ASTM A758/A758M-00(2005)

(Specification)Standard Specification for Wrought-Carbon Steel Butt-Welding Piping Fittings with Improved Notch Toughness

Standard Specification for Wrought-Carbon Steel Butt-Welding Piping Fittings with Improved Notch Toughness

ABSTRACT

This guide covers standard specification for wrought-carbon steel butt-welding seamless or welded fittings specially processed to ensure better notch toughness. Heat treatment shall be required for all types of fittings. Fittings with mandatory radiographic examination of welds shall be included. Cast fittings and fittings formed from all weld metal, shall not be included. Heat or cast analysis shall be conducted wherein the material shall conform to the required chemical components for carbon, manganese, phosphorus, sulfur, silicon, vanadium, chromium, nickel, molybdenum, copper, and lead. The fittings, as represented by tensile test specimens taken subsequent to final heat treatment, shall conform to the specified values of tensile strength, yield strength, and elongation for the applicable grades of steel. Mechanical tests such as tension test and transverse guided weld bend test shall be performed on the fittings.

SCOPE

1.1 This specification covers wrought-carbon steel butt-welding seamless or welded fittings specially processed to ensure better notch toughness than that to be expected in fittings manufactured to the requirements of Specification A 234/A 234M.

1.1.1 Included are elbows, caps, tees, reducers, and other type fittings covered by ASME B 16.9.

1.1.2 Heat treatment is required for all fittings.

1.1.3 Fittings with mandatory radiographic examination of welds are included.

1.1.4 Supplementary requirements are provided for use when additional testing or examination is desired.

1.1.5 Cast fittings, and fittings formed from all weld metal, are not included.

1.2 Several type of fittings are provided, as follows:

1.3 It shall be the responsibility of the purchaser to determine whether material meeting the requirements of this specification is satisfactory for the service application.

1.4 This specification is expressed in both inch-pound units and SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A758/A758M – 00 (Reapproved 2005)

Standard Specification for

Wrought-Carbon Steel Butt-Welding Piping Fittings with

Improved Notch Toughness

This standard is issued under the fixed designationA758/A758M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope SI units are shown in brackets. The values stated in each

system are not exact equivalents; therefore, each system must

1.1 This specification covers wrought-carbon steel butt-

be used independently of the other. Combining values from the

welding seamless or welded fittings specially processed to

two systems may result in nonconformance with the specifi-

ensure better notch toughness than that to be expected in

cation.

fittings manufactured to the requirements of Specification

A234/A234M.

2. Referenced Documents

1.1.1 Included are elbows, caps, tees, reducers, and other

2.1 In addition to those reference documents listed in

type fittings covered by ASME B 16.9.

Specification A960/A960M, the following list of standards

1.1.2 Heat treatment is required for all fittings.

apply to this specification:

1.1.3 Fittings with mandatory radiographic examination of

2.2 ASTM Standards:

welds are included.

A234/A234M Specification for Piping Fittings of Wrought

1.1.4 Supplementary requirements are provided for use

Carbon Steel and Alloy Steel for Moderate and High

when additional testing or examination is desired.

Temperature Service

1.1.5 Cast fittings, and fittings formed from all weld metal,

A275/A275M Practice for Magnetic Particle Examination

are not included.

