ASTM C1681-09

(Test Method)Standard Test Method for Evaluating the Tear Resistance of a Sealant Under Constant Strain

Standard Test Method for Evaluating the Tear Resistance of a Sealant Under Constant Strain

SIGNIFICANCE AND USE

This test method is intended to determine if a joint that is subjected to a mechanically induced cut will resist tear propagation during normal joint movement. A sealant with a high resistance to tear propagation will typically perform better than a sealant with a low resistance to tear propagation.

SCOPE

1.1 This test method evaluates the impact of an induced tear on a sealant specimen that is dimensioned, cured according to the guidelines in Test Method C 719 and then subjected to a constant strain. It is effective in differentiating between sealants that are used in dynamic joints subject to abrasion, punctures, tears, or combination thereof.

1.2 Since this test method is for the evaluation of tear propagation, an adhesive failure to the substrates provides no usable data regarding tear propagation. This would be considered a failed test and that data would be discarded, or at least separated from the other data from specimens that did not experience an adhesive failure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1681 − 09

StandardTest Method for

Evaluating the Tear Resistance of a Sealant Under Constant

Strain

This standard is issued under the fixed designation C1681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

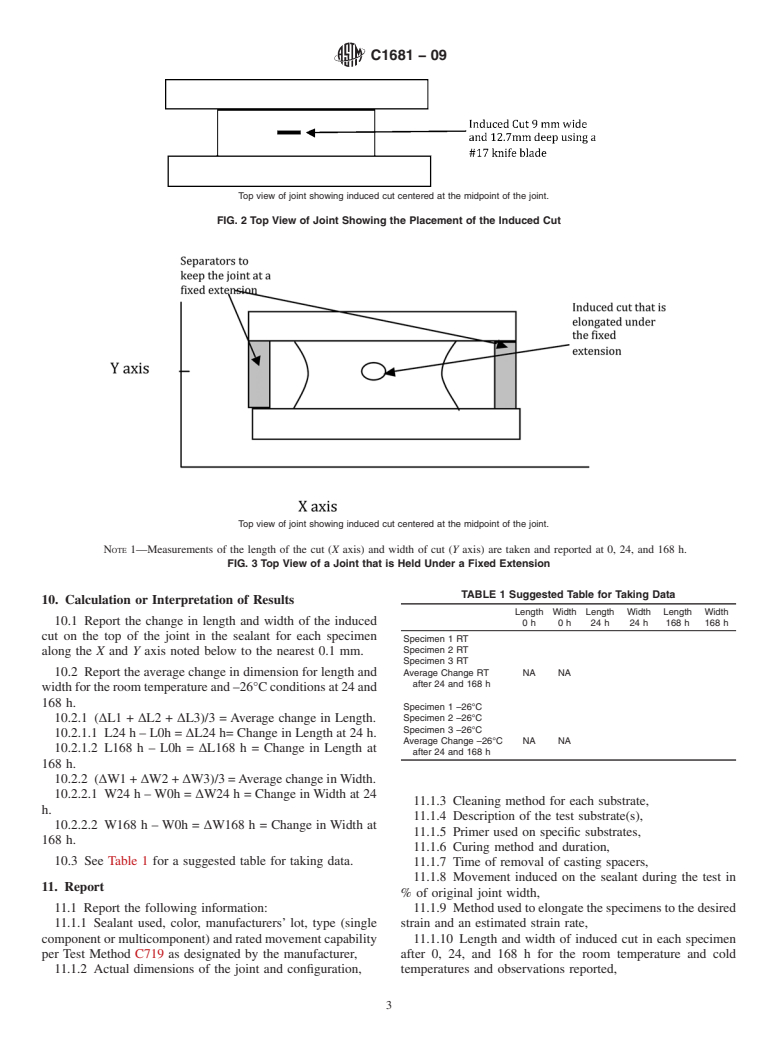

1. Scope 3.1.2 separators—rigid spacers used to maintain a constant

strain on the joint specimens during the testing period while

1.1 This test method evaluates the impact of an induced tear

maintaining parallel bond surfaces.

on a sealant specimen that is dimensioned, cured according to

the guidelines in Test Method C719 and then subjected to a

4. Summary of Test Method

constant strain. It is effective in differentiating between seal-

4.1 Test specimens are fabricated and cured in accordance

ants that are used in dynamic joints subject to abrasion,

with Test Method C719. At the end of the 21-day cure period,

punctures, tears, or combination thereof.

an induced tear is created in the specimens by making a cut

1.2 Since this test method is for the evaluation of tear

with a sharp blade in the midpoint of the joint. The specimens

propagation, an adhesive failure to the substrates provides no

are then extended to a specified strain at both standard

usable data regarding tear propagation. This would be consid-

conditions and at –26 6 2°C (–15 6 3°F). Propagation of the

ered a failed test and that data would be discarded, or at least

induced tear is measured at 0, 24 and 168 h.

separated from the other data from specimens that did not

5. Significance and Use

experience an adhesive failure.

