ASTM B4-79

(Specification)Specification for Tough-Pitch Lake Copper-Refinery Shapes (Withdrawn 1980)

Specification for Tough-Pitch Lake Copper-Refinery Shapes (Withdrawn 1980)

General Information

Standards Content (Sample)

dUJ~ : AMERICAN NATIONAL ANSI/ ASTM B 4 - 79

'Jij 11 STANDARD

Standard Specification for

1

TOUGH-PITCH LAKE COPPER-REFINERY SHAPES

This standard is issued under the fixed designation B 4; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval.

1. Scope E 53 Chemical Analysis of Copper (Electro

4

lytic Determination of Copper)

I. I This specification covers tough-pitch

E 54 Chemical Analysis of Special Brasses

lake copper wire bars, cakes, slabs, billets, in

4

and Bronzes

gots, and ingot bars.

E 62 Photometric Methods for Chemical

1.2 Two types of copper are included as

4

Analysis of Copper and Copper Alloys

follows:

E 527 Recommended Practice for Number

1.2.l Low-resistance lake copper (UNS

ing Metals and Alloys (UNS)5

Cll300, Cll400, Cl 1500, and Cl 1600*) (Sec

tions 4 and 5).

3. Ordering Information

l .2.2 High-resistance lake copper (Sections

3.1 Orders for material under this specifica

4 and 5).

tion shall include the following information:

1.3 Although this specification includes cer

3.1.l Type of copper (l.2),

tain UNS designations as described in Rec

3.1.2 If cakes, slabs, or billets are ordered for

ommended Practice E 527, these designations

electrical use, it must be so stated (Table 2),

are for cross reference only and are not speci

3.1.3 Silver content, if desired (4. l and Note

fication requirements. Therefore, in case of

5),

conflict, this ASTM specification shall govern.

3.1.4 Shape and dimensions of each piece,

NoTE I-Low-resistance lake copper under this

and

specification corresponds to the designations

"FRHC" and "FRTP" as shown in Classification

3.1.5 Quantity.

B 224. This copper may also be used to produce

copper corresponding to designations "ATP," "STP,"

4. Chemical Requirements

"FRSTP," "DHP," "DHPS," "DPA," and "DPTE."

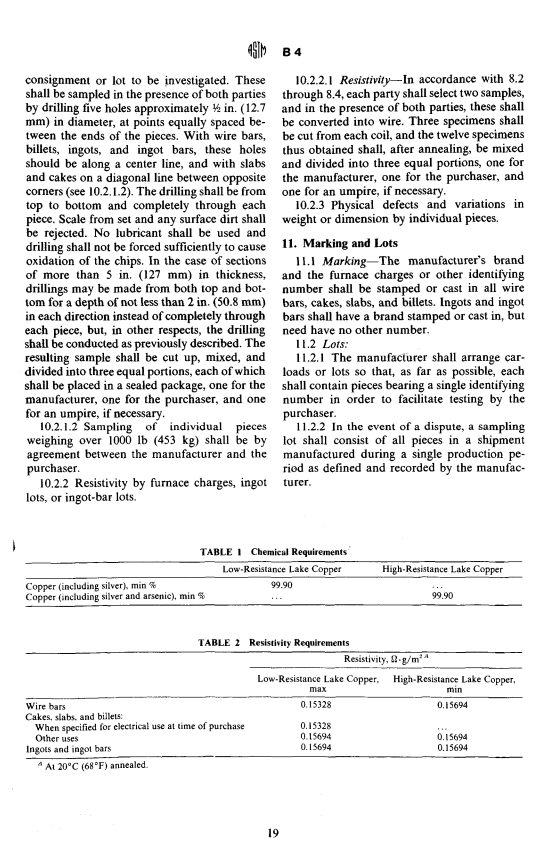

4.1 Copper of each type shall conform to the

NoTE 2-High-resistance lake copper under this

specification corresponds to the designation "ATP" requirements as to chemical composition pre

as shown in Classification B 224.

scribed in Table I.

l.4 In order to be classified as lake copper, Norn 5-By agreement between the manufac

turer and the purchaser, the addition of silver up to

the copper must originate on the northern pe

a nominal 30 troy oz/short ton (0.102 %) will be

ninsula of Michigan, U.S.A.

considered within the specifications; silver being

NoTE 3-This specification has been drawn to

cover the peculiar trade situation that has classified

the large production of copper from this geographical

1

This specification is under the jurisdiction of ASTM

district as a product in a class by itself.

Committee B-2 on Nonferrous Metals and Alloys.

N01f,4-The values stated in U.S. customary

Current edition approved Jan. 26, 1979. Published March

units are to be regarded as the standard.

1979. Originally published as B 4 - 11. Last previous edition

B4-77.

2. Applicable Documents • New designation established in accordance with ASTM

E 527 and SAE 11086, Recommended Practice for Number

2.l ASTM Standards:

ing Metals and Alloys (UNS).

: Annual Book of ASTM Standards, Parts 6, 7, and 44.

B 193 Test for Resistivity of Electrical Con

2 ~ Annual Book of ASTM Standards, Parts 6 and 8.

ductor Materials

Annual Book of ASTM Standards, Part 12.

3

B 224 Classification of Coppers 'Annual Book of ASTM Standards, Parts I to 10.

17

---------------------- Page: 1 ----------------------

84

counted as copper in the chemical analysis, with no sion greater than 8 in. (203.2 mm). The weight

individual silver analysis to exceed 35 troy oz/short

of copper in ingots and ingot bars shall not

ton (0.12 %).

exceed that specified by more than IO %, but

otherwise its variation is not important.

5. Physical Requirements

5. l Electrical Resistivity-Copper of each

7. Workmanship, Finish, and Appearance

type shall conform to the requirements for

7. l Wire bars, cakes, slabs, and billets shall

electrical resistivity prescribed in Table 2.

be substantially free of shrink holes, cold sets,

NoTE 6-"Resistivity" is used in place of "con

pits, sloppy edges, concave tops, and similar

2

ductivity." The value of 0.15328 S2,g/m at 20°C

defects in set or casting. This requirement shall

(68°F) is the International Annealed Copper Stan

not apply to ingots or ingot bars in which

dard for the resistivity of annealed copper equal to

2

physical defects are of no consequence.

JOO% conductivity. The value of0.15694 S'J,g/m is

for annealed copper of97.66 % conductivity.

8. Specimen Preparation

6. Dimensions, Weights, and Permissible Var

8.1 Each resistivity test specimen shall orig

iations

inate normally as a casting of suitable size

poured during the casting period of the furnace.

6. l Standard Sizes and Shapes of Wire Bars:

6. l.l One size of mold shall be used for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.