of Steel Forgings

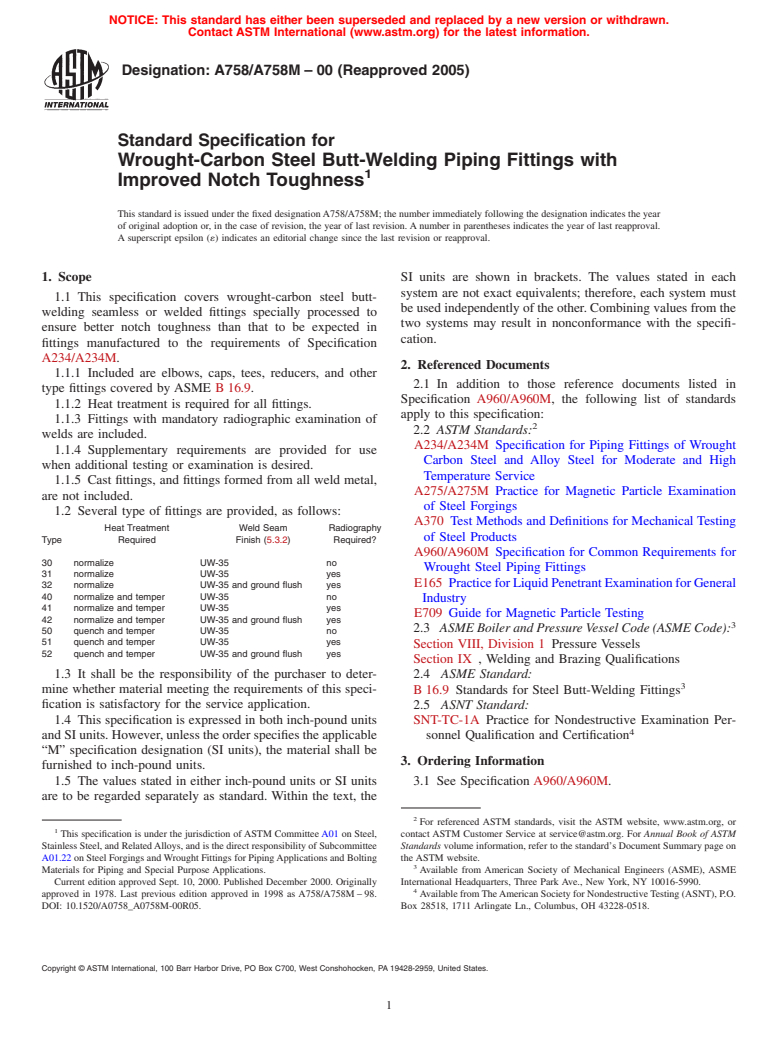

1.2 Several type of fittings are provided, as follows:

A370 Test Methods and Definitions for Mechanical Testing

Heat Treatment Weld Seam Radiography

of Steel Products

Type Required Finish (5.3.2) Required?

A960/A960M Specification for Common Requirements for

30 normalize UW-35 no

Wrought Steel Piping Fittings

31 normalize UW-35 yes

E165 PracticeforLiquidPenetrantExaminationforGeneral

32 normalize UW-35 and ground flush yes

40 normalize and temper UW-35 no

Industry

41 normalize and temper UW-35 yes

E709 Guide for Magnetic Particle Testing

42 normalize and temper UW-35 and ground flush yes

2.3 ASMEBoilerandPressureVesselCode(ASMECode):

50 quench and temper UW-35 no

51 quench and temper UW-35 yes

Section VIII, Division 1 Pressure Vessels

52 quench and temper UW-35 and ground flush yes

Section IX , Welding and Brazing Qualifications

1.3 It shall be the responsibility of the purchaser to deter-

2.4 ASME Standard:

mine whether material meeting the requirements of this speci- B 16.9 Standards for Steel Butt-Welding Fittings

fication is satisfactory for the service application.

2.5 ASNT Standard:

1.4 This specification is expressed in both inch-pound units SNT-TC-1A Practice for Nondestructive Examination Per-

and SI units. However, unless the order specifies the applicable

sonnel Qualification and Certification

“M” specification designation (SI units), the material shall be

3. Ordering Information

furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units 3.1 See Specification A960/A960M.

are to be regarded separately as standard. Within the text, the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction of ASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel, and RelatedAlloys, and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.22 on Steel Forgings andWrought Fittings for PipingApplications and Bolting the ASTM website.

Materials for Piping and Special Purpose Applications. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved Sept. 10, 2000. Published December 2000. Originally International Headquarters, Three Park Ave., New York, NY 10016-5990.

approved in 1978. Last previous edition approved in 1998 as A758/A758M – 98. Available fromTheAmerican Society for NondestructiveTesting (ASNT), P.O.

DOI: 10.1520/A0758_A0758M-00R05. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A758/A758M – 00 (2005)

4. General Requirements 6. Chemical Composition

6.1 HeatorCastAnalysis—Theresultsshallconformtothe

4.1 Product furnished to this specification shall conform to

requirements for the applicable grade as specified in Table 1.

the requirements of SpecificationA960/A960M, including any

6.2 ProductAnalysis—Productanalysismaybemadebythe

supplementary requirements that are indicated in the purchase

purchaser.Theresultsshallconformtotherequirementsforthe

order. Failure to comply with the requirements of Specification

applicable grade as specified in Table 1.

