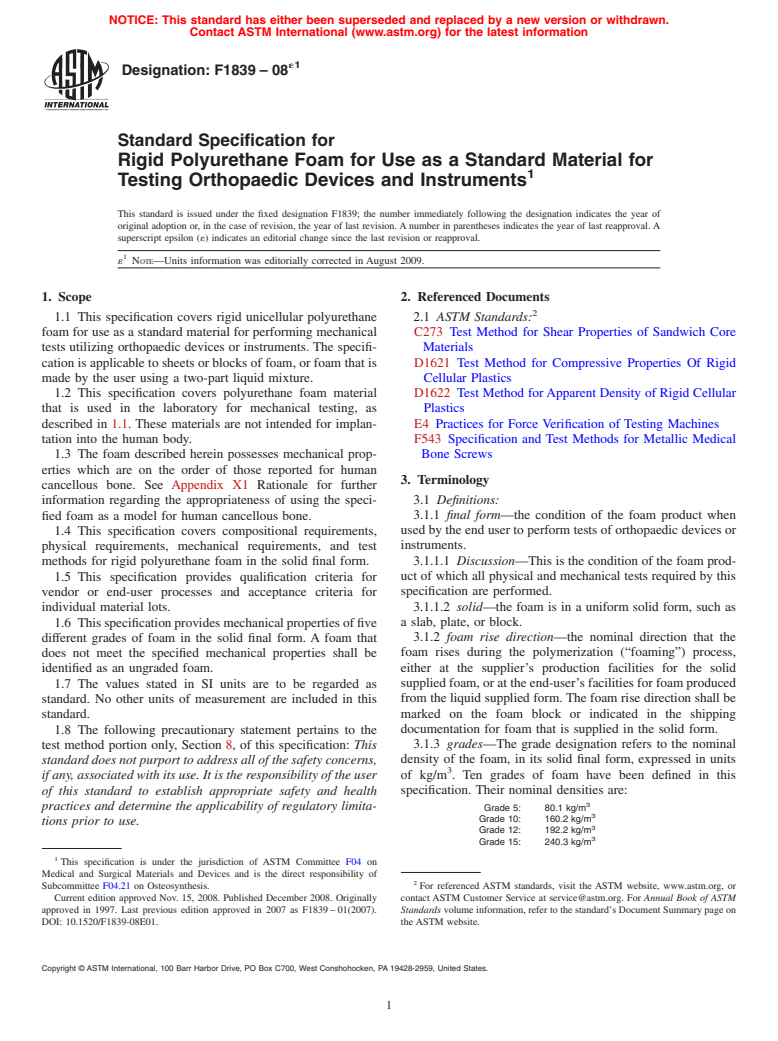

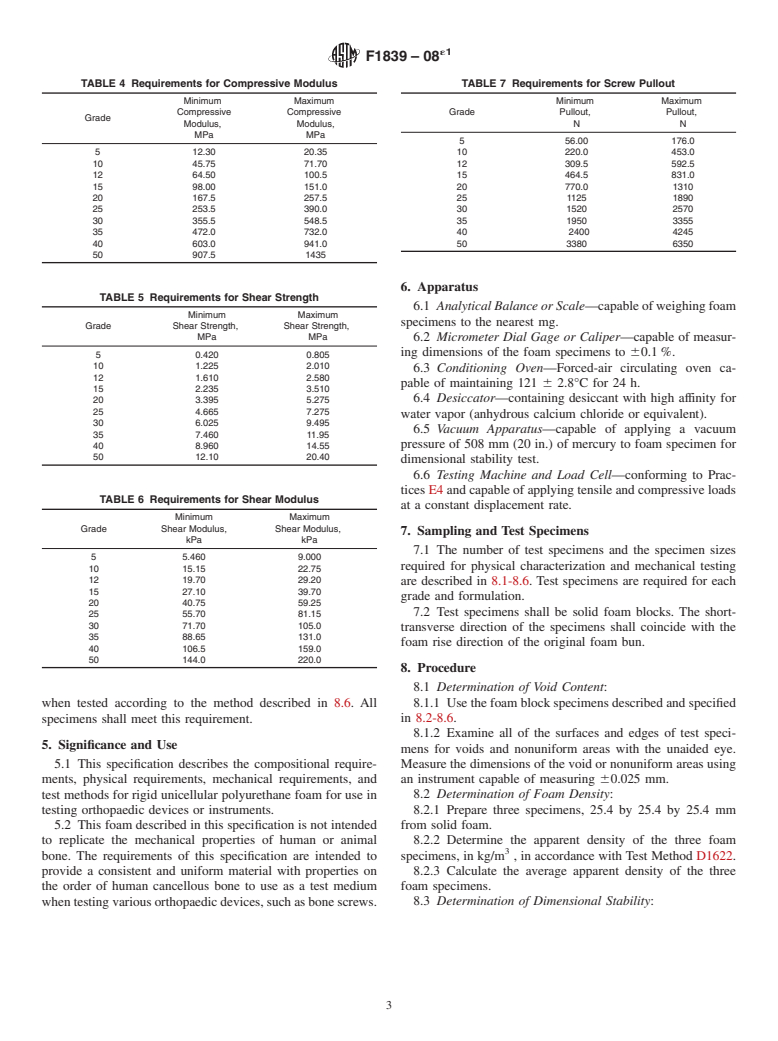

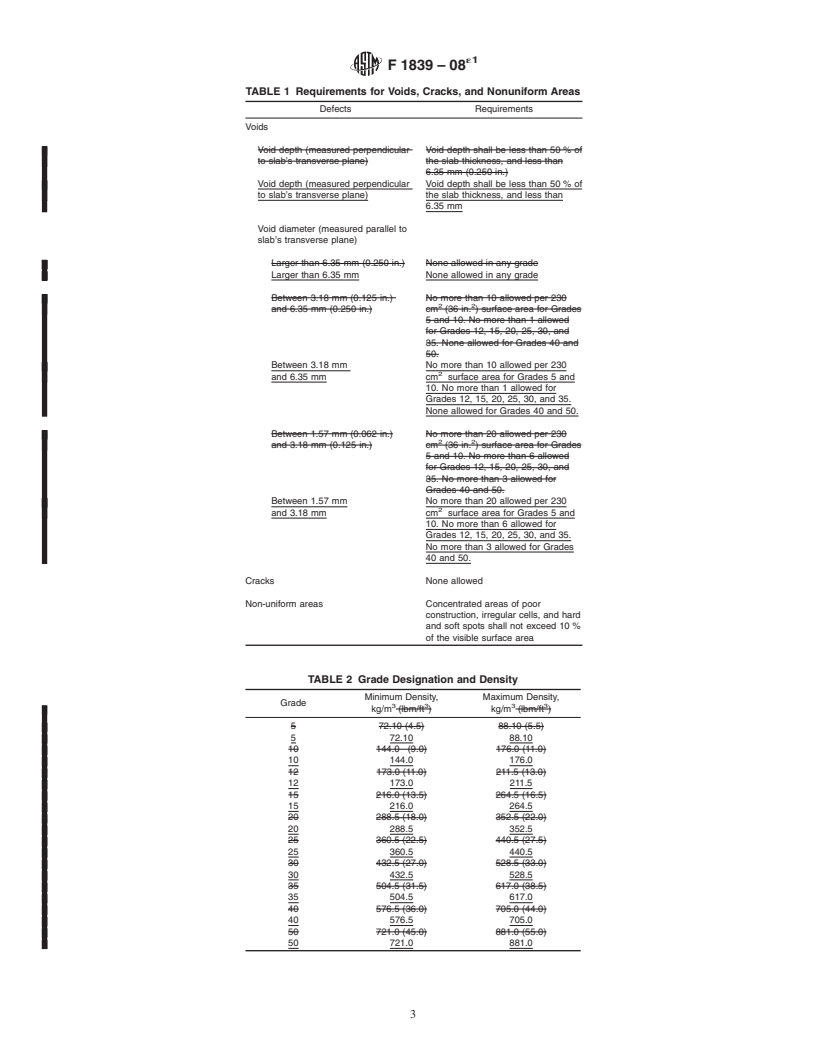

3 TABLE 1 Requirements for Voids, Cracks, and Nonuniform Areas

Grade 20: 320.4 kg/m

3

Grade 25: 400.5 kg/

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F1839–01 (Reapproved 2007) Designation: F 1839 – 08

Standard Specification for

Rigid Polyurethane Foam for Use as a Standard Material for

1

Testing Orthopaedic Devices and Instruments

This standard is issued under the fixed designation F 1839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information was editorially corrected in August 2009.

1. Scope

1.1 This specification covers rigid unicellular polyurethane foam for use as a standard material for performing mechanical tests

utilizing orthopaedic devices or instruments. The specification is applicable to sheets or blocks of foam, or foam that is made by

the user using a two-part liquid mixture.

1.2 This specification covers polyurethane foam material that is used in the laboratory for mechanical testing, as described in

1.1. These materials are not intended for implantation into the human body.

1.3 The foam described herein possesses mechanical properties which are on the order of those reported for human cancellous

bone. SeeAppendix X1 Rationale for further information regarding the appropriateness of using the specified foam as a model for

human cancellous bone.