1.3 This standard does not purport to address all of the 5.1 This test method is intended to determine if a joint that

is subjected to a mechanically induced cut will resist tear

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- propagation during normal joint movement. A sealant with a

highresistancetotearpropagationwilltypicallyperformbetter

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. than a sealant with a low resistance to tear propagation.

1.4 Thecommitteewithjurisdictionoverthisstandardisnot

6. Apparatus

aware of any comparable standards published by other orga-

nizations. 6.1 Adevice capable of extending the test specimens to the

specified strain.

2. Referenced Documents

6.2 Freezer, to maintain a constant temperature of –26°C.

2.1 ASTM Standards:

6.3 A suitable measuring device such as calipers able to

C719 Test Method for Adhesion and Cohesion of Elasto-

measure the induced tears to 0.01 mm.

meric Joint Sealants Under Cyclic Movement (Hockman

Cycle)

6.4 #17 Knife Blade,9mm( ⁄8 in.) wide.

3. Terminology

7. Reagents and Materials

3.1 Definitions:

7.1 Spatulas, for use in applying the sealant.

3.1.1 casting spacers—rigid spacers made of an anti-

7.2 Caulking Gun, for extruding sealant from cartridges

adherent material used in the fabrication of joints to maintain

when applicable.

the joint dimension during the extrusion, tooling and curing of

7.3 Glass Substrates—twelve substrates, with minimum

the sealant material.

dimensions of 25 by 75 mm (1 by 3 in.) of the same finish are

required for each test specimen. Glass is the default substrate,

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on

however as mentioned in the scope, this is not an adhesion test,

General Test Methods.

therefore the sealant must exhibit excellent adhesion to the

Current edition approved Jan. 1, 2009. Published February 2009. DOI: 10.1520/

substrate. Other rigid substrates in the above noted dimension

C1681-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or are indeed acceptable.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.4 Casting Spacers—Made from polytetrafluoroethylene

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (PTFE) or a suitable rigid material shall be used with each test

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1681 − 09

specimen to which the test sealant will not bond and will spacers.Maskoffthetopofthesubstrateedges,extrudethetest

provide the appropriate joint dimensions and configurations. sealantintothecavitytakingcaretofillintheallofthecorners,

These spacers are machined to provide exact joint dimensions tool the top surface flat, and remove the masking tape.

1 1

of 12.7 by 12.7 by 50.8 mm ( ⁄2 by ⁄2 by 2 in.). See Fig. 5 in

8.3 Single-Component Sealants—Prepare six test specimens

Test Method C719.

as described in 8.1 except that no mixing of components is

7.5 Separators, to provide a constant strain on the specimen

required. Condition the sealed cartridge or bulk container at

while maintaining parallel bond surfaces.

standard conditions at least 24 h before use.

7.6 Substrate Cleaning Material.

8.4 Cure specimens made with multicomponent sealants for

14 days at standard conditions. During the second week of the

7.7 Primer, if required on the substrates.

curing period, free the compound from the spacer blocks at the

7.8 Asuitablemeasuringdevice,suchascalipers,capableof

ends and bottom without damaging the sealant bead.

measuringtheinducedcutinthesealantandadditionalchanges

8.5 Cure specimens made with single-component sealants

in the cut to 0.01 mm.

for a total of 21 days at standard conditions. See 8.6.1.

7.9 Marker, to identify the exact placement of the induced

cut. 8.6 Separate the casting spacers from the sealant as soon as

practical during the curing period without damaging the

7.10 A device which holds a #17 knife blade 9 mm ( ⁄8 in.)

sealant. Fourteen days is typically necessary.

wide to induce the cut into the test specimens. See Fig. 1.