A960/A960M constitutes non-conformance with this specifi-

6.3 The steel shall not contain any unspecified elements for

cation. In case of a conflict between the requirements of this

the ordered grade to the extent that it conforms to the

specificationandSpecificationA960/A960M,thisspecification

requirements of another grade for which that element is a

shall prevail.

specified element having a required minimum content.

5. Materials and Manufacture

7. Mechanical Requirements Mechanical Requirements

5.1 The steel shall be killed and shall be melted to a fine

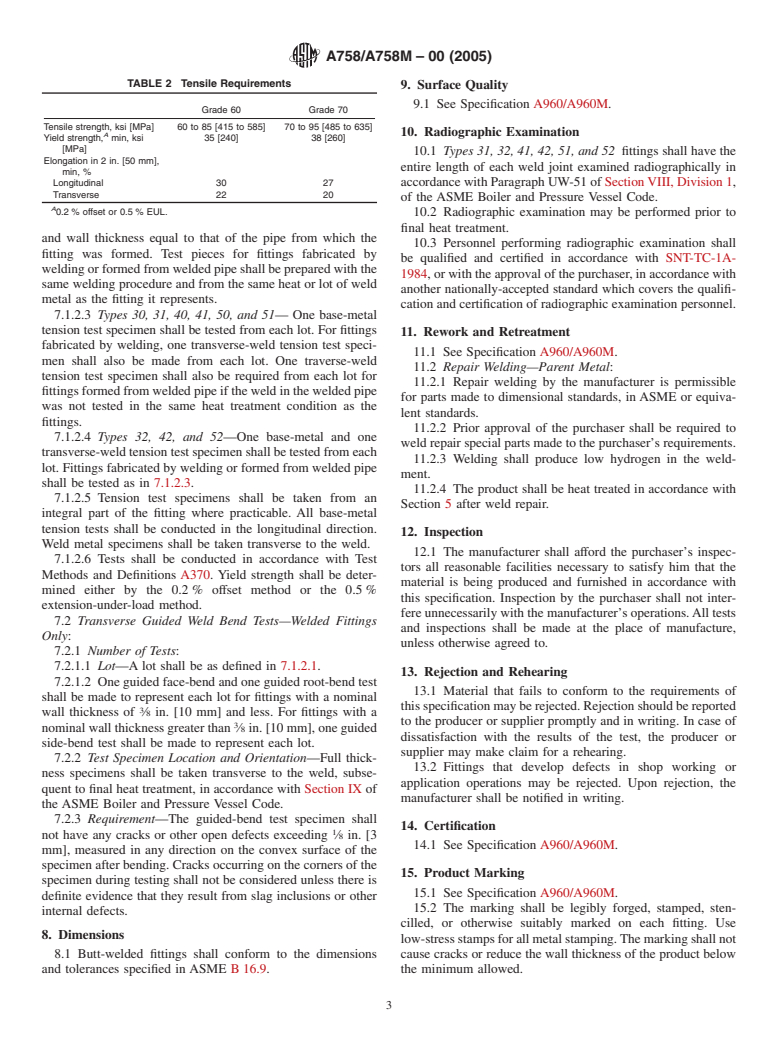

7.1 Tensile Requirements:

austenitic grain size practice.

7.1.1 The fittings, as represented by tensile test specimens

5.2 Thestartingmaterialshallbewroughtandintheformof

taken subsequent to final heat treatment, shall conform to the

blooms, billets, slabs, forgings, bars, plates, sheets, seamless

requirements for the applicable grade as specified in Table 2.

pipe or tube, or welded-with-filler-metal pipe or tube. Cast

7.1.2 Number and Location of Specimens:

products shall not be used.