1.4 Thisspecificationcoverscompositionalrequirements,physicalrequirements,mechanicalrequirements,andtestmethodsfor

rigid polyurethane foam in the solid final form.

1.5 This specification provides qualification criteria for vendor or end-user processes and acceptance criteria for individual

material lots.

1.6 This specification provides mechanical properties of five different grades of foam in the solid final form.Afoam that does

not meet the specified mechanical properties shall be identified as an ungraded foam.

1.7Unless otherwise indicated, the values stated in SI units are to be regarded as standard. The values in parentheses are given

for information only.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 The following precautionary statement pertains to the test method portion only, Section 8, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 273 Test Method for Shear Properties of Sandwich Core Materials

D 1621 Test Method for Compressive Properties Of Rigid Cellular Plastics

D 1622 Test Method for Apparent Density of Rigid Cellular Plastics

E4 Practices for Force Verification of Testing Machines

F 543 Specification and Test Methods for Metallic Medical Bone Screws

3. Terminology

3.1 Definitions:

3.1.1 final form—the condition of the foam product when used by the end user to perform tests of orthopedic devices or

instruments. The condition of the foam product of which all physical and mechanical tests required by this specification are

performed. —the condition of the foam product when used by the end user to perform tests of orthopaedic devices or instruments.

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.21 on Osteosynthesis.

Current edition approved Oct. 1, 2007. Published October 2007. Originally approved in 1997. Last previous edition approved in 2001 as F1839–01.

Current edition approved Nov. 15, 2008. Published December 2008. Originally approved in 1997. Last previous edition approved in 2007 as F 1839 – 01(2007).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F1839–08

3.1.1.1 Discussion—This is the condition of the foam product of which all physical and mechanical tests required by this

specification are performed.

3.1.1.2 solid—the foam is in a uniform solid form, such as a slab, plate, or block.

3.1.2 foam rise direction—th

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F1839–08 Designation: F 1839 – 08

Standard Specification for

Rigid Polyurethane Foam for Use as a Standard Material for

1

Testing Orthopaedic Devices and Instruments

This standard is issued under the fixed designation F 1839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information was editorially corrected in August 2009.

1. Scope

1.1 This specification covers rigid unicellular polyurethane foam for use as a standard material for performing mechanical tests

utilizing orthopaedic devices or instruments. The specification is applicable to sheets or blocks of foam, or foam that is made by

the user using a two-part liquid mixture.

1.2 This specification covers polyurethane foam material that is used in the laboratory for mechanical testing, as described in

1.1. These materials are not intended for implantation into the human body.

1.3 The foam described herein possesses mechanical properties which are on the order of those reported for human cancellous

bone. SeeAppendix X1 Rationale for further information regarding the appropriateness of using the specified foam as a model for

human cancellous bone.

1.4 Thisspecificationcoverscompositionalrequirements,physicalrequirements,mechanicalrequirements,andtestmethodsfor

rigid polyurethane foam in the solid final form.

1.5 This specification provides qualification criteria for vendor or end-user processes and acceptance criteria for individual

material lots.

1.6 This specification provides mechanical properties of five different grades of foam in the solid final form.Afoam that does

not meet the specified mechanical properties shall be identified as an ungraded foam.

1.7Unless otherwise indicated, the values stated in SI units are to be regarded as standard. The values in parentheses are

mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 The following precautionary statement pertains to the test method portion only, Section 8, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 273 Test Method for Shear Properties of Sandwich Core Materials

D 1621 Test Method for Compressive Properties Of Rigid Cellular Plastics

D 1622 Test Method for Apparent Density of Rigid Cellular Plastics

E4 Practices for Force Verification of Testing Machines

F 543 Specification and Test Methods for Metallic Medical Bone Screws

3. Terminology

3.1 Definitions:

3.1.1 final form—the condition of the foam product when used by the end user to perform tests of orthopaedic devices or

instruments.

3.1.1.1 Discussion—This is the condition of the foam product of which all physical and mechanical tests required by this

specification are performed.

3.1.1.2 solid—the foam is in a uniform solid form, such as a slab, plate, or block.

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.21 on Osteosynthesis.

Current edition approved Nov. 15, 2008. Published December 2008. Originally approved in 1997. Last previous edition approved in 2007 as F 1839 – 01(2007).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F1839–08

3.1.2 foam rise direction—thenominaldirectionthatthefoamrisesduringthepolymerization(“foaming”)process,eitheratthe

supplier’sproductionfacilitiesforthesolidsuppliedfoam,orattheend-user’sfacilitiesforfoamproducedfromtheliquidsupplied

form. The foam rise direction shall be marked on the foam block or indicated in the shipping documentation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.