8.6.1 The producer may request conditions other than those

specified in 8.5 for the curing period of single-component

8. Conditioning

sealants provided they meet the following requirements: (1)

8.1 Multicomponent Sealants—Prepare six test specimens

The curing period shall extend for 21 days; and (2) The

for each type of substrate that is to be used in the test. After

temperature during the curing period shall not exceed 50°C

maintaining the unopened sample for at least 24 h at standard

(122°F).

conditions, mix thoroughly for 5 min at least 250 g of base

compound with the appropriate amount of curing agent.

9. Procedure

1 1

Extrudethesealant12.7by12.7by50.8mm( ⁄2by ⁄2by2in.)

between parallel 25.4 by 76.2 mm (1 by 3 in.) faces of similar

9.1 Within 8 h after the cure period (14 days for multicom-

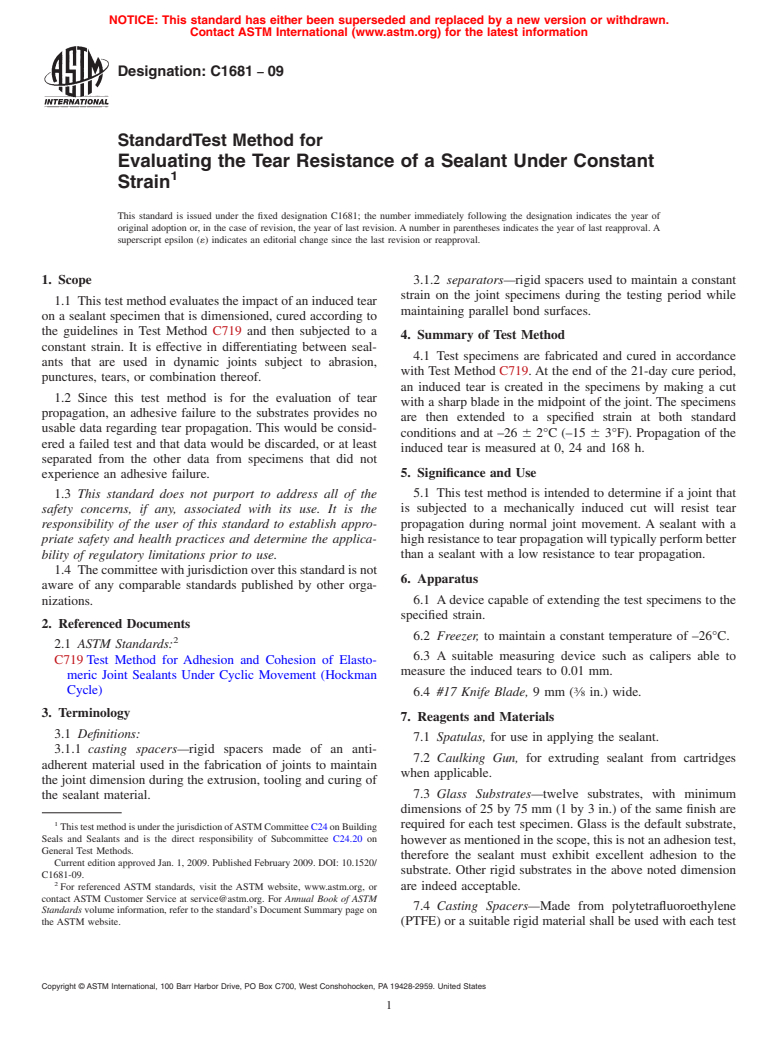

blocks or plates. Use appropriate casting spacer blocks to form ponent or 21 days for single component products), mark the

the proper size of the bead. Apply polyethylene adhesive tape exact location for the induced cut with a permanent marker and

3 1

or any other suitable inert release agent to the inside surfaces then induce a cut, 9 mm ( ⁄8 in.) in length, and 12.7 mm ( ⁄2 in.)

of the spacers to prevent adhesion of the spacers to the sealant deep with the #17 knife blade. See Fig. 2. Make the cut as

after cure. Use adhesive tape, rubber bands, or clamps to hold parallel as possible to the long direction of the sample, located

the test assembly together before and after filling it with the directly on the midpoint and go perpendicularly through

compound. In the case of a pourable-type compound, use thickness of the sealant.

masking or any other suitable tape to retain the compound.

9.2 Extend all specimens until the separation between the

8.2 Clean the test substrates using the methods suggested in

substrates provides the desired/specified extension (in the

Test Method C719. Fabricate the joints using the casting

absence of a specified strain, the sealant shall be strained to its

Test Method C719 movement capability).Apply this strain at a

minimum rate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.