7.1.2.1 Lot—For tension testing, a lot shall consist of the

5.3 Any forming process, fusion-welding process, or com-

fittings from a heat, in each heat treatment charge, with

bination of such processes, may be used.

nominal wall thicknesses within ⁄4 in. [6 mm] of the nominal

5.3.1 Allweldingshallbefusion-weldedinaccordancewith

thickness of the test specimen. In addition, for Types 32, 42,

the requirements of Section IX of the ASME Boiler and

and 52, the lot definition shall include each heat or lot of weld

Pressure Vessel Code. Welding procedures, welders, and weld-

metal. If heat treatment is performed in a continuous or

ing operators shall be qualified in accordance with Section IX

batch-type furnace controlled within a range of plus-or-minus

of the ASME Boiler and Pressure Vessel Code.

25 °F [14 °C] and equipped with calibrated thermocouples and

5.3.2 All welded joints shall be finished in accordance with

recording pyrometers, and records of heat treatment are main-

Paragraph UW-35 of Section VIII, Division 1, of the ASME

tained, all fittings heat treated in such a furnace are considered

Code.

to be in one charge. For furnaces not so equipped and

5.3.3 Welded joints of Type 32, 42, and 52 shall be ground

controlled, each batch constitutes a charge.

flush.

7.1.2.2 Representative Test Piece—For instances in which

5.3.4 Welded joints ofTypes 31, 41, 51, 32, 42, and 52 shall the tension test specimen cannot be obtained from a fitting due

be examined by radiography in accordance with the require- to size limitations, a representative test piece may be used.The

ments of Paragraph UW-51 of Section VIII, Division 1,ofthe test piece shall be from the same heat and shall be heat treated

ASME Code, and shall conform to the requirements of in the same heat treatment batch or charge as the fittings it

Paragraph UW-51. represents, and shall have had approximately the same amount

of working as the fittings. In addition, for fittings manufactured

5.4 Heat Treatment—All fittings shall be heat treated sub-

from bars, plate, or forgings, the test piece shall have a

sequent to final welding and forming.

cross-section equal to or larger than the greatest cross-section

5.4.1 Types 30, 31, and 32 fittings shall be normalized by

of the fittings it represents. Test pieces representing fittings

uniformly heating to a temperature in the austenitizing range,

manufactured from pipe shall have a nominal outside diameter

but not to exceed 1700 °F [925 °C], and subsequently removed

from the furnace and air-cooled individually to room tempera-

ture.

TABLE 1 Chemical Requirements

5.4.2 Types 40, 41, and 42 fittings shall be normalized in

accordance with 5.4.1. After normalizing, the fittings shall be Element Cast or Heat Product

Analysis Analysis

temperedbyheatingtoatemperatureintherangefrom1100°F

Carbon, max, % 0.27 0.30

to 1200 °F [595 °C to 675 °C], soaking at that temperature for

Manganese, % 0.85–1.20 0.75–1.25

⁄2 h minimum per 1 in. [25 mm] of thickness, but not less than

Phosphorus, max, % 0.035 0.040

15 min, and then air-cooled to room temperature.

Sulfur, max, % 0.035 0.040

Silicon, % 0.15–0.30 0.13–0.33

5.4.3 Types 50, 51, and 52 fittings shall be quenched-and-

Vanadium, max, % 0.05 0.05

tempered by uniformly heating to a temperature in the auste- A,B

Residual elements

Chromium, max, % 0.25 0.25

nitizing range, but not to exceed 1700 °F [925 °C], and then

Nickel, max, % 0.25 0.25

quenching in a liquid media from the austenitizing temperature

Molybdenum, max, % 0.08 0.08

to a temperature below 800 °F [425 °C]. After quenching, the

Copper, max, % 0.35 0.35

Lead, max, % 0.05 0.05

fittings shall be reheated to a temperature in the range from

A

1100 °F to 1250 °F [595 °C to 675 °C], soaking at that Individual limits of chromium, nickel, molybdenum, and copper may be

exceeded by 0.05 % provided that their total does not exceed 0.90 % in both the

temperature for ⁄2 h minimum per 1 in. [25 mm] of thickness,

heat and product analysis.

but not less than 15 min, and then air-cooled to room B

These are not to be added to the melt and shall only occur as a result of

temperature. unavoidable residuals from the melting stock.

A758/A758M – 00 (2005)

TABLE 2 Tensile Requirements

9. Surface Quality

9.1 See Specification A960/A960M.

Grade 60 Grade 70

Tensile strength, ksi [MPa] 60 to 85 [415 to 585] 70 to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.